Leaderboard

Popular Content

Showing content with the highest reputation on 05/25/24 in Posts

-

If the hood will not slide off there might be a catch on the left side as you look at it. open the door and feel up inside to the left. Hoods normally slide of or lift off. Due to age it can be a very tight fit so a little force is needed but be careful not to pull the whole case with movement in side over, you don't want it to come crashing down. The lines are fraying and need replacing it isn't even on the pulley.4 points

-

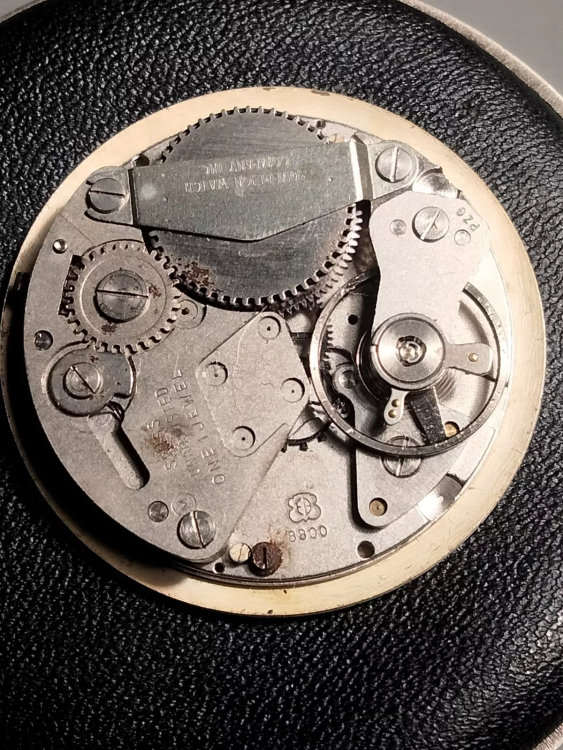

Hi all, this is the one I asked about opening the case a couple of days ago; I've just finished re-assembling it, its running well and looking quite nice. The strap is the one it came with, which is Gruen branded branded. It's a bit dried up but a couple of doses of Lexol should see to that. It just needed new spring bars as one had disintegrated and the other was too short. The case has some rough spots in the plating, such as the upper right strap lug, but nothing too obvious at a distance. I have sent enquiries to a couple of local platers to see if it can be refinished at a reasonable cost. I've not tried any electroplating yet and I'm going to start with nickel on another very badly worn one, originally chrome or nickel plated, rather than a gold one.3 points

