Leaderboard

Popular Content

Showing content with the highest reputation on 04/16/24 in all areas

-

Casio MDV106G-1AV Gold DURO200 I'm going on a long family vacation to Southeast Asia this summer and wanted a cheap but reliable beater in case I lose it, break it, or get robbed. Quartz movements aren't my thing, but I'm not dogmatic and this was a cheap option. A few years ago you could buy it for under $50, but since this particular model with the Marlin fish has been discontinued, you have to pay about double that, but I still thought it was acceptable. Sure, I could wear one of my cheap and very reliable Vostok Amphibian divers watches, but I have a personal relationship with them (having put a lot of work into them) and don't want to risk losing them. Strangely, I feel very excited. Maybe because I haven't bought a brand-new watch in over 10 years! The only downside is that this is the watch Bill Gates has been seen wearing, and I'm not exactly a fanboy of Bill Gates. Anyway, who cares!?4 points

-

All the best, family always comes first, and I believe you have made the right call that you mother deserves your full attention. However, when you need a little outside distraction the guys here will always be available for some banter or a heated discussion on lubrication .3 points

-

Quartz watches like mechanical watches need to be serviced from time to time. If they been exposed to foreign substances like leaking batteries getting into their gear train then they definitely have to be serviced. But servicing a cheap quartz watch does not make economical sense it's cheaper just to replace the entire movement.2 points

-

Hi. When pulling the stem out to setting position look in the hole/s for a small tab moving into view this will br the release tab. Push gently. Attached is the user manual . You will need to skip through the Japanese version. Seiko 8B53 usermanual.pdf2 points

-

Hi you could clean the contacts with a fibre glass pen brush and try again, or remove the battery and spin it up on a line release too just to free the train and hands then refit the battery with the clean contacts. Or a Richard suggested just change the movement, looks like a miyota 2030 or 2035. Cheap to replace fron cousins or HSWalsh.2 points

-

Here you are a video by our good friend J D Richard. https://www.youtube.com/watch?v=LMxoZjRaH502 points

-

I recognize myself all too well. It takes a lot of experience and discipline to recognize when it's time to cancel and come back at a later time. Very well said! We should have a forum dedicated to this topic as it is critical to achieve success when working on watches. It's a lot more important than most other things related to watch repair. And yes, just a short break can make a world of difference!2 points

-

Thanks waggy, group WhatsApp chat # # Nanna # was launched yesterday evening, 22 members already. Ps. By the way those oils that you're using I'm not so sure you have it quite right yet2 points

