Leaderboard

Popular Content

Showing content with the highest reputation on 04/11/24 in all areas

-

Hi. At least you found a contributory factor, it needs very little to stop a watch so a good clean should suffice, get some good oil the likes of 9010, it available on the net in small phials so no need to spend a fortune.2 points

-

The wire should be usualy 0.3-0.4 mm hard brass and the gap should be about 2x-3x thickness of the spring2 points

-

I couldn't resist Ross, and have started hacking some brass I have left over from the balance holder. Construction is under way ! What lapping paper do you use ? Alex uses 6, 3, 1, and 0.5 micron. Cousins don't have 6 micron, but they have 5 (4500 grit). I have 3000 grit wet and dry, so I'm wondering if I could go from that to 3 micron, 1 micron, and 0.5 micron (is this final one really necessary ?) I need to find some glass The hardest thing was finding the parts I knew I wanted, but had no idea what they are called. I found them eventually2 points

-

Send the bloody things back. These are not expensive but they will get you started. https://www.hswalsh.com/jewellery-tools-equipment/jewellers-bench-tools/jewellers-watchmakers-pliers/economy2 points

-

I've just got a very strange Q&Q watch. The movement (Q&Q 2604) has several parts in ... plastic! I know this is the case in other watches, such as Seiko 5, but that caliber has an escapement wheel, a lever and a balance finger made of red plastic. That's incredible! The funny thing is that is works quite well. I disassembled partly the movement because it didn't work, and then reassembled it (6 pivots under the same bridge ...) and it's ok. I guess this watch won't work well for a long time, but this is an automatic watch which indicates the hour, minutes, seconds, date and day, and it was very cheap when produced. As I understand, Q&Q belongs to Citizen. Has anyone had the opportunity to see such a "plastic caliber"? Here are the details of that movement : https://17jewels.info/movements/q/q-q/q-q-2604/2 points

-

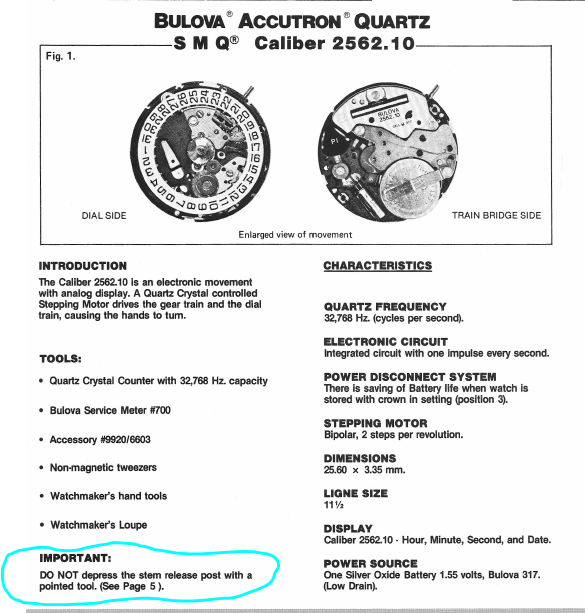

JohnR725, thanks so much for the amazing amount of information. That must have taken a bit of time and effort and I appreciate it. In addition to some great documentation which I have saved, I have some key takeaways from your comments which I’ll summarize here for the benefit of other new people: 1. Improper stem removal procedure may have knocked some parts (sliding pinion) out of place but most likely nothing is broken. I may have to disassemble the watch and keyless works to fix things. 2. In the absence of clear direction, default to the set position (#3) for removing the stem (I understand that is your preferred approach only and not a general documented recommendation) 3. When asking a question about a watch always include the movement number and a picture. People who are not familiar with the movement number may be familiar with the movement by sight. Also, identical movements can have different movement numbers. 4. Newbies need to learn how to distinguish the movement number and manufacturer from the watch manufacturer and model. It’s the movement that matters. 5. Available on line documentation is frequently saved in incomplete PDF files, with only portions of the parts lists and service information saved in the file. This requires multiple searches to obtain the complete information. 6. VERY IMPORTANT- don’t stick pointy things in screwdriver shaped holes. I have a feeling this is going to come back to bite me. I may have dislodged some keyless works parts. The setting lever to be precise. Oh well, more experience disassembling. Thanks for taking the time to help me along the path.2 points

