Leaderboard

Popular Content

Showing content with the highest reputation on 03/03/24 in all areas

-

Sooo, after initially following @HectorLooi's advice and kinda abandoning this project and then following @VWatchie's advice of waiting patiently for a good deal on a complete set, my moment has come: For an incredible 125 EUR, I managed to get a pristine (basically unused) "new style" Steiner set. It's the large set with the center wheel runner. In addition to two perfect lantern discs (hidden under the covers), a another perfect pair of spare runners were also included. The burnisher was not included, but after such a bargain on the tool, I treated myself to a new Bergeon burnisher. And a pair of retractable keyholders ;-). Now I need to practice.5 points

-

MO-3 is comparable to Moebius HP1300 and to be honest MO-4 can be the same, but I use Moebius 9504 in place of the MO-4 which is for high friction parts, but as I said you can use HP 1300 instead. There is a big difference in viscosity of these two lubricants, as Hp1300 is 1300 centistokes which is pretty thick and 9504 is only 305 centistokes, but I find it better in the situation for high friction parts. If you ask 10 watchmakers which lubricants they use, you'll get 15 answers!4 points

-

Hello all, So for my birthday, I asked my wife for a stereo-microscope (actually, I told her exactly which one I wanted). I've read many times (and seen this video of Alex https://youtu.be/tAtATqwI5A4?si=NlU3TwHFBwpDKitw) that a good stereo microscope would be a "game changer". I resisted for the longest time, and ended up buying a staking set, jewelling set, glass press... heck, even a Jacot tool. But now I made the jump. And OH MY GOODNESS, it is so much more amazing and "game changing" than I ever imagined. I go the Amscope SM-3TP (https://amscope.com/products/c-sm-3tp-hd), with light ring and 0.5 Barlow lens. It delivers the perfect amount of magnification and working distance. (Please note that the 3TP version allows you to use full stereo vision while using the camera port at the same time. The 3T version used by Alex (see video link about) will force you to either use stereo-vision for your eyes and NOT use the camera port at all, OR use the camera port but only have mono-vision on your eyes. The camera port and the left eyepiece share the same "tunnel" and there's a lever that you pull/push to decide which one is active. I definitely recommend paying 20 bucks more to get the 3TP.) I think that one really needs to experience a stereo microscope like this to fully appreciate how incredible it is. Pictures (which are two-dimensional) will never do it justice. To see three-dimensionally is SOOOOO useful. I've never oiled a pallet stone with such perfect accuracy and ease. And I can see in perfect clarity how the drop of oil spreads over the next 3-5 escape wheel teeth. Until I apply another perfect drop in the perfect spot. And INSPECTION: my goodness. You'll find the tiniest speck of dust or debris with ease. Honestly, I'm over the moon with this new acquisition. After using it for 3 days, I can't even imaging how I lived without it.4 points

-

See, my wife is a doctor, and she is willing to hear about all my feelings... But some of them should be never shared. About the pieces of springs - it is a common solution used by many watchmakers in the past. And the results are not bad at all, especially when this is the dial side cap stone. I use to call this side 'down' or 'bottom' side of the balance or movement. There are watches made with such plate made entirely of steel instead of jeweled plate on the dial side. A pocket watch is not expected to work in dial down position for a long time.3 points

-

3 points

-

A microscope takes the horological experience to a different level. Parts that you thought were clean are not, parts that you see no fault are faulty. I am greedy I have one over my lathe + two on my desktop one powerful Olympus which gives in incredible clarity and a AmScope which gives a high working space.. Also a digital scope purchased for me by my other half, its clarity is poor but does give the ability to copy what’s in view.3 points