-

2 points

-

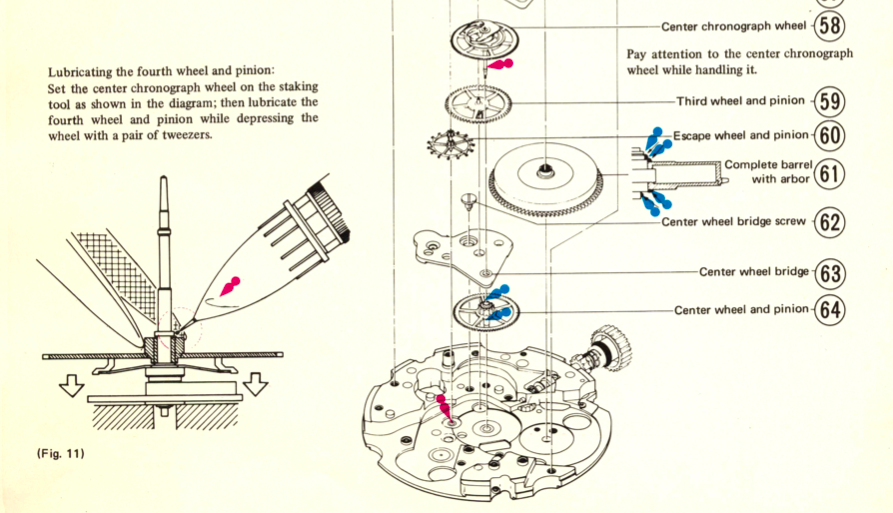

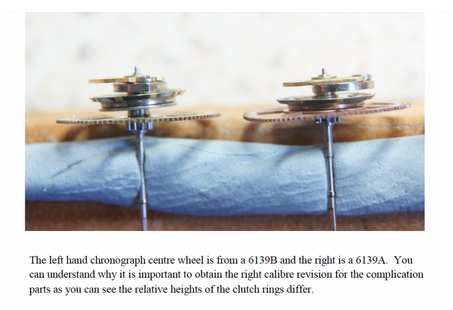

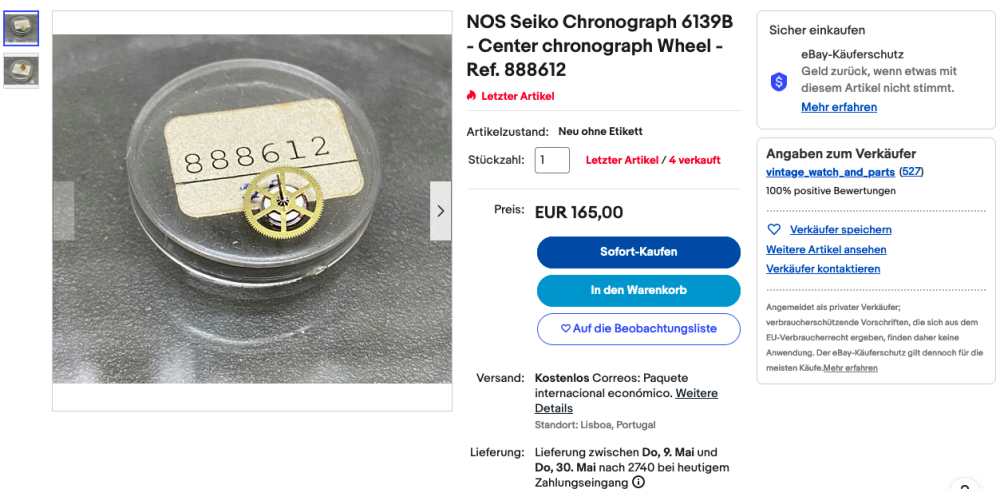

I am certainly not the first one who happen to ruin the chronograph center-wheel of a Seiko 6139B. The internet, when you search for it, is littered with stories, even here on WRT there are some. One of the problems is that the service manual of the 6139A is readily available on the net, not so with the service manual of the 6139B. On top, reading other forums & stories, there are people who claim that there is hardly any difference between the 6139A and the 6139B movement, so the 6139A service manual will suffice. However, one of the crucial differences is the design of the chronograph center-wheel. Also the Seiko reference numbers are different. For the 6139A, the reference number for the chronograph center-wheel is 888610 and for the 6139B: 888612. To lubricated the 6139A chronograph center-wheel, the following graphic picture in the 6139A service manual is given; One has to press down the sprocket and oil it. Unaware of the difference in chrono center-wheel design, I pressed down on the sprocket, but there was no movement. Perhaps not understanding or interpreting the drawing correctly, I pressed with the tweezers on the 4th wheel. This caused the 4th wheel, which turned out to be a press fit to the sprocket by the 6139B, to strip off the sprocket. Thereby me joining the line of all the others, who tried this before and are now searching for "how to fix" this misfortune. In an older thread on WRT, member @ricardopalamino place a picture in which he shows the difference in center-wheel design between the 6139A and the 6139B. To the left the 6139B and to the right the 6139A. As can be seen on the left center-wheel, the 4th wheel is pressed onto a sprocket. Pressing down on it, as shown in the 6139A service manual, gives a ruinous result. People did several attempts to repair the damage, but so far, I haven't found a success story. Here is one of the attempts; Reading what already has been tried, I tried a different approach ..... but sadly failed too. Nevertheless, I'll show what I've done; perhaps somebody may fine-tune or expand on the idea and has success? In my staking set was an anvil with a 4.5mm hole, exact the size needed to fit the chrono center-wheel "up-side-down". The distance between the clutch parts and the 4th wheel was 0.25mm. To support the 4th wheel as close as possible up to its center, I used feeler gauge blades, on one side a 0.25mm blade, and on the other side a combination of 0.15mm + 0.10mm blades. This allowed me to tap the sprocket back onto the 4th wheel ...... The thickness of 0.25 blades doesn't prevent some "spring" action, and so my 4th wheel was slightly deformed. The re-attachment seemed successful, but when trying to true the wheel, the connection failed again Currently there is a NOS 6139B chronograph center-wheel on eBay. Last Sunday the price was €150, on Monday the seller increased the price to €165 !! Prevention is better than the cure and I do hope that anyone in the future, searching for a 6139 manual, with read my "Warning". As for my Seiko, I'm not going to invest €165 for one part and since the rest is pretty good, I will sell the watch for "parts or repair"1 point

