Leaderboard

Popular Content

Showing content with the highest reputation on 03/07/24 in all areas

-

4 points

-

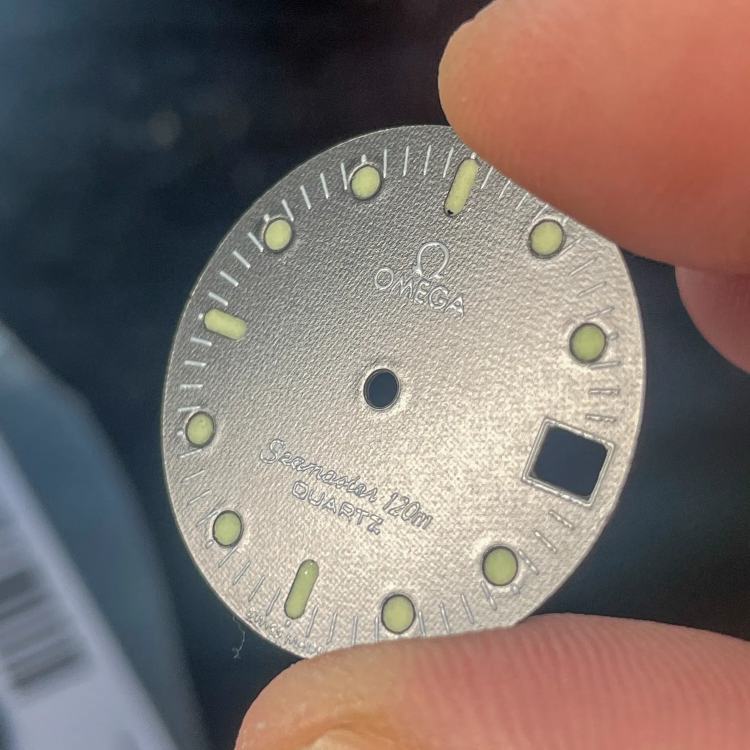

Nowadays I find tools a lot more fascinating than watches. Just owning some expensive watch wouldn't bring me any joy. Using thousands of € worth tools fixing a cheap old piece of crap, now that's something! If I was filthy rich I'd probably invest in old beaters anyway. Some old Rolex exp would be nice. Watches used to be for telling time but they've become this luxury brand price tag queuing contest, at least for some.4 points

-

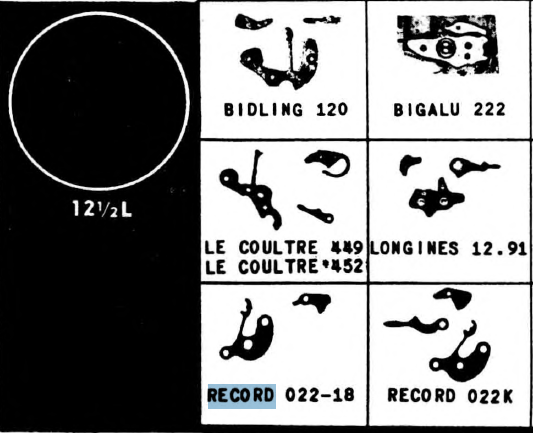

It looks like a Record 022 or 022k movement by the shape of the setting cover. I found a link to a photo for the 022k - https://www.buzzufy.com/blog/2017/02/03/record-caliber-022k-movement-specifications-and-photo/ From the 1930's. The link says 17 jewels. It looks close. Also link to this site with a similar watch -3 points

-

Each arm ( beat adjustor= mobile stud carrier & regulator arm) , has a circle at one end with a slot cut in them making a C ring, the C ring wraps around the setting . To minimize the risk of bending the arms , insert the cutting edge of a safety razor blade under the C riing near the slot, half of the C ring snaps out of its groove, Next grab the arm in a stout tweezers to prize up the arm. beat adjustor arm is mobile, once cleaned/ reassemble / lubed and wound , move beat adjustor arm to bring the impulse jewel in- beat, then move the regulator arm to regulate the escapement. Good luck2 points