-

Differences between Vostok 24XX parts: Introduction I like the Vostok 24xx movements for several reasons, one of them being that they are so affordable. A mistake made never spells financial disaster. They have been reliable Russian/Soviet union workhorses for decades with (perhaps to some) surprisingly good accuracy. Another reason and the reason for this thread is that the parts of these movements most often are interchangeable, but not always! Most of the time the parts used in these movements (2409, 2414, 2415, and 2416 being some of the most popular) are interchangeable, and the sellers on eBay often mix and match parts from non-working movements to build a working watch. For example, don’t be surprised if you find a train wheel bridge stamped 2409 (w/o date complication) mounted on a 2414 (w/ date complication) or vice versa. As far as I know the Vostok 24xx movements have been in production since the early 1970-ties, and there are sometimes slight differences between the same parts between these movements and between generations of these movements. The purpose of this thread is to try to document these differences to facilitate any work made on these movements. I’m a hobbyist, and what follows are my personal observations. I make mistakes and sometimes draw the wrong conclusions. When and if you spot my errors, please let me know! I encourage anyone with any experience of the differences between the parts of these Vostok 24XX movements to contribute. Thank you! My first topic will be about the click. Please see the next post!1 point

-

RichardHarris is right, something is out of place, it happens, you might be able to remove the circuit and straighten it out too....1 point

-

I have already mentioned to Mozart that I can't find PDF of the book, and that he should buy it.1 point

-

A little update on this if anyone is interested: I have found some time to open it up and really have a proper look at the movement. The markings indicate that it hasn't been serviced since August 1992. This seems consistent with the state of the movement, as there were small pieces of gunk built up between teeth, under the mainspring barrel etc. . While I couldn't identify a specific piece of dirt that was impeding the movement, it seems highly likely that this was the cause for the stoppages. It's proving somewhat difficult to clean the teeth on the escape wheel and the center wheel, but a few more rinsings in lighter fluid/99,9% IPA should do the trick (I would really love to have a cleaning machine). Overall the movement is in good shape, all of the jewels look great and it honestly just appears to me like the issue was a lack of service. Obviously at this point in time the movement is not back together, so I will refrain from celebrating until the thing is actually ticking away and keeping good time! I will update once more once I've put it back together.1 point

-

I agree. It must be it. Perhaps, the yolk spring is not engaged properly. It appears that the setting lever spring assembly (plate) is slightly tilted / not sitting flat? It would be nice to see a pictures without the setting lever spring assembly.1 point

-

The main thing is to make sure that what ever the position you have the regulator the hairspring is free and stays in shape.1 point

-

Cheers Hipps! I've ordered myself a couple of long and short nosed plyers. I'll leave Temu for the Mrs birthday presents1 point

-

Have you properly greased the parts? If the yoke is sticky on its post it might not move enough under the push of the spring to slide the clutch across. I had something similar once (with a much crappier movement than this) with the yoke sticking under the cover plate. Have you followed the tech sheet for reassembly and lubricating? It’s freely available. https://www.watchys.ch/index.php?controller=attachment&id_attachment=211 point

-

Yes it is. But the stem is called a stem and not a winding stem. Because there is nothing to wind.1 point

-

Something has dropped out of place in the keyless works. Try it with the watch dial side up, if not joy, you'll have to remove the dial.1 point

-

Platform is the small separate plate with the escapement and balance on it.1 point

-

The only thing I can see, is the yolk seems to be a long way away from the set lever in the first photo. A problem with the yolk spring?1 point

-

1 point

-

Well that moved along quickly. So its a Pierce cal.130, with a broken spring at least. Between my original post and now I was wondering how the movement accommodated driving the hands round and allowing the reset. I had come to the conclusion that friction must be involved and was going to look closer at all the leaf springs dotted around the main plate, seems there might also be a rubber or fibre component involved. I've attached photos of the dial side - plenty of wear there. Thanks for the links, time to start learning more. That's why we do this, isn't it?1 point

-

Hello and welcome from Leeds. Read this thread https://www.watchrepairtalk.com/topic/28237-please-help-me-buy-a-polishing-machine/?do=findComment&comment=2378701 point

-

Hi, new member (name's Will) here I am into a lot of Citizen Eco-Drive, Tissot, Hamilton and the other middle-tier brands (not at the point of buying too luxurious watches). Recently bought 3 Soviet watches (probably not the dial but the movement) and hence have A LOT of concerns (and interesting points of these watches to share, too). I would want to learn more about fixing and maintaining watch conditions!1 point

