Leaderboard

Popular Content

Showing content with the highest reputation on 03/06/24 in all areas

-

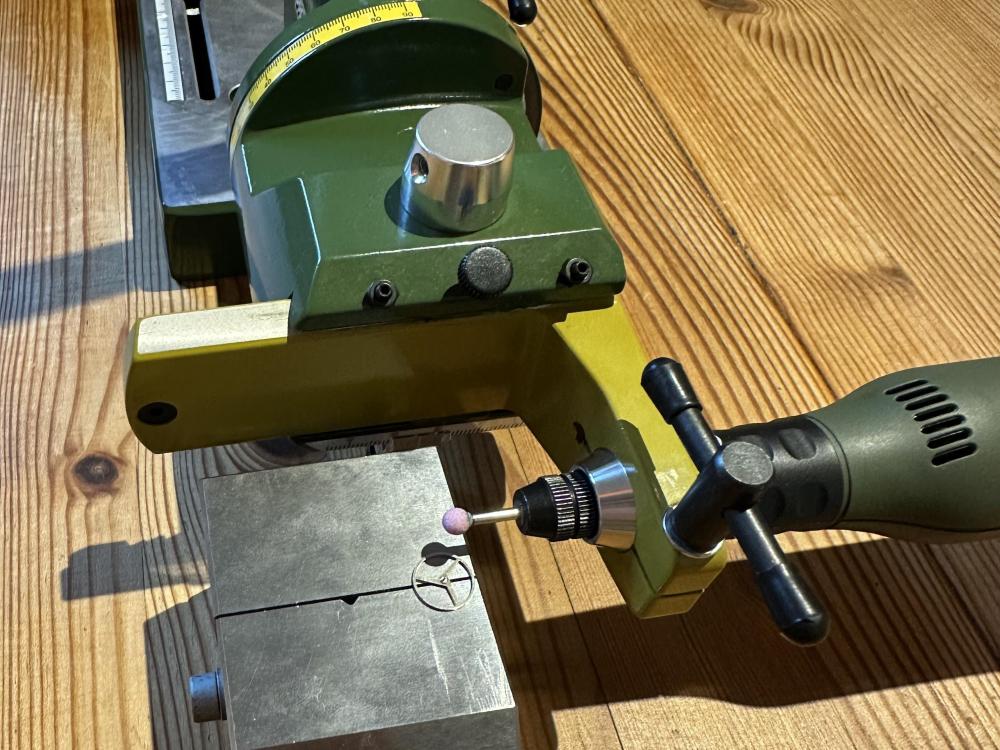

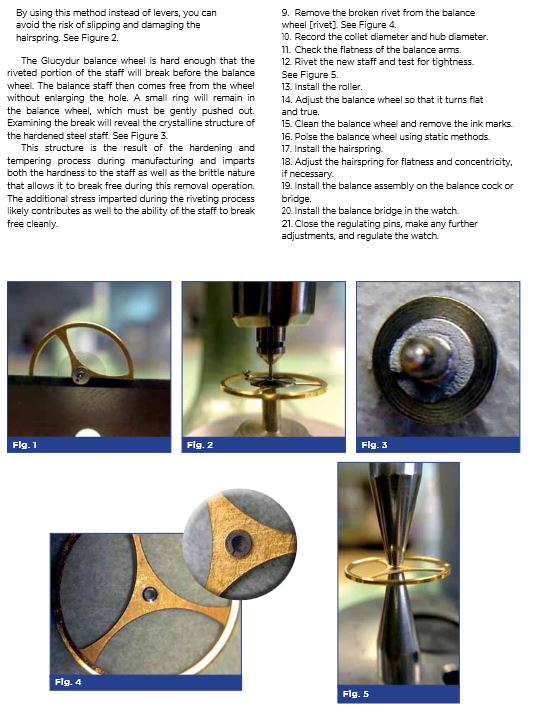

I don‘t have to do this task (replace balance staff) often, maybe one time in a year. As I ruined a Valjoux 72 balance wheel by pushing the staff out without any work on the staff before, I became a fan of the „grind the hub away“ method. So here is a description of my amateur without lathe setup. I put the balance in a vice, hub side up. I use my micromot with a ball grinding attachment. Then I grind the staff away freehand until the rest of the hub is maybe 0.5 mm. Then I put the micromot in a stand and adjust the height roughly. Now I grind away the hub step by step by putting sheets of paper (0.05 mm thickness) under the vice. Stand and vice have to be placed on a very flat table of course. When the hub is grinded down to about 0.05 - 0.1 mm you can punch it out in the staking set (correct support from the downside!), the thin rest of the hub will just break off, no damage to the hole, as many others already mentioned. As always you should first try this with a balance from the scrap box.6 points

-

You'll always be holding the stake so it doesn't follow through to even get close the the balance arms and be tapping it lightly enough so you don't lose control over that stake, but I do understand that it could happen that the stake hits the balance arm. That would be down to the technique you use when using the stake and a watchmakers hammer. Always have control of the stake and accidents are less likely to happen. I'm going to do a video (not like there aren't many showing this) to show how to perform both methods of removing a balance staff by cutting the hub and using a staking tool. My website/SEO guy is always on at me to add more content to my YouTube channel, so this will get him off my back for a while and maybe give me impetus to post more techniques5 points

