Leaderboard

Popular Content

Showing content with the highest reputation on 05/21/24 in all areas

-

6 points

-

The best advice I received when starting watch repair was don’t force anything.. screws, lifting bridges etc etc.. The other vital skill is using tweezers without losing the part., for me never hold a part tightly and the tweezers must be dressed.3 points

-

I decided to do a little improvisation last night. I had a case where the sides were extremely worn, dented, etc. The case lines were nearly worn completely down. I've wanted a lapping machine for some time but those are far too expensive for my humble budget. I improvised by hooking up one of my sanders to a voltage regulator to bring the speed down as much as I could. I put some 1000 grit paper on the disc and started to gently work the side of the case. I'm quite surprised at what I was able to accomplish with these rag-tag tools and bit of creativity. I'm limited by the table because it can only adjust to 45 degrees, so there are some angles on that case I won't be able to reach properly. While looking up pictures on the internet of other examples of this case it looks like there was not a sharp line between the side wall and the lugs, so I just tried to bring back a gentle curve between those to sides. Not too bad for my first attempt! I'm going to keep moving forward and go up to 2500 grit and see what I can get out of this before moving on to the polishing wheel.2 points

-

Too true! I particularly enjoyed fixing the end shake issue with my brand new Chinese horia clone. I have now used that to improve 3 non runners - would have paid for itself already if I ever got round to selling the projects I have worked on!2 points

-

I'm just about to clean the parts of a Cal 684 which has a similar Winding Gear (#1464). I plan to clean it in my usual way (ultrasonic with Elma solutions) then dip in Lubeta V105. As for Epilame. The only parts I'll be treating are cap/pallet jewels and escapement wheel. I'm not splashing my precious fluids all over the place !2 points

-

Yes, Mine has a support for the blade that can be safely hit like this one https://www.amazon.co.uk/Rolson-62841-Tradesman-Knife/dp/B0044D9MC6/ref=sr_1_37?crid=3HWJF1HL4J8D7&dib=eyJ2IjoiMSJ9.X58oai8WcFho_-XqfR-lLQbU8lQKhf1vtFKAWbXR4EAhqVWR_eMy5h1DhaCULvkpA6XT0GaNFLHt_kJ0kPrhXFo0nYd8yJ4JgruoXDG9XjViAQOyAiBUkOhC9W9qQfGr0SMKpxIUrGOBkTjtTPTuM9IOTnb-dEAzbcZVvniVcEuMFGK9SITyDO6ryUU8ERkHt8f2Vy9Ks0QFO06KSJz65C2p7S3o2lOaUoO9kw61KyNtaaYYwdZzyuM2uRywODaigUn0u8RHMPR0dOa3WSrq8vE1iV5Et_561SFfvkhSGTQ.9QrdWVoCJpLVkrflNS1sxaY56ys4iiJspEFpUgLIRdg&dib_tag=se&keywords=stanley+knife&qid=1716289527&sprefix=stanley+knife%2Caps%2C77&sr=8-37 I use a brass hammer. You could use a very light pin hammer. A watchmaker's hammer would be a bit too light to use. I'm not sure of the weight, but looking at Cousins, it looks like a 60 or 84g brass hammer. I would go with the 84g one. A lot of the process is about feel, so you don't damage the case or bezel. Don't twist the tool! You may think it would make it easier and quicker, but that's when the damage starts to happen and be especially careful around the lugs. Once you have done a couple, you'll get a feel of it. Some bezels feel like they're not coming off and you start to doubt what you are doing. The trick is to be deliberate in your actions, rather than tentative. If you perform this task with the total belief that the bezel is coming off, that is exactly what will happen. First, be totally sure that the bezel comes off in the way you expect. Rub the blade against a piece of 400 grit wet and dry until blunt2 points

-

@VWatchie I expect dunking it for a while in acetone will loosen it up, that being the main ingredient of nail varnish remover. Tom2 points

-

No, only about 1000f. But i took pleasure in roasting these annoyingly magnetized parts2 points