-

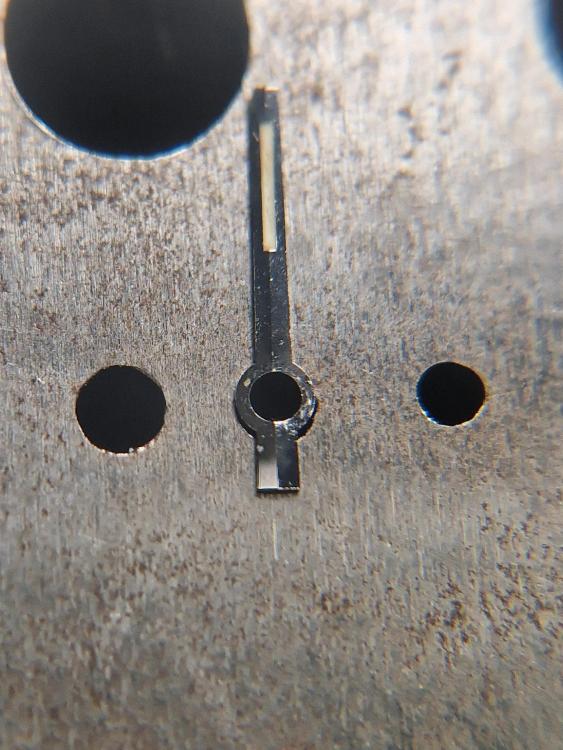

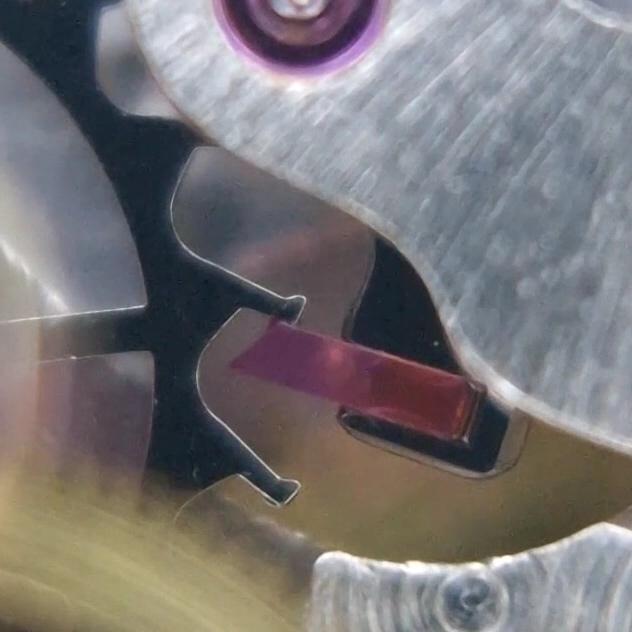

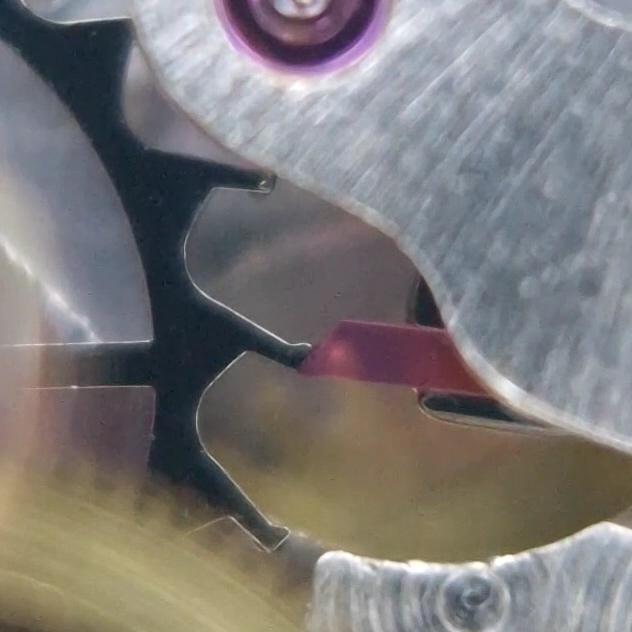

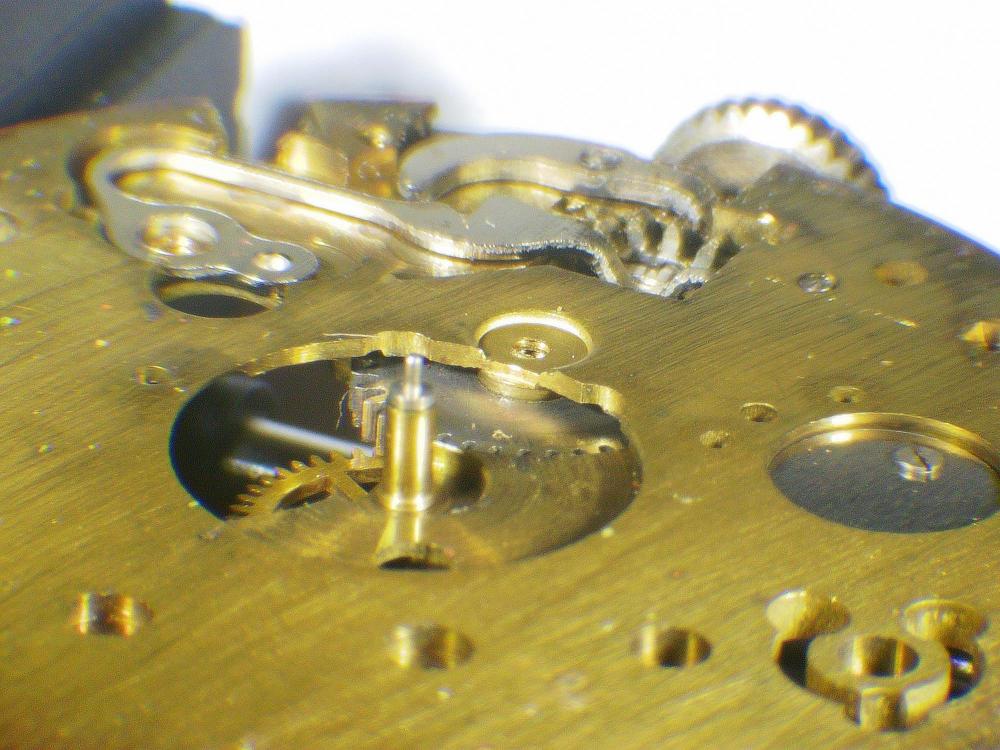

The hairspring collet is so off-centered that when the balance is put in it's pivot holes, the 2nd coil overlaps the 1st.2 points