-

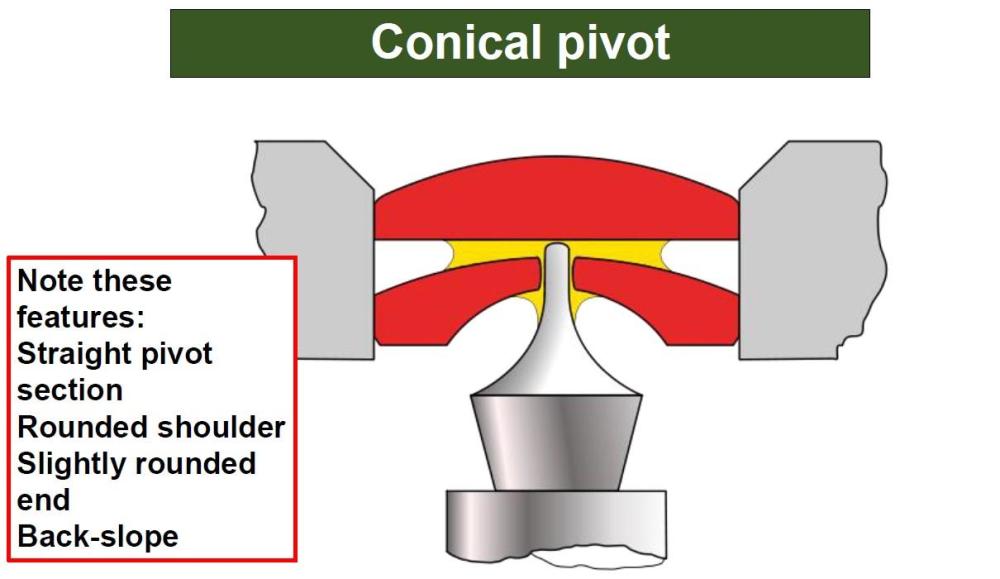

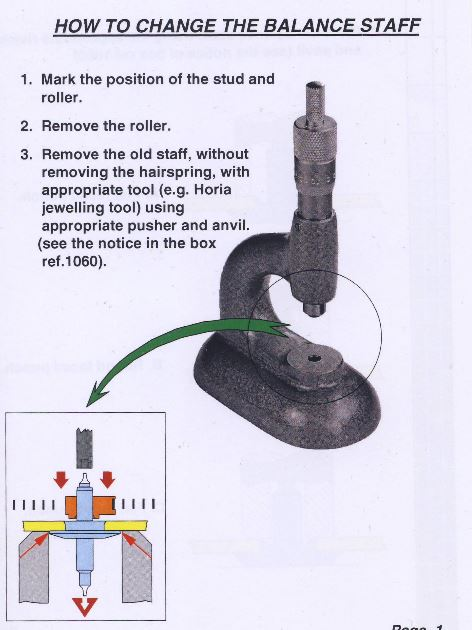

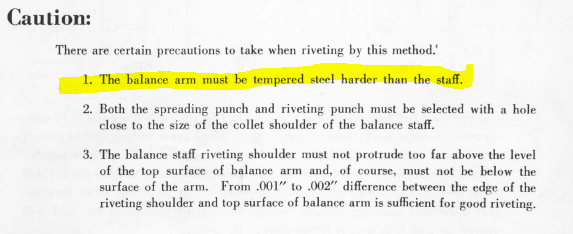

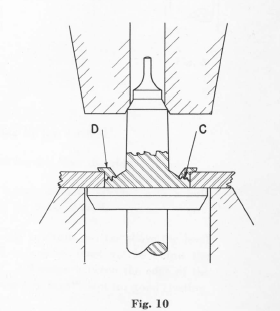

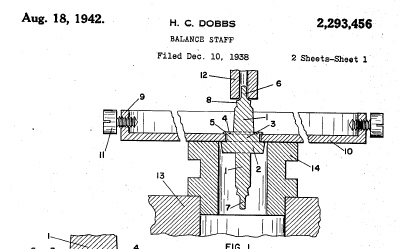

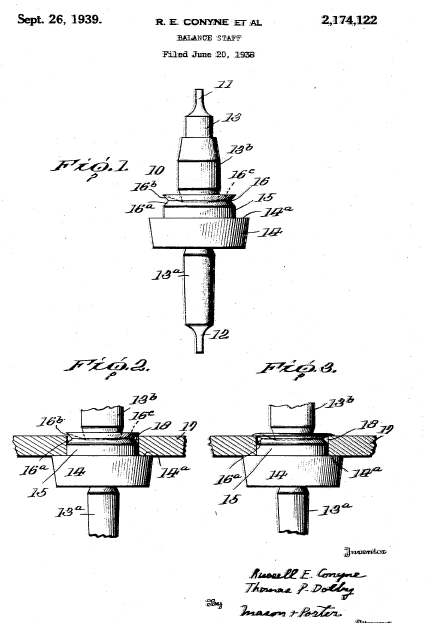

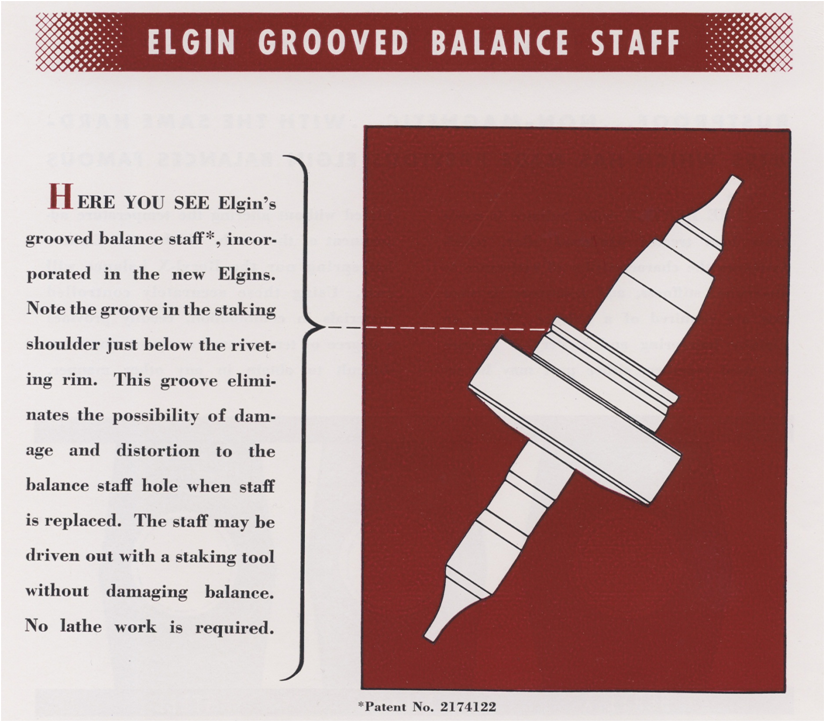

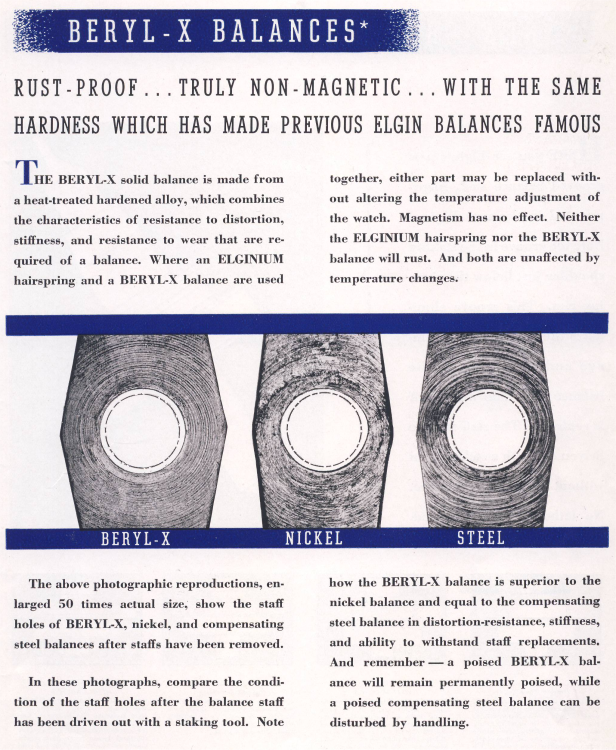

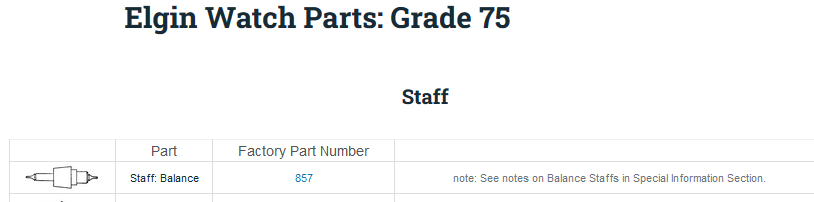

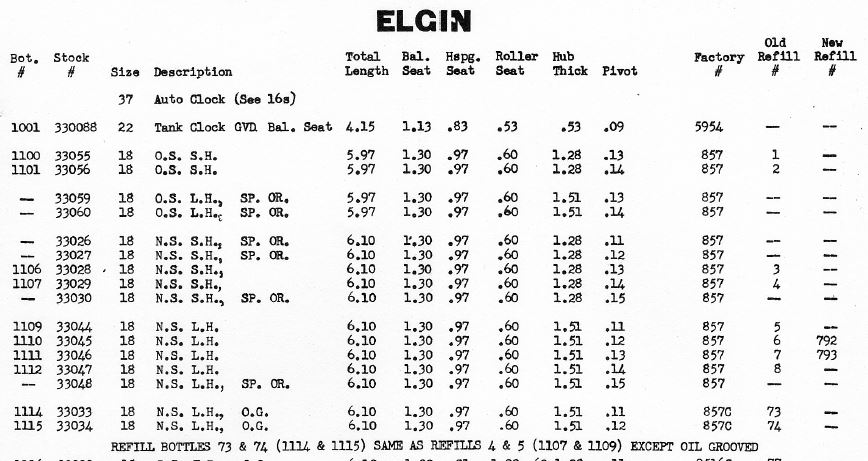

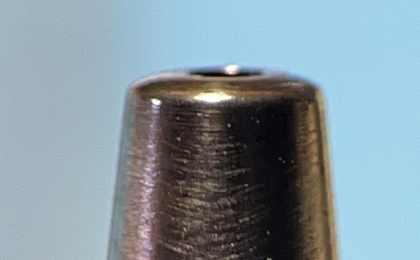

yes one of the problems with the group is it can't stay on track and were going to discuss all the theoretical first which I'm going to do to because everyone else does it and then we'll get back to the problem of your watch. one of the things I like locally as we have the remnants of well at one time it was in AWCI chapter but we left them and still are functioning. One of the people who's given a lot of lectures was the head watchmaker of the service center for chain of jewelry stores it has stores all up and down the West Coast and a few other places. So he would comment share the knowledge from people like Rolex. So Jeff demonstrated a particular Rolex that we found or I found quite fascinating. The particular Rolex you could not remove the hairspring there was no way to get it all. He remove the roller table by using a lathe and holding onto the roller table and just rotating the balance of removing up that way it was the easiest way. Otherwise he may have used razor blades or something to get the table off don't quite remember because that's not what I was impressed with. So how to get the hairspring off the Rolex how to get the staff out easy it's designed very specifically designed exactly what I quoted above.using the Horia tool and all the special bits and pieces that came in a really nice wooden box and probably cost a small fortune. And asking everybody to be really quiet in the room he started pressing and then the rivet sheers off with a pleasant pop. Then he picked up the rivet part that popped off and walked around the room and showed us there is a beautiful ring were the rivet just sheared right off because it's designed to do that with the only way that you can remove the staff is that as the staff has to be pushed out of the hairspring collet it's designed to work this way. then here's a snippet from a AWCI magazine from 2014 and how exactly are they removing the staff here's something that Rolex has so punching out is the work of the devil but yet Rolex and AWCI says pushing out is there a difference or is there something else going on that were not paying attention to? I always find the term in school interesting? the reason for this is schools can vary depending upon the instructor if you start gathering up people to specific schools and asked specific questions he begin the wonder if you even went to the same school at all because of various instructors how people were taught etc. etc. so for instance my first school the instructor liked to weaken the rivet as he called it. Balance staff in the latest that he would just take a little whiff of metal off and then using either the two methods quoted above knock the staff. Then later on in the other school we had this really nifty tool that just ground the hub off in the staff fell out which worked perfect providing it was set correctly for the particular size watches we were all doing. Then this discussion has occurred somewhere else in the universe remember the person Jeff I mentioned he was annoyed with the discussion somewhere else in the universe and get a lecture for us. So in his particular lecture he