Leaderboard

Popular Content

Showing content with the highest reputation on 05/20/24 in all areas

-

I put this quick vid together today when I was replacing the tropic crystal on this Rolex Oyster Perpetual. It wasn't the greatest filming, but hey!4 points

-

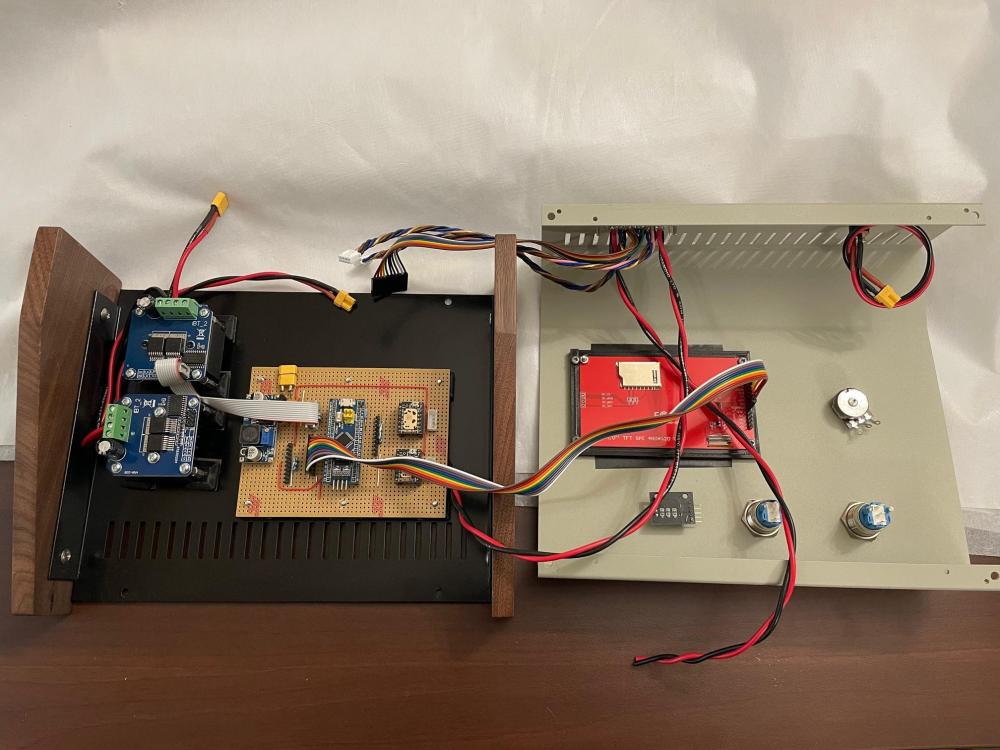

The cleaner smells of ammonia, but it's not too bad; just keep it covered as far as practical. I use an ultrasonic machine on a kitchen worktop. The rinse does not smell strongly, it's vaguely like paraffin. I did check the safety data sheets before buying it & it's said to be safe in normal use. My dedicated watch cleaning machine is still a work-in-progress; four position linear, based on 1L kilner jars for station spacing, to have a heated dryer in position 4. It uses standard, readily available parts as far as possible to make it easy to reproduce, plus 3D printed bits for the custom parts. (The horizontal drive motor is out at the moment while working on the stepper drive software)4 points

-

3 points

-

I don't wear or own a watch. I have 12 clocks in my home but I only wind one per week, each week it is a different one. I'm funny that way.3 points

-

My Omega Seamaster aqua terra. It's just me, very understated but classy ( not that I'm classy). I don't like dive watches, the bezel puts me off or any kind of bling. I prefer indices to numbers. I don't have any other luxuries, not into clothes, seldom go for expensive meals etc. So it's my little treat to myself. Not my watch but exactly the same, just got home and taken it off.3 points

-

3 points

-

3 points

-

The setting could have been silver plated? I doubt it would be solid silver. I initially tried various liquids for cleaning, with pretty mediocre results. Eventually I forked out for the gallon-size containers or L&R #111 cleaner and #3 rinse. That stuff, cold, at three to six minutes a stage in the ultrasonic, works superbly; the results are immaculate even on things that are disgustingly bad when they go in.3 points

-

One I have and it's a French Strike on a bell with Garnish worth around £1,000. I'll take a photo of it tomorrow so you can see it.2 points

-

When you are having fun restoring false economy exits via a window. Your time and money dont always matter Col , what does matter is that you breathed new life into something that was dead and destined for a scrap heap. That has to feel good doesn't it ? Some of my favourite watches to wear are my first attempts at repair. With a face that only its repairer can love , Rolexes pah !!! give me a Smiths pin pallet any day of the week.2 points

-

2 points

-

Speaking of 404 reboot.... I have another category of watches... Those that I wished I had not gone above £4.04 when I bid for them!!! Someone probably should have also told me to stop before I put a new stem, crown, crystal, escape wheel and then adjusted the end shake on the escape wheel. This was all on watch that had a EB 8800 pin lever movement in a worn gold plated case with a snap on case back (basically everything I try to avoid!).2 points