-

Funnily enough, when heating iron or what watchmakers use for making tools which is 'tool steel', or what is also known as 'high carbon steel', as it has a carbon content between about 0.06 to 1.6% carbon content, (but don't quote me on those percentages!) and can be hardened and tempered, when the steel reaches a cherry red, around about 1450 to 1500 degrees Fahrenheit it becomes non-magnetic, so if you placed a magnetic close to or on it there would be no effect at all. I believe it is the steel/iron turning to austenite from martensite, if I remember what I read in an old metallurgy book I picked up in a car boot sale; It's a bit of an esoteric read! In years gone by, cattle bone was used to encase the small piece of steel to be hardened and tempered, so the carbon from the bone was soaked up by the steel when heated for several hours at a particular temperature, in effect 'case-hardening' the steel. It's amazing what we came up with many years ago. We humans are very inventive, yet very destructive.2 points

-

2 points

-

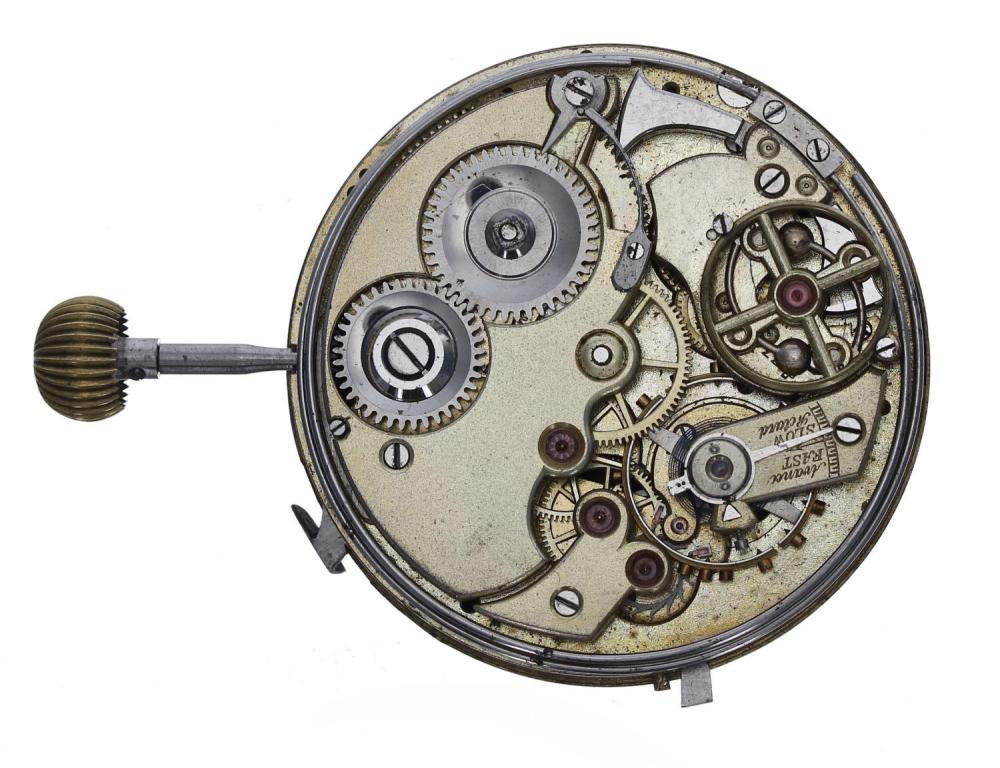

Show us the movement. I can't find the dial but it looks genuine to me.1 point

-

That's great Col, i firmly believe once you have gained some knowledge you just have to jump in and crack on.1 point

-

It'll either be great or Ill burn the house down.:)1 point

-

OK thank you a just want say thank you to everyone who replieded me on this web page when I needed help on this watchrepairtalk have learned so much even with the pallet adjustment a can do it now all thanks to you all been a very great help God bless you all.1 point

-

1 point

-

1 point

-

There is a name for a timepiece and set like this OH, i forget what its called now . Thats lovely OH Got it garnitures. Have you ever worked on it ?1 point

