Leaderboard

Popular Content

Showing content with the highest reputation on 04/17/24 in all areas

-

I took the leap into this wonderful hobby about 4 months ago! I've had some success in restoring cheap movements I've purchased at antique stores and flea markets, etc. My best result was a 1970 Spiro Agnew watch I picked up for 5 bucks. No strap or bracelet. It only ran sporadically and had a cracked crystal. It was a Ronda 1213 IIRC. I even had to retap the threads for the screw for the balance cock and surprisingly it worked! I still make a lot of mistakes and have had to abandon plenty of movements due to fatal mistakes. My technique is slowly getting better but still would be called "extreme novice." Hope to get to know you guys! mthomas2 points

-

2 points

-

Casio MDV106G-1AV Gold DURO200 I'm going on a long family vacation to Southeast Asia this summer and wanted a cheap but reliable beater in case I lose it, break it, or get robbed. Quartz movements aren't my thing, but I'm not dogmatic and this was a cheap option. A few years ago you could buy it for under $50, but since this particular model with the Marlin fish has been discontinued, you have to pay about double that, but I still thought it was acceptable. Sure, I could wear one of my cheap and very reliable Vostok Amphibian divers watches, but I have a personal relationship with them (having put a lot of work into them) and don't want to risk losing them. Strangely, I feel very excited. Maybe because I haven't bought a brand-new watch in over 10 years! The only downside is that this is the watch Bill Gates has been seen wearing, and I'm not exactly a fanboy of Bill Gates. Anyway, who cares!?2 points

-

I don't know why I was limited to a 3DPrinting forum, but oh well. I managed to grab a much coveted Meyer's No.58 Movement holder off ebay, but it only came with the second to smallest jaw inserts. Not to be detered I reverse engineered how to machine the jaw inserts. Here is the Flickr Album. https://flic.kr/s/aHBqjAGuFJ I made a small insert set as a test and then made a set for size 16s pocket watches. I'll make a few more to fill out the set. I made these from Aluminum, but might try glass-filled Delrin as an experiment The drawing could easily be used to design the jaw inserts for 3D printing in Nylon or a hard Urethane1 point

