Leaderboard

Popular Content

Showing content with the highest reputation on 04/12/24 in all areas

-

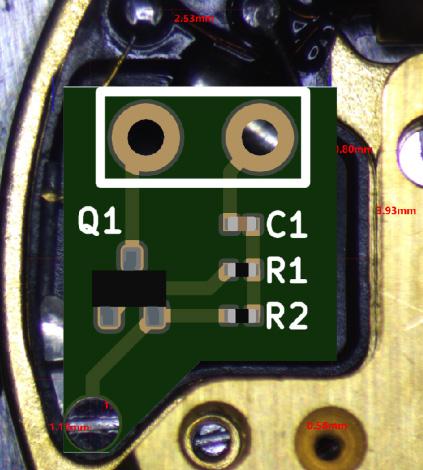

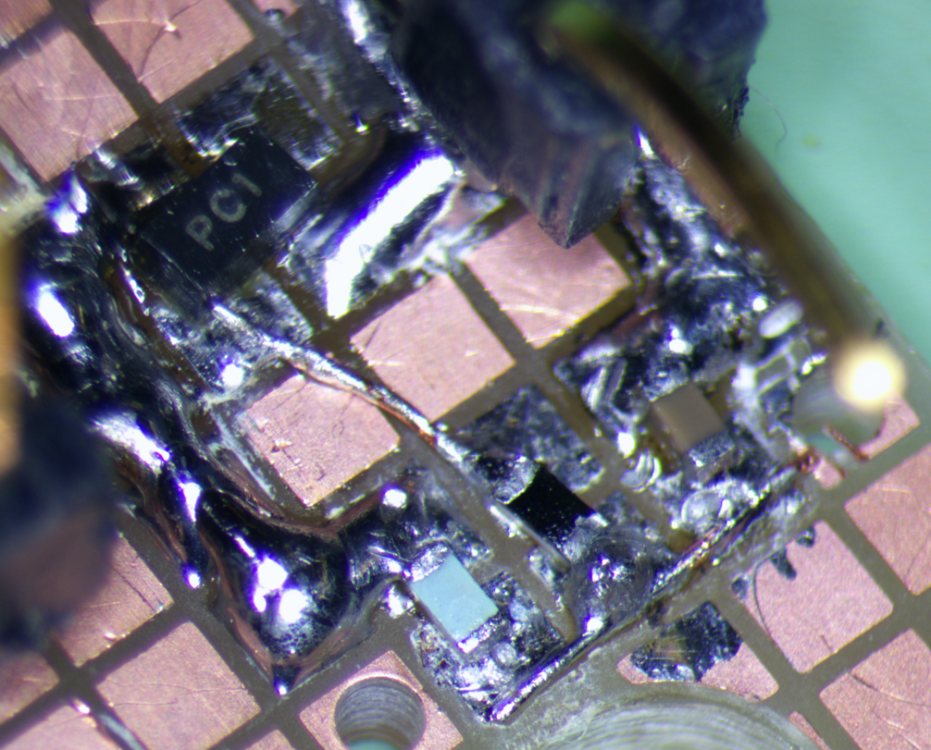

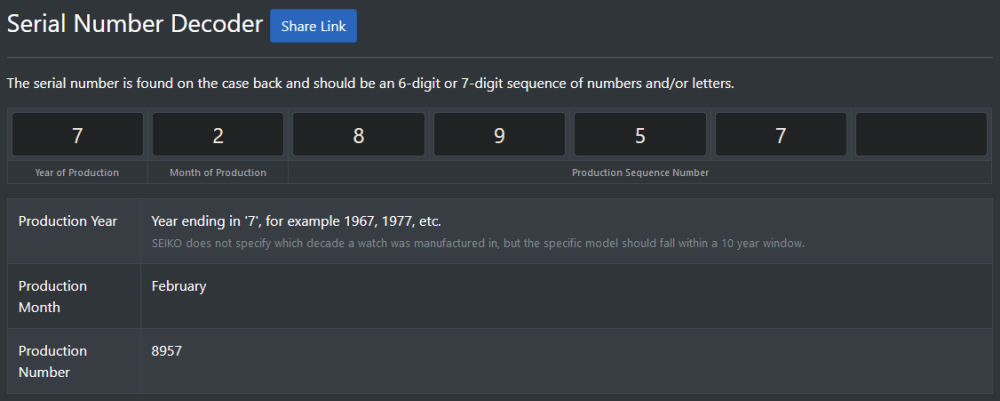

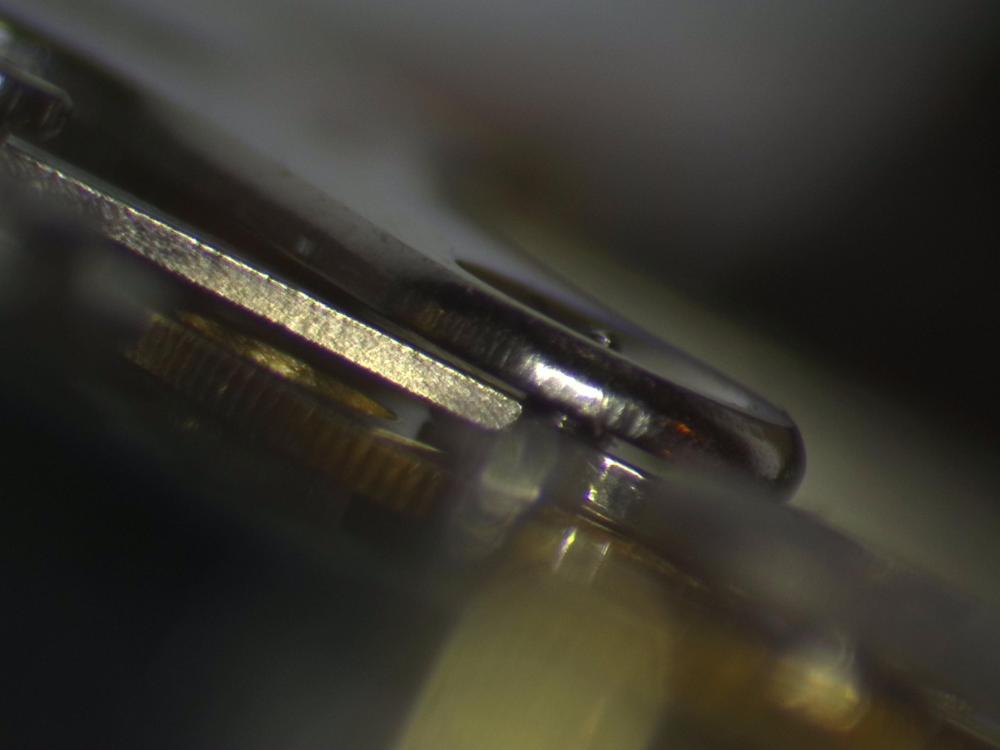

Well, the first attempt was a wash because I bought 22nF capacitors instead of 220nF. So after a second order, I soldered everything onto my SMD breadbaord. I de-soldered the electronics from a 218 movement that I had previous tested and hooked my little circuit up in its place, and hooked the whole thing up to 1.4v from my power supply. ...and realized I'd gotten the pinout of the transistor wrong. After I removed and re-soldered it in the correct orientation, I realized I had the connections to the coils backwards. Once I fixed that, THE FORK STARTED VIBRATING! I could not have been more excited!!! If you haven't guessed, my somewhat evil plan is to make a surface-mount PCB replacement for the resistor, capacitor, and transistor in the 218s. Why? Because why not? The transistor is in a SOT-523 package, the resistors and capacitor are 0402 (1005 metric) packages. I have to redo the circuit to get the transistor pinout correct, but here's what I have in mind:6 points