-

You have to check if the post on which the hammer sits and is pivoted has not untightened. It is on thread and often gets loose and thus lets the hammer have significant free play. The bearing on the hammer also can get loose and has to be checked for tightening, but I don't remember if in this movement it is on thread or not. If there is no problem there, You must take care that the hammer falls on the heart not too high above the wheel surface and in the same time the wheel not to be able to go down as much as to be enough free place between the heart and the cock for the hammer to get in between. What I mean is if the cock is lifted up (like it seems looking at the picture) in order to place the wheel higher, it will not help as the wheel will go down easy. The axial free play of the wheel should not alow the hammer to get above the heart. So if the hammer hits the heart not in place, it must be solved by changing the hammer position rather than the wheel position. It can be achieved by bending the hammer or the post on which it sits, but both lead to risk of break. If such correction needed, I would rather anneal the hammer localy close to the bearing and polish it to clean the blued surface after. PS Now I see that what i have written about the post is not correct for this calibre, as the hammer has different bearing type here. But no mater, the hammer should not have significant free play1 point

-

1 point

-

1 point

-

1 point

-

yes there is always a chance. or have enough friends and send the image and get the answer back I have below. then if you are in the Seattle area the person who gave me that occasionally gives lectures on these watches yes I remember the watch with the rubber clutch just didn't remember what it look like. This is a Pierce 130. Good luck with it. It has an internal rubber clutch that must be replaced when it is serviced. then now that we know what it is we can search for it. a little information is found at the link below https://mb.nawcc.org/threads/pierce-130-and-134.178909/1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

1 point

-

yes quartz watches have simpler keyless works but removing the stem in the wrong position can result in sometimes things relocating themselves and unfortunately that requiring disassembly to put things back. Fortunately sometimes with some quartz watches you don't even have to remove the movement from the case you can get at them from the backside once you remove the circuit board as a lot of times will be under the circuit board if you're lucky. Otherwise you'll have to remove the hands and dial to get at it that way. then movement numbers are outstanding so we know what you're talking about but even better is a movement number and a picture. Often times people look at the picture and say oh and will give you an answer based on that similar to other things or in this particular case I can say oh I've seen this before. This is because in the world the watches they've made a lot of them. so complements of the Internet we have a picture of the movement yes it's vintage and there's a heck of a lot of plastic as you're new to this I thought I would expand your question to something? I'm attaching three separate PDFs and I'm going to snipped out an image from one of them. one of the problems that comes up and watch repair is service information is it available? The answer is sort of sometimes. For instance the 944.131 PDF you'll notice only has two pages of parts. Which conceivably for that document is all that it had as we would need the base caliber which will likely what it had more parts but even this one might have had an entire service procedure but a lot of times when they are converted the PDFs way back when they did not include any of the service information. So a lot of time she'll get parts lists only no service even though the service part did exist. Then the 944.011 manual we get more information. We get the test procedure and of course the parts list but no servicing information. then another confusion for newbies and watch repair is who made their watch? Watch companies that make watches don't always make their own movements they purchase them like Bulova we get the best manual of all and of course they gave it its own part number. then if you look at the Bulova PDF right on the first page is a caution. There other cautions for removing the stem like the proper tool the push on the button to prevent the setting parts from relocating themselves then on page 5 we get the caution which wasn't even one of your concerns. yes often times on watches you're not supposed to use pointy tools to push you should use a screwdriver as they designed it to limit how far you can push but only if you use a screwdriver. Often times you'll see the whole for pushing and there'll be a slot right in the middle to remind you to use a screwdriver rather than a pointy tool. Bulova 2562.10.pdf 3918_ETA 944.011, 944.111_smaller.pdf 3920_ETA 944.131.pdf1 point

-

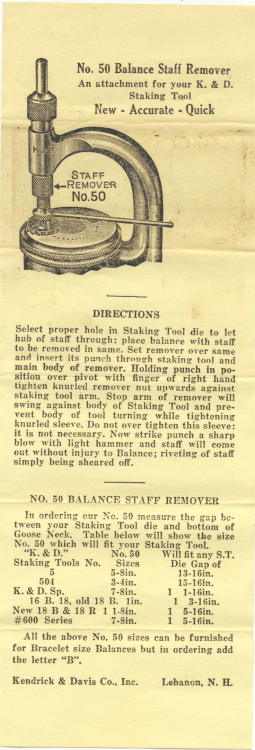

technically they're all a balance staff that comes in a variety of sizes. Other than the size I don't think there's normally a difference in these staffs. So might be better defined the staff by watch size rather than a terminology of this watch is tiny for instance. but then there is the other minor issue of terminology. terminology in watch repair is interesting in that depending upon location there will be a different term for some of components. Then time also changes things as terminology even in locations has changed over time. So for instance a balance staff for an American pocket watch should be defined as a 18 size staff number something for an Elgin pocket watch for instance. With 18 size being a important factor versus the Swiss size definition of ligne. or there is the other thing like watchmakers are enthusiastic to embrace other people's tools that's why we have ligne as a measurement as I think it came from somewhere else. Or mainsprings they can come in a variety of measurements including millimeter, inches and Dennison all on the same package sometimes. Watchmakers definitely like their terminology of being confusing. Out of curiosity I looked up one of the other tools and sure enough at the bottom is bracelet. but they really do think some size definition with a number would be much better as I have actually be honest no idea what size that is other than I think of it as small but seeing as how everything and watch repair is small that doesn't really make for a good definition.1 point