-

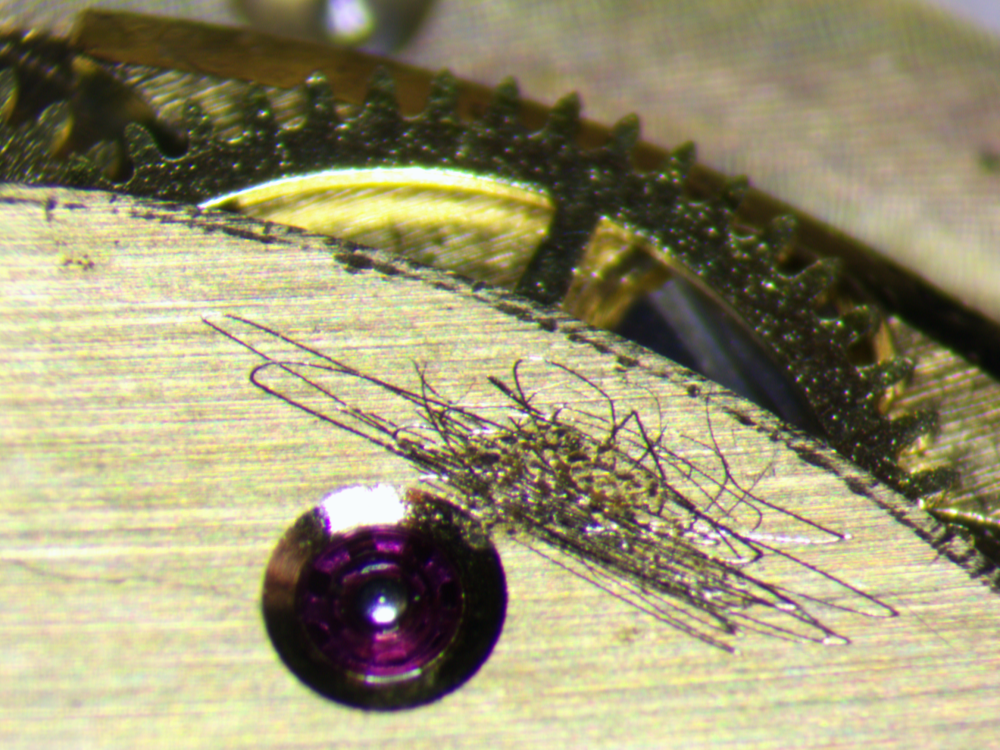

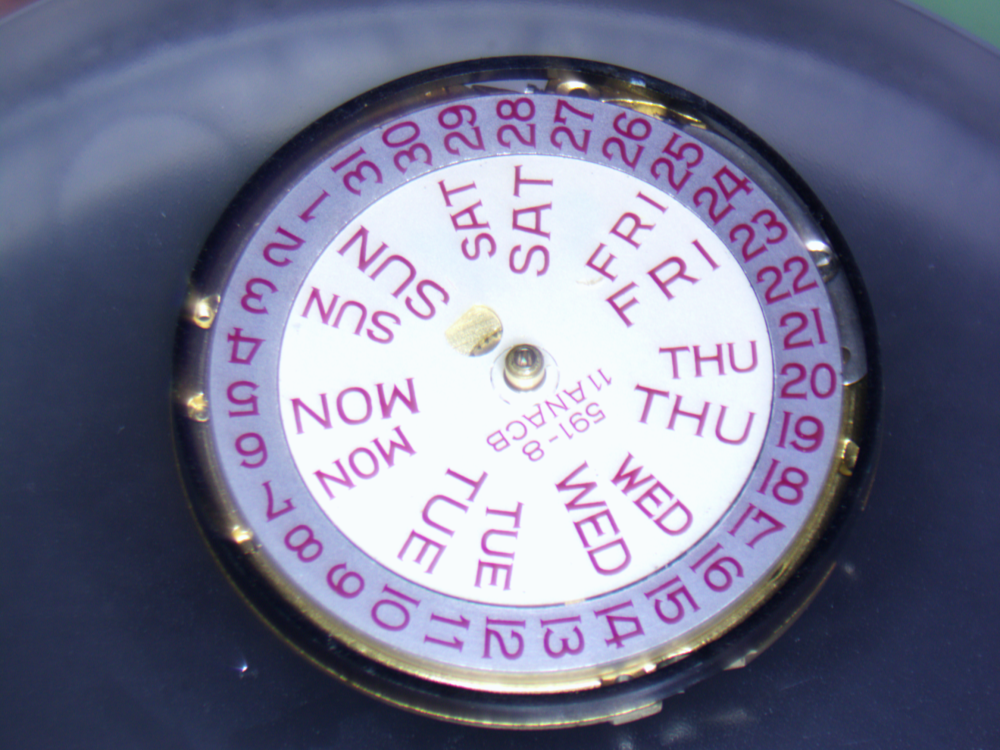

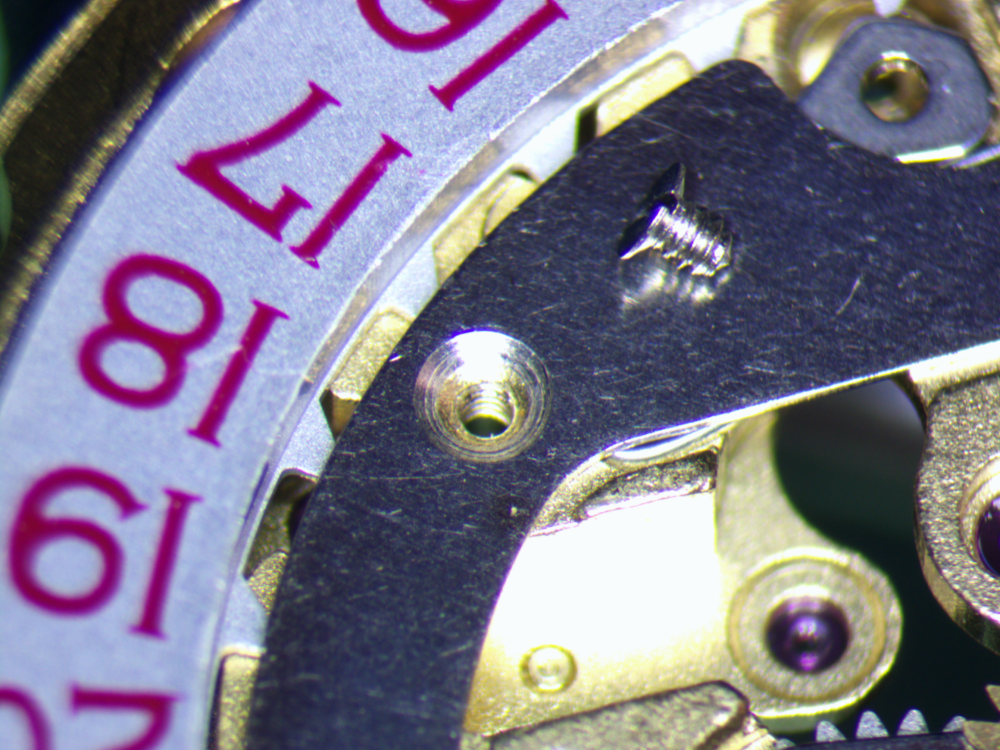

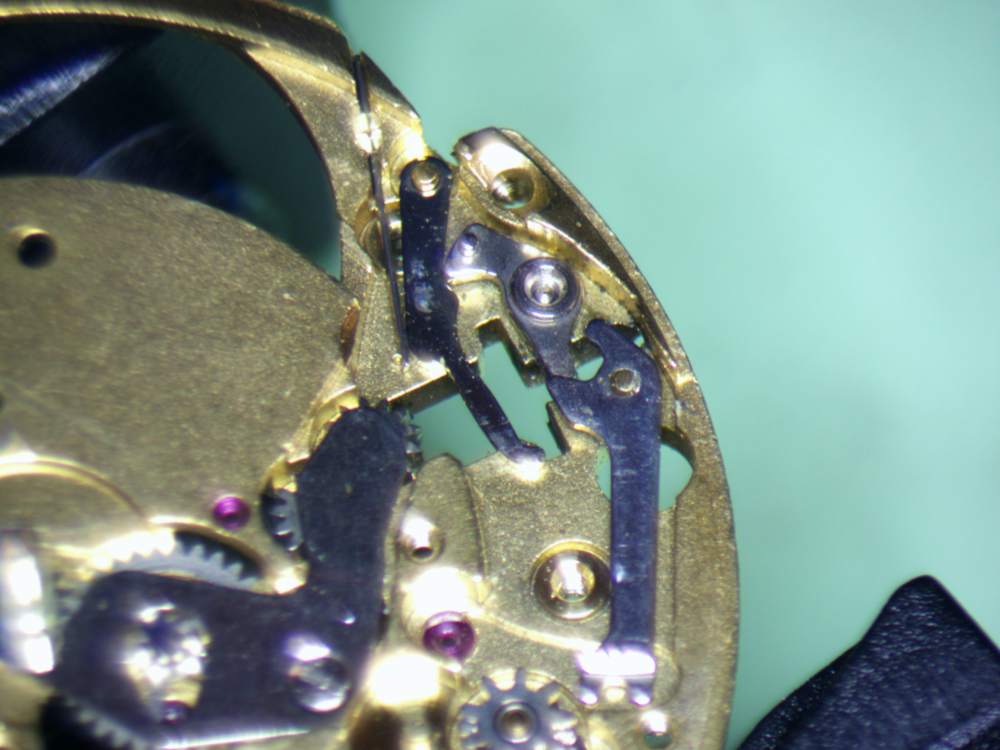

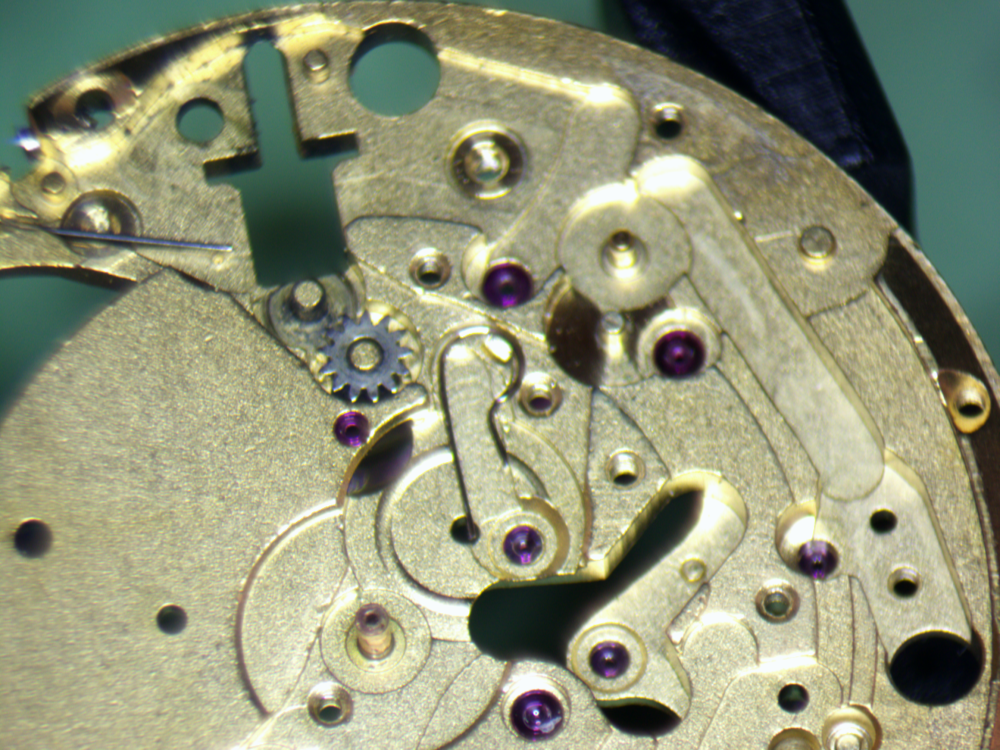

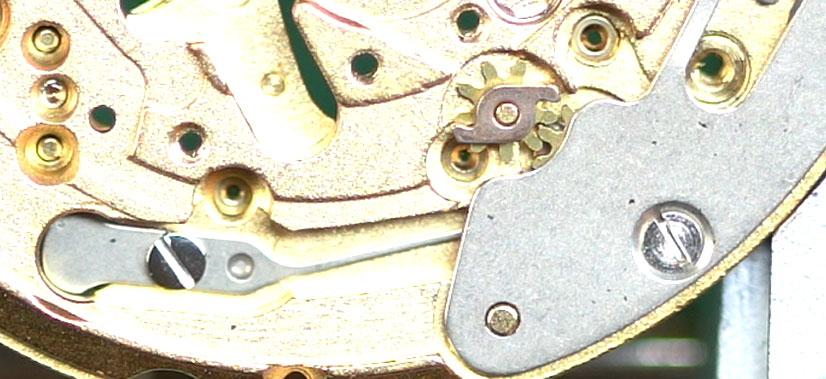

Recently picked this guy up, and took it apart for cleaning tonight. Looks super clean inside as far as wear and tear goes, but there are puddles of oil everywhere! Hopefully a good cleaning will bring the amplitude back up. I did learn that the automatic bridge is spring loaded, which you can see below in the yard sale of wheels and gears all over the place. Sorry in advance for all the pictures and if some aren't in perfect focus. I take a lot of progress pictures through my microscope, and I figure if someone is here looking for help, they might be useful to them. And this is where I stopped, since I got into the wine.1 point

