Leaderboard

Popular Content

Showing content with the highest reputation on 04/13/24 in all areas

-

Thank you all so much, i can't begin to express my emotion for your kind words. Finding just a lttle time to do other things besides thinking about my mum is difficult. Today has given me a slight break for some distraction and i will get around to thanking you all individually. Today my mum is leaving the hosiptal to stay in a rehab facility after making good progress with her communication, from being unable to speak at all to nearly stringing a sentence together in less than a week. Not everthing makes sense to us and she struggles to find certain words often substituting one with another that can be relevant but not always. Its a blessing she is still Physically good, the part of her brain affected is communication, so that is words through all aspects, speech, reading and writing. She knows in her head what she wants to say but doesn't fully know how to retrieve or form them in the correct order but she's a fighter and tough as old boots even at 87. Thank you so much again for the support, you are all so very kind. I will be back again to cause trouble so watch out . Bye for now x3 points

-

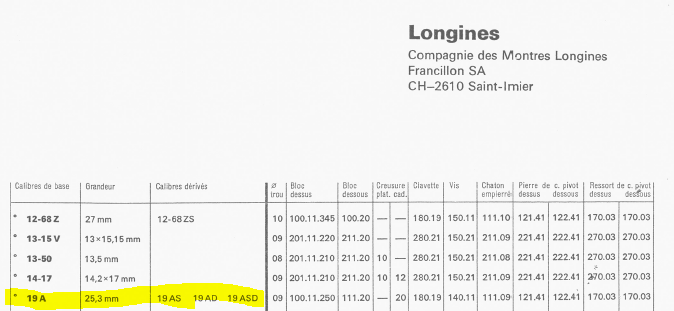

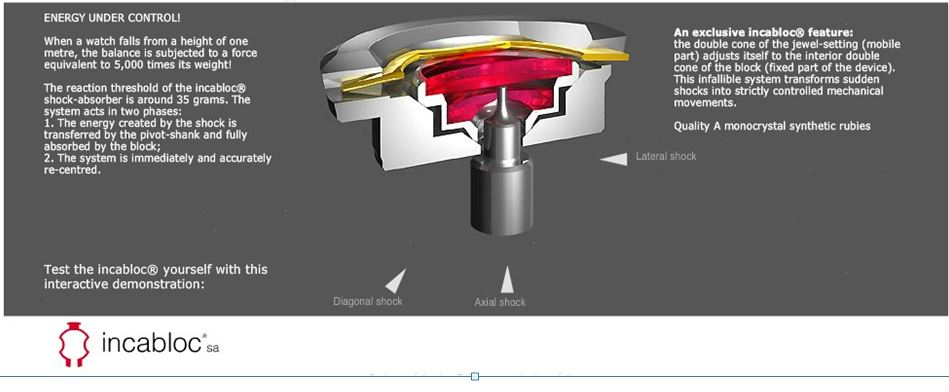

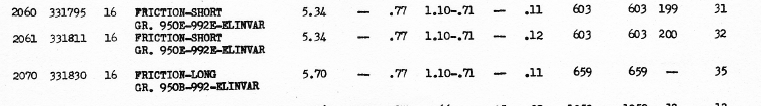

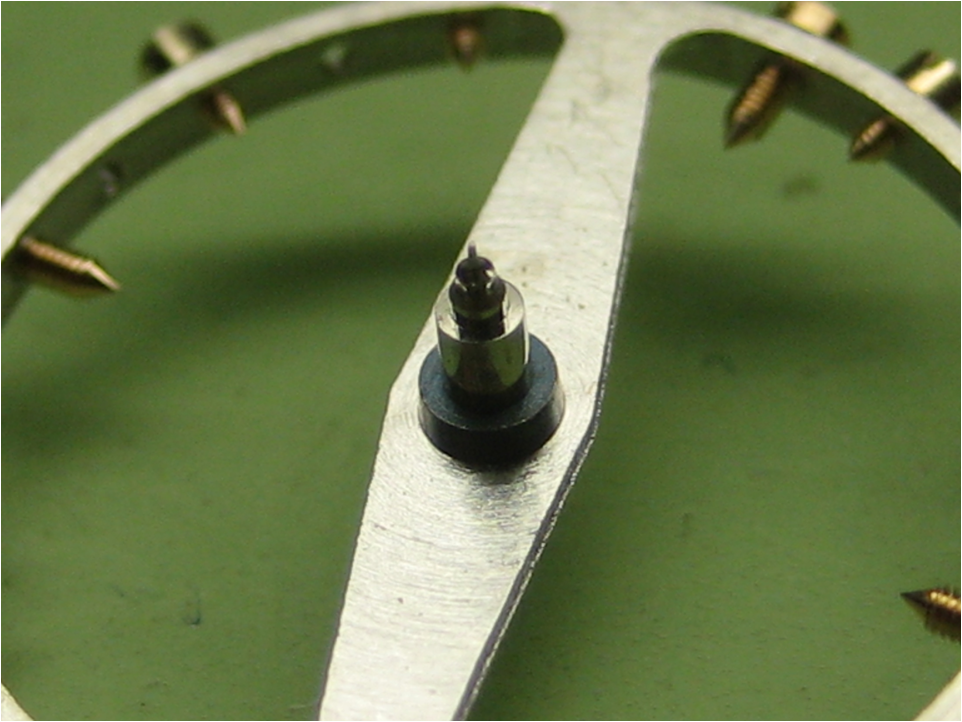

I was looking at your pictures and maybe this is an optical illusion but it appears to be you have hairspring issues Then one of the sources I like for watch parts is this http://cgi.julesborel.com/cgi-bin/matcgi2?ref=LON_19AS What would be nice to see the other side of the balance bridge because of give us an idea of what's holding in your balance jewel assembly as it will have to come apart to get the spring in. Plus we can have a look at your balance wheel and see how bad the hairspring really is then I found a listing of the balance parts Of the shock system Then they get a better idea of things I have an image of what the upper jewel assembly looks like Then looking online I found another source for parts https://www.ofrei.com/page1776.html3 points

-

I have just looked at the charity shop purchase" topic. The hour hand is the style spade very popular. You need the length to be just inside the outer line of the minute line on your clock dial.2 points

-

I use these. They're silicon so softer than the traditional bench mat, which means that things are less likely to roll or bounce. The little recesses in the top edge make really useful holding pens for parts prior to transfer to a parts tray or project box proper, and when they get a little grubby they can just be washed and they come up like new. They're also cheap as chips.2 points