-

Woohoo! As you can see, on my desk by the demagnetiser, is two sets of files. On top of the plastic cupboard, which you cant see, but it is there, is a bench vice. Prepared, I am.2 points

-

We all start with an interest in watches, then watch fettling, that quickly degenerates into being a tool collector and restorer. Tom2 points

-

Like an Irish decorator i once worked with on a building site, he was told to paint the porch at the front of the show house in green. Yes he painted the site manager's car2 points

-

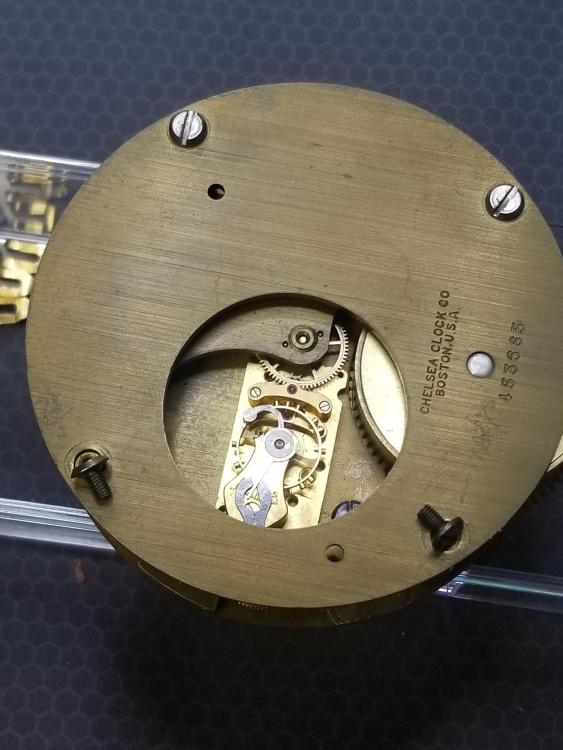

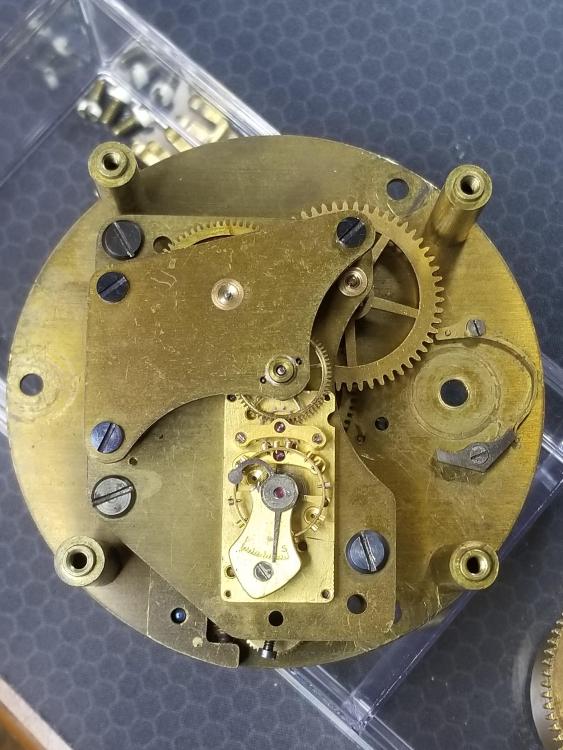

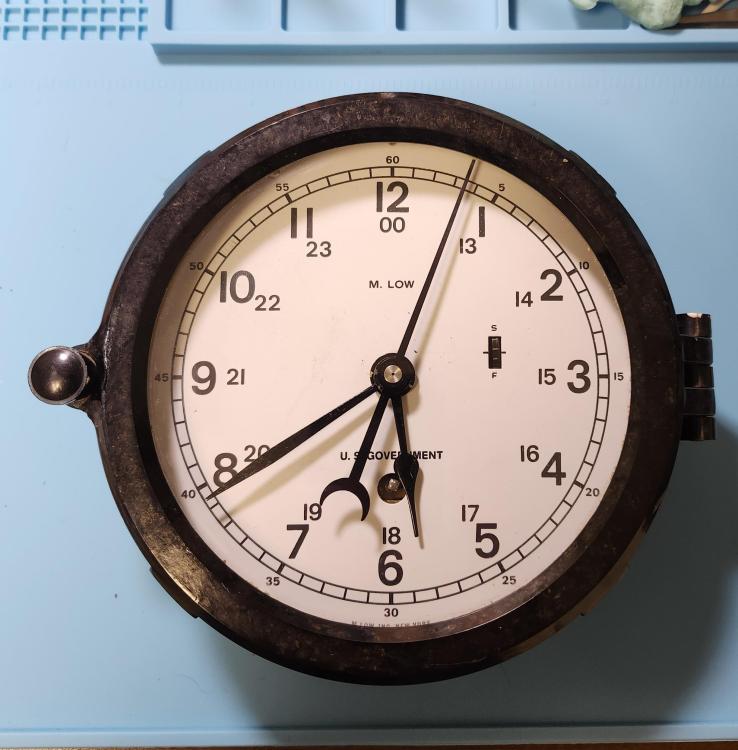

Yes, the Hermle is modern - it was purchased in the early 80's. It was taken to a clock repair shop for a service in the 90's (I have the receipt for the service...) It was absolutely dripping with oil when I opened it. Runs just fine now and does the nautical "8 Bells" chime like it should. The case on the Chelsea is made of Bakelite. It's a bit discolored, but it kind of adds to the character. I've attached a couple of pictures of the movement that I took while disassembling it.2 points