-

Hi everyone, I've been here two years now almost to the day and have loved every minute of it. During this time I've connected with folk that have suddenly disappeared leaving me sad and wondering why they left and what happened to them, its now my time to leave for a while. But first i want to thank everyone for all the help, advice and banter over the last two years I've met some incredibly kind and amazing guys. My time has become limited and precious, so watchrepair and visiting the forum is taking a backseat for the moment, although i may pop in occasionally when i have time. This is due to a personal life change regarding my 87 yr old mum who had a stroke on Sunday. My learning here is on hold while i do some teaching of my own, helping my mum to talk and communicate again . Thanks again for making my time here so enjoyable and i hope to join you all again soon. Take care and look after yourselves, make every minute of the day count, time is so precious x.3 points

-

Hello everyone, Caught a vintage watch collectors bug and decided on expanding my skills with basic watch servicing. Bough some cheap basic tools and non working Jaquet-Droz from 60's with AS 1767 movement and now off to find out what oils to get and where they go ( I think this is most confusing part for me so far ).2 points

-

But that is a different pair of shoes, I never talked of that. I assume that the tool will not reach the hole, no matter what you use. Easy with simple stake, too, if you keep the stake between your fingers while hammering. When I push the staff out after removing the hub, I use a stake with cylindrical pivot, a bit smaller than the hole. As I said, no punching method or tool can protect the hole - from widening by the distorted staff - from distorting hole and balance arm to a funnel-like shape if the rivet is too thick (happened to me decades ago). I apologize if I seemed to be condescending, tried to say it friendly, but meanwhile I am tired of repeating the facts. But I know now, we had different issues in mind. Regards, Frank2 points

-

As the hammer is fixed in place by two shouldered screws, try to switch the places of the screws, as they can be a little different.2 points

-

2 points

-

Hi @Neverenoughwatches, I will keep you and your Mum in my prayers. A caregiver's job is a tough one. I have known nice little old ladies to undergo drastic changes in their demeanor after suffering a stroke. Patience and understanding is essential in all circumstances. Never lose your cool or be condescending. Try and enroll in a caregivers training course. It really helps. You cannot take on the role of a caregiver 24/7. You need to get a relief caregiver. You need to take care of yourself before you can take care of others. Do not be afraid to ask for help. Hope to hear from you soon.2 points

-

You’ll need to get a new winding stem - they can usually be found on ebay quite cheaply and are specific to the watch movement. Next, get the back off the watch and remove the broken stem. There’s either a screw or a push-down button near the stem to allow it to pull out. Hopefully there’s enough to grab. Thirdly, you’ll need to get the crown off the broken bit of stem. This will probably be threadlocked. Maybe use heat, or a solvent such as acetone to loosen the glue. There looks to be enough stem there to grip it and unscrew. Then, after fitting the new stem you’ll need to shorten it - suggest you look this up on1 point

-

Take care @NeverenoughwatchesIt's fortunate your Mum has you to help!1 point

-

No worries Frank! I see where you're coming from and thanks for clarifying! I would really hope someone, @Jon(!?) would make a video of how to punch out a staff using a staking set without first removing the hub or the rivet. Yes, Frank, you have clearly demonstrated that it is destructive, but for those of us who have no other option and are willing to risk it. I haven't tried it but one dear WRT member whom we haven't seen in a long time, @HSL (anyone in touch with him?), recommended I try to remove as much as possible of the rivet before punching it out by using a razor-sharpened stake. Yes, I know, it is the hub that you must remove using a lathe, but at least I would think/hope that removing the rivet would be a step in the right direction.1 point

-

1 point

-

1 point

-

Hello a welcome to the forum , to add to old hippys document the As. Service /perts sheet incase you drop somthing. 2493_AS 1767_Smaller.pdf1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. This might come in handy for you. 704789946_TZIllustratedGlossary(2).pdf1 point

-

When it is in its case are you sure the stem is pushed right home. A common cause is if the button is screwed to far onto the stem it is not right home. So try a little longer stem if you have one, or a button with a longer pipe.1 point