-

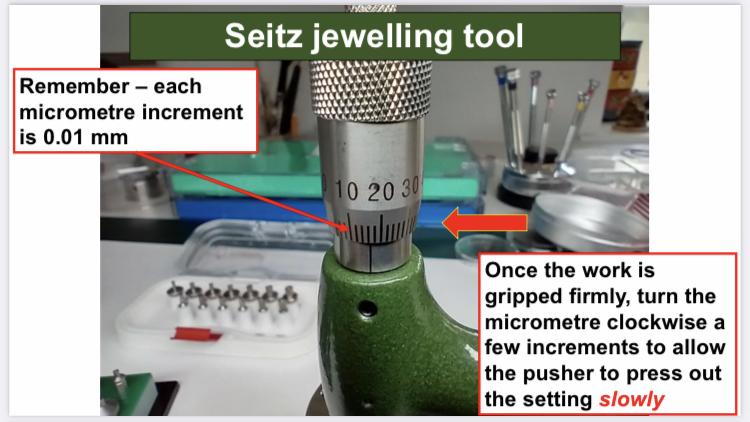

It only works with the newer versions of the Seitz jewelling tool, not the older ones It only works with the newer versions of the Seitz jewelling tool, not the older ones I've reposted the original PDF file, as the original one became unavailable when I edited it, so sorry about that. If you want the PowerPoint presentation with videos, here's the link to my cloud storage, but it won't be there forever. You will need a newer version of Microsoft Office to play the videos, otherwise they won't play https://docs.google.com/presentation/d/15lXEoRsUF_xKhRB0XaoMU566s7LB279V/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true3 points