-

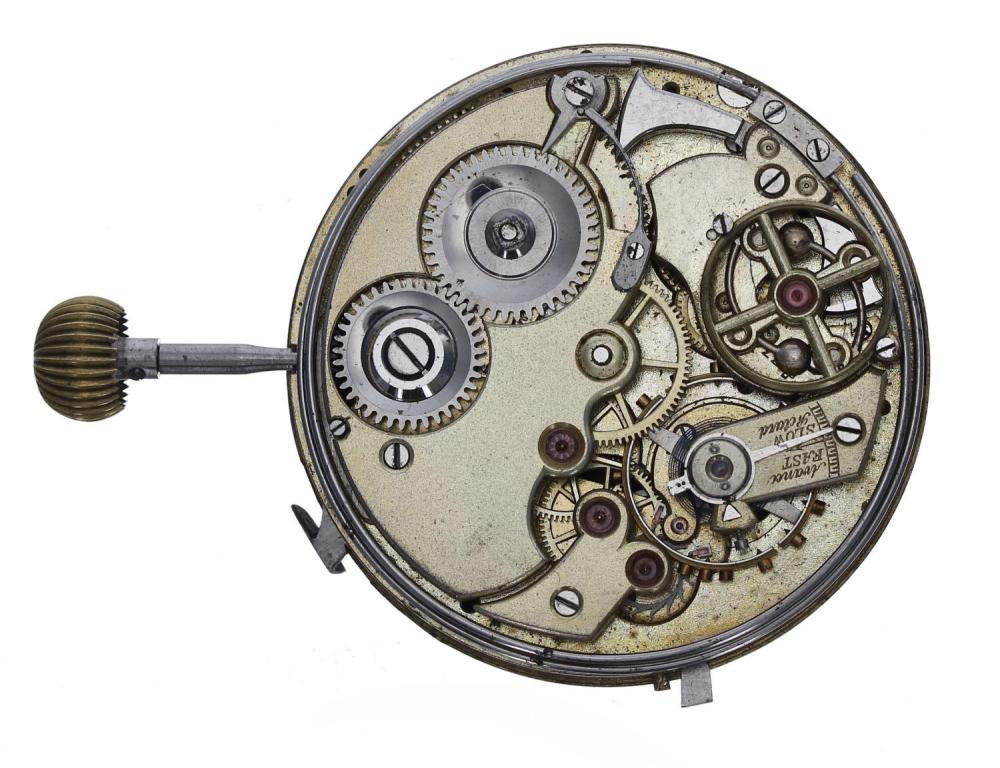

The problem is that this movements were not produced with the modern level of standartization, there for parts from one didn't fit well to another, even if they may look the same. May be it doesn't concern the winding stems, but yet there are not spare parts for such movements in supply companies, not even clear calibre identification possible. And where calibre identification is possible, there are no Ronda numbers for the balance staff or the winding stem for this calibers in the data bases.2 points

-

Despite having to change up your magnification and get your head into the super micro mech zone, I admit I'm not adverse to buying women's watches. You can finish up working on some good high end movements for a fraction of the price of men's. They also finish off that little black dress number and heels look on Saturday night outs. I would laugh but i have had some very odd Saturday nights out , ok go on then I'll laugh, i just made that up....ahem...2 points

-

These are some from a couple of job lot ebay batches totalling 40+ watches I got a few weeks ago, ~£2 or less each. I'd only looked at a couple of specifically interested ones so far, as I already had others of interest to look at I've just gone through some of the smallest ladies ones. I was expecting them to be mostly cheap quartz, but only one of them was - the others are all look like good quality mechanical ones! There are also a good selection of other types, including a couple of nice looking old Casios - and some blingy things..2 points

-

To be honest, they're not a good movement to have in a chronograph for several reasons. The first is the chronograph mechanism is a 'bolt on' module; If you look at the side of the watch case the crown won't be in line with the pushers, therefore only the branded company would have the ability to swap out the module because they aren't designed to be serviced and definitely not by an independent watchmaker. Secondly, the ETA 2892 A2 is a great movement, but when the chrono module is used with it it becomes pants, in my opinion/experience. So, going back to your watch. The problem isn't with the base movement, which is the 2892A2, as there would never be that amount of backlash/flutter in the gear train of that particular movement, it is with the chrono bolt on module that the problem lies and when the chrono sweep second hand is engaged the flutter of the second hand is remedied by the stability of the chronograph mechanism negating that flutter. Everything in the chronograph mechanism of that movement is powered by a wheel in the centre where the cannon pinion/driving wheel would normally be. I think it is a crappy design deliberately engineered to be disposable due to the time taken to service the module. Give me a 7750 any day!2 points

-

I state Yorkshire because nobody has any idea where Hull is. Welcome Greg, i tend to only answer my wife when she says something watch realated to me, like " will you come off that bloody forum " . Strangely enough she is also a member of our group, i think that is only to make sure I'm behaving .2 points

-

I remember dipping cherry steel into some kind of carbon powder at school to case harden it. And watched a video about annealing steel a few months ago when making my setting lever. The guy used a magnet to determine the steel's core temperature . Get a blow torch on them or you could really flip and use an oxy torch and melt those suckers.2 points

-

No, only about 1000f. But i took pleasure in roasting these annoyingly magnetized parts2 points