-

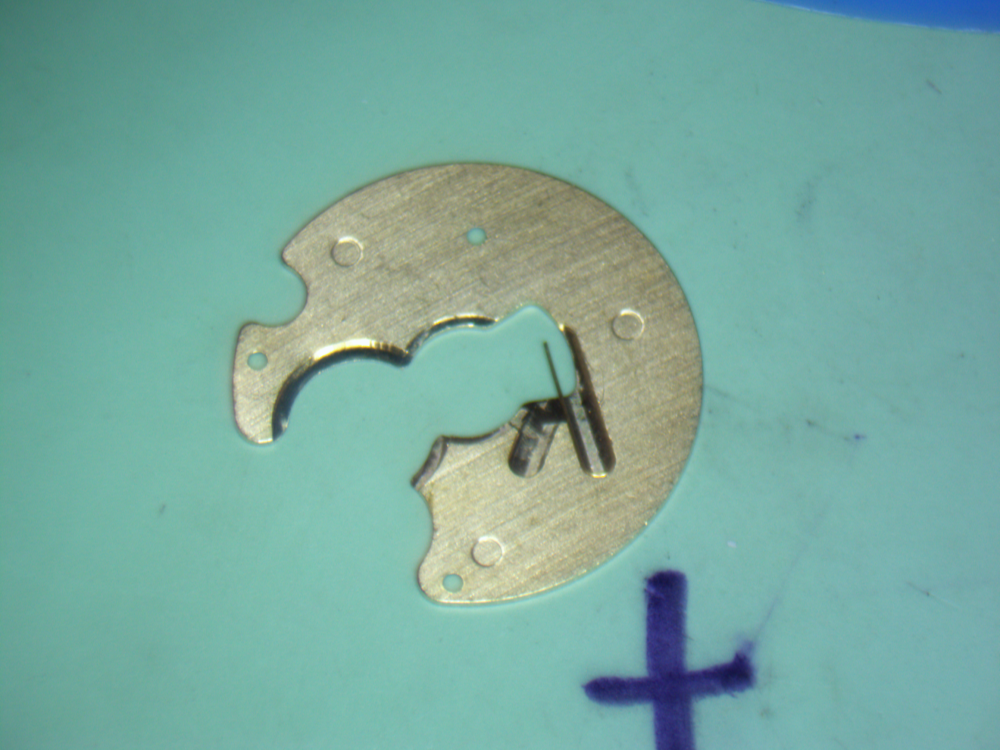

One of the reverser wheels came off with the bridge but they are interchangeable. The Bulova tech sheet also has a diagram (attached). I thought your date corrector looked like it was in the correct position. Just to confirm, the quickset works by pulling and then pushing the crown in and out to advance the date. Bulova_11 AOAC, D, B.pdf1 point

-

The 11AN/11AO family is probably my most worked on movement (working on one right now). I've had the auto bridge spring into the ether myself. Bulova tells how to wind down the mainspring in their tech sheet but I've never had success following their instructions. There are definitely some quirks with the movement: oiling the upper sweep second wheel pivot and the dial side pivot of one of the auto works wheels which is inconveniently placed between the spokes of the escape wheel. the Date Corrector Setting Wheel has to be placed in the exactly correct orientation or the quickset date change will not work. the setting wheel that interacts with the sliding clutch goes chamfer up. I've made my own 'tech sheet' for it and shared it in case it's of use to anyone. Bulova 11AOACB.pdf1 point

-

It's very ..... purple It looks like a nice movement. It will be interesting to see how well it runs. I'm still on the look-out for my first Bulova1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

1 point

-

Ah, this helps. The spring was left hand wind, and the shock setting looks very Seiko, so maybe a I have a Chinese movement version...1 point

-

Here you are a video by our good friend J D Richard. https://www.youtube.com/watch?v=LMxoZjRaH501 point

-

Hi. Thing to do is measure the battery space. Diameter. X depth .. I have seen it listed as sr626sw. 377 measure to check then check the dimensions of the 377.1 point

-

Thank you to both of you! I've been somewhat derailed by this quandary for a couple of days now. I am guessing that the point of the wider tweezers is to support the whole spring at the same time in an effort to prevent it going under tension... I have already discovered the Zen of a clutter free space, and trying to keep my work well away from the edge, however the most terrifying of the flights wasn't so short, I had my work in the middle of the table and nothing else around. That particular launch was towards me. I distinctly recall feeling the spring hit my left hand as it escaped. I only found it by dumb luck, on the floor, between the legs of my chair. I need to order a pack of replacements just in case. I think I recall a thread discussing where to find them, and the differences between the clones and the authentic ETA ones, pointing out that they're not interchangeable (the clones being longer IIRC). Now I just have to find that thread again. What I haven't mastered is the zen of the search function here. I'm sure I"ll get that down eventually. So this is similar to, but different from one of the posts I had found in my original searches (or maybe I'm just hallucinating, I can't find the post I thought I remember). The bits about the corner filled in a gap in what I'd read before. At least I have a more clear picture in my head about what needs to happen now. Yes, I've learned about how touchy these springs are. What I'm not sure I have a good grasp on is the understanding of what causes the spring to flex, other than to say "the slightest little touch" I think I'm going to try a small bit of Rodico to position the spring next time.1 point