-

I ment that my feeings sometimes frighten myself, nothing more.2 points

-

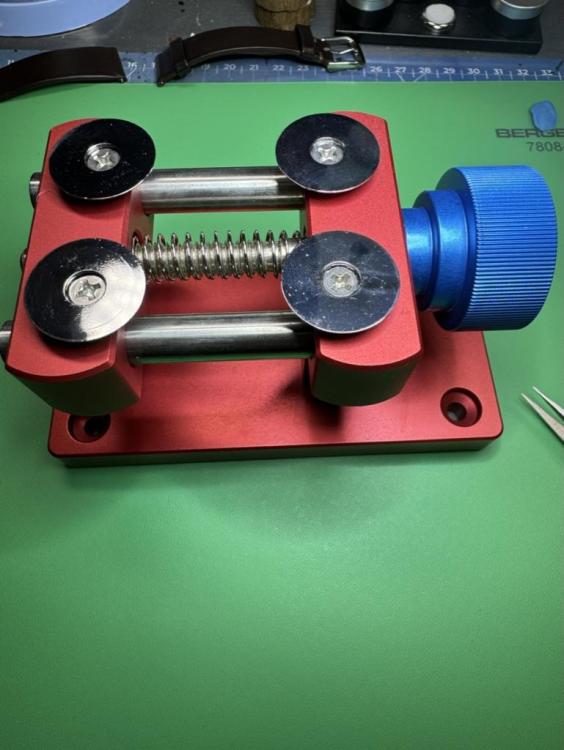

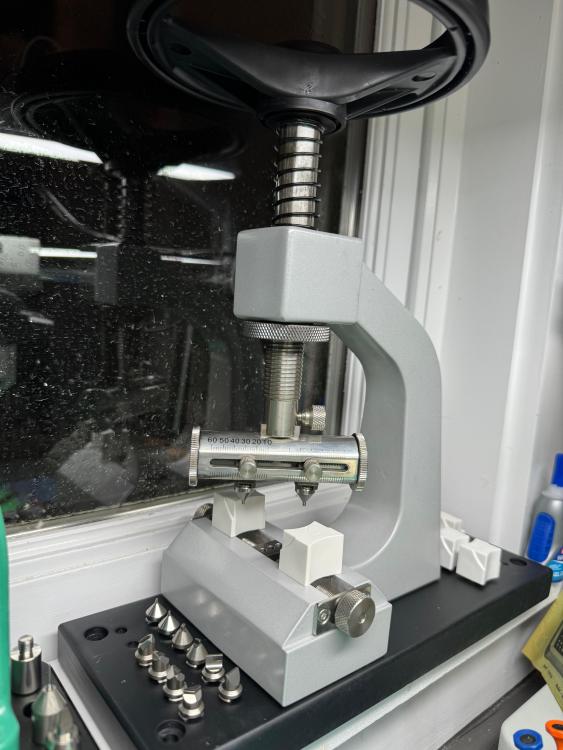

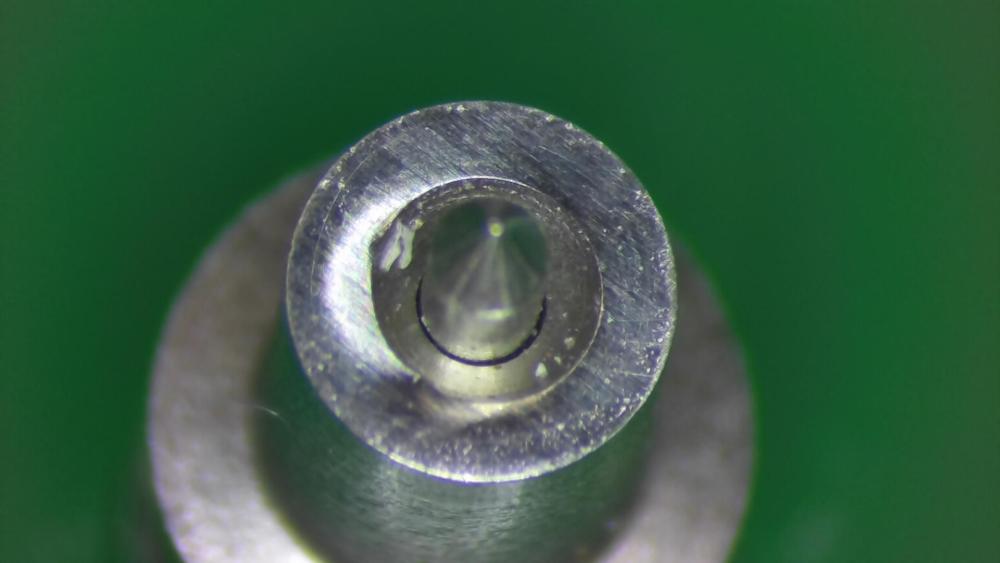

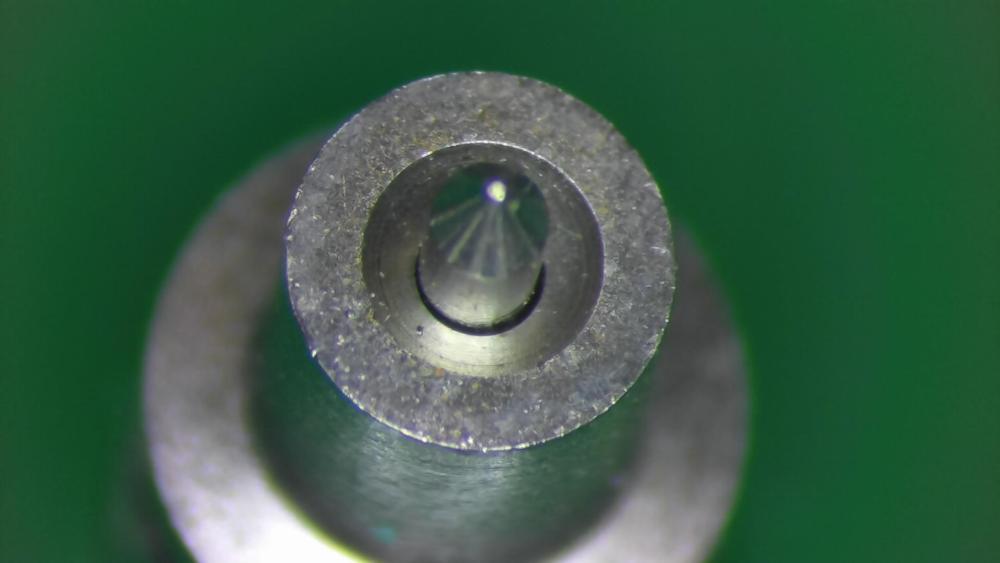

I went ahead and made another order for some more tools from the Kwong Yuen factory. Main purchases were Case Opener, Bezel Lift, Strap Puncher, Tube Remover, Jewelling Set, and a set of screwdrivers. Some pics below, happy to take some more pics of anything if someone wants more details. I measured the jeweling set, and I'll say the sizes seem consistent, but a little small compared to the printed numbers. Pushers seem to come in about 0.04mm less than marked (220->216). As far as I'm concerned that shouldn't affect its effectiveness much. The actual pushing edge looks decent, but could be dressed to a mirror finish. They come apart and back together without any issues. Here is one pusher out of the box. and after a little dressing.. (first time trying, and probably needs a bit more):2 points

-

It might be that generic springs of the same size can be used among different brands. Sometimes they fit the arbor ok and sometimes they dont. The spring's inner coil to fit the arbor is something that isn't specified when ordering, so we are either lucky or we aren't. Get yourself some practice springs to play around with heating and bending then when the time comes that you need to modify you have experience under your belt to do it for real.2 points

-

The op has inspected the jewels and all seems fine. Except he has a cap jewel missing. I think maybe his "fine" is somewhat different to our fine lol. For things to be more fine that cap jewel needs to be not missing. Or am i missing something, possibly some diplomacy2 points