-

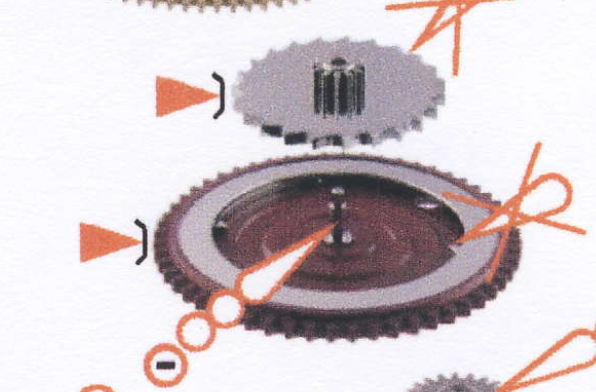

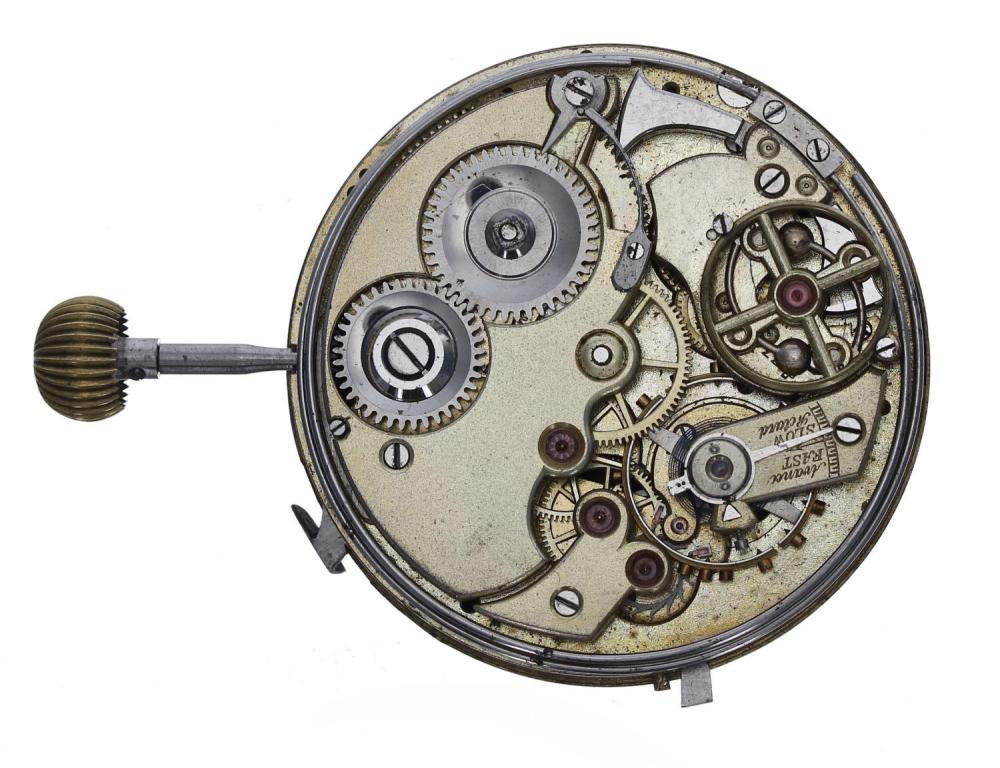

Following up on this old thread. I bought another one of these clocks on ebay (I just love these old electrics with Westminster chimes). Did a full disassemble and clean and had the same issue with the chime not having enough strength. Well, since the last one I serviced, I learned how to disassemble the MS barrels. I guy on the NAWCC forum had done it. The picture I am attaching is from him (I did not take pictures). So, I took this clock apart again and disassembled the chime barrel. Oiled the spring, and reinstalled. Wow, it made a world of difference. I would say this is the most complicated horological unit I have ever worked on. Complicated, because there are five different things that must be calibrated...one of which must occur while assembling the plates. While I have worked on more complex watches (alarm watches), there is no calibration beyond setting the hands.2 points

-

2 points

-

That sounds good Ross. I'll mention a couple of things if thats ok,that may or may not help and you may already be aware of them. If i start at the top, the pegwood and lighter fluid for pre cleaning , not all lighter fluids are the same though and it can be difficult to work out what you have. So lighter fluid is mostly naptha, also known by many other names such as benzine, probably more accurately described as petroleum ether. Lighter fluid also has other ingredients that relate to what it is actually used for ie. to improve the flame necessary to burn with the use of a fluid fill lighter and it could be these other chemical ingredients that often leave a residue on the surface of watch parts that many of us see ( try the drop on a mirror test ). So logically we want to make use of the same cleaning ability of petroleum ether but without the added ingredients that cause residue. We can do this by purchasing pure grade petroleum ether which is available from Ebay, I've just had a look and its around £25 / litre yes it is more expensive than lighter fluid, i guess maybe a tenner more per litre. So just a couple of notes to add to this, when choosing a lighter fluid, naptha, benzine, whatever you want to call it or the form you buy it in, try to get hold of one that is labelled " light distilled " or "light naptha " also sometimes called " light aliphatic " this is the carbon to hydrogen ratio, an example of its equation might be something like C3 H6 , its these two symbols that tell you how light or heavy the naptha is. The higher the H ( hydrogen) atom value is the lighter the chemical is and will evaporate quicker. High C ( carbon ) atom naphtha is heavier , evaporates more slowly and may be the cause of too much left residue on watch part surfaces. So in summary aim for a higher H value than C carbon value on the label. I'll find a good example of what to look for and come back with it. Other things to note are 1. A professional brand cleaner like Elma or L n R is probably cheaper than the petroleum ether, certainly when the ether is bought in one litre bottles and it could even be cheaper than the lighter fluid which is in the region of £1.50 for 100ml - 120ml tins. So thats more or less covered the cleaner to use, but now try soaking your pegwood in your cleaner ( lighter fluid ) before pegging the jewels, it will soften the pegwood making it a more pliable dirt dissolving tool . You can leave any watch parts that have shellac on them soaking in lighter fluid, i used to do it all the time when i started and was using light fluid and i know oldhippy did this as well when he was in the trade. I've done it overnight before without any problem to the shellac, so a couple of hours soak will be absolutely fine. Its just NOT to do that with the isopropyl as that will almost certainly soften the shellac .2 points

-

Never. Good comment about the DIY thread. Yes I have seen it. Adapted a few thing to make my own systems of cleaning. Adam and Gentlemen are my 'go to' for inspiration. I only have about 18" by 18" as my working area for cleaning. I have adapted. This is my system. After disassemble and checking I begin the clean with pegwood and lighter fluid. Fiber brush if needed. Everything , except shellac items, balance bridge and pallet fork, into lighter fluid jar. Large items at base and others into baskets. Jar into ultrasonic warm water. 3 x 2 min. Balance and Pallet in small tray and lighter fluid dripped and allowed to gently clean. All blow dried Everything from jar moved into 2nd jar containing Isopropyl alcohol. Ultrasonic 3 x 2 min. Balance and pallet dripped with Alcohol for under 1 min. Everything out and placed under nail blower for 10 min. Before assembly I recheck all parts for damage. This is when I make my decision to order parts as I can see what needs to be done. My system in now pretty good. Well, at least for an amateur.2 points