-

Funnily enough, when heating iron or what watchmakers use for making tools which is 'tool steel', or what is also known as 'high carbon steel', as it has a carbon content between about 0.06 to 1.6% carbon content, (but don't quote me on those percentages!) and can be hardened and tempered, when the steel reaches a cherry red, around about 1450 to 1500 degrees Fahrenheit it becomes non-magnetic, so if you placed a magnetic close to or on it there would be no effect at all. I believe it is the steel/iron turning to austenite from martensite, if I remember what I read in an old metallurgy book I picked up in a car boot sale; It's a bit of an esoteric read! In years gone by, cattle bone was used to encase the small piece of steel to be hardened and tempered, so the carbon from the bone was soaked up by the steel when heated for several hours at a particular temperature, in effect 'case-hardening' the steel. It's amazing what we came up with many years ago. We humans are very inventive, yet very destructive.2 points

-

2 points

-

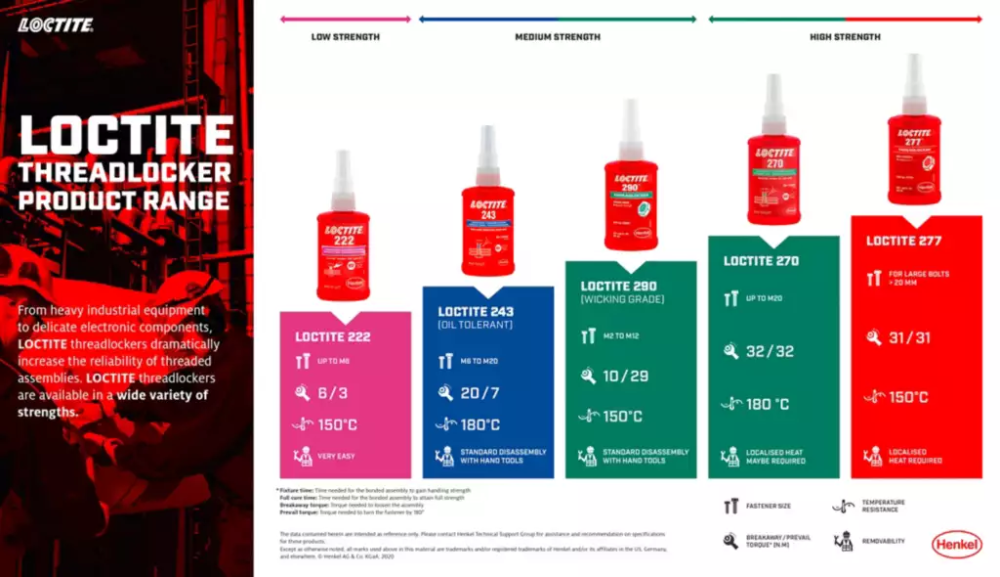

I think they all have their pros and cons, the one I suggested is a threadlock loctite product (Loctite is now owned by Henkel), In general I use the current one that is recommended on their Loctite page (link here) I use blue (243) for the actual crown the (stick is actually 248 which is the stick version of 243), like I said it is very convenient for using on stems. Blue holds the crown for everyday use, but can be removed if you need to with a little heat. I use the red 277 for things like stem extensions where I have no intention of ever removing it. The purple I don't use (but I have seen some youtubers use it) as I think the blue is removable so why take the risk on a weaker product. This is interesting, and a useful bit of information to know2 points

-

attached is the tech /parts sheet. . Can one ask how come it’s full of water. After being told that the waterproofing was not guaranteed. Problem being electronics don’t mix especially withe the power source being attached. You may be lucky but I should look out for a replacement movement or working donor to rob the movement from. C720.pdf2 points

-

Hello, I am a software engineer and all day spent in front of my computer makes me want to do something more manual as a hobby. I like the mix of intricacies and basic technology of mechanical watches, the fact that such marvel could be built manually hundred of years ago fascinates me. So I decided to combine the two and learn "watchmaking" (between quote as I don't expect to ever be able to make a watch). My first goal is to be able to service a mechanical watch. My current status is that I am pretty good at breaking small parts in watch movements1 point