-

I have a height adjustable desk and it's fantastic. Gives you so much flexibility to switch between microscope and non-microscope work. Also when working with the microscope only, you'll change the working height (your eye-level) frequently. Your back/neck will thank you very much for an adjustable desk!2 points

-

2 points

-

I am sorry. My pen is sometimes more sharp than neded, and this is due my temper. The idea that someone might think the plates may be made not of brass, but of still, made me wonder how and why is this possible. But Rich is right, i don't see any difference in the meaning of the both phrases. See, the main problem of no jewels Timex watches is the wear of the balance staff tips. They wear for 2-3-4 years of constant use and the watch may still work, but with lo amplitude and bad timekeepinng. The way to restore the movement is to sharpen the tips and if they have been sharpened allready 2-3-times, then the cup bearings must be restored too. Just forget the other bearings, no significant inprovement will happen from there.2 points

-

Hi please keep in mind that English is not the first language of many folk here. Words and phrases can have slightly different meanings to different people. Consider Nev's words again as the question it was meant to be. # what makes you think there are steel plates in Timex movements # what makes you think ? = why do you think ? This is a change of just two words only, yet the perception of the attitude of the questioner can be very different . To Nev they probably are exactly the same and perceived the same. Nev's first language is not English and is still learning to understand it's idiosyncrasies better.2 points

-

I have wanted a Robur watch crystal press and dies for a long time, but when considering the cost of about £510 (CousinsUK, excluding shipping and VAT) I just couldn't defend it. However, as the Robur-like press, shown in my video, now and then shows up in various YouTube videos I got curious and ordered it from AliExpress. I don't think it's on par with the Robur press, but for the price, it seems like a decent option. In the video, I happened to mention that I was going to link to my WRT service walkthroughs, so below is the list in case anyone would be looking for it. Hope you'll find my video useful! My Service Walkthroughs: Citizen 8200A ETA 2892-A2 2804-2 2836-2 955.112 2772 2472 2824-2 Vostok 2431 2409 Enicar 161 Miyota 8205 9015 Tissot 781 Omega 268 Orient 46E40 Unitas 6380 63251 point

-

My currency is BGN (Bulgarian Lev), which is fasten to EUR, so 1EUR = 2BGN I am afraid we have stollen the conversation away from the OP problem...1 point

-

Haha that was it Nev, we got there in the end They're brill Nev, 0.2mm diamond disks they work great with my new little milling machine. I paid less than £1 each, what is your currency ?1 point

-

This is the mainspring you need from Gleave and Co. https://gleave.london/search.php?search_query=seiko 7009 mainspring§ion=product Fits a treat! Cousins don't sell this, that's why I go to Gleave and Co in Clerkenwell, here in London. @Birbdadyou can manipulate that spring you have already in the barrel to close it up slightly. I've closed up the inner coil in a mainspring a lot bigger than the one your having problems with without having to heat the coil. First get a piece of brass wire or steel rod about half three quarters the size of the barrel arbor. This is placed in the inner coil so you don't crush or kink the inner coil of the spring, then with sturdy tweezers (carbon steel) start pinching the inner coil in various places around the inner coil. Be even in your pinching. It will take about 10 minutes or so, but it will slowly work the inner coil slightly smaller to fit the arbor. You'll be surprised at how much it will close that coil. You can't close it that much, but enough for what you require judging by your photo of the coil and arbor in situ. Take your time and make sure you always use the brass wire to not over do it. Be careful, as @Neverenoughwatcheshas already pointed out, not to scratch up the barrel or arbor hole/bush in the barrel. Very easily done, as it is soft brass. I'm sure you will close it up enough to grip the arbor. I've closed up inner coils much bigger than yours. Make sure you use a rod of steel or brass to stop the tweezers from completely crushing the inner coil. This part is imperative to the process, so don't overlook it, thinking that you will have control to how much your squeezing that coil with your tweezers, because that's where it all starts to go downhill and next thing you've got a fooked mainspring that is no good to man nor beast. Been there, done that, got the T shirt! Let us know how you got on.1 point

-

This disks can be used to entyrely form and grind figure springs and setting lever springs of hardened steel I'm not sure if I got it, what i thought is that I may be need to share my feeligs with some psychologist, but if we have not one in the group, then I can use the dentist... A, now i see that i have typed 'filling' instead feeling. This is my bloody english...1 point

