Leaderboard

Popular Content

Showing content with the highest reputation on 05/04/24 in all areas

-

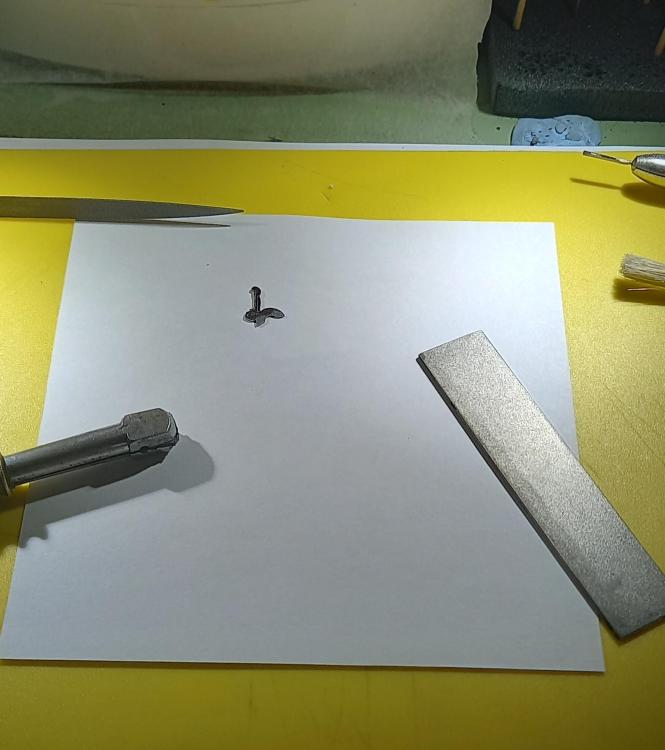

Tah-dah. A mini blow torch to harden it, then quench it and just a lighter held under a brass mainspring barrel that the part sits in to temper, Its important to wipe off any grease from fingerprints with ipa, you might be able to see i missed a bit at the top of the arm. Its a very satisfying process. I now just need to deal with the more difficult repairs, anybody any good at replacing rubbed in jewels ?4 points

-

4 points

-

Finally figured out why my hands are so god damn steady. My mum 87 years old , 4 weeks after her stroke and has a macular hole in both eyes, she wiped the floor with me and my lad at a kids stacking chairs toy game. Here she in rehab placing the last chair into position, bloody ' Supergreatgreatgran' i hope I'm half as fit at her age3 points

-

I'm confused, I can see the click in the usual position next to the ratchet wheel. Surely the click spring is there?2 points

-

That looks like normal behavior to me. That movement only winds in one direction, not both, so when the rotor turns anti-clockwise it winds the main spring and so is fighting against the mainspring tension. As a result it will turn under its own weight but it won't free spin. When it turns clockwise though it has no resistance and so can spin freely.2 points

-

Removed a couple of mm of grout from every tile joint on the floor and regrouted it this morning. Final clean up tomorrow and then I am going to start moving things in from where I have them in the garage. Just have to work out the layout of the room once I start moving things in. Garage just didn't work out. So if you are setting something up, don't consider your garage. Not really a viable option.2 points

-

2 points

-

The part is roughed out with a speed run diamond disk. Finish both the ends first that way the spring doesn't get any stress and then go ahead and bring the jumper down to size last. Slowly cutting my time down. This one will be 3 hours when its finished, two hours is very doable with some practice from start to finish inc. a little polishing up on the main contact points.2 points

-

New Great wheel arrived, rebuilt the watch and managed not to break anything. Had a minor issue with a screw I'd found to use to secure the date corrector wheel - it was fouling the escape wheel. Changed for a shorter one and it seems all good. Running pretty well I think - not yet adjusted it, will let it run for 24 hours first.1 point

-

Either of those ideas might work. Did you try putting a thin layer of rodico on the cocktail and then push the screw through it. Afterwards, soak in one dip1 point

-

I would use some binding wire around the part before heating it. It protects the steel from being burned. I know that sounds strange, as you're going to heat it with a blowtorch, but if a part is thin and delicate the steel can literally burn away before your eyes, which isn't funny if you've put hours into the job. I bought some tools steel from Cousins a few years ago which turned out not to be tool steel, because it couldn't be hardened or tempered. I wasn't impressed, as I had spent two hours making the part for it to be useless.1 point