-

I’m unable to find the A2 oiler you’re referring to on Aliexpress or elsewhere, but given you’re mention of eccentric screws etc it sounds like you’re referring to an automatic oiler. If you’re a beginner, I’d encourage you to stay away from automatic oilers for now, and perhaps permanently. They have their place in production environments and service shops where you’re repeatedly handling lots of watches with the same movement. Outside that environment, and particularly whilst you’re learning, you’re much better off using simple dip oilers. You will get a feel for picking up greater or lesser amounts of oil depending how you dip them, and have much better control over how much oil you place in each jewel. Learning to apply the right amount of oil to each location is very important. The amount of oil a given jewel and pivot requires will vary with the size of the pivot. Fine escape wheel pivots require far less oil than a third wheel, which in turn requires less than the second/centre wheel. Too much oil is possibly worse than too little, it will leave the pivot/jewel interface and get drawn away from the setting. You might see decent performance right after you service a watch, but performance will deteriorate quickly as the oil migrates and the effective service interval will be significantly shortened. Getting a feel for gathering the right amount of oil on an oiler and using the right amount on each pivot is an oft neglected and important step in learning to service watches well. It is one of the factors that separates professional quality service from some hobbyists. You won’t learn this with automatic oilers and you will be using too much on some pivots and too little elsewhere, if for example you use one oiler filled with 9010 for all pivots requiring that oil. You can’t correctly adjust the volume of oil dispensed at each pivot as you move through the watch, they’re designed to be adjusted to correctly oil one particular location in one calibre of watch when used in production or brand service centre environments. You would be better off buying simple dip oilers and spending the money you save elsewhere. Hope that helps, Mark2 points

-

I bought the 10ml bottle from Cousins, and it should last years. I do larger parts in the mesh at the top of the bottle. I tried doing the cap jewels at the top of the bottle, but after inverting for 30s and removing the cap, it's a struggle to find them. Meanwhile the lid is off, and your precious fluid is evaporating away. So now I use a syringe with a fine needle, suck up the tiniest amount. I push the cap stones and pallet fork (to avoid getting any on the actual fork) in to some pith wood, and put a few drops on each jewel2 points