-

When you have the matching set it adds to the value. I bought it because I like the colour of the case.1 point

-

Not a clock guy but have had a poke around a grandfather clock. First place I would look is the drum that the weight cord is wound up to, if the cord is tangled that could be the issue. The cord/gut can also get very hard which if it is tangled would be easier to replace the cord/gut. OldHippy would be the chap to ask. Tom1 point

-

No hurry getting into balance hairspring work. It belongs to advanced repair. Nevertheless, the Chronglide videos are helpful (there are several) and here is one for dealing with entangled springs. Best of luck!1 point

-

I agree, it's so sad how we chose to use our inventive abilities. I saw this video about what would happen if a single Russian nuclear bomb detonated in New York and it scared the living daylights out of me. Everyone should see it, especially our politicians who I'm not sure are aware of the destructive power of nuclear weapons. They don't seem to worry much. Perhaps they think they will be safe in their bunkers. In the video, it is mentioned that just a single intercontinental ballistic missile "SS-18 Satan" corresponds to over 530 Hiroshima bombs. It's all beyond comprehension. Humanity and civilisation wouldn't stand a chance. Sorry for going OT again!1 point

-

OK Rich, may be You are just a little bit more worried than really needed. Who am I to say, jus a newbie here but... Such a big forum will not collapse in any case, exept if the people loose their interest to participate. If something happens to the owner, then senior members will be able to handle the forum. Let me show an example where one of the moderators of the russian forum (thow He was not russian), a man of great knowlage abd big heart, passed away in 2023. Thow His personal site is still working, the russians coppied the whole site to safe place here. I mean, all depends on the people and if they need to do something, they will find the way. Actually, the forum is place where people can meet and share. As a final measure, people can share their phone numbers and use Viber to comunicate, at least people who are interested to keep connection between each other.1 point

-

Please OH, we should all be proud of our collections what ever they are. If we can't show them off here then we can't show them anywhere. Our favourite gives us a story to tell of why we love it, that story also tells others something about ourselves. These are some of the things that make our forum and our community so amazing .1 point

-

One I have and it's a French Strike on a bell with Garnish worth around £1,000. I'll take a photo of it tomorrow so you can see it.1 point

-

When you are having fun restoring false economy exits via a window. Your time and money dont always matter Col , what does matter is that you breathed new life into something that was dead and destined for a scrap heap. That has to feel good doesn't it ? Some of my favourite watches to wear are my first attempts at repair. With a face that only its repairer can love , Rolexes pah !!! give me a Smiths pin pallet any day of the week.1 point

-

You have the right idea, buy another and keep practicing. I can't find a new balance wheel, so go ahead and try to repair the one you have. Watch plenty of videos first.1 point

-

1 point

-

I don't wear or own a watch. I have 12 clocks in my home but I only wind one per week, each week it is a different one. I'm funny that way.1 point

-

That black stuff - I had similar things happen with evaporust! In that case I understand the evaporust eats the iron oxide away without hurting the metal but it can leave behind a layer of carbon which was in the steel that got oxidised. I spent ages trying to perfect a cleaning regime with various different stages in jars in an ultrasonic bath. In the end I switched to washing all but the balance and pallet fork in IPA and gently brushing it with a small artists brush. I would estimate that I have found an extra 20º of amplitude doing this! It also takes me no longer than waiting hanging over a tank to move stuff to the next jar If it is really bad then I have used the IPA as a prewash and go through my old routine1 point

-

These are some from a couple of job lot ebay batches totalling 40+ watches I got a few weeks ago, ~£2 or less each. I'd only looked at a couple of specifically interested ones so far, as I already had others of interest to look at I've just gone through some of the smallest ladies ones. I was expecting them to be mostly cheap quartz, but only one of them was - the others are all look like good quality mechanical ones! There are also a good selection of other types, including a couple of nice looking old Casios - and some blingy things..1 point