-

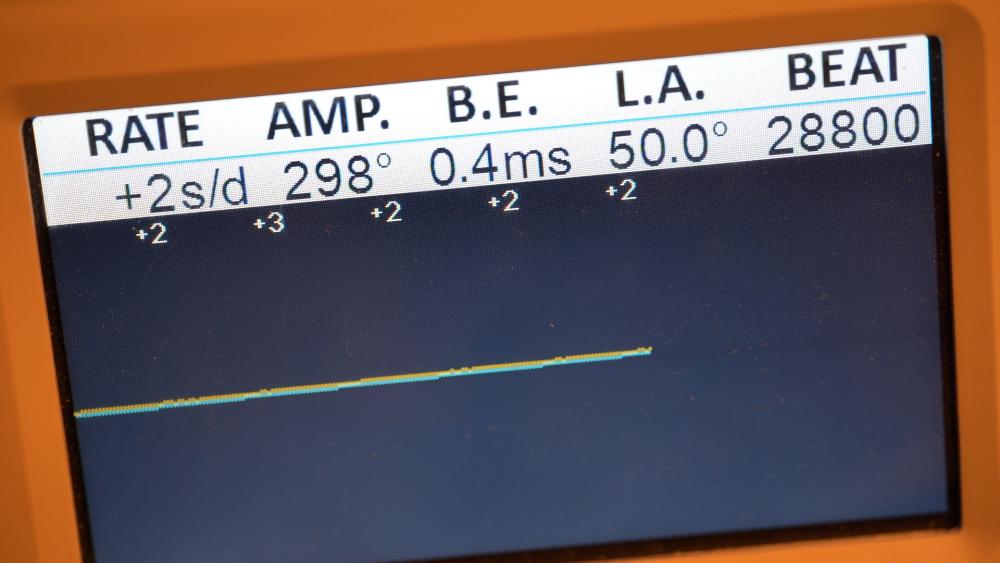

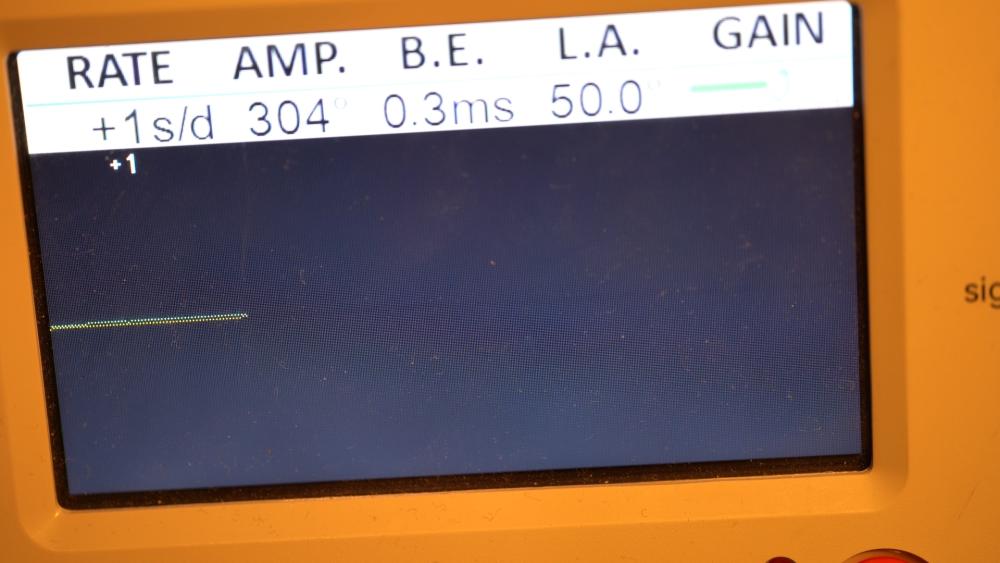

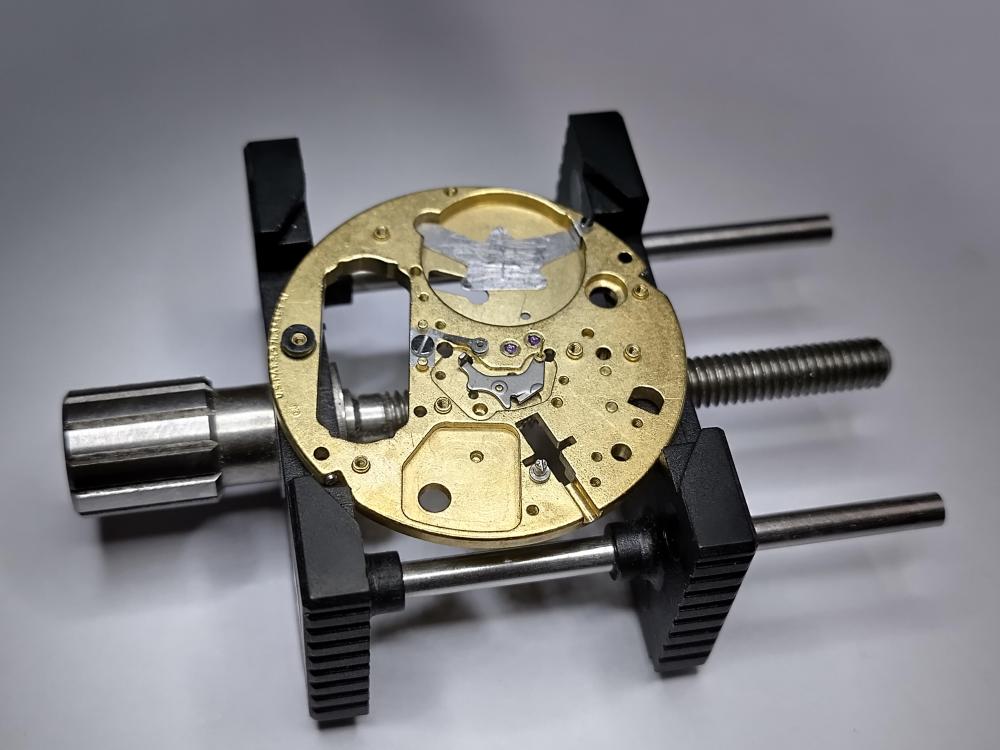

Hello Watchbangers! Welcome back to my usual watch repair report! It feels like an eternity since I’ve also had a bunch of other side projects and the upload schedule has changed but its good being able to present another solid watch! Now todays watch was, as always, bought over the local German eBay. It caught my eye because it was a swatch watch, but not any crappy swatch! It was a swatch with a mechanical movement! Till then I always thought that swatch only produced those small junky mechanical watches but low and behold! A swatch with a solid movement! And for the solid price of 50 Euros, with included box, papers (definitely super important ) and shipping I just had to snag it. Now before we jump into the whole process, here is a link to the full 4k commented video version on YouTube for the lazy readers out there: Now let’s go! After receiving the watch, this was the starting state of the watch: As you can see the outer appearance was still very good! The acrylic case has some scratches that would be easy to polish out and through the back, a clean looking movement was to be seen. The only thing which stood out was that the watch did not run after being wound. The seconds hand ticked a bit but stopped after a quarter of a minute. I was not sure what the issue was there, but I assumed that a good old service would do the trick! Disassembly: We start by prying off the see through case back. We unlock the watch spacer ring and movement in a counterclockwise direction from the case and lift them both out. We remove the hands. As you can see their condition is pretty good and the lume is pristine! After that we can just lift the minimalistic “chapter” dial from the watch face as well! Now we can carefully unlick the movement spacer ring and separate the two. Careful not to use too much force and snap the poor piece of plastic in half. After we have achieved in isolating the movement, we can strap it into our trusty holder. Unscrew the nicely blued rotor screw and lift of the smoothly signed rotor. I must say that the font reminds me of Comic Sans haha. Then unscrew the two screws for the automatic module. Flip it over to disassemble the whole automatic gear train. Once that is done, we can come back to the pretty movement body. A closer look reveals the stamped ETA 2842 marking. The numbers next to the caliber are probably the quality grade I assume. Unscrew the balance bridge and lift out the whole balance wheel carefully. I was super surprised at how tight the balance wheel and spring was sticking the bridge when lifting out. Usually, the wheel just droops into infinity xD The movement was already empty on mechanical power so I took out the pallet fork system here. Don’t forget the unwind the watch when doing this! Moving on we can take out the winding wheel above the mainspring and the click spring for the winding. You can see that these is a good amount of lubrication residue under the click wheel! Probably some Molycote DX I would say. Then we can unscrew the barrel bridge and take that away. Disassembling the train wheel bridge, we can see the whole power transmission journey laid out in front of us. I take out the whole gear train including the complete mainspring barrel to finish taking apart the whole back side of the movement. We can now flip the movement around. On the front side we can take of the minute wheel and hour wheel which is the canon pinion and the transmission wheel to the setting system. Now we can take away the small transmission wheel which engages and disengages when the setting system is used. Moving on to unscrewing and removing the smooth golden system cover. I was super careful here not to slip and scratch the cover since everything would be seen when looking down at the dial-less watch. Lastly, we can just simply take away the three parts of the setting system. Oh and the two part-clutch