-

Definitely worthwhile, if you are working with old watches - just be sure it's an actual Geiger counter, not one of the vast range of scam/fake "Radiation detectors" on ebay & amazon etc. that detect RF or static electricity... In the mean time, I'd put the dial and hands in zip bags & wipe down the work area with a damp cloth to pick up any dust, then discard the cloth. The emitted radiation from radium lume is not normally harmful - but inhaling or ingesting a single particle of the material can cause serious long term harm, so do take care with it.1 point

-

Sometimes you can see a burn mark on the dial from hands that have stayed in one place for decades, which is a clincher, but I don't really see that here. An inexpensive detector could let you know for sure, but considering the dial/hand style and the darkened condition of the dots on the dial in the absence of any clear water damage, I'd give 90% likelihood that there is radium there. Tritium is usually marked out on the dial, and although it moves to yellow and tan as it ages, it doesn't get as "toasty" as those dial spots based on what I've seen.1 point

-

Thanks, that's useful to know. Will save some expense. "school in the 1900s" ! I didn't know you were so ancient @nickelsilver1 point

-

Feels about right, just choose the right steel , and you can play around with the shape and the arm thickness to suit how stiff it needs to be. Thanks John, Its spring steel John Cs100, i haven't h&t it yet but i will be doing. Marking out is quite straightforward, the black helps to see it. What i did realise is to leave plenty of meat at the end of the arm, you can take material off but you cant put it back on again. I would like to have a go at from scratch without the minute bridge for a template1 point

-

The Rodico trick is fiddly with such a small screw, it's just to get the thread started. Using a balance screw holder is easier, but it's still fiddly to get the screw in the holder Yes, being a bit rough, they do mark the balance screws a bit. So, another thing to add to the tool "wish list". Thanks for reminding me1 point

-

As Jon said balance screw holder makes it a pleasure to deal with these guys, and the cheap one Mike linked should work fine- even if they're a bit rough they should be ok on the hardened steel stud screw (balance screws are much softer thus the expensive multi-size sets).1 point

-

1 point

-

Welcome, you have a great start, AWCI is an excellent organization, there is also a lot of info/help here too...1 point

-

Is the steel you're using tool steel? If it is, have you thought about hardening and tempering it to blue so it would be springy? Nice job! I've got my second year students making a setting lever from scratch in a couple of weeks time. All they'll have is a compass/dividers to map out the screw holes and the indentation where the setting lever peg clicks for winding to hand-setting. Very similar to how you have done it1 point

-

I use these https://adjustingvintagewatches.com/tools-for-adding-weight/ I picked mine up from a watch fair years ago. Great for this type of work and for removing poise screws to fit timing washers. Cousins do a set, which aren't cheap, but I find that more than one size is definitely needed https://www.cousinsuk.com/product/balance-screw-holders-set Otherwise, if you have a really small pin vice that'll work.1 point

-

You're right Rich on the op's first picture there does appear to be a spring popping out under the ratchet wheel, wonder why its not on the dial side ?1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

I'd suggest using "hide glue" (eg. Titebond) rather than PVA. That's what is used in musical instruments, specifically as it can be re-worked when heated, rather than being permanent. Also, while PVA wood glues are incredibly strong on clean, bare wood - they are next to useless if there is any old residue sealing the surface of the wood, it just does not bond.1 point

-

1 point

-

Thats the same artical i read Mark, suggesting that 2 models were registered in 1918 and marked as Rebberg Dèposè on the movementa these two are usually known as the Aegler Rebberg. A little misleading but yes seems like there were more Rebberg calibers. https://www.vintagewatchstraps.com/aegler.php#:~:text=The word Rebberg%2C the German,the Swiss register of trademarks.1 point