-

Yep you're well on your way to being a tool junkie Ross. I think we spend nearly as much money on plastic cases. I have to admit I'm the same, I'm not pulled by the expensive brands at all and certainly nothing new or modern. If someone gave a Rolex i would sell it . I'm in my happy place using all the gadets and gizmos to fix the unfixable. Yoda1 point

-

Ok fella, oil of cloves mate , takes the edge off it. @HectorLooi might have a better suggestion for you.1 point

-

1 point

-

I remember my grandfather asking me if I were stranded on a desert island and could only have one tool what would it be. The answer is a file. With a file you can make all the other tools.1 point

-

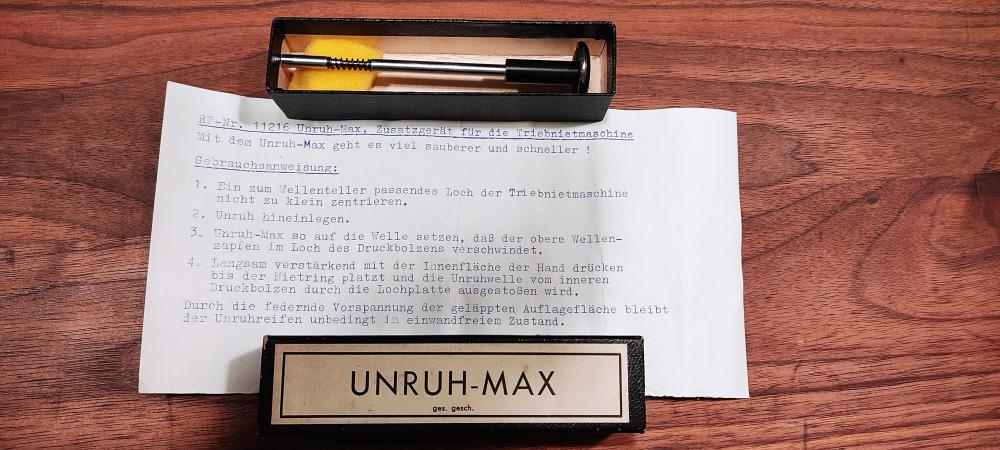

They are a good tool for removing a balance staff. Better than using just a stake, as the balance arms are held firmly in place at the same time the spring loaded part does its job1 point