-

Try pressing all four buttons at the same time - every segment on the screen should show for a second or two, plus it beep. That's a "hard reset" which should get it going, if the battery is making proper contact and there is no fault. I've just tried it with an old Klik of mine, with a new battery. If that works, it may take anything from a few minutes to a few hours to lock on to the time signal and set itself. Keep it away from computers & wifi devices etc. to minimise interference until it sets. Edit - mine set itself while I was typing that! Not bad seeing it's not been used for years.1 point

-

Which myota movement is it, they're pretty cheap. You could just replace the movement.1 point

-

The hole just offset from the stem, below the one over the stem in the second photo.1 point

-

1 point

-

Nothing is lost at this stage. But You first have to take out the clutch part from the pinion. Then next is to fix the wheel table to the pinion. If it can not be riveted, then must be soldered. Then trueing, and clutch part reattaching. It is possible to make a bush that will stay press fitted between the table and the clutch and will hold tight the table in place instead soldering.1 point

-

1 point

-

The original 6139A manual is very clear in how to disassemble and how to assemble ...... step-by-step. However I haven't seen the 3169B manual, even in the Japanese version around, which clearly highlights the difference in center-wheel. 6139A Seiko Technical Guide.pdf 6139_A.pdf 6139A.pdf 6139b.pdf 6139B repair guide jp.pdf1 point

-

Hi as an addition a pertaining to the assembly of a 6319B which will be handy for those working on this caliber Polly's 6139 guide.pdf 6139A.pdf 6139B.pdf1 point

-

This post has some pictures that describe how to get the spring back into the setting without having to disassemble anything. With patience, this approach works. The advice that the spring will ‘float’ back in when positioned just right is spot on. If you try to push it so it flexes and pops back into the setting, it’ll probably just fly away, as you’ve already found. Hope that helps, Mark1 point

-

If you read the NAWCC link : it says, this cal. has a fine teeth clutch, no rubber. Frank1 point

-

What is written in that little name plate translated from French to English is Verified and guaranteed tool1 point

-

The Chinese incabloc springtend to take flight at the slightest provocation. There is no need to push out the setting as some post suggest. You just need to grip the spring and muscle it in. My favorite tool for accomplishing that is an eyebrow tweezer. It has to be wide enough to grip across the width of the spring. Then get one end of the hinge in first and turn spring till the other end seats in. Next, use a pegwood the keep the spring forward to prevent the hinge from slipping out from behind. You might want to keep your table clutter free, as the spring would probably take a few more short flights.1 point

-

Wire for what? if it's steel then only certain types of steel can be hardened ie high carbon steels: "Mild steel doesn't harden very well. It doesn't have enough carbon. Get something like O1, silver steel or if you want to go full watchmaker, then Sandvik 20AP". Source1 point