-

I can't quite make out if that's sarcasm or not Nev . And speaking of dentists i bought some of the seperating disks your were talking about a few weeks ago. brilliant idea and so much cheaper and easier to use than slotting files. Great tip.1 point

-

Had a Patek in with the cap jewel glued in place, missing the (Kif) hole jewel. So the staff was running on the diameter that contacts the setting in event of a shock- but it was actually running! Have definitely seen bits of mainspring clamped down to make up for a broken or missing cap jewel too.1 point

-

Thats an interesting solution to a missing cap jewel. I've seen that recently, discovered under a balance top plate, maybe wasn't here on our forum. If its a filling you have Nev i think you should speak to HectorLooi, he used to be a dentist1 point

-

Now brace yourself for when you realize it has uses beyond watchmaking! Recently in another sphere of lunacy, I've been digging into leathers from different species to try to figure out how to tell the difference (specifically between horse and cow leathers). Also very useful for making/repairing electronics. Also, I modified a watch oiler (the biggest one in the set that never seemed to get any use) to fix skips in vinyl records. Also, I found micrometeorites in the driveway with my daughter (lots more coming on that front no doubt). Like you, I was very much on the fence about buying a microscope, and I have ended up using it for so many things beyond what I thought I would.1 point

-

1 point

-

1 point

-

1 point

-

There is no mainspring winder made for short springs of this size.1 point

-

You did not follow my instructions. Depends on where the break occurs. It's just like your house electrical wiring. If the wire to your fridge is broken, only the fridge doesn't work. But if the main wire supplying the whole house is broken, then everything doesn't work. The design of this watch has a screw going through the (+) battery clip and through the (-) battery terminal. You have to make sure that the insulator keeping the 2 apart is placed properly and there is no short circuit.1 point

-

I also saw that video 1-2 months ago and was delighted! I only had/have the Seitz. It works perfectly well with the turning knob. And yes, nice to see the 0.01 increments.1 point

-

@Jon The PDF in the first post is no longer available. I downloaded it earlier today but future readers will likely be disappointed. Perhaps you can try to upload it again!? Thanks! Too bad PowerPoints can't be uploaded. If it's OK with you I'll PM you my email address. You can then send me the PowerPoint (hope it's not too large) and I'll place it on my OneDrive and share the link in this thread.1 point

-

Hello hello, well, maybe to close this topic with my final update. Of course, my obsessive side got the better of me People who know me personally wouldn't be surprised. I just kept wondering if I had made a mistake or if there was any dirt somewhere. So I ended up disassembling/cleaning/reassembling/reoiling the watch two more times (except the mainspring barrel, because I don't have a mainspring winder).. Well, what did it do? NOTHING. Exact some outcome (amplitude at full wind and after 24h). A bit frustrating (especially, since I lost one cap jewel in the process which cost me 35 EUR to replace) to do all this work for nothing, BUT now I have certainty that there definitely is nothing wrong. The last assembly/oiling and inspection was also with my brand-new stereo microscope (see post linked below). So I am sure that everything is spotless and oiled really well. But one additional thing, and @Jon mentioned this in his post earlier in the thread: when I install the automatic works and rotor-wind the watch a little bit (swerving the watch around for 2min) after a full manual wind, amplitude will shoot up to 295 degrees for about one minute. Then it settles back to 270, then 260 where it stays for a while. In the end, I'm happy with the final result. As @JohnR725 always says: what matters (for most watch company specifications) is amplitude AFTER 24h -- and timekeeping, of course. Both are perfectly within spec. So, done and done. )1 point

-

Hi if you are missing a cap jewel the balance end shake is effected and un less rectified will have an adverse effect on the movement ie. If the watch is placed in a position with the missing cap jewel the staff shoulders can rub on the setting and cause all manner of problems.1 point

-

1. Impulse jewel is not in plase, move it down and glue it with shellak. 2. Demagnetize the whole balance and the lever. It is of significant importance when the roller and the fork both are made of steel. Here the guard pin is not separate part, it is part of the fork which can not be regulated and should be OK if all is original.1 point

-

Hi there, Check if roller rubs on fork horns, in which case it should run OK if the movement is flipped upside down. Check if the guard pin rubs on roller. Make sure balance rim doesn't rub on fork cock. Good luck.1 point