-

Since 1978, Seiko has put an alphanumeric code on the back that tells you how to take the case part. Which your watch doesn't have, being from 1977. But there is a document Seiko used to publish with a table, and a scanned copy exists, and 6139-710 is in it (the last digit isn't used). So you're lucky. This case has class type F4: You are supposed to remove the bezel. The edge of the bezel extends over the glass. The crystal has a large bevel on the top that allows this. Because of that, it's likely a standard flat replacement glass will not fit. Seiko 3. Casing Guide.pdf2 points

-

Hello all. My notifications aren't working, anyone else having issues. I've checked the settings and I should get notifications.1 point

-

Yes classic problem of American pocket watches not running out of the case. Then each of the watch companies had of one or more methods of dealing with this which can lead to confusion. Especially for the ones that are not obvious like a screw as to where exactly the screw needs to be to put it into the mode so to run out of the case. At least Hamilton colors their screws are pretty blue color C can recognize what it is but where is supposed to be can be interesting. This is why oftentimes is easier just to run the watch in the case or if you doing timing adjustments just don't Put the dial side components on.1 point

-

Well, I ment this kind of post in this kind of movement This was because I didn't see the movement first and the problem described is often found in such type movements... The angle pointed on the picture is a contributing factor. I would try to put something like a small washer under the wheel to limit the vertical free play by forcing the heart stay closer to the bridge. Will this make the resetting reliable? If such solution chosen, then take care to make the friction spring under the wheel work normally regardles of presence of the washer1 point

-

!!! This movement is with negative remontoir and stays in setting position when out of the case. This will stop the gears from moving no mater if the cannon pinion is correctly adjusted. You need to switch to winding position to release the geas so they can turn free!!! I would say that this cannon pinion is more normal than the others, which are considered normal. Yes, You must slightly deform the 'tongue' towards the center to increase the friction. Put something (steel wire, broach... with slightly smaller diameter) in the cannon to prevent too much bending. One must learn to feel if the resistence when setting hands is normal, not enough or too much. Too much will do harm like break the minute wheel teeth or other bad things. Not enough means not reliable hands movement.1 point

-

Looks like the landerton 39 according to the bestfit book although no mention of the pusher / s1 point

-

HI, it looks like a Landron 39 to me but I can't identify it, unfortunately you might have to un-case and pull the hands and dial off, the dial screws are on the same side as the picture showing, when this is done we can hopefully finger print the setting bridge for ID, wait for another member to come forward with more knowledge as it is early in the post, I look forward to seeing the maker....1 point

-

1 point

-

Very wise words from @Mercurial, I agree entirely Maybe the above advice could be pinned in the forum "Lubrication Techniques, Oils, Greases, Epilame Treatments" ?1 point

-

We will miss you. Hoping things work out well for your family. Take care1 point

-

When you turn the bottle back up, if you immediately remove the lid, the fluid takes a while to drain through the mesh. I tried using an oiler to pick up a little Fixodrop, bit it evaporates too quickly.1 point

-

Never any harm in exploring new ideas, even if they’re at odds with established best practice. The two issues I see with using glue are that the next watchmaker to replace the staff won’t expect to encounter glue securing it, or know what kind of glue it is and therefore how it might be removed without damaging the parts, and given concentricity is of utmost importance when restaffing, ensuring the staff is glued in an oversized hole such that it’s centred isn’t trivial. Uneven mass distribution can have a dramatic effect upon the poise of the balance wheel, but the effect is much greater at the balance wheel rim than it is near the staff. This is why the safety cutout on the roller table, the roller jewel and the shellac securing the roller jewel don’t upset poise much, they’re very close to the centre. A blob of shellac or glue on the rim of the balance will upset poise significantly, though. Best Regards, Mark1 point