-

1 point

-

The fact that you have witnessed coils of the hairspring clinging or sticking together explains why the watch is running so fast. If you reduce the length of a hairspring, the watch will run faster. When hairspring coils stick or cling together, this effectively reduces the active length of the hairspring, so the watch runs fast. As nevenbekriev has said, the most likely culprit here is oil or other contamination on the hairspring causing coils to stick together. Cleaning the hairspring as he describes will solve the problem. Occasionally the contamination causing the hairspring coils to stick can be very stubborn to remove, in which case I suggest ultrasonic cleaning in acetone, naphtha or a commercial watch cleaning solution. Magnetism can also cause coils of the hairspring to stick together, if the hairspring is made of an alloy that can be magnetised. Finally, your watch has what is called a pin pallet escapement. They are considered to be less refined, but quite rugged compared to a traditional Swiss lever escapement. They are quite forgiving. They do require lubrication, if you haven’t done so already, find instructions for lubrication of these escapements to get optimal performance from this watch. Hope this helps, Mark1 point

-

Hi, there are original staffs and hands on Ebay currently, exact parts are out there....1 point

-

What You decribe as lever behavior is more or less common for pin lever movements. Actually it is normal, but may benefit from proper lubricating the pins/escape wheel teeth. So You problem is the hairspring. Probably it is only 'sticky' and washing it in accetone or pure petrol will bring it to normal state. Drying with hairdryer helps much after the washing. Of course You can try to demagnetise the balance and the cock. The problem will be solved when the sping doesn't stick on ocasion, e.g. when one grasps several coils together with the tweezers, they should get separated by themself imediately after released. Some chance exists that the spring is bent where the coils touch, but try firs what i have writen above.1 point

-

What I consider ebay "Paydirt" - taking the back off a watch and finding years worth of accumulation of crud around the edges, so it is as previously worn rather than someone else's failure or Frankenstein attempt they are getting shut of. And even better when you also find an immaculate movement with no sign of rust or chewed up screws! Another couple I think are fantastic old ones, from an ebay job lot (under £2 each). They both look like they have been worn to death, with little plating left. The "Claridge" one (upper) has the date 1922 (or 23) scratched in the back, and the Ingersoll has 2/48/FW in the back. (Is that when it was sold, or serviced)? The movement in the Claridge looks like it was a reasonably high end one at the time, from the finish? It's also got quite a fancy dial. That one tries to run, but is very sticky. The Ingersoll is only a pin escapement type, but it's still going strong with good amplitude!1 point

-

I order to boycott the Swiss (not really ) I like to try a Seiko (6139-7100). Bit of an iconic 1970's model, nick named "the Helmet". Below sellers pictures and it seems to kinda run ...... according to the sellers watchmaker; ceased due to dried up oil and the seller didn't wanted it serviced, hence sold as defect. Case, glass & original bracelet should be in "super" condition ......... Curious what's under the hood !?1 point

