Leaderboard

Popular Content

Showing content with the highest reputation on 05/01/24 in all areas

-

4 points

-

Even the amount picked up by the smallest oiler can be too much. I made my own oiler with a 0.2mm wire. And I use the amount picked up by the smallest black oiler and use that to transfer an appropriate size droplet to the tip of my homemade oiler. The final amount of 9415 used is so small that it seems ridiculous.3 points

-

I assume you're using 9415? the concerned with 9415 and I'm attaching a PDF from Omega is too much can cause a decrease in amplitude. This is why you look at what they do they go to extreme lengths to put extremely tiny quantities. so as you've discovered proper lubrication of the escapement increases the amplitude. We've seen it on this group where people are having typically newbies issues and I will ask if they lubricated the escapement the usual answer is no they had not because and once they did they saw spectacular improvement. one of the amusements with lubrication tends to be so many variations. For instance I was in a classroom once and the students all came from for the most part accredited schools in watch repair. So the instructor asked how did we lubricate our escapement's and I don't remember the actual quantity but it's really quite amazing how many people can interpret slightly different ways of doing the same ask. Of course the instructors method was the approved one. This was the place a drop of oil on the impulse face of the exit stone. Allow one third of the teeth to go by and place another drop then another third and your escapement should be lubricated. But sometimes and yes it will show up in the timing machine you'll see in your regular line because if the oil didn't transfer all the way around to the other stone that does cause a issue with the timing machine. Oh but when I was in school we were using 9010 as 9415 did not exist yet although 941 did which is an oil recommended for escapement's. it has to be dissolved in a proper solvent with the right amount of concentration as you want a microscopic layer on whatever your treating. My understanding is the vapor process is the very best but the vapors are not good for human consumption. The reason why the vapor process is nice is that it puts a very very thin coating on versus dipping in a solvent which can vary depending upon the concentration. 8645_WI_40_rules for lubrication cousins.pdf3 points

-

2 points

-

2 points

-

Just realised my previous reply could be misunderstood. I epilame treat the pallet stones (not the entire fork) but I do not let it run dry before applying the Moebius 9415. George Daniels is likely turning in his grave over the use of epilame, oiling, and the use of the Swiss lever escapement.2 points

-

I'd like one of those for my staking set. I bought a cheap roller remover, thinking I could just file the jaws down so that it worked well. It didn't, so I ended up buying the Bergeon version, which does work well. Though, as @Neverenoughwatches points out, you do have to be careful not to damage the roller of staff. Rollers are very soft and easily bent whilst trying to remove or refit.2 points

-

I recently helped my mentor to service 7 Seikos and he told me not to lubricate the pallets. His reason was from his experience from the advanced classes that he conducted, his students all ended up with worse amplitudes after oiling the pallets. I have to admit that I had the same problem when I oiled the exit jewel, like so many videos on YouTube show. I actually ended up with worse amplitude. But now I oil the escapement by oiling the teeth of the escape wheel. I think Rolex used to train their technicians this way. I find that I get about 20° -40° increase in amplitude oiling the escapement this way. I've only started playing with epilame recently. I got a bottle from a Chinese seller on AliExpress. It's supposed to be Episurf Neo but everything on the bottle is in Chinese. When the bottle arrived, half of it had evaporated or leaked. And when I brushed on a thin layer on a mirror, it dries rather slowly and even feels a bit tacky. When I did the oil spread test, like my experience with stearic acid, the treated and untreated surface of the mirror yielded similar results. The contact angle of the oil drop looked about the same for both the treated and untreated surface. When I epilamed an actual pallet fork, the escapement was so sluggish that I couldn't even get 180° amplitude. I dunno if I got conned by the seller but the results are just not convincing.2 points