fell out while turning the movement so keep an eye on those too! With this last step, the disassembly of this Swatch ETA 2842 has been completed. Cleaning Process So this cleaning process has also been done the manual way. However! I did buy a cleaning machine now which I’m setting up and testing slowly. It should be in use in a few more weeks and then I can introduce it to you all! And clean my watches with it of course. Now the usual way of cleaning the watch parts is using lighter fluid and isopropanol alcohol for the rinse. And that’s exactly what I did! Now usually I also obviously service the mainspring and lubricate the balance jewels but this time I used the practical development of globalization and bought myself replacements for the complete barrel and balance of AliExpress to save some time and build into the Watch. Lubrication Here is a list of the used lubrication for the watch and their used areas. Moebius 9010 – Oil for jewel bearings with high rotation parts Moebius HP 1300 – Oil for slower moving parts and bearing. Molycote DX – Grease for high friction points on lever, wheels and contact points. Moebius 9415 – Grease for pallet jewels and escapement Crystal Polishing As mentioned at the beginning, the see through plastic case and case back had a number of tiny scratches from the years of use so I just polished them out with a rotary tool and some Polywatch. You can see a video of the method on my channel I think, but here was the result: Reassembly For the reassembly, we can just reverse the disassembly steps which I wrote down. I must however share a super smooth picture of the reassembled aftermarket balance. It just looks so good! Timegrapher Test And after everything was recased again I slapped the watch on to the timegrapher to see how well my work was done. Here are the the results without regulation: Looks like the aftermarket balance and mainspring barrel really do work out nicely! I did however regulate the watch a little to this: Just lowered the rate and beat error a little and bumped the amplitude up a few degrees aswell Final Results: I am very happy with the final results! The service went super smooth and I am glad that i tried out aftermarket parts for the first time. Now we just have to see how long these will actually last. Otherwise it was exciting working on my first swiss calibre! They definetly have a different style of design and function. A sort of different personality of a watch I would say Anyways I hope you all enjoyed going through the walkthrough and hope that this will help anyone looking for some sort of guide! If there are questions or comments, please comment! And critism is also always welcome! Till next time !1 point

-

1 point

-

1 point

-

Only joking mate, well mostly . 3 years ago i wanted one and didn't know any different. Funny how a little knowledge can completely change your view of things. Do you have that special one though, that means more to you than all of the others ? Personal items can mean so much more than what they actually are or what they are worth. Those aspects dont even enter into the equation if its a gift or an inherited item.1 point

-

One of the problems when looking for spare parts of course is identifying the watch you're looking for spare parts for. But there's the other problem what makes you think that whoever made this watch actually had spare parts available for the watchmaker?1 point

-

1 point

-

1 point

-

Yeah... I'd say it's Leeds anyway. Used to hang around with a few friends there back in the day when single and young, going in The White Swan regularly before it became a restaurant. Bramley, as in my username.1 point

-

Yeah not much going on in the town , Scarborough is a bit better,but the missus and me love York. Good antique shops there, The antiques center on stonegate has a good selection of vintage watches, top price though.1 point

-

York is nice, Scarborough Bridlington . Brid has a good carboot every thursday till 12 o'clock1 point