totally watch that he had been at whole bunch of balance staffs for and I think he staff did at least 10 times and drove the staff out every single time with no problems at all done. So what does this demonstrate? Now to understand better we have to go back to a previous lecture yes Jeff is given lots and lots of lectures. In a previous lecture Jeff and Doug gave a staffing lecture on Jeff did modern watches and Doug did pocket watches. Too long ago to remember the exact details of everything but the general consensus was you can not the staff out as long as it's not in super tight. in other words with a rivet is over the arms or something else is going on and tapping is not going to take it out you're going to have to cut things or something else? One of the lectures I think the last one especially if it's the beryllium copper balance wheels or brass you just remove your hairspring roller table and then use alum and dissolve the staff out after all it's still in the rest of it's not it can be safely dissolved out. now we're back to the interesting problem of balance staff? Do we have one procedure for everything across the board with no variations of course not that assumption would be extremely stupid which is the problem with some of this discussion. The Hamilton watch company the Elgin watch company and Rolex have all designed specific staffs that will break. They've specifically say in their literature you can knock the staff out Elgin even goes so far as to bring up the balance wheels themselves. I'm attaching a PDF from the Hamilton watch company replacing a balance staff. it's an interesting handout explaining of that somebody skilled in replacing a balance staff shouldn't have an issue but those starting out or going to have issues which is why they have a handout. like everything else in watch repair requires practice and knowledge of what you're doing. on the first page there is some cautions let me snip out the image because we get something really interesting that I've highlighted? notice the reference to the balance arm simplistically it has to be harder than the staff itself which would either be steel in this particular case which brings up the problem of watches with brass or soft balance wheels. The unfortunate problem of variations another major problem to watch repair one method doesn't necessarily work everywhere now on the second page you are reading the second page are you not? Sometimes I think when I attach PDFs no one bothers to read them at all. They show weakening the rivet and gently tapping the staff put. Which means using any one of the tools for driving a staff out work just fine as the rivet should be weakened and it should come out. then notice on pages 3 and 4 explain in detail about their new staff designed specifically to do what and explain how to put it in how it looks etc. and basically we end up with this picture the staff is designed to be driven out safely without problems. while looking for the Elgin balance wheel issue here's something interesting if you're ever looked up watch patents I'm convinced that everything has been patented at least once every single aspect of everything which of course presents challenges for other companies at the time. Here's an interesting image the taxes interesting it basically says a multi-method assembly method with one aspect being used for disassembly or basically break the rivet when you knock your staff out here's an Elgin patent as the patent was granted obviously it has to be somehow different than the Hamilton yet achieves the same goal a way of