-

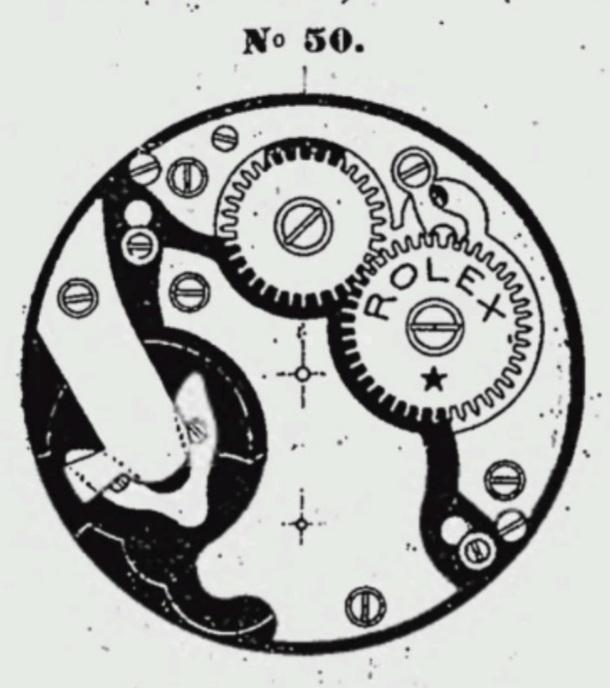

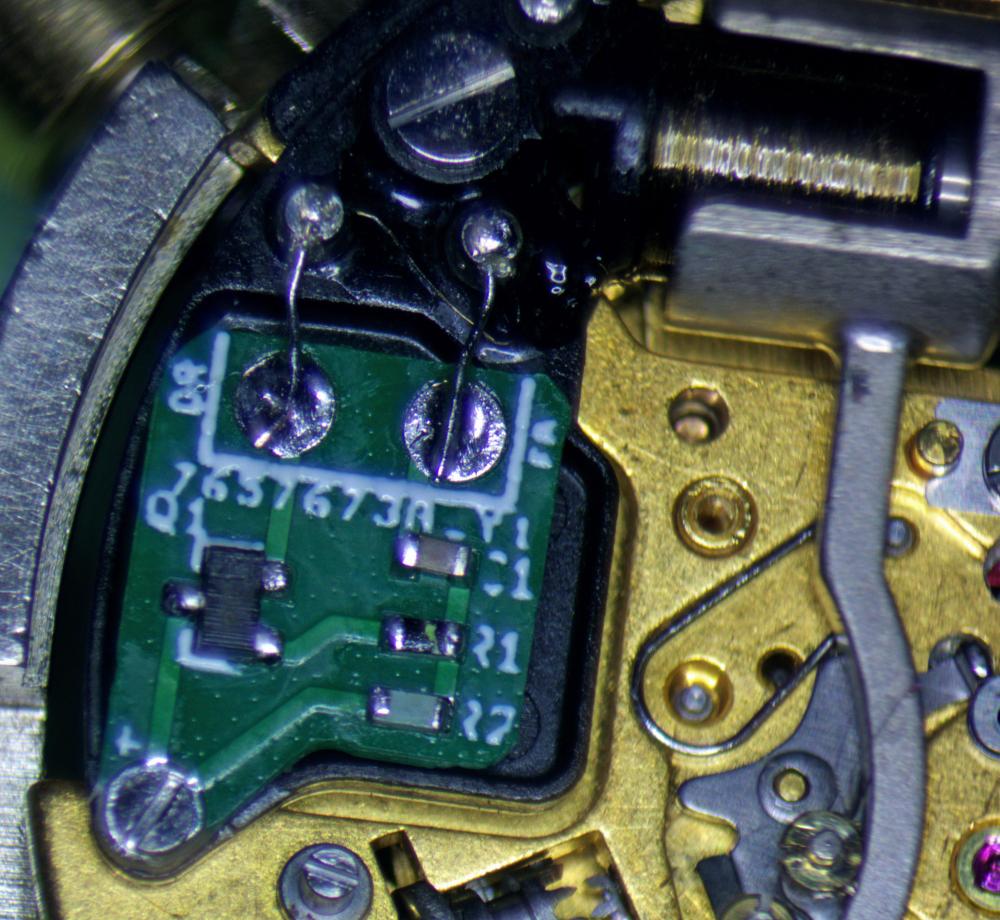

I wish that was the case. The Aegler movements used in the early days by Wilsdorf & Davis (for brands like Rolex and Rolco) came in several sizes and without designated calibre numbers that survive. They become a bit easier to identify during the 1920s. Below is an Aegler-Rebberg, 25.74mm in diameter. It’s from a woman’s Rolex wristwatch. Stamped Rebberg and 500 on the dial plate (but it isn’t a Rebberg 500, it’s the wrong size). I’d be interested if anyone can identify the movement. It is based off the Aegler Nr.1, circa 1903, but they based many many calibres of different sizes on it. The closest I have to a positive ID is the ‘Rolex Nr.50’ circa 1917, but no dial side images or movement sizes are available in the references. There are identical looking movements in many sizes. The 25.74mm of this movement is a particularly strange size for the era, it equates to 11.41 lignes. Best Regards, Mark1 point