-

I usually just use 2 pair of pliers to remove the roller ( just kidding ) I want one,I have an adjustable free standing one. But i really like the little bradux tool that nips under the roller with two tapered jaws that lift it off. You can get under a scope with it to see in detail how the job is going. There is some technique involved to stop you chopping the staff, doesn't particularly matter if the staff is already broken but it naffs up the tool's jaws if you crunch the staff, and the jaws need to be in good shape to prevent damaging the roller. But well worth a try if you've never used one and you can find one that hasn't been misused or buy a one new. The trick is to keep one of your fingers between the two arms to soften the squeeze, with a little practice its a handy little to. I will now prepare myself for an onslaught of negative feedback on it2 points

-

2 points

-

Used with the correct fitting staking punch it will remove the roller.2 points

-

Coffee is easy for me, strong and black. Hehe. Let us know how you get on with the crystal.1 point

-

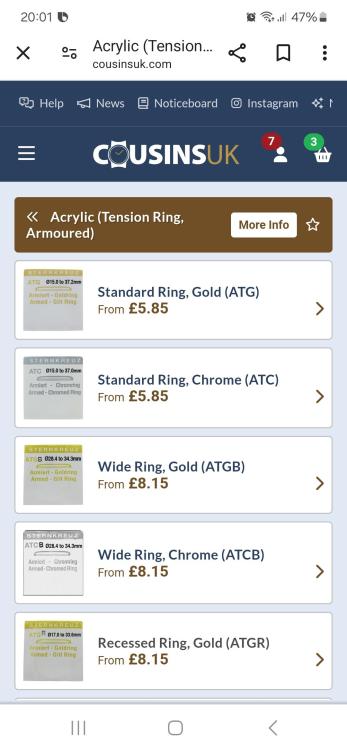

This tells you how to fit the glass and they type of tool needed, but there are loads of this type of tool. https://blog.esslinger.com/how-to-press-a-tension-ring-fit-watch-crystal-into-place-with-a-watch-crystal-press/ When it come to buying the glass make sure you buy the one you need with the correct colour tension ring.1 point

-

1 point

-

Not necessarily . According to Ranfft : "except bridge shapes no differences known between 984, 1009, 1010, 1013, 1028, 1033, 1035, 1038, 1048, 1050, 1055, 1077, 1084, 1089, 1091, 1141, 1211, 1218, 1231, 1259, 1277, 1285, 1313, 1377, 1440, 1614" So take your pic. It's an earlyish one, as no Incabloc, so probably 1930-40s1 point

-

I haven't yet but I will take it out tonight! Thank you. Will post pics of dial side tonight too.1 point

-

Did you have a look under the ballance? Often the movement maker/number is hidden there.1 point