disassembling your staff from the balance without destroying everything Elgin was even so happy with their staff they had a handout with a talk about its wonderful features and how to use it identify it etc. here's something important for Elgin their nifty new balance wheel which basically Hamilton has also pointed out if the balance wheel arms are harder than the staff itself you can drive the staff out. now hopefully everybody grasps that everything is possible all the methods can work and all the methods can fail. There is no perfect method as usual and watch repair their lots of different ways to achieve the final goals and lots of ways to destroy the balance and everything else in the watch. identical? let's repeat the steps of replacing a balance staff as we are now aware it's 100% identical it was made by the Elgin watch company with the correct dimensions and it's perfect and yet it doesn't work let's just review anyway? in the procedure especially on vintage always best to use a micrometer and measure the old staff and the replacement staff the dimensions have to exactly agree. It would also be nice if they agreed with whatever you perceive is supposed to go in this watch. Which is easy we only have one balance staff so says the pocket watch database how many mistakes could they have? so as you can see only one balance staff one balance staff number and there's a note? This by the way is my favorite balance staff because how many balance staffs are there? All with the same part number of all of variations and for this discussion we can explore all of that because the balanced seat is 1.30 mm to all the staffs should work they just won't be the right staff but they should still rivet just fine. in addition to the specifications above is the replace of balance staff actually made by Elgin or as an aftermarket and is the shape of the riveting shoulder the same as what the original had yes there can be other sizing variations then in this entire discussion this is the only picture I see like this and we really need a slightly different angle to see what we need to see because this despite its curvature looks almost concave a little bit at the critical part and if not it's flat with the curvature and is that what is specified for doing a balance staff? Yes I see images above and they don't quite correspond do they? then this is a interesting picture isn't it? I have to go and find another balance staff to look at but definitely you haven't push the rivet down at all and I don't know I just don't like the look of this. Hamilton technical data number 129 replacement of broken balance staffs.pdf5 points

-

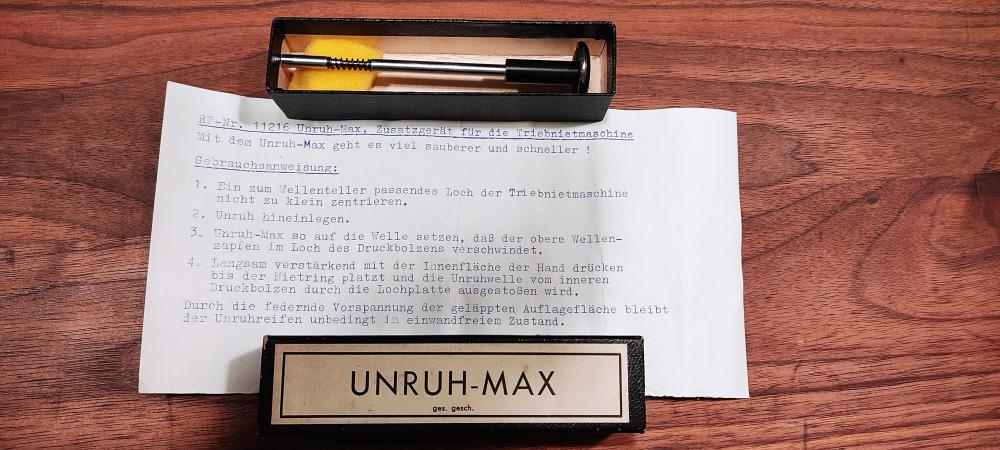

Sure, but you need to move to Munich. Here's my translation, which doesn't add much to NEW's description of how to use it. Ref. No. 11216 Unruh-Max, accessory for the staking set It's much quicker and cleaner with the Unruh-Max! Instructions: 1. Choose a hole on the staking set which is a good fit to the hub but not too small, and centre it. 2. Place the balance in the hole. 3. Set the Unruh-Max onto the staff so that the upper pivot disappears inside the hole in the clamping bolt. 4. Using the palm of the hand, slowly increase the pressure until the rivet flange breaks and the staff is ejected through the staking plate by the inner clamping bolt. Due to the spring-loading on the lapped contact face, the balance wheel remains in absolutely perfect condition. Guaranteed perfect results? Don't ask me, I've never used it. It came with a staking set I bought. I'm in the hub-cutting camp.3 points