-

1 point

-

1 point

-

@Nev: sure I have an UnruhMax (Unruh=balance wheel). I threw it in the backmost corner of a drawer after my first totally damaged spoke/hole (some decades ago)! Repeat it 100 1st or so times: No tool, if Platax, Unruhmax, etc can support the area around the hole when punching the staff out. For doubters I can show the picture again . And I have a question to all hole punchers for closing: where do you punch? - on the hub side and spoil the flat seat, rivet side still too wide? - on the rivet side and produce a groove where the rivet should grip? Then say good bye to ever get a tight rivet with this wheel… Frank1 point

-

It is indeed an early Record 022 K, sometimes marked on the 3rd wheel bridge, has a different crown wheel to later versions. II have two of these, good movements. Looks like the barrel teeth have been caught when decasing ?1 point

-

Well I'm English and I always say Porch. So am I still arrogant?1 point

-

There is an issue with the balance spring most likely. When segments of the coil stick to each other or to the balance cock the rate starts speeding up. Make sure the hair spring is not bent (should be spaced evenly), 100% clean and not magnetized.1 point

-

You can demagnetise the fully assembled watch, or just the movement, or if disassembled all the (steel) components individually. Obviously, the first option is the easiest, but sometimes the case is designed to shield the movement from magnetism. I doubt this is true with Elgin pocket watches, but as you are disassembling anyway, your best option would be to demagnetise the whole movement outside the case. There are a wide range of demagnetisers available, in all price classes. In my experience, the cheap blue ones with the red button work fine if used correctly.1 point

-

1 point

-

Please do, I love the site being international and as said before I respect anyone who can speak a foreign language, my weakness. How about speaking Swedish words in English, the pronunciation will be different to how we natives pronounce them. Whilst in skagen, I asked a shop keeper how the name was pronounced and it was nothing like the English version. For example, a make of German car was Porch, not Porche(r). Hehe, typical arrogant Englishers.1 point

-

1 point

-

This was said several times here - it is not possible to cut the rivet fully without touching the arm, and even when rivet is cut, still remains spreaded part of the seat that is not able to be cut. I am not sure how clean I explain, but see the rivet on this picture and try to choose a line where the rivet must be cut and will see what i mean.1 point

-

Not long ago there was a discussion about a tool for grinding the bottom part of the staff togrther with the hub This is on the same principle as @Delgetti uses with His method. This tool is usefull specially for those who don't have or use lathe. I have seen similar self made tools in the russian forum and will try to give link here if manage to find the thread. Here is link with images of one http://forum.watch.ru/showpost.php?p=2410366&postcount=101 point

-

My Thoughts: I think the winding stem has been pulled out and away from the setting lever pin. You could remove the stem from the movement and re-fit it, I have done a Tissot 2481 and from memory it is a push release rather than a screw. But most likely the the yoke has come out of the slot in the clutch wheel which would cause the issues listed. Either way its dial of to fix the problem Just a correction to my previous post: Couldn't edit my post # The dial does not have to come off, just to remove and replace the stem #1 point

-

1 point

-

This is what i use with a staking tool ( not skilled enough yet to cut the staff out but I'm practicing ) umax ? It has a spring loaded vice that clamps the balance arms to the staking anvil. Hand pressure to load up the spring then an internal punch that pushes out the staff. It does a reasonable job of breaking off the rivet, as an aside piece of info the shelled off ring is 0.09mm thickness from a 10.5"' AS 1187, visible on the inside of the wheel hole.1 point

