Leaderboard

Popular Content

Showing content with the highest reputation on 05/27/24 in all areas

-

I enjoyed this: https://www.bbc.com/news/articles/c4nn7gew9zxo4 points

-

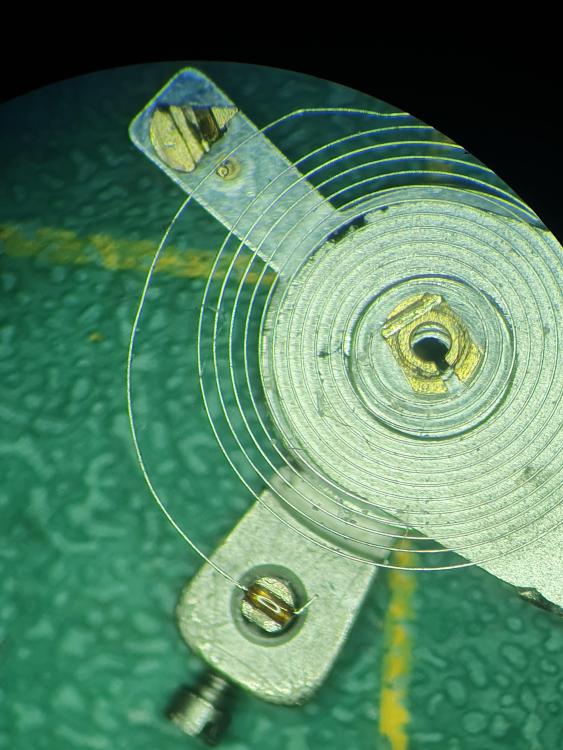

Both ends of the Poljot 2612.1 hairspring were "secured" with some kind if crappy glue. They came loose when I was straightening the spring. I placed all parts on the balance cock and used liquid shellac (dissolved in a bit of alcohol) to attach them again. I found using liquid shellac works easier then heating the solid stuff. The job is already fiddly enough without the need for a heatsource as well, but you need to be patient as it takes a few days for the liquid shellac to fully harden.3 points

-

Unitas Was the original Swiss manufacturer now of course it's made by Swatch group or specifically ETA. I have a link to their website and while I was there I downloaded the tech sheet for you which I'm attaching. Oh and as this is the newest version of the tech sheet it of course has the etachron regulation system which Yours being the older version does not but otherwise everything else is exactly the same. https://shopb2b.eta.ch/en/6498-1-6498-1-5.html Nice that you're the first one that's there it's always bad with other people been there before you as they can get very creative with things that will cause problems. Then don't think of this is a pocket watch think of it as a large wristwatch because that's basically what it is. It's why it's the classic choice for training watch repair. Although usually for training and watch repair we recommend purchasing the clone eight by the Chinese as it's considerably cheaper than the Swiss version that you have. But otherwise this is basically just a really large wristwatch very nicely made and they typically run very very well. ct_6498-1_fde_482382_10.pdf2 points

-

Problem Solved!!! I went through my bag of "Watches I never wish I had bought / bid on" and found another watch with an EB 8800 (a 1 jewel version with a bent hairspring) and decided to swap parts until it worked. After trying the mainspring barrel I tried swapping the winding and sliding pinion - turns out it was the winding pinion. It was very hard to see on the inspection. The breguet teeth on the winding and sliding pinions are very shallow on this movement and didn't look obviously broken. At 22x mag under the microscope you can see they are worn - but I missed it at the 10x. Here is my best effort of a photo (I don't have the gear to take it through the microscope)2 points

-

Unitas. https://ranfft.org/caliber/10349-Unitas-6498 Why isn't it working? Another link with the incabloc https://calibercorner.com/eta-caliber-6498-1/2 points

-

Hi Rich, Yes, You can polish the arbor pivots and the barrel holes, but it will be beter to burnish them. The normal reason one will do it is if there is bad surface by the manufaturing or signs of degrdation of the surface due butting from no lubrication or hard particles for example, and it is done to prevent the bearings from fast wear when working in such state of surfaces. Othervice, do not expect significant change in amplitude because of the polishing. This is what I think, but You can try before/after with no change in other conditions and make own conclusions.2 points

-

I got one of the Chinese mainspring winder sets a couple of years ago. Initially, I was also of the opinion that they were useless. But recently I worked on a couple of movements that had winders specific for that caliber and they worked perfectly. So the China winders are so caliber specific that they don't work as a universal winder. My go to winders now are the vintage K&D winders and the K&D adjustable winders. But I had to modify the arbors by cutting off the arbor hook and drilling a hole through the arbor and driving in a steel pin. Now the arbors can wind in both directions. I had to adjust the lengths of the pins in the adjustable set as they were ridiculously long. But once in awhile, I'll come across some strange mainspring that just won't fit any winder. So learning how to wind a mainspring by hand is an absolutely essential skill.2 points