-

Sorry, no native speaker, will do my very best. The table is the fixed ground level. The stand with the micromot and the grinding attachment is standing on the table, so the grinding ball has a fixed distance to the table. I lift up the vice with the balance in steps of 0.05 mm by putting sheets of paper beneath it. 1 sheet, grind away hub material by moving the vice around under the rotating ball, put next sheet so vice goes 0.05 mm higher, grind away hub material, next sheet and so on.3 points

-

Let's take this one step further and say that surely Hamilton/Elgin/Rolex wouldn't have not only developed, but bragged about the -- for want of a better term -- breakaway rivet if there was not a problem with watchmakers deforming balances. This isn't a discussion of best practices, but trying to address a mindset of either taking shortcuts or not having the proper skill or equipment. There are watchmakers without a lathe to cut the rivet, so they must seek less recommended methods to get the job done. There are watchmakers who learned from a teacher to punch rather than cut and in deference to a mentor will continue that tradition even when shown a better way. Then there are watchmakers who see a single purpose tool and determine that if the tool exists it must be because it's the proper way to perform a task. In other words, it's much easier to limit the damage with tools and redesign of parts than it is to change peoples' minds. Let me give you another example from the IT world. Everyone agrees that data needs to be backed up. Best practices suggest that it be performed at least daily and a copy is stored locally and off-site for both security and disaster recovery. And that backup needs to be tested and verified periodically. Whole industries have sprung up around data recovery specifically because best practices are either disregarded, debated or not known. And many operating systems now have auto reminders (aka nagware) that won't go away until some sort of backup is enabled specifically because people just don't do it. I consider myself educated and will most likely be cutting rivets going forward. Thanks to all.3 points

-

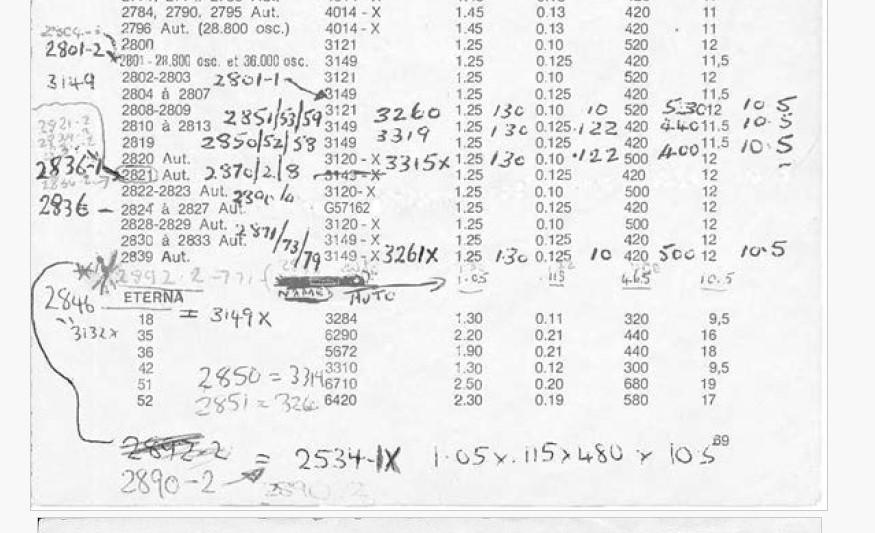

I don't take it like that, so no worries. I understand that both Cousins and Gleave advertise the same GR mainspring as 2377X, but the point I'm making is sometimes what mainspring advertised isn't what is sold. That's why I said about the mainspring for the ETA 2824-2. So, Cousins have that spring as a GR57162 which is 1.23 x .134 x 400 x 10.5. Gleave and Co. have the spring for an ETA 2824-2 as a GR3149X which is advertised as 1.23 x .134 x 400 x 10.8 and a GR3149X on Cousins website is down as 1.25 x .125 x 420 x 10.5 Now look at the GR mainspring size table I've attached and it says a GR57162 is 1.25 x .125 x 420 x 12 and the GR 3149X is 1.25 x .125 x 420 x 12 There is a lot of conflicting information right there! So, when I bought a mainspring from Gleave and Co. for the 7S26C, I actually bought an original Seiko 7009 spring from them and not a GR spring that they advertise, now I don't know what Gleave and Co. will actually send you here and now today, but last year it wasn't what they advertise now as the spring needed. You can email or phone them and ask for an original Seiko spring if they still have them. I've bought springs from Cousins in the past and when measured they are not the size that was advertised, so I'm assuming that people assume what they have been sold is what was advertised and what they require, which isn't always the case. 99.5% of the time I buy my mainsprings from Gleave and Co. and so do many watchmakers here in London, because if there is a problem with the wrong size being advertised or being received they will sort it out, where as Cousins more than likely won't, because they believe that they sent you the correct spring from the start and once the spring is out of its retaining ring, all bets are off, so to speak. Those same watchmakers, who I personally know, have been through all this with Cousins, so don't really bother with that kind of crap shoot anymore and rely on Gleave and Co. not to make those kind of mistakes. I think what I have said is a pretty important issue that many aren't aware about, especially when the springs inner coil won't fit the arbor and several springs are trashed in the process. I always tell my students, 'Never make assumptions!' Unless someone is measuring the dimensions of the mainspring, then don't assume it is the correct size just because someone says it is and relying on a sticker with a GR number on it that has been put on the packet by the seller. Me too!3 points

-

There's one here if any one is looking for one. (Not mine by the way :-))2 points