-

1 point

-

Hello @Qutadah and welcome to the forum. For simple parts lists, I usually find this page to be the most comprehensive: https://watchguy.co.uk/cgi-bin/files You can then choose the manufacturer, such as Rolex (https://watchguy.co.uk/cgi-bin/files?subdir=Rolex&dir=Technical Manuals&action=documents). The guy also keeps an amazing list of mainspring sizes: https://watchguy.co.uk/cgi-bin/mainsprings For MANUALS/service guides, everything gets much trickier. Good luck.1 point

-

I like your enthusiasm to be able to repair and service watches, although working on quite small movements such a Omega 260 and Rolex 4211 isn't where I would start. These are very small and old movements, which probably have a lot of issues and need more than just servicing to bring them to their optimum working values. I don't want to discourage you, in fact quite the opposite, but if you want to learn the basics in watch movements and servicing them I would start on something that works flawlessly and is big, such as an ST36, which you can pick up from Cousins or AliExpress for not a lot of money. If you need spare parts, just let me know, as I have loads and will be happy to give you what you need when they spring off into another dimension. I use these movements for my first year lessons/classes, for the reasons I have mentioned. As @Klassikerhas already mentioned service manuals for Rolex are very restricted and usually you may just get a parts list for older movements, which might not be as helpful as you wish. Hairsprings will always come with a balance and be known as 'balance complete' as the hairspring has to be vibrated to the correct BPH for the balance wheel, although a replacement hairspring can be 'vibrated' to the correct speed to suit the balance, but that isn't something you'd be doing as someone new to this. What I would suggest is start with the basics in learning how to service a watch that is perfectly running to start with, then learn about fault finding and alleviating those faults before starting on vintage watches that are full of problems and faults, as your frustrations may lead you to believing you are not any good at this, which is quite natural. Mark Lovic, our founder, does a very good course that you can buy https://www.watchfix.com/ I also hold beginners courses in London, but also online real-time online courses athttps://www.jonthewatch.co.uk/evening-watchmaking-courses1 point

-

The caliber number is what you might call the type i.d. for the movement. The number you gave appears to be the model i.d. of a ladies' watch. Is that right? Time for some pictures. Do you feel confident about taking the back off?1 point

-

Thanks for this image. I'm a newbie and it answered a question that I had! I just found this forum yesterday, and I'm ecstatic!1 point

-

you do not have to unpin the hairspring but you do have to remove the balance wheel from the bridge which are going to have to do for cleaning purposes anyway. To remove the balance wheel there are two separate steps of getting it off the bridge. first you need to loosen the hairspring stud screw. It's in the image below this will allow you to push the stud out but not yet and once it's out gently screw it back in again so doesn't fall out it's a pain to put them back in when they fall out then you remove the balance bridge with wheel flip lid upside down because you need to release the hairspring between the regulator pin and boot. you can see a side view picture here of understand better of how to free the hairspring up we can see a side view here notice I marked something that's basically a screwdriver slot. So with the bridge upside down you put a screwdriver in here gently turn 90° or just enough to free up the hairspring so I can slide out then you can gently flip the whole thing over and pushed the hairspring stud out and in the whole thing should be free of the balance bridge. here's something that would help out in addition to the help from the group. a PDF on servicing platform escapement's Servicing a Platform.pdf1 point

-

News Update 29/02/2024 Yesterday Cousins and its legal team went to the High Courtin London to oppose the application by Swatch to have our UK claim struck out. The case was heard by Mr. Justice Michael Green, a High Court Judge who also sits in the Competition Appeal Tribunal. In previous news stories, I have explained the arguments that we intended to bring, and I will not repeat them here. However, I am in no doubt that by the end of the day, Judge Green had a full picture of the consequences for Competition if Cousins action is not allowed to proceed. It was noteworthy that the Competition and Markets Authority sent a member of their Legal Team to observe proceedings from the Public Gallery. As expected, after more than five hours of evidence and legal argument, Judge Green advised that he would consider the matter further and release a written verdict in due course. Afterwards, our legal team said that the case had gone as well as it could have done, and better than they had thought likely. There is no fixed timetable for the verdict, it entirely depends upon the workload Judge Green has, but we hope to be able to advise you of the outcome in a matter of weeks rather than months. Regards Anthony1 point