-

1 point

-

1 point

-

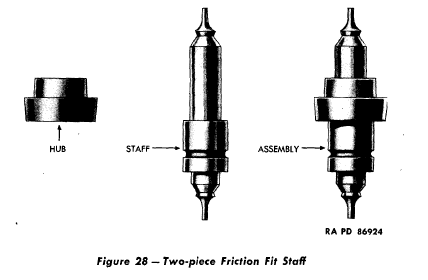

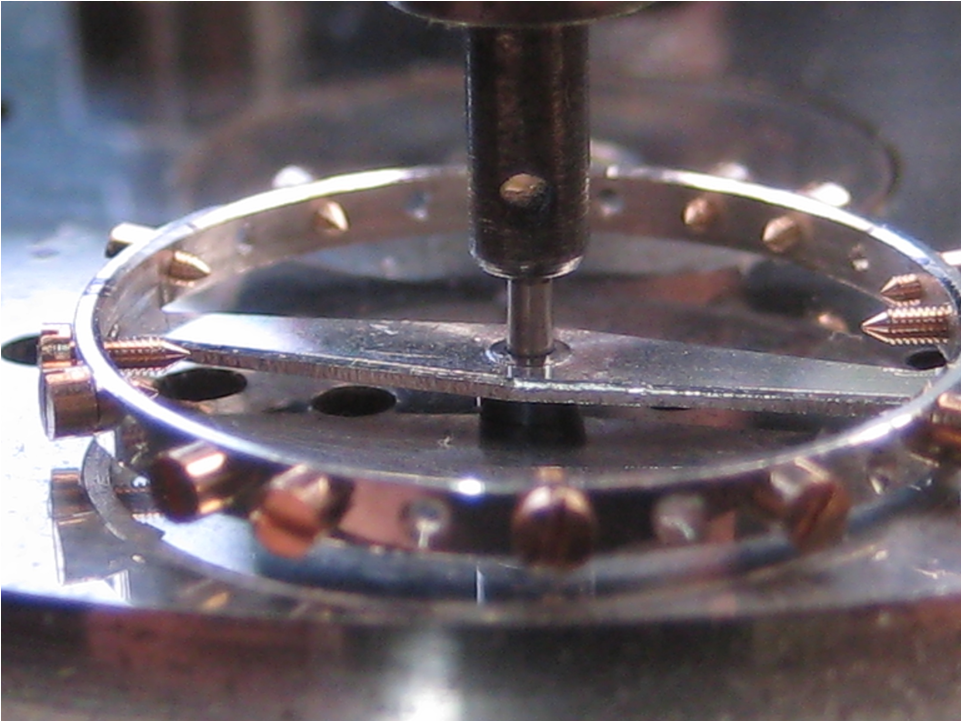

Just a reminder this is watch repair there are lots and lots and lots of variations. Your friction staff is a Waltham friction staff in the image up above requires special parts for your staking set. Hamilton used a different arrangement like the image below. Even though there's a groove showed in the staff the 992B does not have. So you can see the hub on the left staff in the middle and how they would look together. The reason for this particular example in the book was that they were some watches that they had upgraded the friction staff and they put the groups of people with no beyond the blued hub what was going on but on the watches like the 992B they didn't do the Dimensions would be better because there are some minor variations. For instance of the friction staff's there are three of them at least for the 16 size 2 of them are the same for size with the pivot difference in the 992B only comes in one size So visually though staffs will look identical casually at least. So here's what your hub looks like with the Hamilton staff. As you see is a lot easier to work with them the Waltham all you have to do is support the blued steel part and gently knock out the friction staff from the other side of course In other words on the staking set it will look like this. A picture of the staff A picture of measuring the staff which why would I do such a stupid thing is measured the staff? Because there's only 1992B staff there's no need to measure except there does seem to be some minor variations. I have a suspicion that some aftermarket staffs are not made quite the right dimensions and then they will not friction in the hub there too big or occasionally get one that loose because somebody drove a big staff in when they shouldn't have Here's a picture testing the staff in the balance hole jewel even though there's only one size it's still nice to check before it's in the balance1 point

-

Hi and welcome. You've got the bug as well, welcome to the club! If you need any help with what lubricant goes where, DM me. I teach this subject so might be able to help.1 point

-

Not to state the obvious, but buy a demagnetiser! If the hairspring is sticking together then this will increase the timing rate. If you demagnetise the movement, at least it takes the problem of being magnetised off the table and being the possible problem and you have a way of demagnetising any other watch you service. This may not be the problem, but watchmaking is all about eliminating everything that couldn't be the problem and ending up with the possible, then the probable.1 point