-

2 points

-

In my experience, it can be done and it doesn't necessarily elongate the balance arms if done carefully. I admit, the amount of material is a lot thinner than a plate, but it is possible and given that in some cases it's the only option left, as many here don't have the skillset to turn a new oversized balance staff to suit the oversized hole Again, this isn't an option to most here and I respect that you are able to perform this task, but this is a forum with watch enthusiasts and not necessarily 'watchmakers', so offering advice outside the skillset of most isn't always that helpful, with all due respect That's a really great way to do it. Watchmaking is all about finding a way to overcome the problem with what you have in your toolbox and in your head. I like the way you thought this one through and hopefully that will help others alleviate this problem. Nice one! Sorry about that... If a platax tool or staking tool is used to just punch out the staff, there is a risk of opening up the hole If the lathe isn't an option, then the way to go would be a platax tool or staking tool to punch out the hole. Staking tools do have a specialised tool for this. I liked @Delgettiway of removing material before punching out the old staff; definitely a safer way than just punching it out. Don't get me wrong, as I've used just a punch to remove the staff in the past and it worked fine and didn't open up the hole. I find it a lot safer to cut the hub or rivet first and then remove the staff. As I will always say, there are more than one way to perform a task, or skin a cat and I never want to dispute what works for someone, or try to say my way is better. I can only tell you what has worked for me from my experience, rather than from an opinion without an experience behind it. When I learn from anyone, if they have an experience, I will listen and maybe learn, if they have an opinion then maybe I'll pass on it, thank you very much.2 points

-

Thats what i meant when i said # without even trying #, i cant pinpoint exactly what it is, but you dont realise it comes across as kind of funny. Some of your words come out with an Irish accent . I laughed when you went into broken word sentencing, the introduction of the die adaptor, " and...it....looks....like............this". There is no guile about you, just honest and as you say personal and authentic, # this is me, this is my new tool ( and i love it, so I'm gonna stroke it for a few seconds ) and off we go. Like a classic movie that you enjoy watching over and over again.2 points

-

Hello, a flat dome is not a problem. But your punch seems to be bevelled at the hole, this is the problem. The bore must have a sharp edge to the domed face, dome beginning directly at the hole (see Jon‘s drawing). Worn punches can be touched up (domed in a lathe, flat ones in the staking tool with flat grinding / Arkansas stone). Frank2 points

-

Great review watchie, you need to do more, somehow you make them humoured without even trying2 points

-

2 points

-

Hello Qutadah, I'll try to keep this short, but it's a big subject with a lot of possible answers. As always, it depends. For some calibres, especially older ones which are no longer in production, you can get parts lists and even service instructions. A good source is the Cousins UK website, or the kind people on this forum. That doesn't guarantee that you can still buy the spare part, however. Some parts are interchangeable between calibres. For this information you need the Best Fit catalogues, also available here from time to time. None of this applies to Rolex, who are extremely restrictive with information and spare parts. This practice is common amongst the big brands, and it makes spares hard to come by and very expensive. With mainsprings, it's usually possible to find a generic part from a manufacturer like Générale Ressorts which will work fine. With hairsprings that doesn't work. You need to find the complete balance assembly.2 points

-

I have wanted a Robur watch crystal press and dies for a long time, but when considering the cost of about £510 (CousinsUK, excluding shipping and VAT) I just couldn't defend it. However, as the Robur-like press, shown in my video, now and then shows up in various YouTube videos I got curious and ordered it from AliExpress. I don't think it's on par with the Robur press, but for the price, it seems like a decent option. In the video, I happened to mention that I was going to link to my WRT service walkthroughs, so below is the list in case anyone would be looking for it. Hope you'll find my video useful! My Service Walkthroughs: Citizen 8200A ETA 2892-A2 2804-2 2836-2 955.112 2772 2472 2824-2 Vostok 2431 2409 Enicar 161 Miyota 8205 9015 Tissot 781 Omega 268 Orient 46E40 Unitas 6380 63251 point

-

1 point

-

1 point

-

I wouldn't feel bad about not knowing what this tool is I had two of them in my staking set. Occasionally our local watch group would have meetings of mystery tools bring your mystery tools. As watchmakers have a habit of accumulating tools beyond watch repair. Nobody knew what my mystery tools were? The staking set I had came from a company that refinished dials we wondered if it was something to do with that? that I'm not sure we've covered all the methods of removing staffs. Scroll down the page at the link below the Kirk's safety balance staff remover. something different also demonstrating the innovative nature of watchmakers so many ways to do something or perhaps so many tools to sell to watchmakers. https://www.daveswatchparts.com/BalanceStaffRemovers.html1 point

-

Not long ago there was a discussion about a tool for grinding the bottom part of the staff togrther with the hub This is on the same principle as @Delgetti uses with His method. This tool is usefull specially for those who don't have or use lathe. I have seen similar self made tools in the russian forum and will try to give link here if manage to find the thread. Here is link with images of one http://forum.watch.ru/showpost.php?p=2410366&postcount=101 point

-

They're a nice little gadget, better than a stake. Its good to know if the punch hole is empty. It has a clearance hole in case a pivot breaks off but if a pivot is jammed in the hole that might be fun getting it out.1 point

-

I thought I'd give you the benefit of the German instructions.1 point

-

Dont change anything about it watchie, it's informative and naturally funny . You just need to practice your oyrrishh accent ( thats Irish if you are from anywhere except Oyrland ).1 point

-

Its a vintage item, i doubt if they are still available, I've been trying to remember and looking on the net for it. Something like umax ? Urmax ? I'm not quite sure. I have a feeling Frank has one @praezis1 point

-

Ah ok watchie, i actually thought you were meaning that , i should have included that. If you are superskilled like obviously i am then you dont follow through. Ah ok watchie, i actually thought you were meaning that , i should have included that. If you are superskilled like obviously i am then you dont follow through.1 point

-

This is what i use with a staking tool ( not skilled enough yet to cut the staff out but I'm practicing ) umax ? It has a spring loaded vice that clamps the balance arms to the staking anvil. Hand pressure to load up the spring then an internal punch that pushes out the staff. It does a reasonable job of breaking off the rivet, as an aside piece of info the shelled off ring is 0.09mm thickness from a 10.5"' AS 1187, visible on the inside of the wheel hole.1 point

-

Thanks for your kind words @Neverenoughwatches. It would seem then that I have succeeded in doing what I set out to do. I would never have guessed, honestly! So you are right! Anyway, don't make me too self-conscious or I might lose it!1 point