-

That's one of the Bergeon tools I have. Reasonably cheap, and the tips are well shaped and harder than the cheaper versions. Yes, cheapo versions do work, but you are always reshaping the tips - like hand levers. After fiddling with cheap levers I eventually bought some Horotec ones. Not cheap, but well worth the expense. BTW how can Bergeon justify £56 for a silicone cushion or plastic dial support, when this nicely machined bit of metal is just £12?2 points

-

2 points

-

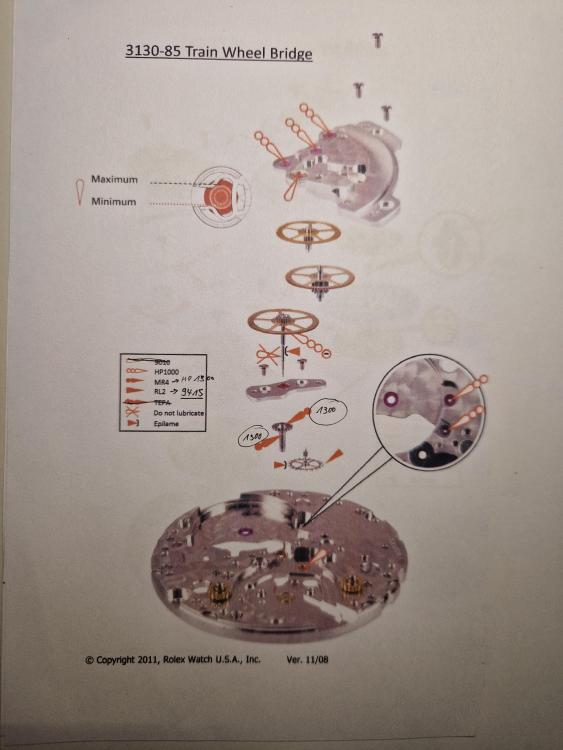

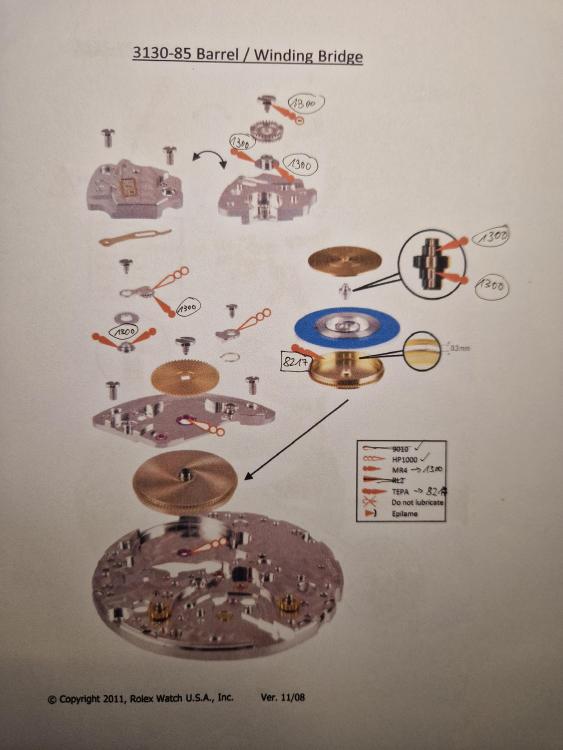

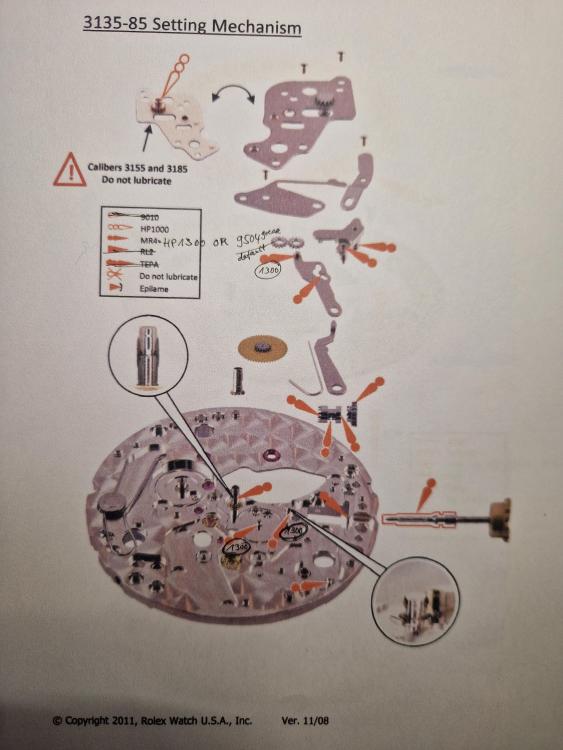

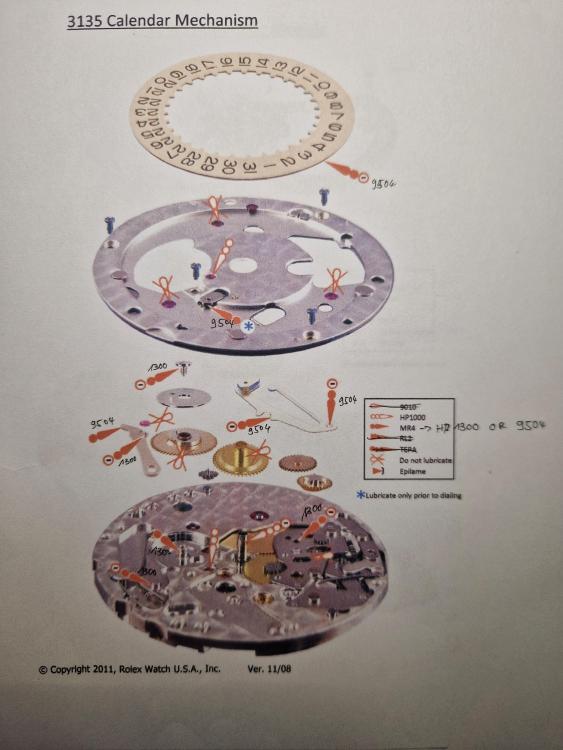

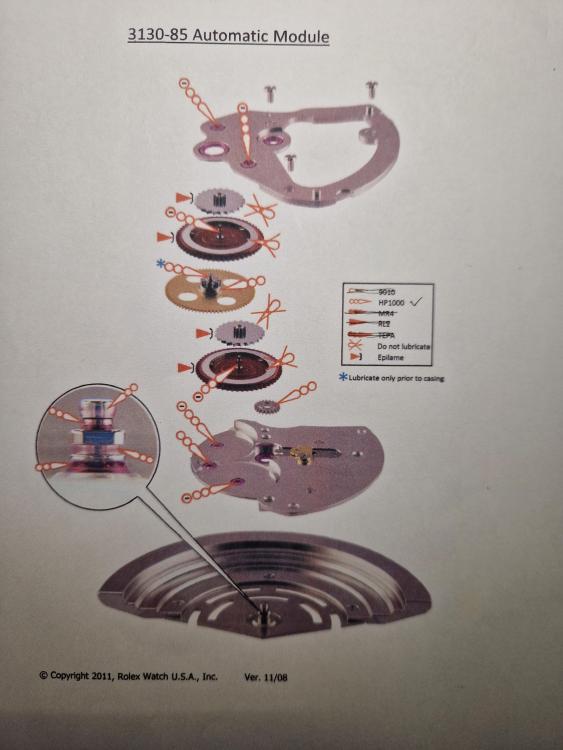

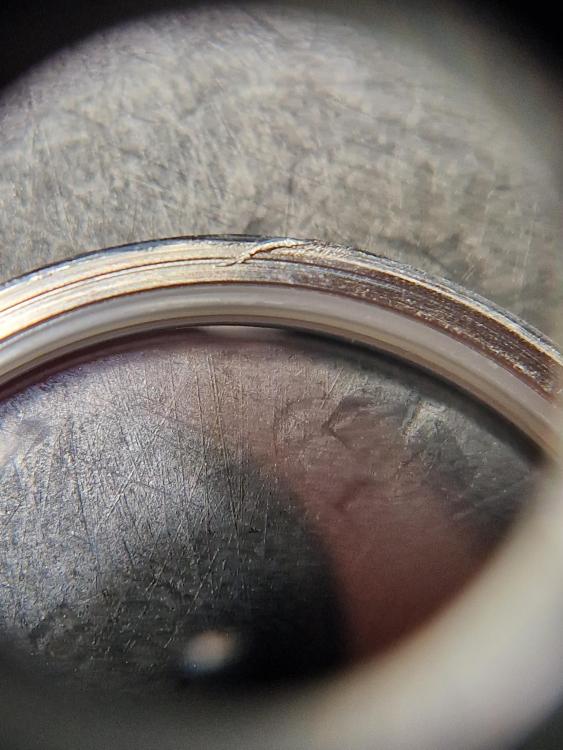

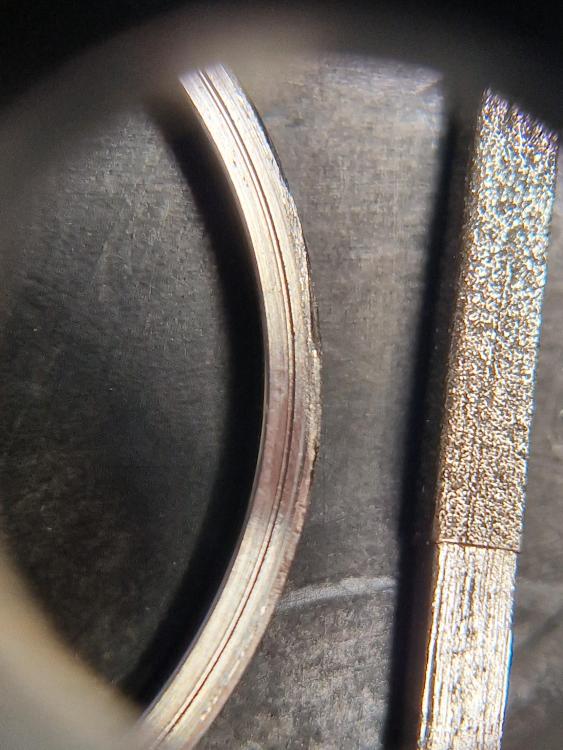

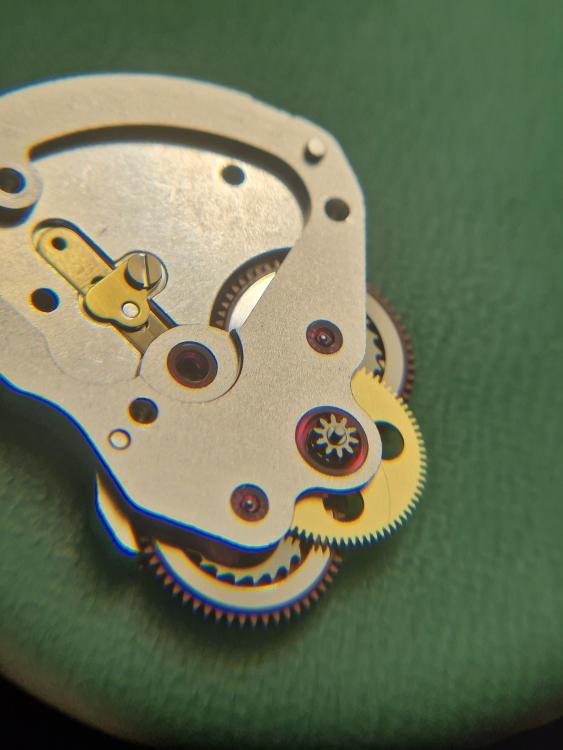

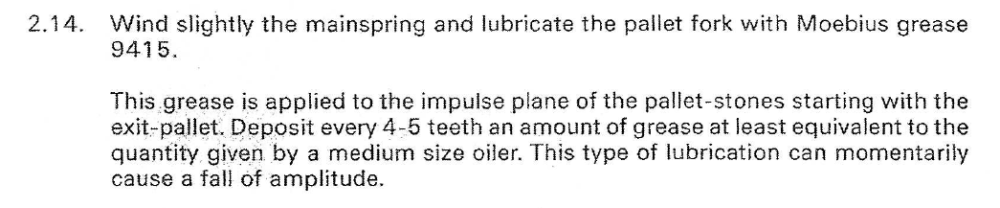

Hello all and merry Christmas (in advance)! I just finished a service on a Rolex 3135 in a lovely Datejust 16220. First, here are some overview pictures of the movement: The watch was in overall good condition, but it was running a bit fast and inconsistent (across positions) and amplitude did not reach 250 even fully wound and dial up. Upon disassembly, I did notice some a bit of dirt and some jewels/pivots had run almost dry. The barrels shocked me again (similar to the Rolex 2035 that I recently serviced): Thanks to @JohnR725, I had access to detailed oiling charts and service training guide: https://www.watchrepairtalk.com/topic/3626-rolex-3135-beat-error-adjustment/?do=findComment&comment=234180 After some good pre- and final cleaning, I assembled exactly as prescribed by the Rolex training guide that I followed the service guide in detail. For lubrication, I followed the Rolex oil chart, also posted in the link