-

It looks like this movement comes with a number of different shock settings. Emmywatch shows that it comes in versions with no shock settings, 'Incabloc', 'shock resist', and 'Supershock'. Perhaps the different settings position the impulse jewel/roller table in a non-ideal position relative to the pallet fork/guard pin. Are you able to check under high magnification if the pallet fork and roller table are able to operate without any interference? Just for fun I took a look and I have one FHF 70 in my collection, a West End Secundus with a non-shock protected FHF70. I had a note with the watch that said, "Movement is stamped 'FHF 70', but the FHF70 looks to have sub-seconds instead of center seconds movement (??)" but that a google search turned up both types for this movement. EDIT: I just took a look in my parts drawer and I have a few of these movements, both in center seconds and sweep seconds, but they all are non-shock protected.1 point

-

1 point

-

I should have done this a long time ago. I would like to say a big thank you to all my followers new and old. If I can help in any way just message me and I will do my very best for you.1 point

-

As I kid, I'd watch Godzilla stomping over buildings and cars and I'd think to myself: Tokyo is a really dangerous place to live... . Cool watch!!1 point

-

[SBGA405] Grand Seiko “Godzilla” Spring DriveI always enjoy coming back at the end of the week to my first Spring Drive watch which is a combined automatic mechanical watch and a high quality quartz — a Spring Drive.Impressive accuracy (10 seconds per month) and wears remarkably comfortable at 44.5 mm in diameter and 95 gm.Love the power reserve indicator, and the colour of the dial amd the watch band.One of my “perfect” watches!!1 point

-

1 point

-

This is the 3th attempt for this specific pinion. Othervice I have made many for pocket watches, but they are much bigger. This is really small. The pictures does'n t show things correctly, there are blinks that my phone camera can't manage well1 point

-

1 point

-

1 point

-

I've never done it, however just today I was reading about it! P.24 - P.38 of this explains the truing procedure for damaged balance wheels. I have no idea if this is still the accepted way of doing it, the learning material is rather old . Hopefully one of the veterans will be along to give you an easier solution. Good luck Joseph Bulova School of Watch Making.pdf1 point