-

I don't usually do it but I just burnished and polished a barrel arbor a couple of weeks ago. The upper arbor was rusted and pitted, so it was a necessary job. I chucked it in the lathe and used the rough side of the pivot polisher first, then the smooth side. And finally polished it with autosol on a wooden popsicle stick. It still had some deep pits but that was all I dared to polish. I also used a smooth broach to smoothen the barrel cap hole before polishing it with a bamboo toothpick.2 points

-

there is certainly a possibility that you B-dip is contaminated. if you've used it for a while and a lot of oil has been absorbed by it over time. In the end, it rather spreads the old oil. It has happened to me the same why you describe it. Since B-dip is ridiculously expensive, I moved to washing benzine and Essence Renata. I highly recommend the latter. Works perfectly. I keep small quantities in small hotel-style mini jam jars and replace the solvent rather frequently. I'd suggest you throw away the remaining B-dip and don't use it anything else.2 points

-

That's right RIch. In sunlight it hardens in 5-10mins, and 2-4 mins under UV light. It can be dissolved with acetone.2 points

-

I recently bought some UV activated resin. I bought it for fixing glasses, but it would work well in this case. It's great to work with. You have quite a long time to work (if you stay out of sunshine) before it sets - I use a cheap UV torch.2 points

-

Actually it looks quite decent? This seems to be a variation amongst the 1000 machines of what they show. So for instance those numbers above the line are showing the rate within the specific time range probably of the averaging range. I'm guessing if you change the averaging range to longer time span the numbers will spread out. Then some of the 1000 machines have the ability to change the basically the gain control which is really nice for watches that have issues with Properly picking up the signal for variety reasons. Then the graphic display this is a classic back to the days of paper printouts before the numbers existed. Yes the vintage timing machines in the past spit out a paper tape you would look at the graphical display to make diagnostics and the see if your watches either fast or slow and out of beat. They just lack the numeric display an amplitude. I'm attaching a couple of PDFs even though the graphical display is on a LCD versus paper there identical to what they used to be so a manual for paper tape machine on interpreting works just fine for the modern timing machine. Timing-Machine-Charts.PDF Witschi Training Course Document Nr. 71.1010D35e.pdf One of the things remember when you're looking at a liquid crystal screen is there are pixels. So it's hard to do a angle when you have pixels. This is where the 1900 is better because the pixels are a lot smaller. The problem with pixels versus a linear display is that you can't actually do an angle sort of. So where's as it is angling up words in this case indicating a running fast as you switching from one line to another that is where you see the weird pixel arrangement. So basically nothing is wrong the display looks outstanding. Oh and timing machine procedures? It's good to establish a procedure like for instance you wind the watch up and let it run for 15 minutes to an hour that's considered fully wound up. Initially you can wind the watch really really tight and get incorrect reading so you need a little bit of settling down time. Then for diagnostic reasons it's always good to check the watch in more than one position. The minimum would be dial-up and dial down and for a wristwatch crown down. Then it's also nice if you wait 24 hours later and checked the watch again which is good for diagnostic reasons.2 points

-

Demagnetize it first and the tools you are using. Get yourself a tin of Ronsonol lighter fluid. A small jar with a screw on lid. Put the balance in that for a few minutes, get some tissue paper put the balance on that then dry with you bench blower, oil both staff pivots and put it back in the movement. This is what I always used to do never had any problems. I have tried one dip and it was rubbish a waste of money. Ronsonol is very friendly to shellac so no worries there.2 points

-

John Thank you so much for the information and attached file. Have downloaded and read it twice already. Good innit? The oil directions are superb. As you said, wrist watch. I am treating it as such. The first training watch from Mark's course is the 6498. I had purchased the 6497. I thought I somehow knew what to do with the watch. My first watch, and now my first Pocket watch. Good when a plan comes together. As I said. Really enjoying this one.1 point

-

1 point

-

What do you know, we're twinsies! Mine was just dried lubricant in the train stopping it up, but I also found a broken mainspring so I'm waiting on one of those now. Looking forward to your progress!1 point

-

Thank you Richard. Not sure why it does not run. Maybe old oil? It has never been opened before. I am the first. The balance moved OK. The pallet fork moved side to side OK. However, although the watch accepted a wind, the train did not move. All of the pivots and wheels appear correct. No damage. I have noted that the jewels and pivots are completely dry. There appears to have been no lubrication at all. No wear on any jewel or hole. Maybe it stopped because of that. I hope so. Possible the owner di not do anything when it first stopped. As I said, virgin interior. I am using brass tweezer to make sure there is no scratches, and am being extra careful with screw removal. No scratches or deformity as of yet. Want to keep it that way on assembly. Already pegged. Tomorrow I will do a full clean and be ready to begin the reassembly. So looking forward to this.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Look on ebay for a Unimat 3 lathe I have two one with the milling attachment and I have loads of accessories. I'm retired from watch clock making but clock making is what I concentrated on. The unimat 3 will handle up to Longcase clock barrels and the center wheel. So unless you are going to service Turret clocks the Unimat will do all you want.1 point