above. One particular issue is the Rolex lubricant "MR4". It seems to be somewhere between a very thick oil (like HP 1300) and a grease (like 9504). I used either HP 1300 or 9504 as a replacement and depending on the particular locations. My final "interpretation" of the oiling (with Moebious oils) is as in the pictures below. Regarding the pallet fork, the Rolex training guide seems to suggest a rather large quantity of 9415. Consequently, I put more than I usually would (but still less than the suggested amount by Rolex). See pictures below. What are your thoughts? For the automatic module, as show in the Rolex oiling chart, I treaded the reversers with Epliame and was VERY light on the lubrication of the "internal pivot" (see screenshot). As prescribed, I did not oil the internal ratchet/click mechanism of the reversers. Case: The previous watchmaker left me a present under the bezel. I noticed that it was not sitting perfectly even on the case. He (or she) must have removed the bezel in a way that damaged it a bit. I filed the damaged metal away with a diamond micro file. Bezel back on with my trusty Robur (with 3D printed adaptors for "standard" M4 dies). The dial and hands also got a bit of cleaning : Before: After: Casing: 1. align the case clamps on the movement with the matching groves in the case. That's how that looks. Turn everything around and slide the movement into position. Insert the stem. Done. At full wind/dial up. Vertical positions are running a bit faster (+8-10 seconds). I may look into regulating that further. I'll eventually post more results. To conclude, my usual "artwork": Merry Christmas to everyone!!!1 point

-