-

I put this quick vid together today when I was replacing the tropic crystal on this Rolex Oyster Perpetual. It wasn't the greatest filming, but hey!1 point

-

I remember dipping cherry steel into some kind of carbon powder at school to case harden it. And watched a video about annealing steel a few months ago when making my setting lever. The guy used a magnet to determine the steel's core temperature . Get a blow torch on them or you could really flip and use an oxy torch and melt those suckers.1 point

-

1 point

-

Ok but in no way am i endorsing the practice, it is purely for my own watch related pleasure1 point

-

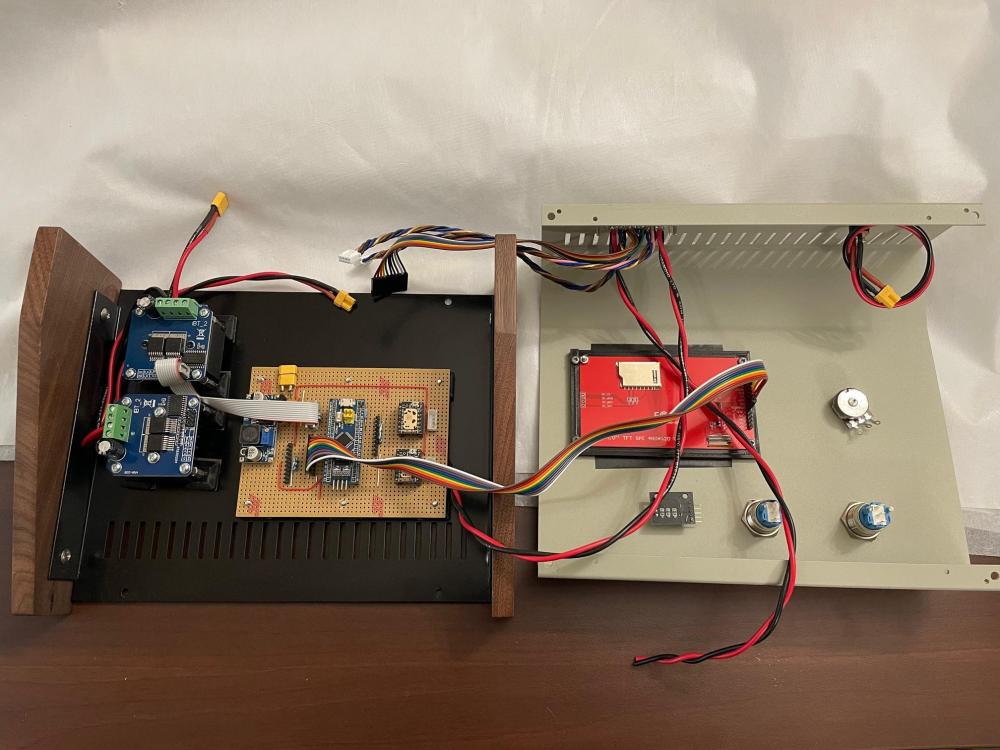

The cleaner smells of ammonia, but it's not too bad; just keep it covered as far as practical. I use an ultrasonic machine on a kitchen worktop. The rinse does not smell strongly, it's vaguely like paraffin. I did check the safety data sheets before buying it & it's said to be safe in normal use. My dedicated watch cleaning machine is still a work-in-progress; four position linear, based on 1L kilner jars for station spacing, to have a heated dryer in position 4. It uses standard, readily available parts as far as possible to make it easy to reproduce, plus 3D printed bits for the custom parts. (The horizontal drive motor is out at the moment while working on the stepper drive software)1 point

-

Some things that we think of as relatively new or modern have been around for a very long time. Alloy mainsprings, balance wheels and hairsprings and epilame for example were developed over 80 years ago. I use clear nail varnish for glueing crowns on, as well using it when making fibre bristle oilers and tweeking tools, its easy to apply if you get a move on after taking it out of the bottle and sets nice and hard.1 point

-

A bit nerve wrecking for sure but it was interesting to watch, good job. for anyone interested here’s the video link Tom1 point