-

All the best, family always comes first, and I believe you have made the right call that you mother deserves your full attention. However, when you need a little outside distraction the guys here will always be available for some banter or a heated discussion on lubrication .1 point

-

The effect that You describe (no friction when turning train backwards and noise + friction when turning forward) is due the oval wear of the 4th wheel bush. The oval lets the 4th wheel tilt and get closer to the escape wheel in normal direction rotation, and thus the mesh with 'scape pinion is wrong. There is a simple way to confirm this - mark the bush, remove it and press it back but rotated to 180 degr. This will restore the correct wheel position and mesh when rotating the train in normal direction. The mowement will start working normally. Well, this is not perfect soluion of the problem as the oil retention will be not as good as with new bush, but if You lubricate with 8200 grease, it will stay in place and work good. Of course, placing a stone there is good, if You can find one with correct sizes. The hole for the arbour in the main plate looks rather punched than weared. So if You have not punched it, then someone before You did. It means that You have to check if the arbour stays upright, as closing the hole by punching it may lead to shifting the hole. What You actually need to check is wether the barrel stays tilted when the movement is wound and let to unwind by train rotation, does it rubb on the bridge or the mainplate or gets dangerously close to the 4th wheel table, and if the mesh with the 2nd wheel pinion is correct. Wear of the barrel bearing holes may lead to similar problems too. Lighter fluid is good for lighters, it is not ment for hairspring cleaning. Well it doesn't mean that it is not possible to use it for hairsprings. But if they stay sticky, then it means that the fluid is not fully evaporating or it has some oil in it solved. You can try to use hairdryer to dry the balance complete. If the spring is OK after drying, then You have the solution. If not, then source some pure hexane, acetone or another fast drying and clean oil solvent. Clean - put some drop on clean glass, wait untill evaporates and see if the glass is still clean.1 point

-

4th wheel bushing hole wearing oval is typical for these movements. The bushing has possibly also been moved while pressing the seconds hand too hard so the end shake is so big that the pivot might even fall out of the hole, stopping the movement, especially with an oval hole. The bushing can be replaced with a jewel from a jeweled train bridge. I replaced one 6105 4th wheel bushing with a jewel from a 6119 train bridge.1 point

-

Here's a video of how to repair a worn barrel hole with a jewel, for the future when your skill level and tool collection has caught up with the problem present in your watch.1 point

-

The hole in the main plate looks kind of oval from here, but it could be perspective. You'll probably want to put the arbor and bridge back in and wiggle it around to check for side shake. I'm not sure about the 6309, but for the 6139 you can get a jeweling kit to replace the barrel bushings, if you're looking to make extra work for yourself I found the same thing, and is one of the reasons I bit the bullet and switched from lighter fluid to L&R 566 in my ultrasonic. It's a night-and-day difference in cleaning quality. That said, I still clean my balances, hairsprings, pallet fork, and cap jewels separately in hairspring dip. It dries fast and leaves no residue. I get mine from Esslinger here. Edit to note the fact that it dries fast also means it evaporates quickly from whatever vessel it's in. I used to use the guy on the right, which everyone sells. Then I found the one on the left and it's once again a game changer. The ground glass seals very well and minimizes evaporation. Link to previous thread on the topic.1 point

-

What I consider ebay "Paydirt" - taking the back off a watch and finding years worth of accumulation of crud around the edges, so it is as previously worn rather than someone else's failure or Frankenstein attempt they are getting shut of. And even better when you also find an immaculate movement with no sign of rust or chewed up screws! Another couple I think are fantastic old ones, from an ebay job lot (under £2 each). They both look like they have been worn to death, with little plating left. The "Claridge" one (upper) has the date 1922 (or 23) scratched in the back, and the Ingersoll has 2/48/FW in the back. (Is that when it was sold, or serviced)? The movement in the Claridge looks like it was a reasonably high end one at the time, from the finish? It's also got quite a fancy dial. That one tries to run, but is very sticky. The Ingersoll is only a pin escapement type, but it's still going strong with good amplitude!1 point

-

1 point

-

Really no one? Tool is used for milling the bearing for rubbed-in jewels. For those without a lathe… Frank1 point