-

When the staff gives, the tip of the stake will follow through and only be stopped by the hole in the balance arms. If you punch just a tad too hard, the tip of the stake will deform the hole. Well, the tip of the stake will always end up in the hole and deform it. It's just a matter of how much. Hope that made it clearer. The below video makes me grind my teeth. Oh BTW, did I mention that I think it's a bad idea to knock out the balance staff using a staking set?1 point

-

Hello @Qutadah and welcome to the forum. For simple parts lists, I usually find this page to be the most comprehensive: https://watchguy.co.uk/cgi-bin/files You can then choose the manufacturer, such as Rolex (https://watchguy.co.uk/cgi-bin/files?subdir=Rolex&dir=Technical Manuals&action=documents). The guy also keeps an amazing list of mainspring sizes: https://watchguy.co.uk/cgi-bin/mainsprings For MANUALS/service guides, everything gets much trickier. Good luck.1 point

-

Interesting way of doing things ! Could you please elaborate on the quote above, as I don't get that one ***EDIT***; Ah, now I see & get it, the grinding tool is fixed at a certain height Clever1 point

-

Absolutely, I will respect that 100 per cent! That would be fantastic and an inspiration, and I wish I could contribute.1 point

-

Congrats! That sounds like a really good and safe idea. Much safer than punching out the staff in a staking tool, which was my only point. And for those having "a mindset of not having the proper skill or equipment" (the audacity not to be ashamed), I'd recommend a Platax tool or a K&D balance staff remover tool.1 point

-

Thanks! It's just an iPhone 8 on a table tripod in between me and the press. The only "secret" (except for the tripod) is to make sure the lens and the hole in the phone for the microphone are free from any dirt, much like a watch movement Thanks! I had no idea I was able to add humorous elements so that's a bonus. Completely involuntary. I know I struggle and stutter with my English and I never do any retakes unless a complete disaster happens like my wife storming in asking why I haven't yet emptied the dishwasher, and I don't make any scripts. All I try to do is speak like I have someone beside me who wants to know what I think of the press. I want my videos to feel personal and authentic, and sometimes it takes a lot of discipline not to edit out what I don't like, for example realising I probably used the wrong word or was struggling to find any words at all. Any particularly humorous section as I'm pretty clueless? Just watched the video, and I am "screwing" around a lot, which I found a bit funny.1 point

-

I'm afraid that sentence doesn't make a whole lot of sense to me @Jon, as "any other method" would include using a staking tool. I'm not a pro, I don't have a ton of experience, and I could be wrong, but for what it's worth... I would strongly advise against punching out a balance staff using a staking tool (as demonstrated in too many YouTube videos) If a staking tool is used it's impossible to avoid having the tip of the punch reach into the hole of the balance arms. Depending on the force used it could not only deform the hole but destroy the balance. The advantage offered by the Platax tool is that it makes it impossible for the tip of the stake/punch to reach the balance staff hole. Perhaps you were trying to say "It's no difference using a Platax tool or a similar method such as a K&D balance staff remover tool to perform the same task"? If so, that would make a lot more sense to me. Surely, the Platax tool and similar tools wouldn't have seen the light of day had they made no difference. Yes, there seems to be some consensus that the safest method is to remove the rivet using a lathe, but if I've understood it all correctly, the true purists (who have nothing to be ashamed of) are not even satisfied with turning away the rivet, but instead the hub. However, if a lathe is not an option, surely a Platax tool or similar tool is safer than punching out the staff in a staking tool, no? If you don't agree, please let me know why and I'm sure I'll learn something new.1 point

-

All those (small) things may help, thanks for the tip That is going to be a bit problematic since the driving unit is light in weight and currently free standing. However, the front bearing of the polishing tool has a recess-groove and since the belt is pulling sideways, the rotating handle is a kind of "secured" sideways. Most likely, it's when the upwards force is higher than the "suction-force" of the oil, the weight of the rotating handle and the "locking-force" of the sideways pull in the groove, that the handle may become "unstable". But to my mind, to archive that force, compared to the size of the rivet-rim, the cutter has to really "dig-in" ......1 point

-

If the screw head polishing tool was raised above the drive the belt would be pulling down on the shaft, helping to keep it in place. A plastic sheet could be cut, lightly greased and held against the shaft with elastic, a temporary crude bearing. I read a post where a soldering iron was used to anneal the staff.1 point

-

Nice idea, but as you say, there are "problems". Being hardened steel, I assume a reasonable amount of force will be required. How did you do it previously? I too don't have a lathe, and use the K&D tool to punch out staffs. I have never noticed any damage to the holes. As mentioned in the previous discussion, it depends on what the balance is made from. I recently changed the staff on a Longines. After removing the staff I examined the hole under the microscope and could see no marks at all. But if I had a lathe ....1 point

-

Very well presented. I had the Robur with all the dies, I found it not to be as good as one of the other types of glass fitting tools which wasn't unlike the Bergeon 5500. It was much better and pressing down I found it much better in fitting then screw down. What set up do you have for making such a good clean and clear speech video?1 point

-

OK, As all can guess, I didn't know that the guy from the video is Mark. Now I am sorry, but what is done is done. Probably all have seen that my pen sometimes is sharper than needed, but that's me and I rather try to obtain beter expressiveness than meaning to offend somebody. But, i sometimes miss... Now to the point - my opinion is that Platax tool is good for taking off the double roller, but should be not used for staff punching. Call me 'radical', but I have said in other forums, that if You have platax tool, make it a present to You enemy. What i didn't like in the result in the video is that balance wobbles eccentricly to much. A Great Person (He is in beter place now) who I consider as my teasher once said that no wobble (both in plane and eccentrical) should be seen under 2,5X magnification when balance rotates. I always do my best to folow this. Now to the OP: See, closing a hole in a plate is to much different from closing of hole in balance arm. A hole in a big plate has many material around the hole and it helps to make the hole smaller as the material has no room where to spread araound so it has to go to the center. The balance arm is narrow and smashing it in the center usually just elongates the arm itself and makes it bend as elongation is different on the both narrowest places where the hole is. And, the hole as a result doesn't want to get smaller at all, but instead of it, the balance deforms badly and forever. So, my advice is not to try to close the hole. The best way to solve the problem is to make custom staff, and if the hole is not in balance center, to center the balance and turn the hole on lathe (this is not for compensation balances). But, I see that in You case this is not possible... What to do now? Do not use moment glue. Do not use shellac. I know that many wil not agree with me here, but I will advise to solder the staff to the balance arm. Use good flux, small quantity of led containing sloder and if the flux is acid containing, use alcaline solution to quickly wash the flux remains after soldering.1 point

