Leaderboard

Popular Content

Showing content with the highest reputation on 05/23/24 in all areas

-

I’ll be getting into them sometime this year, my grandfather’s pocket watch was one of the reasons I got into this rabbit hole. Funny enough last week whilst I was replacing a couple of batteries for the missus she done the old “I just remembered something “ and wandered off. A couple of minutes later she hand me her father’s and grandfather’s pocket watches. Apparently she got them from her brother years ag because I was into watches and thought I might like them. Not looking forward to looking at her grandmothers watch, solid gold and the head is pretty much the size of my little finger nail. Tom2 points

-

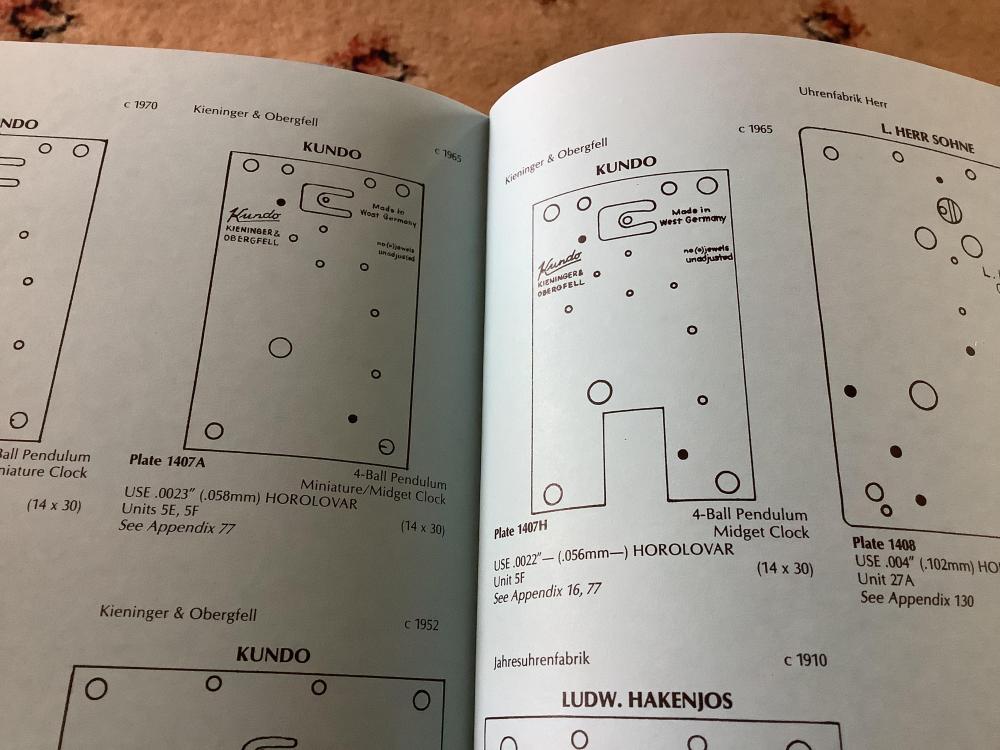

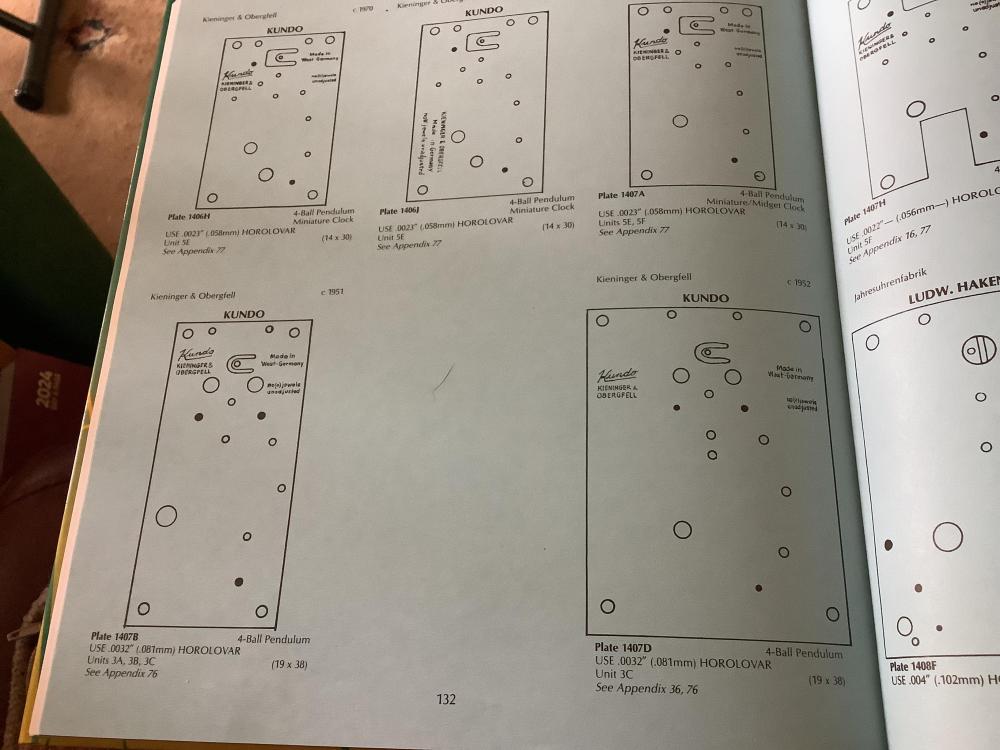

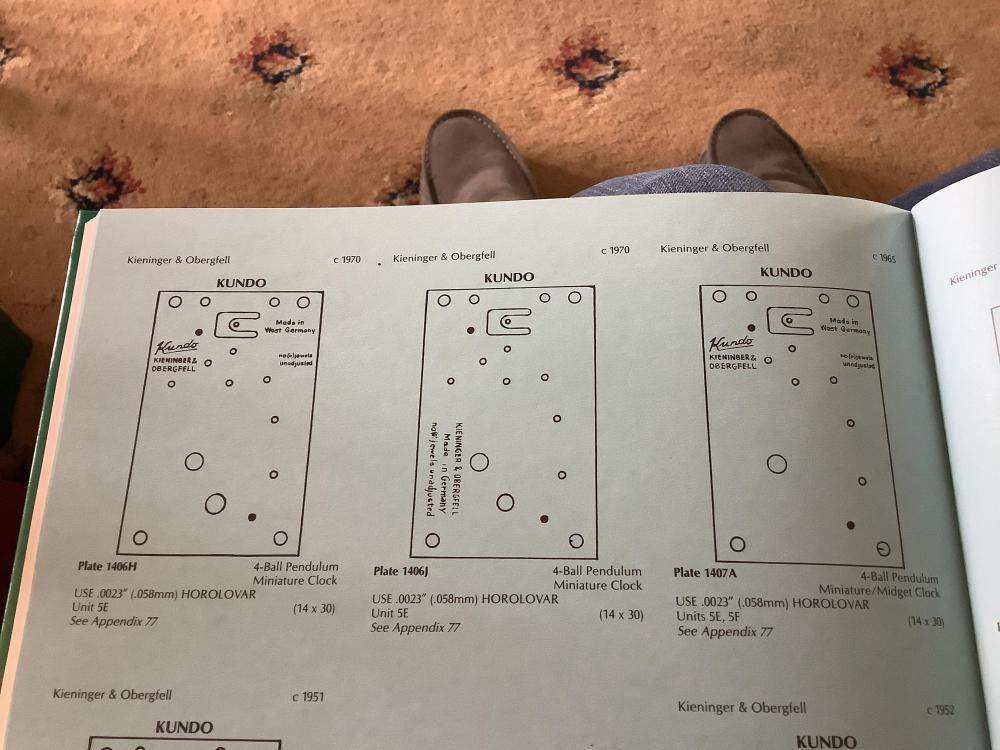

The suspension spring is wrong it should be dead straight with no twists or turns.. The strength of the spring is critical to strong or too weak and you will run out of adjustment. If can supply with the measurements of the movements back plate I can refer to my “Horolovar 400 day clock repair guide” book to give the exact spring you need..2 points