-

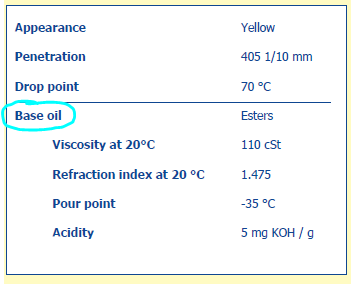

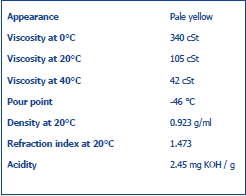

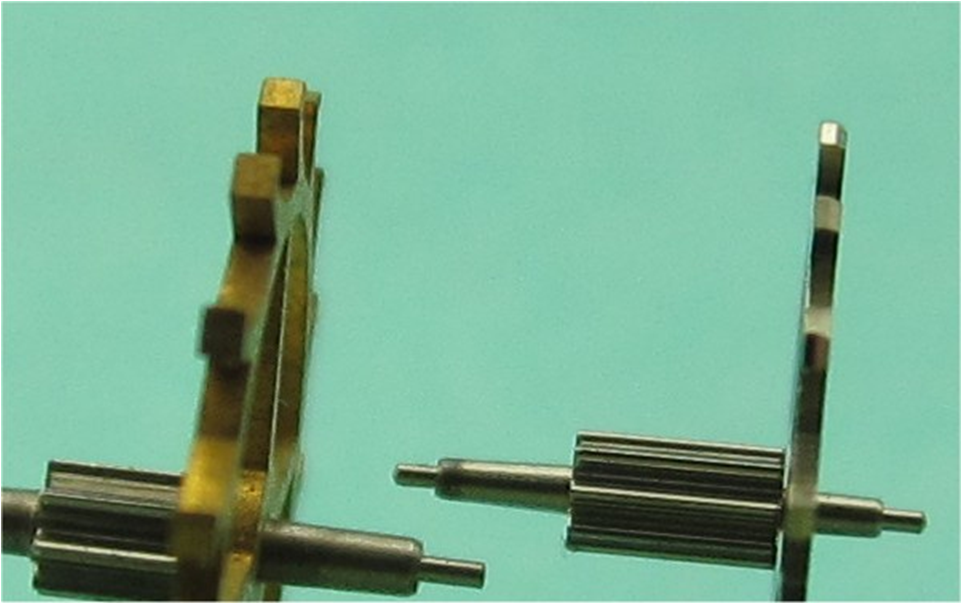

I wonder if 9415 is based on a base oil of 941? it's interesting what questions bring and the tech sheet answers it's the viscosity of the base oil. Then the impact? There is something we're missing here for that which would have a big influence on all of the house image above is 9514 image below is 941.then always interesting when specifications do not exactly agree? They ledge above for 941 indicates 110 viscosity but the image off the spec sheet is slightly less but I guess close enough my understanding of the concern of too much 9415 is as we know the loss of amplitude. But why do we have a loss of amplitude? So impact it's basically oil should be very slippery. But what about non-impact? Like the edges of the escape wheel? Another thing that comes to play here is the shape of the escape wheel itself. Notice on the last a more vintage escape wheel with just a flat surface whereas the modern escape wheels usually made out of steel versus grass much much thinner their contact areas greatly been reduced and sometimes I think there even slightly curved. So is it conceivable at everything that isn't a flat surface on impact is going to be sticky? So this is where the shape of the escape wheel will have a big impact literally on how slippery things are. Oh and for all of you obsessed with worrying about too much 9415 I never worry about it because typically I'm doing pocket watches and it doesn't seem to be an issue at all. on the other hand I'm much more concerned about a watch that keeps time for 24 hours as opposed to the concern of the group of keeping amplitude for 24 hours. Then yes some pocket watches have steel escape wheels and do look like the escape wheel on the right.1 point

-

Yep i can see where you're going with that one Rich. Sooo now that I've frightened the OP into submission . Chief i do apologise for some reason unbeknown to myself I'm in a happy silly mood. So seriously to identify the movement lets have a look at the dial side, learning this part is straightforward, just need a little logic and something called the # BESTFIT BOOKS # . Or the other non American equivalents.1 point

-

I can definitely see elephant and aardvark and possibly some sort of bird with a large beak anyway I'll have a go of getting it flipped over tonight and send some pics1 point