-

Take care @NeverenoughwatchesIt's fortunate your Mum has you to help!1 point

-

I wish you and your family well. Thank you for taking the time to part of our community. You have personally been very helpful to me in my own particular travel forward. Thank you Neverenoughwatches. See you again. Regards Ross1 point

-

Hi, for a rough guide as to what oils to use where, have a look at the Moebius chart here: https://blog.esslinger.com/moebius-oil-charts/ The blue ones are the newer synthetic types, which are longer lasting. The sizes ''' are in "lignes" which are roughly 2.25mm or 1/11th inch. I'd suggest you start with 9010 (the lightest grade), 9104 (the synt-hp, heavier oil) and 9504 grease (for keyless works etc). You can use general silicone grease for rubber cased seals etc. (The "Wristwatch Revival" videos on youtube are pretty good at showing how and where to apply lubrication, to get started).1 point

-

1 point

-

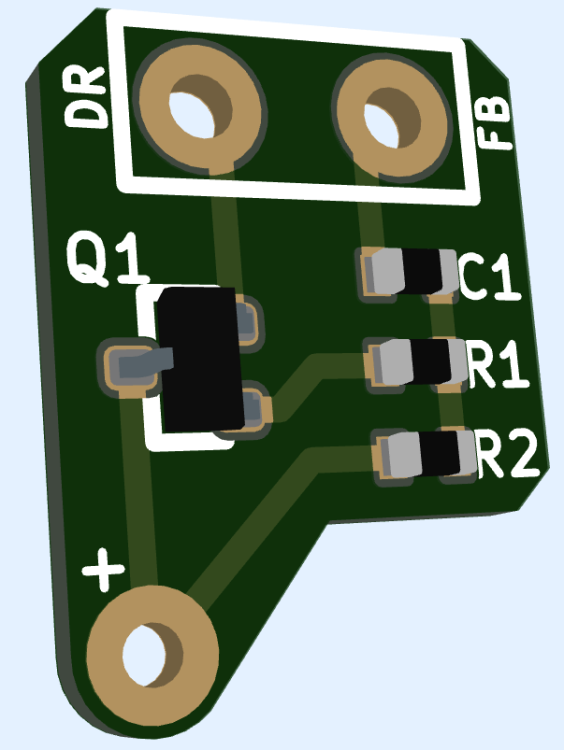

This sure is fun Now that the proof of concept works, it's time to prototype. Looks like I've got just about 1.6mm of height from the plastic component tray to the top of the main bridge. With an 0.6mm thick board and the 0.9mm tall transistor, this should fit without any modifications other than removing the existing components. For anyone wondering, the transistor is CMUT2222A bipolar NPN. R1 is the bias resistor, which is just a 0 ohm jumper for this setup. R2 is the 2.2M ohm resistor, and C1 is the 220nF capacitor. DR goes to the drive coils, FB goes to the feedback coil.1 point

-

Hisstoryman, it is always best to disassemble all capped jewel settings (if possible) to remove the cap jewel, peg out the hole jewel, put the parts through the cleaning machine machine and inspect them under magnification to ensure they’re clean and instant before thinking about oiling. The smallest amount of dirt or dried oil, particularly in a balance jewel setting can really impair the performance of a watch. If you look closely at the capped jewels of the (relatively few) movements where you can’t disassemble the setting, you will usually see little gaps around the cap jewel to allow cleaning fluids to flow through the setting during cleaning. These were designed so ultrasonic cleaning would clean out the setting without disassembling the jewel setting. If you encounter one that does not clean adequately, most are friction fit and can be pushed out, cleaned and then reinstalled with a Horia tool. Once the jewels are cleaned, if you choose to oil them using capillary action, you need a tool fine enough to pass through the hole jewel once you’ve placed a drop of oil on the hole with a normal stick oiler. Once you’ve drawn the oil into the setting by capillary action, check the size of the oil bubble in the setting and add more if necessary. The tool pictured above by nickelsilver, the HOROTEC 17.003, is excellent for this purpose and the tip is fine enough to pass through the jewel hole in almost all movements you are likely to encounter. The Bergeon 5423-A is also advertised for performing the same task, but I’ve found that the tip often isn’t fine enough to enter the jewel hole. You could file one down even finer, but the tool isn’t great for this purpose without modification. In the few instances I’ve encountered a hole jewel that the Horotec oiler can’t pass through, I’ve used either a hairspring pin as nickelsilver describes, or a replacement tampon for a cylinder escapement with a very fine pivot held in a pin vise. I know of people who use a balance staff they’ve replaced that still has one fine pivot intact, glued into a handle as a capillary oiling tool, and that should work well too. Hope that helps, Mark1 point