-

After that the staking blocks would have lost their hardness and would only be good for paperweights.1 point

-

With something like this I expect you will have to make one yourself or have it made for you.1 point

-

1 point

-

Looks like someone forced in a screw that was bigger than the hole. You would probably need to drill it out with a tungsten carbide rod sharpened at the tip to look like a spade drill. I'll see if I can find a video on how to make one. Start with a 0.5mm rod, then work your way up in 0.1mm increments until the walls of the hole weaken the screw enough to break it up. This is a very time consuming, slow process. You'll need to centre the hole properly and not deviate. WD40 helps. The other option is to abandon the hole and use a dial dot. As much as I hate dial dots, this might be the safest option for a beginner. Ok, found it.1 point

-

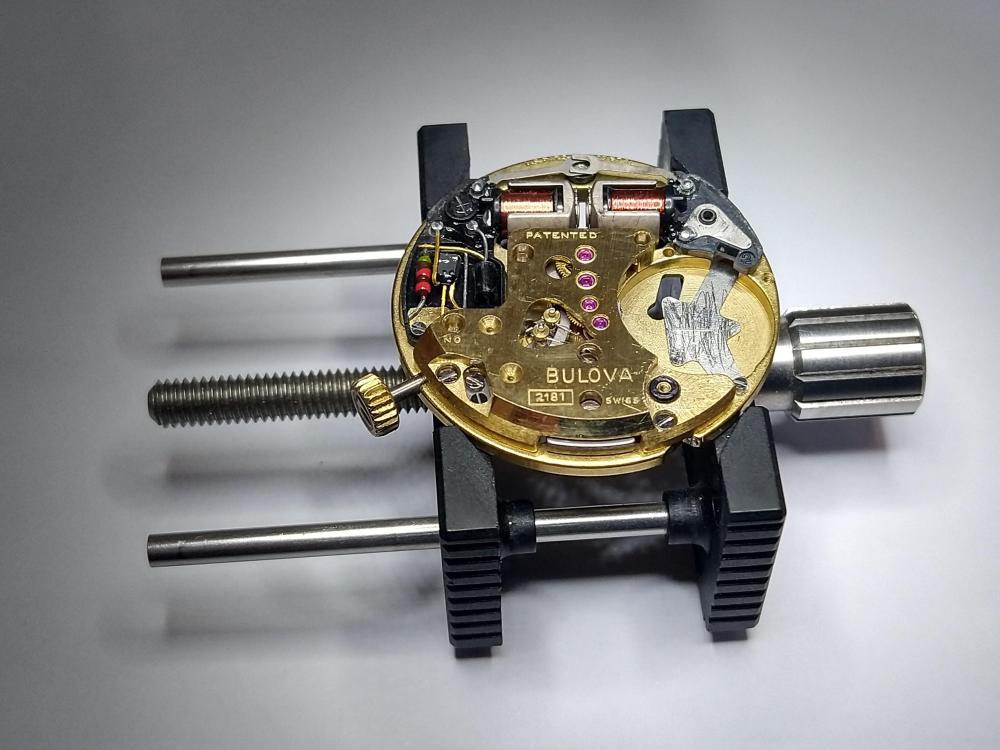

Bulova Accutron 2181 - had an open coil I managed to bring it back into life. Longines 9L - not serviced just pics Eterna-Matic Centenaire "61" - 1438U - not serviced just pics. Longines Cal 431 - not serviced just pics Lemania Cal 4650 - not serviced, just pics. Risieres Felsa 690 - not serviced, just pics. Felca Cal ETA 1080 - not serviced, just pics.1 point

-

My $12 blue one seems to work well enough for movements out of case. However for tools with greater mass, such as my small and large anvils which are highly magnetized the blue unit is useless. For whatever reason, my high current K&D donut unit just doesn’t seem to work, regardless of my attempts to use it as instructed in this thread (magnetizes stuff fine so I know it is energized).1 point

-

That's a really hot bath temperature. I don't recall ever seeing a watch-specific cleaning machine with heat available for the cleaning bath; however ones that have ultrasonic do warm the bath as a result of that. In my ultrasonic tank in which I use a similar product to the Elma, I set the heat to 35 (C), mostly because I don't tend to leave parts in long enough for it to heat from the ultrasonic action. A warm bath does tend to clean better or at least faster than a cold one. I think the ammonia in the Elma has reacted with the plating on the setting at that high temp.1 point

-

Maybe it’s something in your water supply? Worth trying mixing the Elma 1:9 with deinonised/distilledwater? just a thought Tom1 point

-

1 point

-

When I record how much I have spent on each watch I include the postage. UK EBayers seem to be charging £5 minimum these days on postage. Have made a couple of job lot buys recently - based on the average price this one could be 404 reboot project Bad photo from eBay - 1 of 4 watches for a total of £21.19. A Medina with an MST 385 movement - Soaked in oil but looks like it will run again!1 point