-

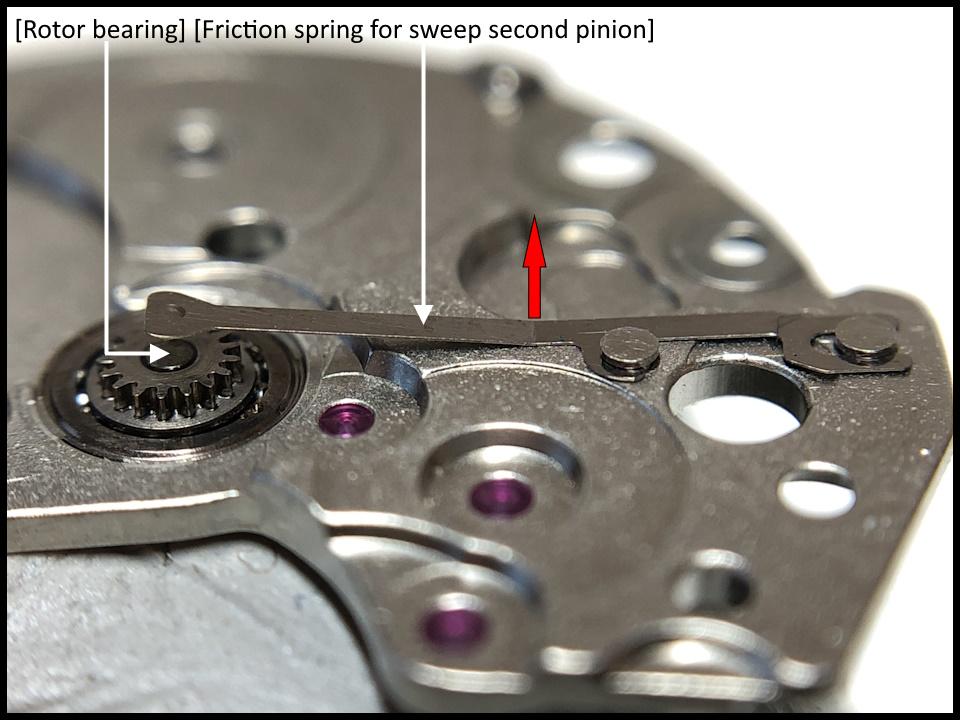

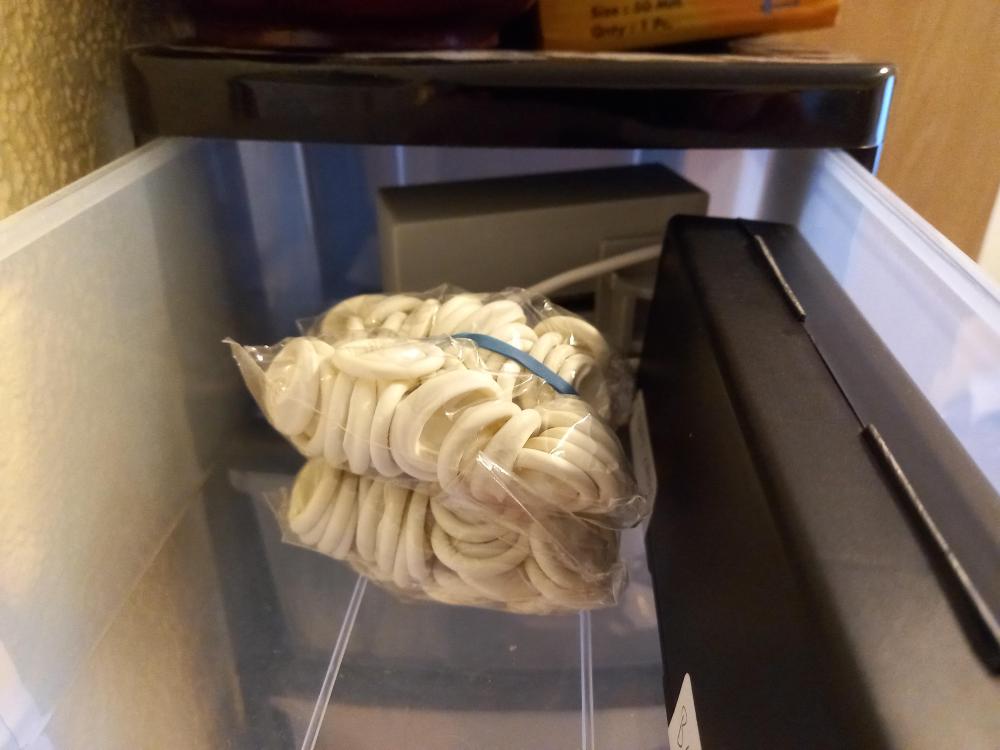

Disassembly pictures here (Please sort the pictures by name in ascending order) Assembly pictures here (Please sort the pictures by name in ascending order) Introduction To make a long story short, I've got about 100 Indian Citizen watches in my possession. It is one of these 100 watches shown in the pictures above. There is no major fault with them other than that none of them work. We all know that Citizen is a Japanese brand, but these watches are manufactured by HMT in India under license, probably sometime in the 1980s or 1990s. So, what do you do if you have 100 fine new old stock Indian Citizen watches that don't work? Well, you service and repair them, and then you sell them for a reasonable amount of money. How hard can it be!? Selling them, once they work, has happily proved quite easy, but repairing them has proved more challenging. So far, every movement has been full of gremlins to defeat. As usual, I want to remind those of you who have no previous watch service experience that this service walkthrough should not be seen as a tutorial on how to service a movement. It takes a lot of tools, consumables, training and know-how to succeed. Fortunately, there are several excellent resources, like WRT, and watchmaking schools online, and believe me, after six years I still find it insanely interesting and fun! About the assembly and disassembly pictures Unlike the disassembly pictures, the assembly pictures document screws, lubrication, and tips and tricks. Regarding the lubrication, I have not found any specific documentation for this movement. Instead, I have used my judgment and experience. It took some experimenting with the lubrication of the date and day change mechanics to get to work smoothly, so I feel a little extra proud of that. About the Citizen 8200A / Miyota 8205 movement The movements in these watches are designated Citizen 8200A on the rotor. In practice, they are identical to Miyota's calibre 8205, and if I'm not misinformed the watch manufacturer Citizen owns the movement manufacturer Miyota so there's a natural explanation. I have previously created a service walkthrough for Miyota's calibre 9015 which is often found in more expensive micro brands. Miyota's 82XX series of movements, such as the 8205 are instead found in more affordable micro brands, but there is no doubt that it is fundamentally an excellent and reliable movement. So, what do you find when you open an Indian Citizen like this? You find a well-constructed, well-functioning, albeit simple movement. In my opinion, it has a minor construction flaw, but I will report back on that. I have no idea how Indian HMT operated, but my impression is that these