-

With something like this a gasket seal for instance if i cant find the relevant information i would use instinct to decide what fits and works best. You have the original gasket ( well maybe its original or hopefully it is )so its fairly easy to determine what material to use. Shape , for that i would look at the gasket seatings, are there grooves or recesses in either the case back or case or both, what shape are the grooves, flat or round etc, how does the gasket sit and behave in those seatings. Next thickness,that is going to be a bit of a guess, especially if the gasket is a soft one that has been heavily compressed over time. This is where a selection is going to come in handy, personally i would be choosing one that is giving me the feel of compression as its coming into contact with both of the mating surfaces. But not so much that the gasket is going to squash out and become distorted, again this is guesswork and feel is required with the allowance of compression over time, something you may want to check after six months. This part is a little moot as without a pressure test, good water resistance is not assured so the watch needs to treated as such and not as if it were a new diving watch ( not that i would treat any new diving watch as if were ). What you want to expect from your efforts is a little accidental rain catch, if you want more water resistance guarantee then a professional gasket replacement and pressure test is what you should be seeking which will be more than the value of this watch. Coincidentally i have the same watch, been searching for a stem for it for a while now.2 points

-

I got a bezel removal tool, it's the silver type that looks like the photo below (not my photo). I read some favourable reviews of the chinese bezel removal tools, it looked ok at first sight needed a little oil on the guide bars and bolt, nice and tight no play or wobble on the end section as it's been wound in, it operates smoothly, the blades looked looked nice and sharp no burrs well made, all good i thought it seemed like a good buy until i tried to use it. The problem is either the blades are too short or set at the wrong angle as the blades don't contact the bezel until the crystal is sat on top of the two aluminium supports pushing the watch case up so the blades will never go between the bezel and case, i've tried a couple of different watches with pressed on bezels, they are not even deep bezels but shallow ones. I've been looking at photos online and trying to compare the angles and distance between the blades, i will have a go at putting a shim under each of the blades lifting it up allowing the blade to contact the bezel, anyone had the same problem. Since posting this i've found a review of the same problem with this tool, the blades are too far apart. I will never buy another chinese watch tool, total JUNK.1 point

-

1 point

-

Hi Murks, I would just measure the old spring and order a generic one closest I can to size. Especially on thickness and height, length doesn’t matter so much as long as the difference isn’t huge. Tom1 point

-

I really must get into pocket watches , its something that i haven’t thought much about. I imagine after tinkering with mens and ladies wristwatch movements for a while that the new scale of pocketwatches will be something nice to get used to.1 point