-

I agree & would have appreciated such a request as "are you sure they are steel rather than electroplated brass?". More to the point, however, I am really grateful for your comprehensive post.1 point

-

you do not have to unpin the hairspring but you do have to remove the balance wheel from the bridge which are going to have to do for cleaning purposes anyway. To remove the balance wheel there are two separate steps of getting it off the bridge. first you need to loosen the hairspring stud screw. It's in the image below this will allow you to push the stud out but not yet and once it's out gently screw it back in again so doesn't fall out it's a pain to put them back in when they fall out then you remove the balance bridge with wheel flip lid upside down because you need to release the hairspring between the regulator pin and boot. you can see a side view picture here of understand better of how to free the hairspring up we can see a side view here notice I marked something that's basically a screwdriver slot. So with the bridge upside down you put a screwdriver in here gently turn 90° or just enough to free up the hairspring so I can slide out then you can gently flip the whole thing over and pushed the hairspring stud out and in the whole thing should be free of the balance bridge. here's something that would help out in addition to the help from the group. a PDF on servicing platform escapement's Servicing a Platform.pdf1 point

-

I wouldn't be one bit surprised if the screw-type crystal press I have made an overview video about has already been covered in this big thread, but I thought I would contribute to it by linking to my post about the video.1 point

-

1 point

-

1 point

-

Yes and no. Hang on for, as Paul Harvey would say, the rest of the story. The pocket watch was given to my grandmother by the Hercules Powder Company, following the 1940 explosion that killed 53 workers. My grandfather was one of them. My father was 11 years old at the time. He was raised by my grandmother and her two sisters. My dad had serious emotional problems and it manifested in not very good ways, but that's a different therapy session. The watch was kept in a junk box. He never used it, or even looked at it. My brothers and I found it in a junk drawer when we were small and ended up being allowed to play with it. I remember popping the case back and marveling at the decoration on the movement. It was magical to me. We only learned of the story behind it after my grandmother passed. Of course, by that time it didn't run. I ended up taking possession of the watch in my teens and held onto it through college and beyond. When I was at the jeweler buying my wife's engagement ring, I just casually asked if they knew anyone who fixed pocket watches. I don't recall what was fixed or how much it cost, but I do remember that it seemed very reasonable (but I guess in comparison to the price of a diamond solitaire, it would be.) For one of our anniversaries my wife bought me a gold chain for the watch and I carried it quite frequently. When I finally passed the watch on to my son, I wrote up the story with as much detail as I knew about how we came to have it. Like life, the watch carries both joy and pain ... and history.1 point

-

Hello lovely watch people, i rarely post up my watches and i should do more of them because we all love to see and read stories about them. So today, i do have a little story of yesterday but first i ask to bend the rules and post not one but two watches side by side. The Sekonda in my picture i believe belonged to my dad's father, i found it while emptying my dad's flat after he died a few years ago. This is the watch that started it all for me, in terrible condition but after 2 failed attempts at restoration it now happily sits ticking away on my wrist most days. As for yesterday's story, i attended 100 miles away from where i live my 93 year old uncle's funeral my mum's brother, a kind and generous loving family man who will be sadly missed. Now his father my other grandfather worked for many years keeping the shipping lanes clear and safe for vessels coming into the Hull docks in the town where i live. After many years he retired and received the traditional retirement watch for good service often a Smiths watch was given. From my mum I became aware of his watch less than a year ago and obviously my interest was sparked so i began to ask questions of it's whereabouts and if possible could i have some photos of it so i could hunt down the same brand and model. Turns out my uncle had given it to his son 20 years ago and pictures promptly arrived on my phone from my cousin. It was indeed a Smiths Astral which by strange coincidence i had already collected 5 of but not that particular model. I began my hunt for the same one and by another strange coincidence i found the exact model for sale in the same 9ct gold case not 400 yards from my house, i was very happy. Back to the funeral, sat drinking with some of my family my mum takes my hand opens it and places my grandfather's watch in my palm " thats for you " she said. My cousin had given her the watch to do with it as she saw fit, six of my family including myself got hmm well rather emotional. As it happens my grandfather hardly wore it, my uncle never wore it and neither did my cousin who had kept it in a drawer for 20 years and could have quite easily given it to his son. I was told yesterday that " it's now in the right hands ". Coincidences are a strange thing, I'm a big believer in fate, my grandfather's brother was a watch and clock repairer and lived just 2 minutes from my house, my treasured new watch was given to my grandfather on his retirement the same year i was born. I kind of believe it's been making its way to me for the last 57 years. If you've stuck with me this long then i thank you and you need a bloody medal . Here is grandpa Jack on the left and grandpa Fred on the right. Soooooooooo happy today .1 point