-

I already have a President "P" and "A", so I'm on my way1 point

-

Just to make sure, the setting lever has two notches in the post that goes into and through the mainplate. The spring (which has an orientation) which holds the setting lever down goes into the top notch, not the lower one. It's also possible that if that spring isn't providing enough tension to keep the setting lever engaged with the stem, when you case the movement and insert the stem it might push the setting lever out of position. I don't think you need to push down on the setting lever post from the train side before inserting the stem on this movement but maybe try so if you haven't yet. Before putting in the stem, look and make a mental note of where the setting lever post that engages the stem is sitting and when you insert the stem make sure the notch in the stem is lined up with that. Also, are you sure the stem is long enough? Are you rotating the stem as you gently insert it to make sure the square part of the stem is lined up with the square opening in the sliding pinion?1 point

-

1 point

-

I have already mentioned to Mozart that I can't find PDF of the book, and that he should buy it.1 point

-

The 248 hammer doesn't sit on a post. There is a shouldered screw that allows the movement of the hammer once it is fully tightened. How far up does the chrono wheel sit towards the jewel without the hammer pushing on it? If it sits too low and there is a slight bend to the hammer, add those two together and there's a recipe for disaster. I still think it's the hammer that needs bringing back to flat. What does the end of the hammer position look like when 'return to zero' and no chronograph runner in place; is it still too high?1 point

-

You have to check if the post on which the hammer sits and is pivoted has not untightened. It is on thread and often gets loose and thus lets the hammer have significant free play. The bearing on the hammer also can get loose and has to be checked for tightening, but I don't remember if in this movement it is on thread or not. If there is no problem there, You must take care that the hammer falls on the heart not too high above the wheel surface and in the same time the wheel not to be able to go down as much as to be enough free place between the heart and the cock for the hammer to get in between. What I mean is if the cock is lifted up (like it seems looking at the picture) in order to place the wheel higher, it will not help as the wheel will go down easy. The axial free play of the wheel should not alow the hammer to get above the heart. So if the hammer hits the heart not in place, it must be solved by changing the hammer position rather than the wheel position. It can be achieved by bending the hammer or the post on which it sits, but both lead to risk of break. If such correction needed, I would rather anneal the hammer localy close to the bearing and polish it to clean the blued surface after. PS Now I see that what i have written about the post is not correct for this calibre, as the hammer has different bearing type here. But no mater, the hammer should not have significant free play1 point

-

1 point

-

JohnR725, thanks so much for the amazing amount of information. That must have taken a bit of time and effort and I appreciate it. In addition to some great documentation which I have saved, I have some key takeaways from your comments which I’ll summarize here for the benefit of other new people: 1. Improper stem removal procedure may have knocked some parts (sliding pinion) out of place but most likely nothing is broken. I may have to disassemble the watch and keyless works to fix things. 2. In the absence of clear direction, default to the set position (#3) for removing the stem (I understand that is your preferred approach only and not a general documented recommendation) 3. When asking a question about a watch always include the movement number and a picture. People who are not familiar with the movement number may be familiar with the movement by sight. Also, identical movements can have different movement numbers. 4. Newbies need to learn how to distinguish the movement number and manufacturer from the watch manufacturer and model. It’s the movement that matters. 5. Available on line documentation is frequently saved in incomplete PDF files, with only portions of the parts lists and service information saved in the file. This requires multiple searches to obtain the complete information. 6. VERY IMPORTANT- don’t stick pointy things in screwdriver shaped holes. I have a feeling this is going to come back to bite me. I may have dislodged some keyless works parts. The setting lever to be precise. Oh well, more experience disassembling. Thanks for taking the time to help me along the path.1 point

-

@Neverenoughwatches Rich I am so saddened to hear this bad news. Mum comes first and I hope to see you back here sometime. I am around if you ever need someone to talk to, I’ll DM my number mate. Tom1 point

-

When you say the end of the hammer slips off the heart, do you mean the hammer rides up and touches the bridge, or rides down and touches the chrono wheel? I've posted a couple of picks of a 248 which shows the hammer is a little high, but there is clearly a gap between the top of the hammer and the underside of the bridge, as you can see in the pic. The action of the chrono sweep second hand is perfect If the hammer is bent, you'll need to straighten it, so it hits the hearts correctly1 point

-

1 point

-

The faces of the hammer have to be flat and "square". Also, the two shouldered screws that hold the hammer in place must provide freedom, but not too much. There really shouldn't be enough room above the cam, even with the chrono runner wheel pushed down, for the hammer to be able to ride up over the cam. Are you sure the bridge is fully seated?1 point