-

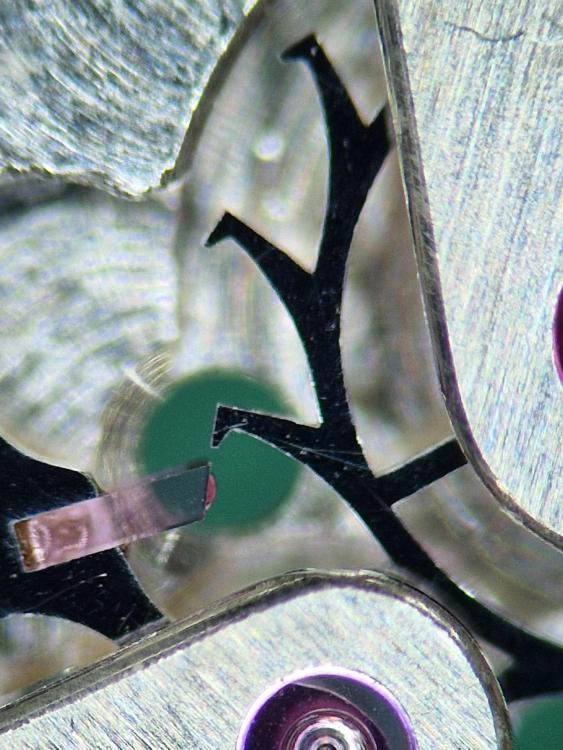

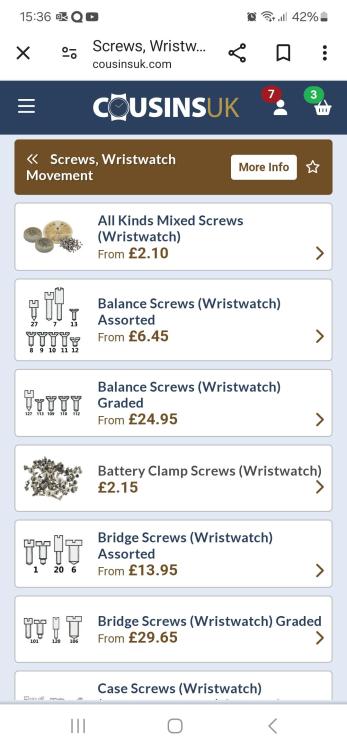

A Schild movements often have left handed crown screws. A pic of the keyless works would help identify it, and the size of the movement. Looks like someone has had a, not very subtle, attempt to decrease play in the centre wheel. And the hairspring looks like it needs some work. From the scratches on the bridges, it looks like it was last serviced by a drunken baboon, but it's a good movement to practice on. Good luck Once we identify it, it's often easiest/cheapest to buy a similar scrap movement for screws/parts1 point

-

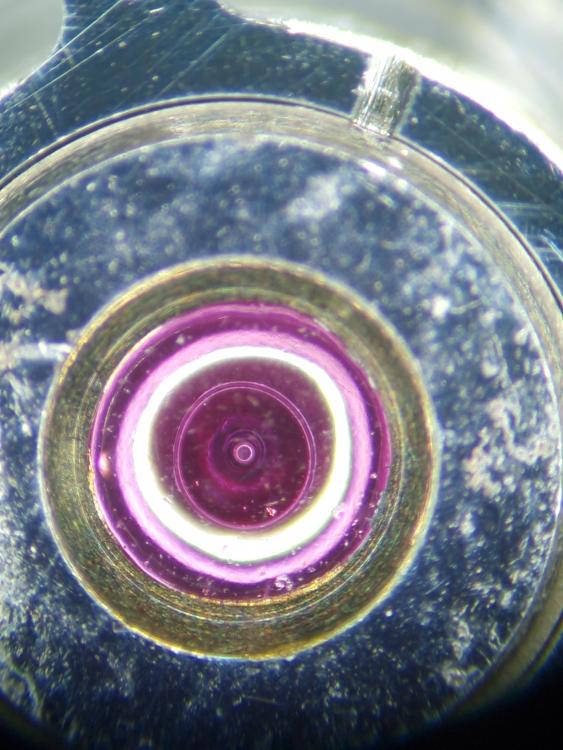

I think it is a tension ring glass and it's broken away from the tension ring. Try your case knife blade between the case and the tension ring or one of your screwdriver blades.1 point

-

1 point

-

1 point

-

ha ha, mine used to look like a Saturday morning Tiswas Phantom Flan Flinger did it.1 point

-

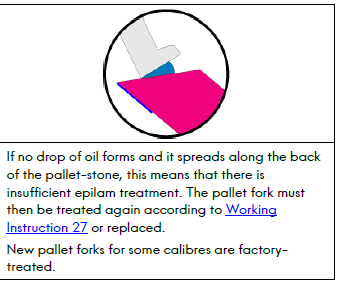

Moebius 9415. Hope that answers your question. Just browsed it through and found a reference to "Working Instructions", but I would need a login for that and I guess that won't happen without being accredited. I'm super curious to know if Omega recommends the "rub of epilame method" on the pallet stones before applying the oil. Can you please check for us @JohnR725?1 point