-

1 point

-

I agree, the balance caps need to be removed as you have described @nevenbekriev, but the wheel train jewels have an oil sink, so won't have a cap and they will stay in place. Maybe I wasn't clear in what I was saying or what jewels I was referring to. I find with non shockproof jewels that placing the setting together and then oiling from the balance side and then pushing the oil through with a very fine honed down oilier works a treat, as capillary action sucks the oil through to the cap, rather than risking the oil moving as you place the cap back. It all depends on the way you like to do it as long as the results are the same. If you do it the way I have described and the oil doesn't suck through to the cap, then this tends to indicate that the gap between the top of the olive jewel that the balance staff passes through and the cap jewel is a little too big, which gives me a good gauge if the jewels and cap are in good order and will hold the oil in place like this picture form one of my lessons1 point

-

Now brace yourself for when you realize it has uses beyond watchmaking! Recently in another sphere of lunacy, I've been digging into leathers from different species to try to figure out how to tell the difference (specifically between horse and cow leathers). Also very useful for making/repairing electronics. Also, I modified a watch oiler (the biggest one in the set that never seemed to get any use) to fix skips in vinyl records. Also, I found micrometeorites in the driveway with my daughter (lots more coming on that front no doubt). Like you, I was very much on the fence about buying a microscope, and I have ended up using it for so many things beyond what I thought I would.1 point

-

A microscope takes the horological experience to a different level. Parts that you thought were clean are not, parts that you see no fault are faulty. I am greedy I have one over my lathe + two on my desktop one powerful Olympus which gives in incredible clarity and a AmScope which gives a high working space.. Also a digital scope purchased for me by my other half, its clarity is poor but does give the ability to copy what’s in view.1 point

-

I have a height adjustable desk and it's fantastic. Gives you so much flexibility to switch between microscope and non-microscope work. Also when working with the microscope only, you'll change the working height (your eye-level) frequently. Your back/neck will thank you very much for an adjustable desk!1 point

-

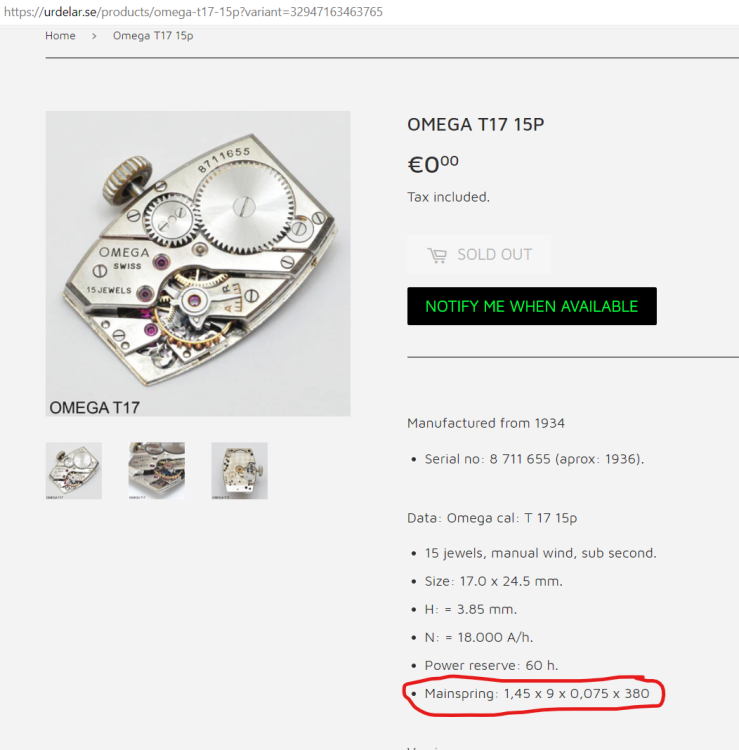

Hello all and hello @Oyster, So, this is interesting. I ordered the GR 3632 and I didn't manage to get it into the barrel... it was ever so slightly too big. A bit strange. But that's not the main thing I want to share. Since I couldn't get the 10mm diameter mainspring into the barrel, I was looking very hard for a 9.5mm mainspring with similar height/thickness/length. I found GR3937 with 1.45 x .085 x 380 x 9.5. Three things: 1. It's a tad longer, so I'm hoping to get an amazing power reserve. 2. It's a bit higher than GR 3632, which had me a bit worried, but it does fit (just!). I had also found one link where 1.45 is actually specified as the correct height for the T17. 3. It's a bit thinner than the GR3632. I believe to understand that mainspring power/torque is a function of "height" x "thickness"-squared. Thus, power of GR 3632 would be 1.4 x 0.09^2 = 0.01134 , whereas the GR 3937 is 1.45 x 0.085^2 = 0.01048. So the GR 3937 is about 7-8% weaker. So after using GR 3937 and oiling only the balance (and the barrel), I'm already getting over 300° amplitude! So I ended up using HP 1300 on the whole train and 9020 (instead of 9010) on the escape wheel. I'ts running at around 315° amplitude now. CONCLUSION: WHY all this long story? I'm just saying the the modern GR mainsprings that are indicated for very old calibres, can easily be over-powered. In your case, I'm certain that's the case. If I had 7-8% more torque from the stornger mainspring (and used thinner oils for the train), I'm sure my T17 would also be knocking.1 point

-

Hi Melamine is ok but its only a layer over chipboard, Unless you use resin bonded which is water proof the normal chip soaks up water and expands. Granite is heavy but a total pratt to drill and cut without special tools. Good and aged mahogany is no problem and virtually water proof due to the tight/dense grain. I have some that was out side here in Scotland for 7 years still good.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)