-

Hi @Neverenoughwatches sorry to hear about your Mum, only 7 older than me. Enjoyed the chats and look forward to your return when things get better. I might give you a blast now an then so keep the channel open.1 point

-

How very sorry Neverenoughwatches to hear about your mum. I have always enjoyed your posts and knowledge and I will miss you. Please keep in touch and let us know how your Mum is recovering. Take very good care and I wish you both good luck.1 point

-

If the jewel cannot be disassembled, you have to rely on the cleaning machine, hopefully cleaning it out. If the jewel can be taken apart, then you need to do so, and make sure it's absolutely clean.1 point

-

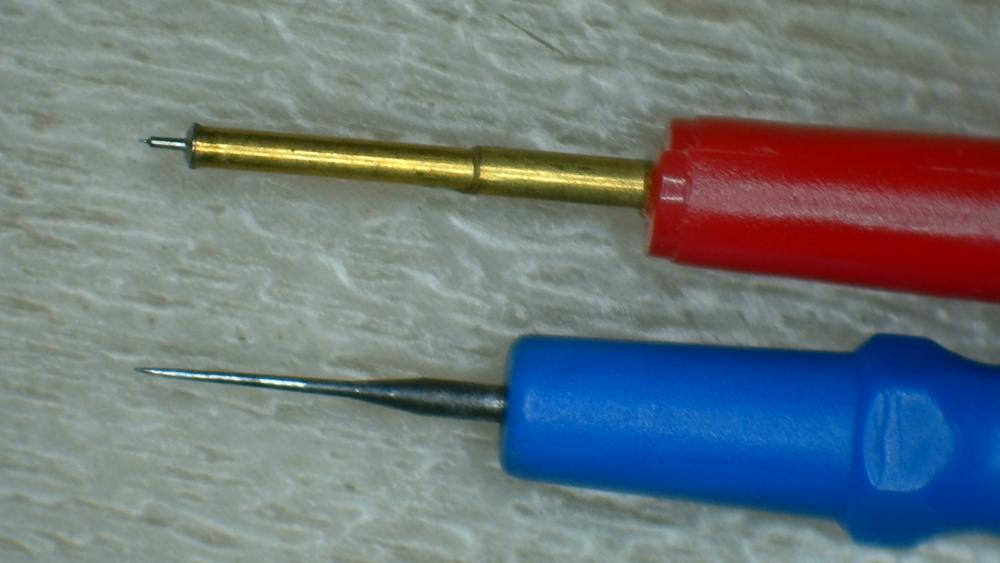

what? We live in the digital world everything is digital today except I believe this is a linear circuit seems like it should need something that's not digital. then I suspect pure digital transistors designed for high-speed switching might not actually be happy to biased it into to a linear mode. I wondered about this because for instance the 214 came out in the early 60s and I don't know how plentiful silicon transistors were? Then yes the 218 is later but the circuitry is basically very similar. out of curiosity as doing a quick patent search the see if it tell us what the transistors they used our and right this instant know they have not been to have schematics though. Then unlike general concept patents Bulova was very nice and made exact patents for a variety of their watches because it wanted the mechanical + aspect patented .then I did remember something about the transistor so I searched for a transistor number and Bulova this came up first all snipped out an image. Now you have at least one transistor that was used in tuning fork watches. So this will give you an idea of specifications. Then yes I really like where the meaning of Accutron comes from you can see it in the title down below. Which works out nice for them now that they have all kinds of electric watches including one powered by static electricity and it does not go against the name which everyone thinks means tuning fork watch. Yes you really should check out the nifty static electricity watch it's really quite amusing. https://www.hodinkee.com/articles/five-star-general-omar-bradley-special-bulova-accutron hadn't quite closed out my patent search basically the patents for the 214 we have this. then before I closed out my Google patent search added in NPN and it only came up three entries of attaching one of them as it says silicon. US3421309 Bulova NPN silicon.pdf1 point

-

1 point