I’ll take a counterpoint on the youngsters- all the under 30s in my extended family are into fashion and trends and have varying jobs/careers where the only common denominator is they provide the disposable income to buy watches, sometimes expensive ones. Most are very excited about my ‘new hobby’ and I’m spoiling them on their birthdays this year with a rescue- the weems already went out but here’s the rest… …I’ll share in the guilt of inflating prices for the stuff what once could be had for a few quid. Except for the 404 a good thing I say…1 point

-

Thanks to this video I undid the tangle. The spring is still out of round and the watch is still not starting when I put the balance in place. Since now I have a second movement, I’ll try swapping the balances to confirm that is the issue The result is not very conclusive. Swapping the balance didn’t make the first movement work. BUT, when putting the good balance back in the good movement I had a hard enough time doing it (it did work in the end but I think my problem is managing to sit the balance pivot in its bottom jewel or to fit the impulse jewel into the fork) that I keep wondering if the failure in the case of the old movement is because I broke it or because I am not good enough at reinstalling balances. I confirm that the main issue is between the seat and the tweezers. after more effort the first movement with its own bal and ou of shape spring started. No doubt the time keeping will not be good but IT’S ALIVE!1 point

-

Absolutely the process of plating doesn't fill in scratches, at best might improve micro scratches. As with watch servicing, perfect cleanliness is a must throughout all of the plating stages.1 point

-

If you go ahead with the plating, ideally the old plating needs removing and any scratches polished out. At a minimum the plating on the lug looks to be flaking and definitely needs removing.1 point