-

I use the same technique for Seiki diafix settings. Remove spring and cap jewel for cleaning. Reinstall, then oil from the back side. I push the oil through the hole with... a whisker I stole from my dog's muzzle! I snipped it off and glued the big end to a toothpick for a handle a couple of years ago, and keep it in a small plastic tube when not in use. Don't worry, he hasn't missed it.1 point

-

1 point

-

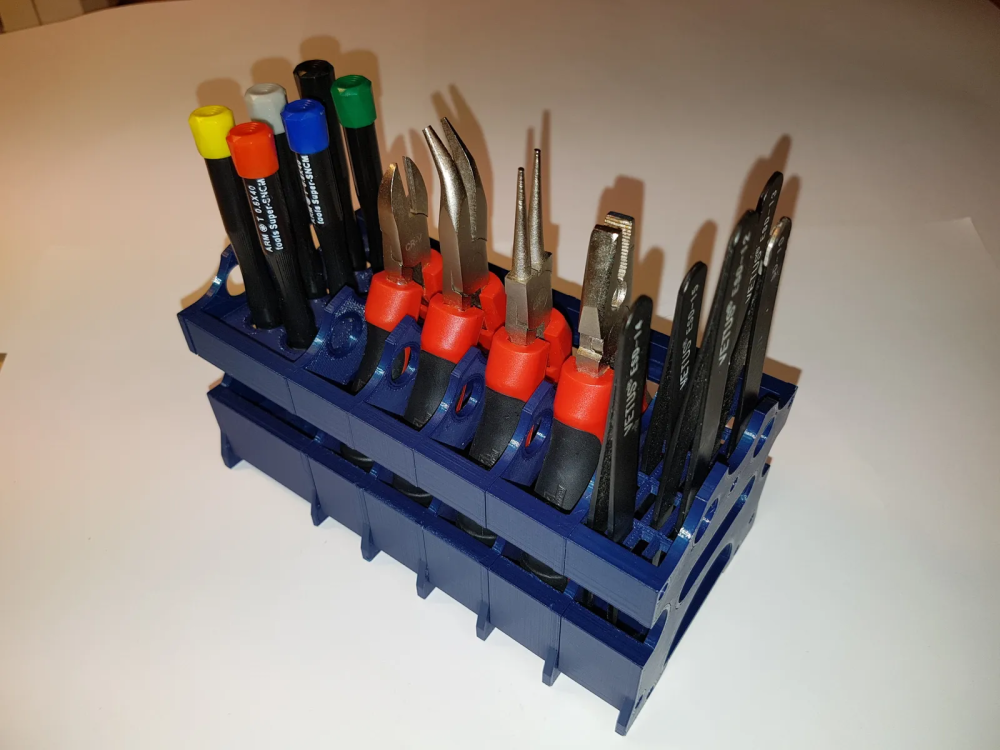

Hey there, just thought I would share this, it's not my work, but I just downloaded and printed some of this modular system and it's working out great - well thought out and practical - you can mix and match as you like. Hopefully someone on here will find it useful also. Remember to give the kudos to the designer :) Link here1 point

-

If you have a crown (button) and the tap size is right and the colour also, but the crown doesn't fit over the pendant tube, these tools are to make the inside diameter of the crown fit the pendant tube. You could also, reduce the size of the pendant tube on your lathe after pressing it out1 point

-

My wife took these pictures today. Not sure if there is a message that I am supposed to get The first bench is the one from my Dad. The second is the one I bought from Maine. The third I bought from someone in Wyoming. The last watch bench came from Dallas. The other bench is just a converted office desk. The last picture captures a portion of the room. This was not staged...and I am a little embarrassed about how it looks. That's me and Cromwell.1 point

-

Now that is what I like to see a lovely mess. Providing you know where every thing is. My work bench was always in a mess, my master would always tell me to clean it. When I had my own workshop it always looked as if a bomb had hit it. Funny really as I like to keep my home very tidy I do not like things out of place.1 point

-

My mentor just seals the part with a slip of paper with the description in a plastic bag. He has a sealer that seals and cuts at the same time. Then puts the little bag in small plastic boxes. Everything is labelled and organized. While me, I keep turning the house upside down looking for things that I know I have, and end up finding things that I don't remember having. Then I get distracted and forget what I was looking for. Anyone else like me, raise your hand.1 point