movements were assembled in an unsuitable environment, to say the least, by people with low-quality tools and a lack of knowledge of what a movement is and how it works. However, the movement parts themselves generally seem to be of decent quality, but when you take the movements apart you find fingerprints, hair, fibres from clothing, glue, and sometimes what I guess could be food residue. I.e. you find everything found in a typical home, so maybe that's where they were put together. As for the lubrication, sometimes it's OK, sometimes it's missing, sometimes it's in the wrong places, and sometimes there's way too much. However, once repaired, serviced, demagnetized, and adjusted these Indian movements work very well, so well that I don't think you can tell them apart from their siblings that are manufactured and assembled in Miyota's factories in Japan. Following are some tips and tricks that I hope will be useful. Stuttering second hand As in many other movements, the second hand is driven indirectly via the teeth of the third wheel, and to prevent the second hand from stuttering around the dial in a jerky fashion, a friction spring is pressed against the short side of the sweep second pinion. If the friction spring is not tensioned enough, it will not do its job. If this is the case, which is quite common, then the distance between the tip of the friction spring and the rotor bearing can be slightly increased by prying the friction spring slightly in the direction of the red arrow away from the rotor bearing. Balance staff end-shake I have long wondered if it would be practical to increase the end-shake of a balance staff using ordinary aluminium foil of the type you usually have in your kitchen, and now I have had the opportunity to test it. I admit it's not a very elegant or perhaps even correct solution, but it seems to work unexpectedly well, at least with this calibre. The aluminium foil that I have in my kitchen is exactly 1/100mm and after I built up the balance cock with two layers the end-shake was perfect. Guard pin The metal that the pallet fork's guard pin is made of on this calibre is unusually soft and therefore easy to deform, above all in height, but therefore also easy to correct. Several of the copies I worked on had a deformed guard pin. Normally, the guard pin should run parallel to the fork horns. Why this problem seems to be so common is hard to answer, but maybe my Indian colleagues were a bit careless with their tweezers when handling the pallet fork, or it's a matter of poor QC. Who knows!? The tip of the sweep second pinion You might think that all the parts for a certain calibre would be identical, and they largely are, but one exception is the tip of the sweep second pinion whose diameter can vary