-

Sometimes you can get the items so cheaply, it's worth paying the extra postage. If it's worth paying $30 for, then it doesn't matter if its $10 + $20 postage or $20 + $10 postage. I can give an actual example. I just this minute bought a watch from ebay and had to pay £7.99 for postage - which is a lot, as it's in the UK. But I only paid £9.99 for the watch (The cal is AS 1951)1 point

-

Very true.I shall take it slow and work on some similar movements before opening up a Rolex1 point

-

Yes, assuming it's a split stem. You have to pull straight out or you could damage the stem or tube. If it's not a split stem, then you'll break the stem or worse. In any event I'd make sure first by working on getting the bezel and crystal off. That way you can confirm it's a front loader. I think I see a notch for a case knife in one of your pictures, but you should first clean off the gunk.1 point

-

Absolutely, only worth paying any kind of premium if tight tolerance is required. Tom1 point

-

1 point

-

1 point

-

1 point

-

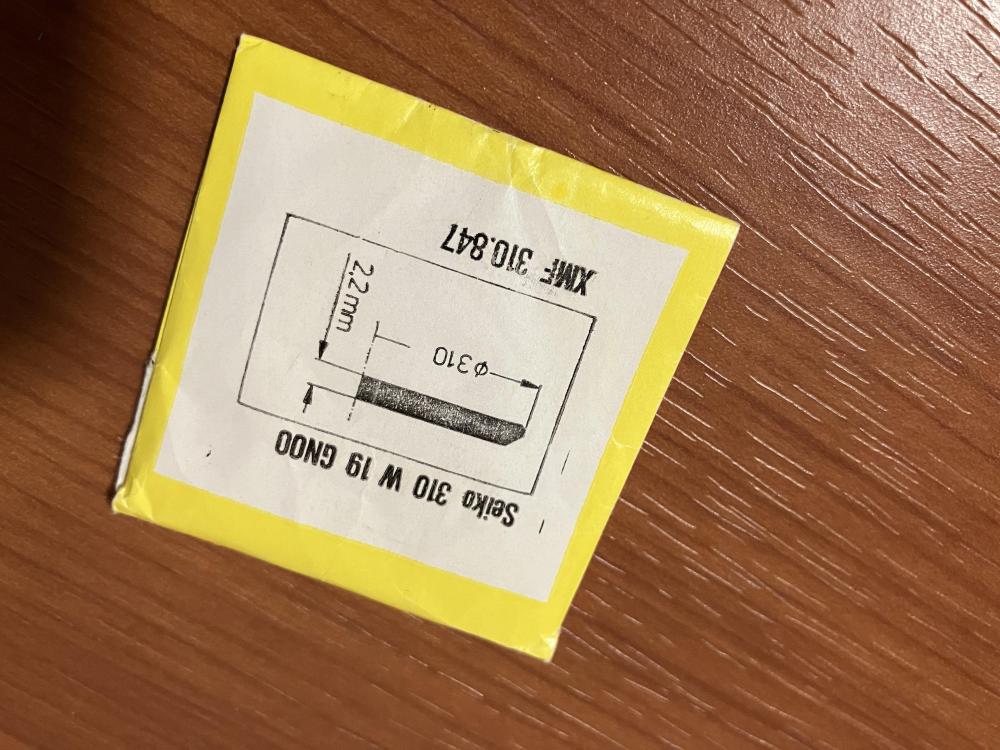

Cousins have it as discontinued so will have a measure as recommended and try to find a generic replacement. Many thanks for the replies1 point

-

1 point

-

I would recommend replacing the gut personally, that stuff gets really hard and likely at the point it is no longer malleable enough to properly untwist. https://www.cousinsuk.com/category/lines-ropes-cords it’s not expensive just fiddly, having done one with the gut I would more likely go with the perlon option now as that should be much easier to knot. All depends how original they want to keep it. Tom1 point

-

So true. If you don't have that, all bets are off as far as I'm concerned.1 point

-

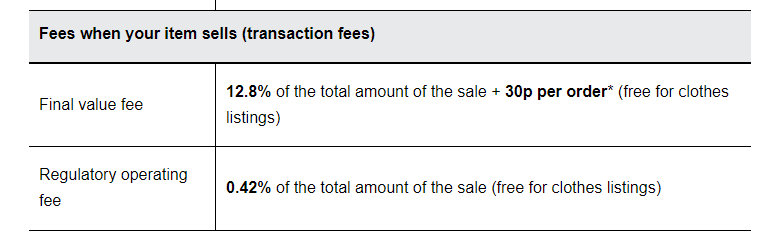

I noticed this recently, and clicked on a couple of items to see why the postage was so expensive. When I looked at the item, the postage was reasonable. It was only the listing that showed a high amount. It seems to have been a bug that's been fixed. This is now the listing for the last item I sell a few watches on ebay, but wouldn't if they took 25% commission ! The selling fees in the UK in 2024 are :1 point

-

It‘s a snap on for sure! Some case backs don‘t provide a slot for the knife.1 point

-

These are some from a couple of job lot ebay batches totalling 40+ watches I got a few weeks ago, ~£2 or less each. I'd only looked at a couple of specifically interested ones so far, as I already had others of interest to look at I've just gone through some of the smallest ladies ones. I was expecting them to be mostly cheap quartz, but only one of them was - the others are all look like good quality mechanical ones! There are also a good selection of other types, including a couple of nice looking old Casios - and some blingy things..1 point