-

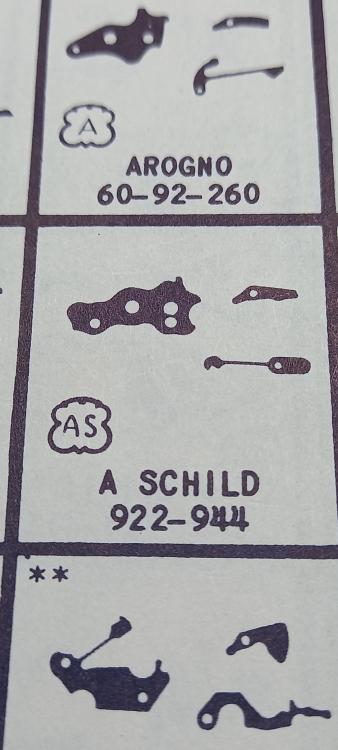

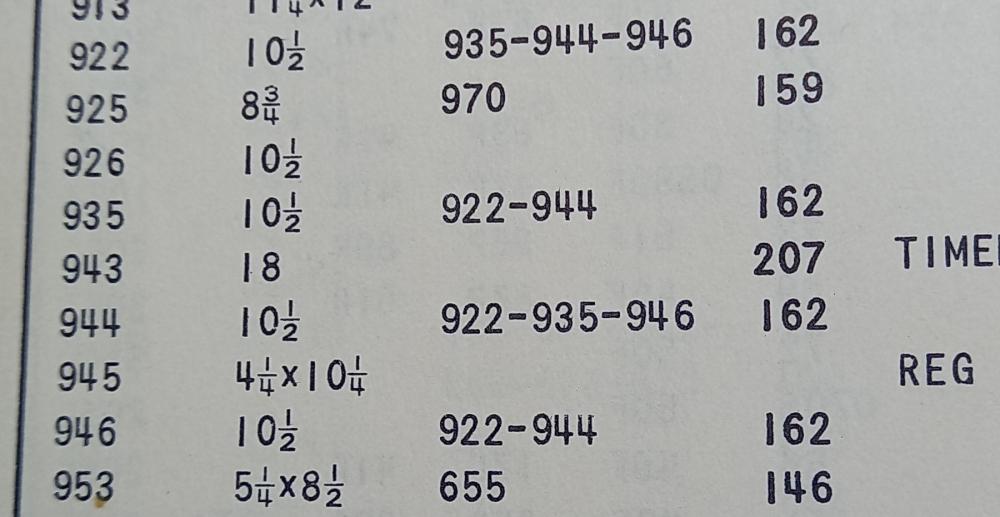

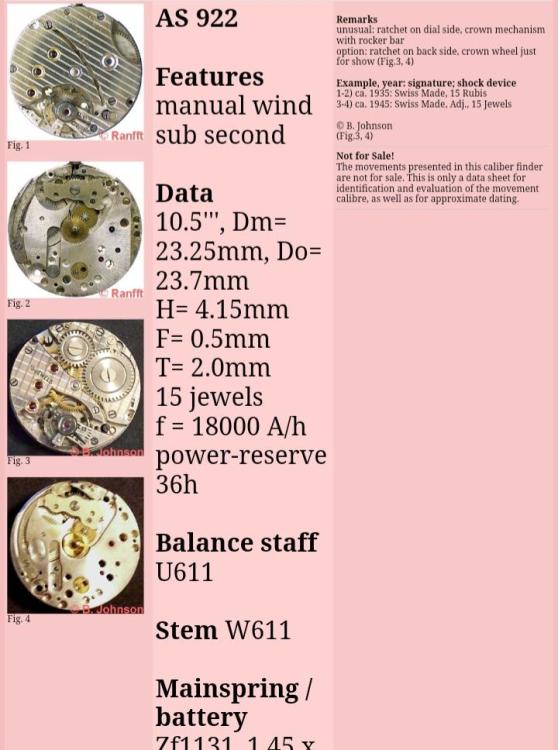

I think that a 814/825 stem would work, there are a lot of compatible parts between these.1 point