-

that is correct for a lot of repairers, I personally like to remove the screws that hold the cap jewels on, it allows for hole pegging and inspection of jewels, some have press fit jewels but not often in wrist watches......oiling can be done like all methods mentioned above1 point

-

If the jewel cannot be disassembled, you have to rely on the cleaning machine, hopefully cleaning it out. If the jewel can be taken apart, then you need to do so, and make sure it's absolutely clean.1 point

-

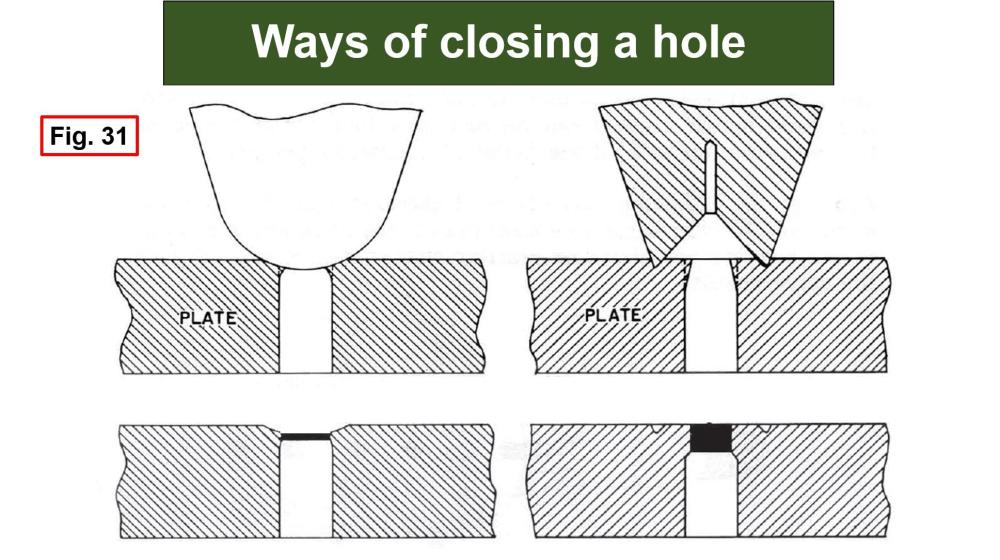

I concur with @nevenbekriev and @nickelsilver. It is a better and safer method to cut away the hub before removing the balance staff. The rivet can be cut back, but I find the hub is a better way to do it. If someone decides to use a platax tool and knows there is a real risk of enlarging the hole in the balance arms, that seems a little foolish to me, regardless of who they are. If you don't have a lathe, then I can see why punching the staff out is the only option I knew of a client who he always asked a potential watchmaker who he wanted to do either repair or servicing of his watches, how they removed the balance staff from the balance, and if the watchmaker said they punched it out with a platax tool or similar, he would walk away and find someone who cut the hub or rivet first. There are obviously more than one way to skin a cat and watchmaking is a very subjective matter based on experience, but I'm sure that anyone who has the experience of cutting the hub off first before removing the staff will realise it is the better method, which is infinitely safer. I would try closing up the hole, because if there is a gap the rivet isn't going to alleviate that. You can use a domed stake on both sides if you have an inverto staking tool, but make sure the domed stakes are the correct size, so when the work is gripped between the stakes, the work doesn't turn and the stakes don't touch each other. Be incredibly light with the hammer! Once the staff is fitted, because you have closed the hole, you may find the staff might not be true to the balance, but you would put it in calipers anyway to true it up so it spun without a wobble1 point

-

From a practical perspective, how many times will a staff need to be replaced on any balance in a watches' lifetime? If the answer is greater than 2, and replacement balances are not available AND the movement is worth repairing, then I could see the argument for cutting away the rivet rather than punching it out.1 point

-

Hi think the best method in this case is to secure the balance cock and press out the stud . This I would say is the least risky option.1 point

-

While cleaning up the case, I polished out the crystal, then gave it a wipe with a paper towel. And that's how I learned that despite being on the inside of the crystal, the Accutron logo wipes right off with a little soap and water I should have been more careful, but live and learn. I'm not too heartbroken, as the crystal has some pretty bad cracks and deep scratches, and I was planning to replace it anyway. I have to say, I still love the results of a quick polish on the wheel with red rouge. Here's a before and after of two Accutron crystals. This was all of 5 minutes' work. Cleaned up and back together. Unfortunately, the lugs measure 17,mm, while all the straps I have are 18mm. I have a suspicion this watch was treated roughly and the lugs may be bent, but I'm not brave enough to try bending them back.1 point