-

1 point

-

I use a mainspring for the Seiko 7009 for the 7S26C and get 300 degrees amplitude. The size is 0.95 x 0.115 x 380 x 10. Those that say Seiko's only get a low amplitude is nonsense. I've never serviced a Seiko without seeing an amplitude of at least 270 degrees. The trick is using a new mainspring, which seems pretty obvious to me, but hey! I've recently serviced a Seiko 7019A, which is over 30 years old with an amplitude of 290 to 300. a 7S26C should definitely get a great amplitude! Every student that services the 7S26C, B and even A variant gets well over 270 degrees amplitude. The problem is most Seiko's never get serviced regularly because it isn't cost effective, so they get run into the ground and parts wear, especially the barrel bridge arbor hole, but if the parts are good, then a good amplitude will be had the majority of the time. Seiko's with low amplitude seems to be an old wives tale that someone else then repeats and if it is said long enough it seems to become a fact, just like an 'over-wound' watch. Don't ever oil the pallet arbor jewels, even though it is recommended in the Seiko service manual. That is a sure way of losing a lot of amplitude. If I had a penny for every time I heard someone say Seiko's have low amplitude......1 point

-

I think you have a few routes if you want the press and die set. It looks like you can purchase it via aliexpress https://www.aliexpress.us/item/3256805193943005.html?spm=a2g0o.productlist.main.17.7172vBFIvBFIE2&algo_pvid=36d147b7-c85a-4e96-98c3-91f5811bfcf3&algo_exp_id=36d147b7-c85a-4e96-98c3-91f5811bfcf3-8&pdp_npi=4%40dis!USD!137.00!137.00!!!137.00!137.00!%402101d69a17073978872681499e2fa2!12000032818712504!sea!US!4296785206!&curPageLogUid=ltM7m3b9GVRw&utparam-url=scene%3Asearch|query_from%3A I wanted two tools and wasn't happy with the shipping cost, so I ended up going a more convoluted route. 1688.com is the internal chinese version of alibaba. (It's owned by alibaba just like aliexpress is). Unless you're in China you can't order from them, you have to go some other route. Sugargoo is a 'forwarder', you put in the purchase order and they buy it from the Kwong Yuen factory via 1688, it gets shipped to them (for free) as their warehouse is in Shenzen, CN. They inspect, and then repackage together all items, and reship it using UPS or whatever from China to you. I had a good experience, but I'd hardly stake my reputation on anyone else going through this process. It takes a bit of a leap of faith. Here is a link to the factory store direct on 1688.com, sometimes theres more pictures and better descriptions here (I use google translate on chrome to understand the page): https://shop9984n72151764.1688.com/page/index.html?spm=0.0.wp_pc_common_header_companyName_undefined.0 Here is a link to the factory store (routed through Sugargoo), they will translate it for you. https://www.sugargoo.com/#/home/shopProducts?source=1688&shopId=2200742215132&sellerId=b2b-220074221513217c67 Here is a direct link (via Sugargoo) to the press, I added "6175A capping machine (green machine)" and "Additional 31-piece die set", https://www.sugargoo.com/#/home/productDetail?productLink=https://detail.1688.com/offer/701338329712.html And here is a direct link (via Sugargoo) to the staking set, I added "130 punch set GY0295 (green)" : https://www.sugargoo.com/#/home/productDetail?productLink=https://detail.1688.com/offer/732431432684.html As for what that tool is, I believe its used to punch out pins to remove links in a steel bracelet. Hope that helps.1 point

-

So, the jacot tool helps you mold a rounded top on the pivot end? Apologies if you already explain this in your jacot tool videos. If so, please let me know and I'll have another, more attentive , look. Thanks!1 point

-

The keeper plate or gear bridge may have been previously shimmed up, the shim gets washed away during the clean and you wont notice it. A bodge solution that works but you can hardly take pride in it. ALSO, I take another look at cap jewels on both side, are they flat or concave,if flat a concave one may save you the trouble of pivot shortening.Bridge lay out looks similar to fhf28, I think you may find concave cap jewels out of fhf28. As said moving end stones is a bad idea as they are known to fall off and wonder loose inside the movement in a couple of month.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)