-

I've been programming, building electronics for, repairing and retrofitting machine tools and industrial automation systems for over 40 years now. I could have retired, but I always have work queued up - and I still enjoy it; also building electronics, robots and animatronics (among other things) as hobbies. There is a vast range of work in machine tool / robotics / industrial automation field, and not all that many really good people, who fully understand the electronics and software side, rather than having been forced in to it from the mechanical side & struggling with anything to do with electronics or software. I can't help with the qualifications side - things have changed too much over the years, & I started my business before I left school. At the time I was getting criticised and even penalised by teachers for spending too much time on the school "computer" (a massive early programmable calculator, really) because computers & programming were a waste of time, according to them! One big problem I am aware of is that a lot of university courses have little to no correlation to real-world industrial machines and equipment - most of the equipment in the field that needs work is old! You have to be an enthusiast and study older system and techniques; it's no good knowing the state of the art electronics & software inside out when you are more likely to be working on a 50 year old machine than a brand new one. The oldest machine I routinely work on was made in 1911; many are from the 1950s - 80s. New machines tend to be under warranties or service contracts, so only the makers agents ever touch them - it's the older gear that gets sold on after it's showing its age and really needs actual engineers!1 point

-

I existed before the term mechatronics engineer existed. I had to combine electricity, electronics, pneumatics, hydraulics and computing just to keep my own equipment working. I have never sub contracted any of my own repairs to the suppliers because I know I could do a better job. For a long time, dental suppliers in my country would bring their dead equipment to me that their own engineers cannot handle. I have accidentally embarrassed a couple of hospital heads of engineering by demonstrating their inadequacy. I think mechatronics is the most under-appreciated, under valued of all the engineering sciences. I had a part-time dental assistant about 25 years ago, who was studying mechatronics in the polytechnic. She was absolutely clueless about the job prospects for a mechatronics engineer. I asked her about her aspirations and she replied that she really wanted to work in the games industry. In our dental profession, equipment have evolved from simple mechanical to electro-mechanical to logic-driven electro-mechanical and currently to computer driven machines. The medical equipment suppliers who employ mechanical engineers and/or mechanical engineers cannot cope with the repairs of the newer equipment. And many times end up changing whole modules and whole machines just because they cannot repair them. But I think HR is afraid to employ a mechatronics engineer just because they don't know what a mechatronics engineer does. Mechatronics is much more fun. It combines almost all of the engineering sciences and produces an all-rounded engineer. But until HR changes their mindset, not all door will be open.1 point