-

1 point

-

Yes, in my experience, 9415 must be applied very precisely so as not to impair the amplitude. It must be checked at a high magnification. Before realising this I got less than stellar results with 9415 and preferred and got better results with thin non-thixotropic oils.1 point

-

Thanks @CYCLOPS and @RichardHarris123 I've not checked under the dial I'll and give you the update if present1 point

-

Thats what i have scott. Read back a little i posted a few pictures. Basically i put a small quantity of around quarter inch in the bottom of a tin and heated it on a leccy oil burner. It doesn't need much heat, stuck the jewels to the lid with bluetack and the fumes coat the surface pretty quickly although the first i did i left for 5 hours but it does only take 5 mins if that. The coating does seem to come off easily so i am not sure if it actually works, but the stuff is really cheap and worth an experiment or two. I have seen that mix somewhere but vapour coat is supposed to be better.1 point

-

A modern restorer would probably try to inject adhesive as suggested and then weight the repair down. Some damp might have caused the bulge originally. Traditionally the veneer would have been sliced and glue eased under the two flaps then again weighted back down and refinished once it had cured. It doesn't look like just an adhesive issue, more than likely expansion of the veneer, worse case it needs a slice taking out. Try some gentle heat on it first , inject glue and weight, to see where it goes.1 point

-

I have seen several mentions of steric acid, how do you use this, I have only seen it in crystal/powder form?1 point

-

Who'd have thought to look at the supposed compatible calibres ? Frank did1 point

-

With luck even possible to fit your 13 lin. movement at all . Those numbers are from 5 1/4, 8 3/4 and 13‘‘‘ sizes, with very different balance wheels! Frank1 point

-

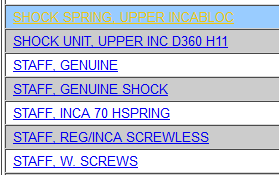

I only looked at the balance staff site which showed four height variations and hub positions possibly down to different length pivots . 3 of them were very similar and a supershock variation that was very different. So maybe this one will fit with a slight adjustment ( I'm not going to mention the words 'shimming the cock' i dont think i can handle that today )1 point

-

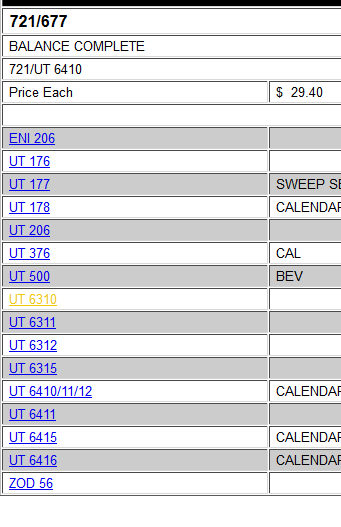

cross referencing parts can be such an interesting so the UT 6310 at least according the parts list is supposed to have some form of shock system for the balance wheel. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=UT_6310 I don't know if the staff heights vary because they're all listed in the same place but there are four separate balance staffs depending upon the type of balance wheel you have. So for instance the balance wheel with screws like yours would use a different staff than one without screws but there's only one listing for one balance complete so Balance complete should fit the watch regardless of which type it is. Basically it indicates that there was an evolution of this watch the older balance wheel with screws than the newer type without.1 point

-

But here there are two variations of the 6310, the staff height will be different There are actually at least four variations of staff heights1 point

-

Hi @Michael20 I think you can get them off eBay. I use the spare ones fron ink cartridge refills, the ends are square cut but will file easy enough. @RichardHarris123 the greaseproof paper trick I believe was to remove marks using a warm not hot iron problem being not melting the veneer glue which is animal based.1 point

-

I was considering just building a watch from scratch, I've heard the nh35 movements have a lot of case and dial choices and apparently they run poorly when you buy them new so a good service is required. But honestly building a watch like that doesn't interest me. I love fixing things. There's nothing more satisfying to me than taking something broken and making it work again. Plus watches are cool and easier to store than a car engine! I only had one engine in the dining room and my wife complained. Hopefully the watches will go unnoticed.1 point