-

1 point

-

That looks very good. Watch out she will have you ironing the clothes next.1 point

-

OK so everyone has covered the veneer and case, I'll give you the springs, I make these myself and are very easy to do, measure the gauge of the wire and order some off ebay, then chuck up a rod of the same diameter or as close as you can get in the lathe, stick one end ( use super glue ) and slowly turn the lathe holding tension on the other end of the wire and keep the coils tight together. Once at the required length cut the wire slightly longer than is required and use acetone to free the stuck en, then using round nose pliers form each end.1 point

-

Yep, I have one of those too. Got mine from Cousins (now discontinued). Yes, a total waste of money! That is 100 % my experience as well. If I were a pro with daily use of a tool, perhaps by several people, I would definitely go Swiss. When buying tools I always try to get used Swiss tools if I can find them for a reasonable price, and if not, I go Chinese.1 point

-

https://ranfft.org/caliber/4167-ETA-2788 2788 Date 2789 Day and Date 2789-1 Day (2 languages) and Date Follow what you have for the 2789 and you will be fine.1 point

-

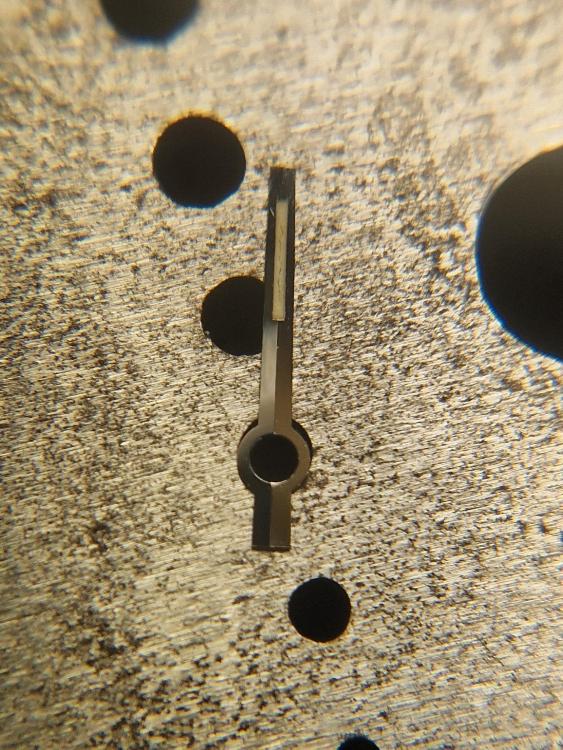

I'm working on a Waldan and have one step to go with disassembly and need some advice with some issues. First, the cannon pinion slipped right off, no resistance at all. I read that ETA movements can be attached to a wheel, which mine is, but it doesn't look like the same kind of wheel with two bars. Am I supposed to take off the wheel, and if so how? Second, I can't remove the stem. The setting lever screw is loose, but I still can't remove the stem and I don't want to yank on it. Of course, the setting lever is problematic for removal. Also, the screw above the clutch wheel, shown, won't budge. I think it holds the center wheel bridge, but not sure. I tried oil, but no luck. Thanks for your help.1 point

-

1 point

-

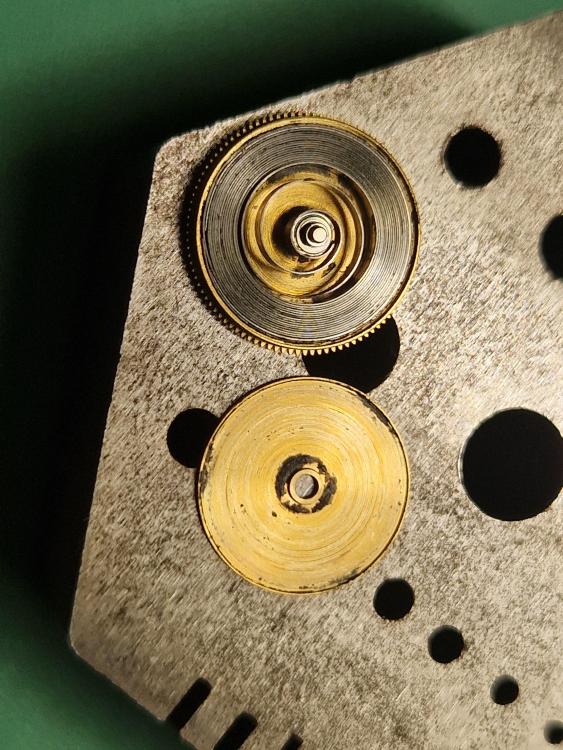

Put the barrel with the silver side and gears side up, push it down around the edge on something hard, the silver part with the gears attached will pop off. I use a watchmaker anvil.1 point

-

1 point

-

The watch is out of beat but as CB says there is also another issue. It could be the hairspring coils are dirty or sticking due to magnetism as the lower line is inconstant. This means something is happening during one vibration causing this. Check hairspring, ruby pin (is it clean), pallet horns (I have seen these where unevenly), pallet stones, pivot holes for balance, pallets and escape wheel. Make sure pallet stones and roller ruby pin is not loose. Most likely culprit is dirt, magnetism or incorrect lubrication.1 point

-

I don't know about the lume, could be radium. Watch this, it explains dial cleaning. https://youtu.be/qzUh4jKfRgY?si=7InKqS2kRAOWt6fe0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.f0fdcb904fb94600b8d08cf1e4ea5a6b.jpg)