-

1 point

-

I thought it might be useful to share this reference of watchmaking threads. It includes the modern threads you would get from Bergeon/Wiru/Horotec sets as well as from the old mysterious thread plates labeled Martin Fils/Perrelet/Latard/Bourgeaux All values in mm. 0.30x0.075 no.1 Bergeon tap, drill 0.24mm 0.35x0.075 no.2 Bergeon tap, drill 0.28mm 0.40x0.100 no.3 Bergeon tap, drill 0.32mm; 0.45x0.100 no.4 Bergeon tap, drill 0.37mm; 0.50x0.125 no.5 Bergeon tap, drill 0.40mm; 0.55x0.125 no.6 Bergeon tap, drill 0.45mm; 0.60x0.150 no.7 Bergeon tap, drill 0.48mm; 0.65x0.150 no.8 Bergeon tap, drill 0.53mm; 0.70x0.175 no.9 Bergeon tap, drill 0.56mm; 0.75x0.175 no.10 Bergeon tap, drill 0.61mm; 0.80x0.200 no.11 Bergeon tap, drill 0.64mm; 0.85x0.200 no.12 Bergeon tap, drill 0.69mm; 0.90x0.225 no.13 Bergeon tap, drill 0.72mm; 0.95x0.225 no.14 Bergeon tap, drill 0.77mm; 1.00x0.250 no.15 Bergeon tap, drill 0.80mm; 1.05x0.250 no.16 Bergeon tap, drill 0.85mm; 1.10x0.250 no.17 Bergeon tap, drill 0.90mm; 1.20x0.250 no.18 Bergeon tap, drill 1.00mm; 1.30x0.300 no.19 Bergeon tap, drill 1.06mm; 1.40x0.300 no.20 Bergeon tap, drill 1.16mm; 1.50x0.350 no.21 Bergeon tap, drill 1.26mm 1.60x0.350 no.22 Bergeon tap, drill 1.32mm; 1.70x0.350 no.23 Bergeon tap, drill 1.42mm; 1.80x0.350 no.24 Bergeon tap, drill 1.52mm; 2.00x0.400 no.25 Bergeon tap, drill 1.68mm; 2.2x0.45 2.3x0.40 in Wiru No.1 tap/die set, 2.6x0.45 in Wiru No.1 tap/die set, 3.0x0.50 in Wiru No.1 tap/die set, 0.213x0.086 Bourgeaux thread no.24, on Martin Fils/Perrelet et Martin 'B' 0.267x0.088 Bourgeaux thread no.23, on Martin Fils/Perrelet et Martin 'B' 0.291x0.091 Bourgeaux thread no.22, on Martin Fils/Perrelet et Martin 'B' 0.312x0.093 Bourgeaux thread no.21, on Martin Fils/Perrelet et Martin 'B' 0.344x0.094 Bourgeaux thread no.20, on Martin Fils/Perrelet et Martin 'B' 0.376x0.096 Bourgeaux thread no.19, on Martin Fils/Perrelet et Martin 'B' 0.414x0.101 Bourgeaux thread no.18, on Martin Fils/Perrelet et Martin 'B' 0.452x0.111 Bourgeaux thread no.17, on Martin Fils/Perrelet et Martin 'B' 0.496x0.120 Bourgeaux thread no.16, on Martin Fils/Perrelet et Martin 'B' 0.563x0.133 Bourgeaux thread no.15, on Martin Fils/Perrelet et Martin 'B' 0.640x0.150 Bourgeaux thread no.14, on Martin Fils/Perrelet et Martin 'B' 0.713x0.159 Bourgeaux thread no.13, on Martin Fils/Perrelet et Martin 'B' 0.782x0.167 Bourgeaux thread no.12, on Martin Fils/Perrelet et Martin 'B' 0.858x0.181 Bourgeaux thread no.11, on Martin Fils/Perrelet et Martin 'B' 0.936x0.200 Bourgeaux thread no.10, on Martin Fils/Perrelet et Martin 'B' 1.008x0.219 Bourgeaux thread no.9, on Martin Fils/Perrelet et Martin 'B' 1.097x0.239 Bourgeaux thread no.8, on Martin Fils/Perrelet et Martin 'B' 1.203x0.261 Bourgeaux thread no.7, on Martin Fils/Perrelet et Martin 'B' 1.299x0.271 Bourgeaux thread no.6, on Martin Fils/Perrelet et Martin 'B' 1.404x0.274 Bourgeaux thread no.5, on Martin Fils/Perrelet et Martin 'B' 1.523x0.289 Bourgeaux thread no.4, on Martin Fils/Perrelet et Martin 'B' 1.641x0.298 Bourgeaux thread no.3, on Martin Fils/Perrelet et Martin 'B' 1.797x0.320 Bourgeaux thread no.2, on Martin Fils/Perrelet et Martin 'B' 1.984x0.359 Bourgeaux thread no.1, on Martin Fils/Perrelet et Martin 'B' 2.169x0.388 Bourgeaux thread no.0, on Martin Fils/Perrelet et Martin 'B' 2.363x0.420 Bourgeaux thread no.00, on Martin Fils/Perrelet et Martin 'B' 0.367x0.087 Latard thread no.20, on Martin Fils/Perrelet et Martin 'L' 0.395x0.094 Latard thread no.19, on Martin Fils/Perrelet et Martin 'L' 0.432x0.102 Latard thread no.18, on Martin Fils/Perrelet et Martin 'L' 0.479x0.109 Latard thread no.17, on Martin Fils/Perrelet et Martin 'L' 0.529x0.115 Latard thread no.16, on Martin Fils/Perrelet et Martin 'L' 0.591x0.126 Latard thread no.15, on Martin Fils/Perrelet et Martin 'L' 0.665x0.138 Latard thread no.14, on Martin Fils/Perrelet et Martin 'L' 0.736x0.149 Latard thread no.13, on Martin Fils/Perrelet et Martin 'L' 0.798x0.164 Latard thread no.12, on Martin Fils/Perrelet et Martin 'L' 0.870x0.180 Latard thread no.11, on Martin Fils/Perrelet et Martin 'L' 0.956x0.196 Latard thread no.10, on Martin Fils/Perrelet et Martin 'L' 1.036x0.209 Latard thread no.9, on Martin Fils/Perrelet et Martin 'L' 1.106x0.219 Latard thread no.8, on Martin Fils/Perrelet et Martin 'L' 1.181x0.233 Latard thread no.7, on Martin Fils/Perrelet et Martin 'L' 1.269x0.246 Latard thread no.6, on Martin Fils/Perrelet et Martin 'L' 1.363x0.262 Latard thread no.5, on Martin Fils/Perrelet et Martin 'L' 1.464x0.284 Latard thread no.4, on Martin Fils/Perrelet et Martin 'L' 1.568x0.304 Latard thread no.3, on Martin Fils/Perrelet et Martin 'L' 1.703x0.325 Latard thread no.2, on Martin Fils/Perrelet et Martin 'L' 1.869x0.342 Latard thread no.1, on Martin Fils/Perrelet et Martin 'L' 2.029x0.352 Latard thread no.0, on Martin Fils/Perrelet et Martin 'L' I extracted these from https://www.improwis.com/tables/threads2.webt1 point

-

1 point

-

timing machines are interesting devices which can tell you all sorts of wonderful information. for instance I'm attaching a PDF tells it all kinds of nifty information. But reality is the timing machine points you in the direction like this watch needs servicing. Or another way to think about timing machines like interpreting a crystal ball some interpretation is required and if everyone on this group looked at your timing machine like a crystal ball we would all have possibly different interpretations perhaps. In other words it's not always an exact science. then the power fluctuations like that things like the mainspring if there's sticky grease old grease that results in uneven power that will give you fluctuations. yyou will notice in the PDF is that it's for a paper tape machine. Everything should be more or less the same except if you're looking for gear train problems it's hard to see on a liquid crystal screen it's much better if your machine is spinning out paper.. Or you get an entirely different machine there's better ways to look for gear train problems unfortunately the machine I'm thinking of is really expensive so that's no help at all in this discussion. So they are simplistic is it points general direction of your watch looks bad servicing is probably required especially if it hasn't been serviced in a long time. Then when using your machine it helps to establish a procedure. Like you wind the watch up wait about 1530 minutes then time and usually dial up or dial down and for crown/pendant positions allowing time when changing positions for the thing to settle down then try not to get obsessed with all those positions it just a good way of looking for problems. But don't get obsessed about your watch keeping time to one second all positions.. Timing-Machine-Charts.PDF1 point

.thumb.jpg.bbcba23f04cb7d00f2222c1f7def116d.jpg)