-

For those of you who are looking for a Seitz jewel gauge, I just want to make you aware that there may be a good opportunity right now at Tradera.com (Swedish eBay). The site has significantly fewer visitors than eBay and I have made several fantastic deals there. 1500 SEK corresponds to approx. £110/€128/$137 https://www.tradera.com/item/1922/631487681/seitz-urmakarverktyg-matare Just to make sure, I'm not associated with this listing in any way!1 point

-

That is the reason why. I think it is better then have them all over the place. Regarding unmerged I can't see the sense.1 point

-

I used to be quite active on The Lotus Forum when I owned my Esprit. I was there for so long, Bibs asked me to be a moderator. I'm not sure how long I did that for, but I think I turned into the second longest serving moderator. When I 'handed back my keys', Bibs made me a Full Forum Member. Normally this is a paid membership. My reward I suppose for helping out for many years. Bibs (forum owner) is quite active on there and if I am not wrong, don't quote me in other words, I think he once said that the money from memberships didn't cover the running cost. He adds money himself to keep it going. Does Mark have any sort of subscription scheme on here? I'll admit that I never paid to be a member on TLF. I should have. I never did. I agree that it would be a good idea that there is some sort of contingency plan for this forum. I intend on becoming more active on here. Life has just been getting in the way recently. I enrolled on Mark's watch course and was keenly doing that, but even that has had to take a back seat for a while. I am looking forward to getting back into that and also starting to do work on the clocks that I have been amassing. To do that successfully, I see myself needing to lean on the other members here. If for whatever reason this forum was to close, I think a great many of us would struggle.1 point

-

Knocked out another 404 last night...when you are in the zone! This watch was a non-runner which I picked up as part of a lot of 8 watches, so works out to be $3.12 per watch. Before: And the finished watch, new crown and stem and the crystal was cracked so was replaced. I also replaced the mainspring as the original was the old steel type spiral and very 'set' - all else is original: The Movement was a AS 1686, but in reading around a little the ACCRO watch company were sued for their use of the five point crown on their Jacques Pere range as it resembled Rolex, see below: ACCRO then reverted to just ACCRO on their watches - I have done some sniffing around the internet and haven't seen another example of ACCRO and the crown together on a dial so maybe I have something unusual, or maybe I was looking in the wrong places .1 point

-

1 point

-

Just a quick update on my T17. I just finished the service and, boy, was this nerve-wrecking.... I bent the hairspring a few times. Stupid accidents. Once it was beyond repair and I had to get a donor movement. The replacement hairspring turned out to be a few millimeters shorter and therefore the watch was running 6min too fast even when the regulator was set to the slowest position. So I needed to get timing washers (see another post here: https://www.watchrepairtalk.com/topic/25505-30t2-adjustment-of-timing-washers/?do=findComment&comment=248100). After all, I'm now, getting a 310° amplitude (fully wound, dial up, lift angle 54°). About 250 in vertical positions. Quite a drop, but apparently not too abnormal for a 90-year-old watch with a slow beat rate (18000bph) and rather heavy balance wheel. After 24h I still get 280 (horizontal) and 220 (vertical). And now the highlight: 66h of power reserve! You may remember that I posted that I used a slightly weaker, but also slightly longer mainspring than prescribed. See my comments above. I used GR 3937 (instead of GR 3632). So I recommend this mainspring and ticker oils (9020 on escape wheel and HP1300 on the rest of the train). Some random pictures..1 point

-

1 point

-

That is true H but 9415 is under the classification of a grease. Theres a lot of oils that have a high viscosity than greases which make little sense to me. But using them both the 9415 seems much thicker than 9010. Very odd, a lube discussion is on the horizon. Might the specified viscosity rating be measured before a thickening agent is added ? Or that rating is on impact ?0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)