-

Hi all, late to the discussion, I'm interested to learn about Dr.Tillwich oils as I'd like to think I'm a bit of a rebel and would like to do my bit to break the Moebius (near) monopoly. Could someone do a quick 'cheat sheet on the equivalents so someone like myself can home in on the right Dr.Tillwich equivalents ie: 9010 = ? HP1300/D5 = ? 9415 = ? 9504/Moly DX = ? Automatic barrel grease = ? Mainspring grease = ? Do Dr.Tillwich do an epilame for pallet jewels, if so what Dr.Tillwich oil would you use in junction with it? I know some of this is already mentioned in some of the previous posts in this and other discussions, but I thought it would be nice to have it summarised all together in one place.1 point

-

At the end of my previous post about The Click, I wrote the following: "EDIT: Looking at the type 1 click wheel (a bit closer) it could be that it could be mounted with the click spring in any of the two locations. Haven't tried it though." I've now tried this and could conclude that the "type 1 click spring hole" must be used with the "type 1 click", and that the "type 2 click spring hole" must be used with the "type 2 click". I guess the barrel bridges manufactured with two click spring holes is a convenience so that it should be possible to use any of the two types of click wheels (depending on what type of click wheel you, or Vostok, happen to have at hand).1 point

-

Differences between Vostok 24XX parts: The Mainspring Barrel I’ve seen two types of Vostok 24xx mainspring barrels, and although similar they are not compatible. I learned this the hard way. As I had just finished servicing the above “Wostok Made in USSR” (I believe called “Sun Rise”), I tried to wind it fully, but half way through the click slipped and created a "chilling sound" in the train. Fortunately the watch survived (well, it’s Russian so I’m not too surprised ;)). The problem, as I later learned, was that I had fitted the watch with a brand new mainspring barrel. When investigating the source of the problem I noticed that the ratchet wheel was slightly wiggling in its slot on the barrel bridge. When the mainspring tension became too strong it would make the ratchet wheel misaligned with the click. Investigating further I could, to my surprise, conclude that the mainspring arbor was "too tall", and that was what made the ratchet wheel wiggle. At this point I compared the brand new barrel with some old barrels, and noticed the following differences. The new arbor is 0.2 mm taller than the old arbor. The new barrel has a slight elevation which the old one lacks. However, the inside and outside diameters of the two barrels appear to be identical. Same with the new barrel lid; it has a slight elevation which the old one lacks. Other than that the dimensions seem to be identical. As far as I can tell, there’s no difference in design or dimensions between the new and old mainsprings (although I'm not 100 % sure) as long as they are for the same calibre. For example, a mainspring for a 2409 will fit both the new and old barrels, and a mainspring for a 2415 too will fit any of the two types of barrels. However, the mainsprings themselves are differently designed for manual (2409/2414) and automatic movements (2415/2416). For example, at meranom.com (which sells spare parts) they sell barrels for 2409 (manual), 2414 (manual), and 2416 (automatic), but .not for the 2415 (automatic). I would assume the mainspring and barrel for the 2416 is suitable for the 2415 as well. Do note, however, that all of these barrels are of the new type with the taller arbor and the elevation on the barrel and barrel lid.1 point

-

Differences between Vostok 24XX parts: The Click I’ve seen two types of Vostok 24XX click wheels and they are usually not interchangeable as the click spring needs to be mounted differently on top of the train wheel bridge. Above is a picture of the first type of click, and it seems to me to be the most common type of click. As can be seen in the above picture the “type 1” click spring hole is farther away from the ratchet wheel than the click spring hole for the “type 2” click (shown in the next picture). The above picture shows the other type of click that I’ve seen. As can be seen, the click spring goes in the opposite direction compared to the type 1 click spring. Hence the click spring hole in the bridge has a different location, which is shown next. The above is not a very a very good picture but I hope it fulfils its purpose of showing the location of the click spring hole for the “type 2” click. As can be seen in the above picture, I’ve seen some train wheel bridges having two holes for the click spring depending on whether you have a type 1 or a type 2 click wheel. The location of the type 2 click spring hole in the picture could be somewhat off as the picture has been photoshopped by me to add it. EDIT: Looking at the type 1 click wheel (a bit closer) it could be that it could be mounted with the click spring in any of the two locations. Haven't tried it though.1 point