-

1 point

-

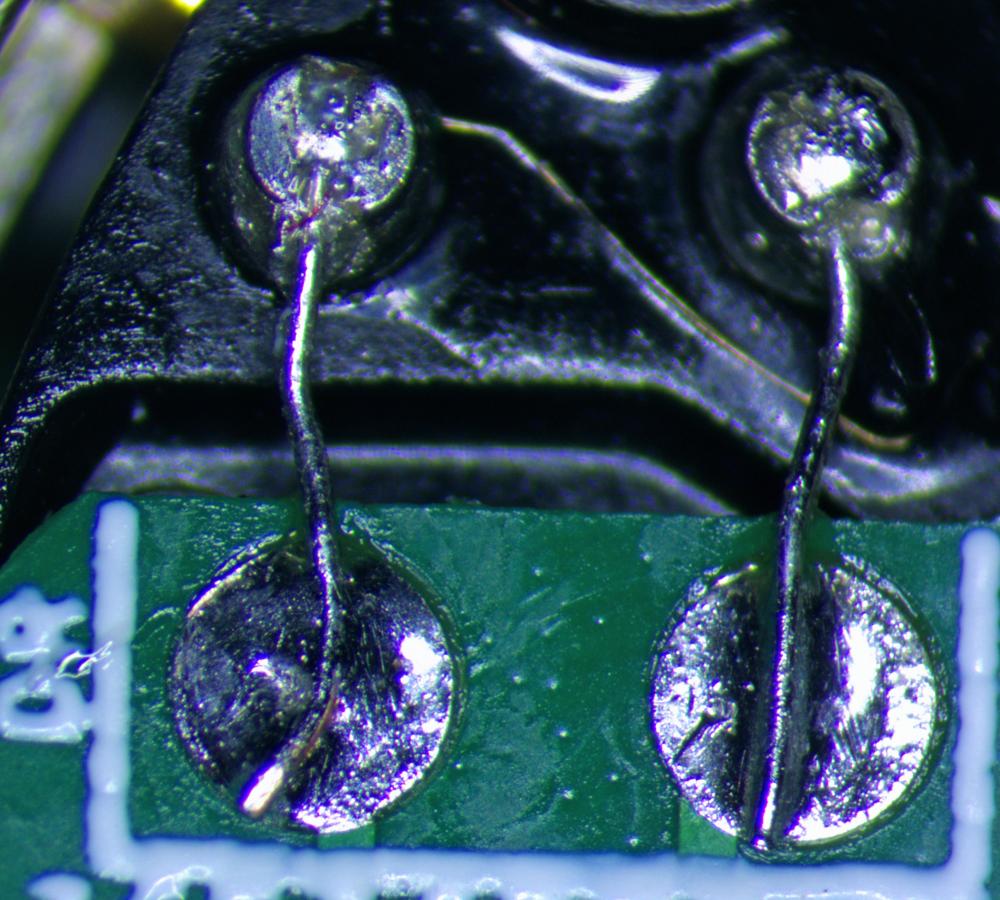

There are some parts on Ebay for the seiko 6020A, it may just be a waiting game for someone to strip one down, NOS will be more scarce . K would strip your movement down to the module then start looking at other seiko movement to see if that coil is used, then seek out a seiko part dealer. Also Retrowatches youtube owner Mike may give you some advice try him on his site . He also hangs around amateur watchmaking groups.1 point

-

Probably easier to get a complete new movement - but CousinsUK list it as discontinued. Maybe someone on here knows a substitute movement ?1 point

-

1 point

-

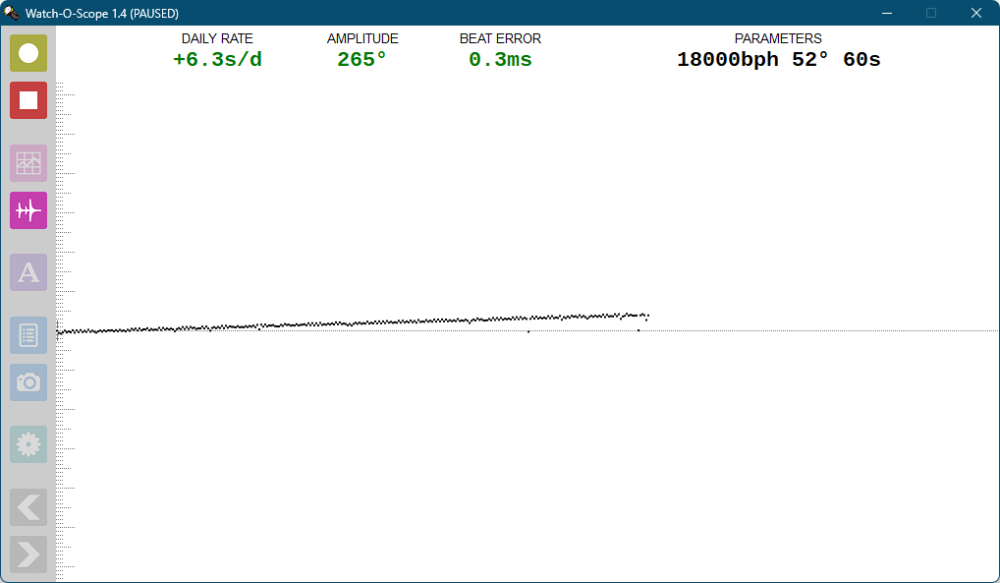

Hello everybody, sorry for the late reply. Thank you all so much for your help and your tips. I got lucky and found a replacement wheel bridge for cheap which actually ended up being in decent condition. I decided not to do anything about the mainspring barrel pivot since I didn't have the right tools and the barrel didn't have much endshake anyhow. I am happy to report that the watch now runs great, I have regulated it to about +-10/s day which is fine by my standards. The timegrapher result looks decent as well, although beat error is around 0.6ms which could be better I suppose. Amplitude reaches over 230 quite consistently which I'm happy with also. My lighter fluid has also been replaced by balance spring cleaning solution and now the springs don't stick to themselves anymore - who would have thought. I'm super happy with this watch, it might not be worth a whole lot but it's awesome that I could restore it and it makes me wear it with pride. To me it's a genuinely good lucking watch, it'll be my daily driver for a while. Thanks again to everybody for their input! I couldn't have done the repair without your help. Here are some images for those interested, the bracelet isn't original but I don't really mind:1 point

-

Something rubbing with the movement of the hands, dial center hole, hands on glass. Motion works rubbing , hour or minute wheel, calander in the process of changing over ?1 point

.thumb.jpg.6f205289b9d3240d01dc76aceacb7b37.jpg)