-

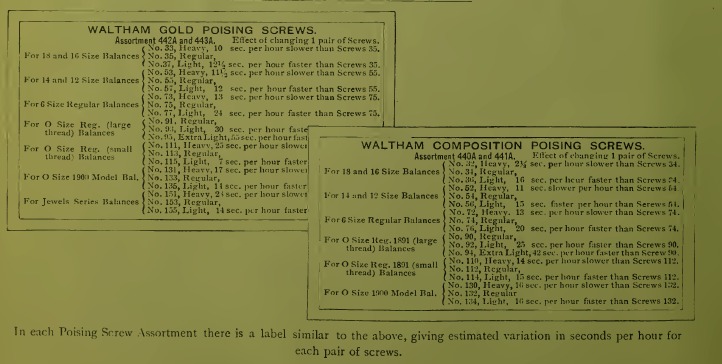

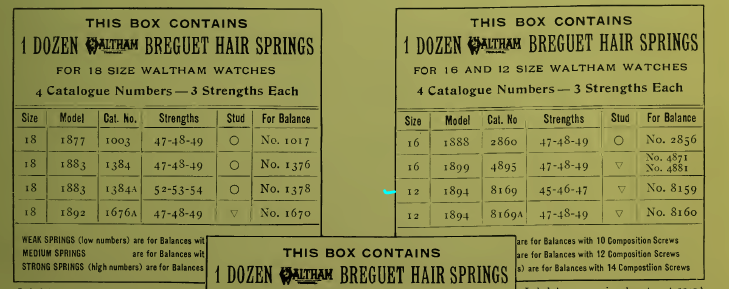

in other words that's not the hairspring for that balance wheel it came from somewhere else? providing the hairspring is flat and not touching the balance arm or the over coil isn't rubbing on the upper bridge. Yes it's common for over coil hairsprings to not be exactly where there supposed to be and their hard to see that they are where there supposed to be. Normally if you are running really fast around 15 minutes it would be because you are missing one of the timing screws. Timing screws have to come in pairs one on one side one on the other if one falls out about 15 minutes is how fast you'd be running. check your balance wheel to make sure all your screws are there in pairs. usually not this fast but you do want to be careful that the balance arms form a nice round circle often times with bimetallic balance wheels people will squeeze them and the wheel will not be round that causes interesting timing problems but not usually as dramatic as this. then just a reminder on modern watches with flat hairsprings a procedure called hairspring vibrating adjusts the hairspring to that exact balance wheel. If you look at parts list for modern watches you typically never see the hairspring separate. In the case of vintage with over coil hairsprings to get the hairspring into the exact shape it's easier to pre-make them. Then the factory would match the balance wheel to that hairspring. then because hairsprings were available separately back then you would also have things like this assortment of screws. Notice in the image the screws are rated per hour and came in either gold usually found a nicer great balance wheels and standard brass. So like your watches about 14 seconds per hour you would mix-and-match the screws to match your balance wheel to your new hairspring. so this is why this isn't working the mean time screws are fine adjustment not meant for matching the balance wheel to the hairspring. oh thinking of assortments is another image out of the catalog it's a shame they overlap the images notice the reference to strengths even for your model of watch? Then unfortunately they covered up part of the image at the bottom but there's a reference to the type is screws found on the balance wheel. the idea would be to find timing screws otherwise you could do a timing washers but typically the maximum effect they have would be three minutes per day and you're going to need a few of them. Then ideally you're only supposed to put one washer under each screw head is not good the double up not that it can't be done but you're really not supposed to. another option you have here is if you still have the other balance wheel see if you have some slightly bigger or heavier screws and do a little mixing and matching just remember to keep them in pairs or you're going to have a heck of a poising issue.1 point

-

1 point

-

For me, a bit of a "kinky" side step; two partially broken vintage quartz watches no less ! They do run and the chronograph functions do work, but, from both, the small chronograph seconds recorder (1/10 sec) doesn't reset and they don't run I've found some instructions on how to reset the small seconds recorder, but it doesn't say whether the recorder hand should run, or not, after a battery change; "Resetting the Chronograph to Zero: If your chronograph and 1/10 seconds subdial hand are not aligned after a battery change, do not worry as this is common and easily fixed. Simply make sure the crown is in normal position (pressed in against the case), the push Button C (bottom left) twice. The second hand will move, press C again. Pull out the crown to time setting mode. Now you can adjust the two misaligned hands: Button A will advance the central second hand forward, Button B will advance the 1/10 second hand forward. Push the crown back in." So, since both of them do have the same problem, it could be simple and the seller didn't know how to reset, or there could be more to it? Is it a coincidence that both movements do run (cal. 3510 + cal 3530) and do have the same problem ?? They added thrill is that these Citizen / Miyota 3510 movements (12 jewels ! ) are discontinued and apparently (very) hard to get (??). Perhaps one of those: "There is a thin line between a Hero and a Zero" Anyhow, without further ado here some pictures of what should be in the post;1 point