-

1 point

-

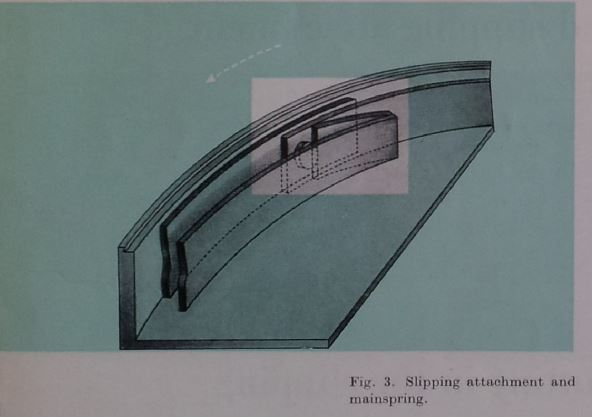

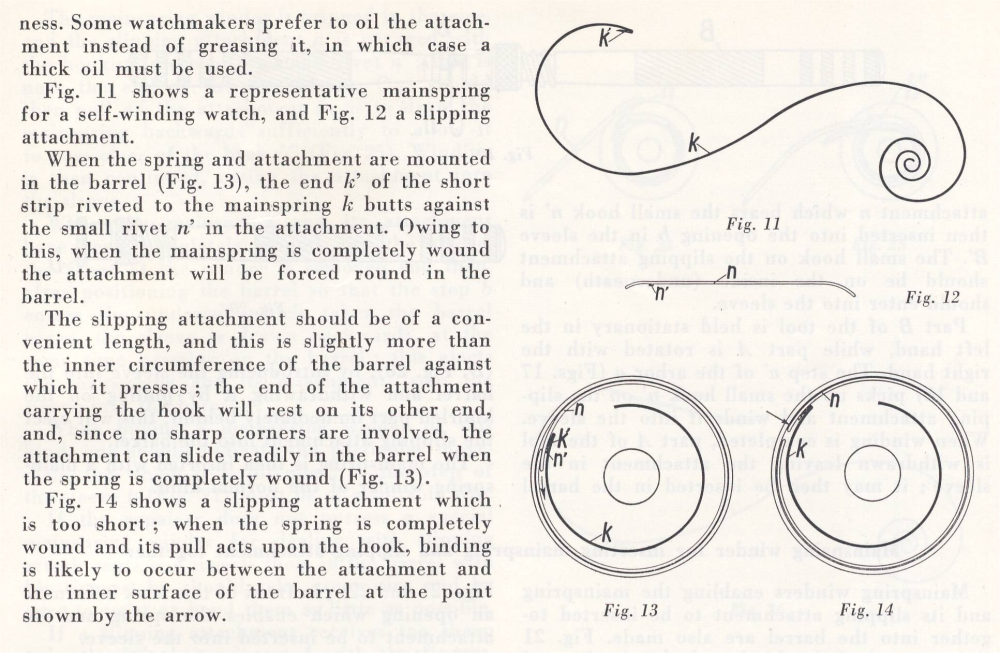

It might not be a hook it might be something like this. But still the mainspring is catching on something on the slip ring because it doesn't have its own outer slipping part like the modern ones. The image below came from some vintage Omega thing I'll have to see if I can find where that has gone to.documentation A different book has this1 point

-

I've downloaded it from the link! Looks like a really handy manual. However it doesn't help with sizing the case back seal. It does tell me it's a flat seal which is good! I think I'll go for an assorted pack from cousins and see how it goes!1 point

-

Yes probably due to some deformation, maybe compression of the posts or burrs forming, or just plain poor original manufacturing standards. But i also do this paying close attention not to alter the intimate positioning of all the components involved with the joint . The pins should still locate with a very snug fit but not so tight that they should have to be forced down to complete the connection. A smoothing broach provides about the least amount of material change you can apply but still broach little by little. I have heard of folk working the the joint on and off a few times without the inside assembly installed.1 point

-

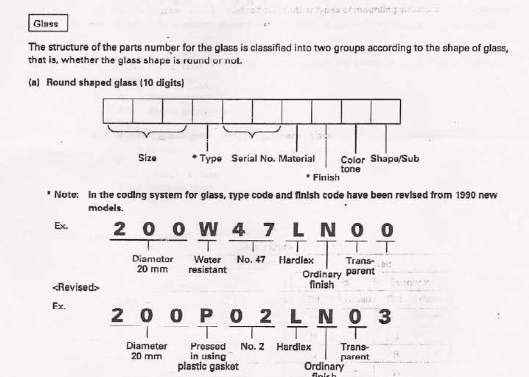

There is a section in this Citizen technical manual that gives a breakdown of the number on the case back, plus a lot more useful info: https://www.plus9time.com/blog/2021/10/3/citizen-technical-information-manual-mid-1970s?rq=Citizen technical1 point

-

Due to my location (and I'm a cheapskate) it takes around 2-3 weeks to get a new crystal, hence I have had to develop my acrylic crystal refurbishment skills to revive the original crystals that come with vintage watches and I thought I would share how I do this as I now have pretty good results, assuming the crystal has only scratches and no cracks or chunks missing here is my process: Use 320 grit wet-dry paper over the entire surface of the crystal evenly to remove the deepest scratches - hold your nerve, this will look terrible after this step Use 600 grit wet-dry paper over the entire surface of the crystal evenly to smooth out the results of the step above Use 5000 grit wet-dry paper over the entire surface of the crystal evenly to further smooth out the results of the step above Use Autosol metal polish (see below) in small circular motions over the entire surface of the crystal evenly with a cloth until the paste disappears, may need to repeat this step 2 or 3 times, this will get you 95% of the way there Use Autosol acrylic polish (see below) in small circular motions over the entire surface of the crystal evenly with a cloth until the paste disappears, rarely have to do more than one application, this will finish the job Side note: I have tried the Autosol acrylic polish side by side with Polywatch and there is no difference in the performance or how it looks/feels - I even got my son to decant some of each into containers in a double blind test and the results were indistinguishable. Hence, in my experience, the only difference is that gram-for-gram the autosol acrylic costs 3.7% the price of the polywatch. Here is a quick example of before and after using the above process:1 point