-

1 point

-

1 point

-

@Neverenoughwatches Rich I am so saddened to hear this bad news. Mum comes first and I hope to see you back here sometime. I am around if you ever need someone to talk to, I’ll DM my number mate. Tom1 point

-

That's very sad news and the forum will be poorer without you. We will keep your seat warm and look forward to welcoming you back when time allows. As others have said, look after yourself and get help sooner rather than later.1 point

-

Take care of both of you mate. May good fortune be with you wherever you go and whatever you do.1 point

-

Read this, it's not about the movement. https://www.bobswatches.com/rolex-blog/resources/what-makes-a-dive-watch.html1 point

-

So sorry to hear it. Take care of Youself and You fammily, this the most important. Good luck and hope to hear from You soon with good news. I have this expirrience and I can say that recovering from stroke depends not only by the severity of the stroke and age, but very much on the care that is thaken for the person.1 point

-

That's really sad news. Wishing you strength and peace as you navigate through this difficult time.1 point

-

Hi @Neverenoughwatches, I will keep you and your Mum in my prayers. A caregiver's job is a tough one. I have known nice little old ladies to undergo drastic changes in their demeanor after suffering a stroke. Patience and understanding is essential in all circumstances. Never lose your cool or be condescending. Try and enroll in a caregivers training course. It really helps. You cannot take on the role of a caregiver 24/7. You need to get a relief caregiver. You need to take care of yourself before you can take care of others. Do not be afraid to ask for help. Hope to hear from you soon.1 point

-

Hi @Neverenoughwatches sorry to hear about your Mum, only 7 older than me. Enjoyed the chats and look forward to your return when things get better. I might give you a blast now an then so keep the channel open.1 point

-

So sorry to hear about your mum, but glad she has you ready to step up and help her recover. All the best, and we'll see you when you're back.1 point

-

How very sorry Neverenoughwatches to hear about your mum. I have always enjoyed your posts and knowledge and I will miss you. Please keep in touch and let us know how your Mum is recovering. Take very good care and I wish you both good luck.1 point

-

1 point

-

1 point

-

I've got about 20 ml of Fixodrop epilame in a smoked glass pipette bottle and squirt a few ml into a small aluminium storage pot (32 mm wide X 18 mm tall) which is tilted on a staking block, so the epilame is just in a corner of the pot. I put my escape wheel in the pot so it is just covered and dip my pallet fork jewels into the liquid one at a time, which takes one minute in total. I draw the Fixodrop back up with the pipette and back into the bottle. I haven't noticed any real loss of liquid due to evaporation over the course of five years I have had this. Obviously there has been some evaporation, but it isn't to the degree that some make out. It has about the same evaporation rate as something like IPA, so I may have lost a millilitre or two. 10 ml in a bottle with a mesh in the neck will last you hundreds of watch parts over several years. The mesh is big enough for whatever you are going to epilame, including keyless work if you so choose. Personally I don't use a mesh arrangement because I don't dip the whole pallet fork into the epilame, because I don't want it getting in the notch and creating a dust when the impulse jewels hits. In my experience, it is definitely worth buying and using, especially with the escape wheel and pallet fork jewels. Lubricating the pallet fork becomes child's play once treated with Fixodrop.1 point

-

Sorry to hear about your mum and it's sad to see you go but you have other priorities.1 point

-

Glueing... Don't forget htat after staff has been attached to the rim, the next operation is trueing. Will the glued staff stand it? I have seen many glued staffs. This is because I am like the last instance in my country. All important antique movements that has not been made well enough by another watchmakers will come to me. For this reason I usually work almost only on movements with serious problems... Well, all the balances with glued staffs i have seen were ugly and worth to be shown in the 'monster gallery', may be that's why I don't like the idea of glueing. This doesn't mean that glueing can't be made well. But shellac will not hold strong and reliable enough.1 point