between different copies of this calibre. It is therefore not certain that the second hand from one copy will fit on another. I have not discovered any more exceptions than this. The Automatic Winding The automatic winding on Miyota's movements, including their premium movements such as the 9015, is unidirectional. I've always thought that would mean it's half as efficient as bidirectional winding, but in practice, unidirectional winding seems to be about as efficient as bidirectional winding. As can be seen from the picture, which shows the underside of the barrel and train wheel bridge, not many parts are needed for the automatic winding. I think this simple and well-functioning solution is elegant! Glue or shellac? The first time I took this calibre apart I suspected that the balance spring was attached to the stud with shellac, but after cleaning the movement in my watch cleaning machine where the final rinse is 99% IPA, I no longer think so. Instead, I think it's glue that simply looks like shellac. A small construction flaw I have had a user of this movement break the winding stem and misalign the threads in the crown believing that he had to pull hard to get the movement into position to set the time. I don't blame him! This movement has what I would describe as a design flaw that makes it impossible to pull out the winding stem when it is in a certain position. When you pull out the crown, the sliding pinion moves inwards (upwards in the picture). If you are a little unlucky then the pin (lug) on the sliding pinion will be right opposite the pin on the day and date corrector (as in the picture) so that the two pins collide with each other. When this happens, it becomes impossible to pull out the winding stem to its extreme position to set the time. If you then use force to pull it out, one or a few parts of the keyless work will unfailingly break. Most likely, the stem will come off and the threads in the crown will become crooked. What one must do as a user of the watch to ensure that the pins do not collide with each other is to rotate the crown slightly while pulling out the stem. When you rotate the crown, you also rotate the sliding pinion, which means that the pin on the sliding pinion does not risk colliding with the pin on the day and date corrector. Other documentation I am attaching a couple of PDF documents for the movement and thank @JohnR725 for links to a couple of interesting articles about the collaboration between HMT and Citizen. That’s it! Thanks for reading! Citizen 8200,8210,8260,8270,8280.pdf Spare-parts-reference-for-the-Miyota-8205-8215-movement.pdf HMT Watches: The Rise and Fall of India’s Watchmaking Titan HMT Watches: A walk down the memory lane1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)