-

I've got one of the cheap Chinese jewelling kits due to arrive any day; I am rather curious just how good it will be? Around 130- for the tool with 24 pairs of pushers & anvils.1 point

-

Alex has a video showing how he polishes the barrel holes and arbor.1 point

-

Hello and welcome from Leeds, England. No stupid questions on here, feel free to ask anything you want.1 point

-

Well I'm a little feared already after seeing that statement and I'm not even doing the job.1 point

-

Ruth Belville, clearly worn out by " using her femininity " to get special access to the Royal Observatory at Greenwich. Wtf . That seems to imply that the Royal Observatory at Greenwich had special access to Ruth Belville's femininity which is why she was clearly worn out.1 point

-

It's a common problem and usually created by someone setting the finger and not really knowing what to aim for and it gets bent out of shape. There are two bends on the finger. The first bend is adjusted to suit that 0.02 mm gap at the 'start' when the hammers come away from the hearts. The end bend can be manipulated to turn the sliding gear tooth properly. I'm guessing by what you have said that the finger is too deep with the tooth of the sliding gear and gets jammed when trying to turn it. Also check that the sliding gear is free to turn by blowing it with a blower and you'll see how free it is and make sure the minute runner turns freely inside the bush. Again fit the runner on its own and give it a blow to see it turn freely. You may find that the runner doesn't turn because of what I have said and it may not have to do with the finger. The drawing from the tech sheet is all you need to adjust the finger properly, but as @nevenbekrievhas said, it's important you understand the theory and marry that with the practical adjustments of the chrono mechanism.1 point

-

You can adjust the finger, no need to replace anything. But firs You need to red and understand well this1 point

-

I think it is authentic too, have not seen the back though, the dial was probably refinished at some point, there are few 321 Omega tachometer chronos on Ebay currently that look close.....1 point

-

Why is it when that little voice says, "This is a bad idea," we always want to talk ourselves out of it? I had the low blood sugar jitters earlier, but insisted to myself that I'd be able to oil an especially tiny cap jewel on my friend's Omega 1001. With lots of concentration, I nailed it. But when I put the hole jewel on top, it was too much oil and it squoze out everywhere. It didn't spread on the cap jewel much thanks to the epliame I'd applied, so it was more than it looked like from the top. Back in the cleaner, dried, re-epilamed, dried. Time for a second try, but now I was more shaky even than the first time. "This is a bad idea," my brain told me. "Take a hike, brain," I said as I watched the oiler jiggle into my microscope's frame. And just like that, the jewel was a tiddlywink and flew out of sight in the blink of an eye. With a strong UV flashlight and the waste of a lot of time I did find it on my desk, but that's some stress I didn't need in my day. So friends, listen to your body, and listen to your brain when it tells you now's not the time for precision work.1 point

-

Hi @WpgRob and welcome to the forum. for YOU, your approach works just great. It is regulated to YOU and YOUR wearing pattern. Perfect. "Regulated to 5 postions" or so would, however, imply that you can give the watch to someone else with a different wearing pattern (e.g. you walk all day whereas the other person sits at his desk all day; at night, you put your watch dial up whereas the other person puts it crown up) -- and it would still run at equal rate/precision. Regulating the average rate with the regulator lever is easy. But regulating across positions, particularly across vertical positions, is much harder (incl balance wheel poising..).1 point

-

From my own experience I’d say avoid these £100 sets. I got one, with steel arbors, and have had very little success. I’ve since bought a 5,6 and 7 Bergeon and have done much better. You won’t need the full 34 piece Bergeon set, and even with that there will still be some anomalies that won’t work (eg a small barrel that needs a larger winding arbor) My tips therefore are: Avoid Chinese sets Get a few Bergeon if you want to have a go Hand wind Replace - Cousins mainspring search function is excellent.1 point

-

1 point

-

Yes, the balance staff length, pivot shoulders and pivot sizes will be different Tom1 point

-

One of the problems with a lot of the videos are they really don't know what they're doing. Typically at the end of the service the put the watch on the timing machine often waiting into the watches fully cased up. As opposed to checking the movement when it's running before it's all cased up. In other words if you're going to have a problem it's nice to bill the work on the dial side without them being there for instance. Then when it is placed on timing machine the only place it in one position they comment how wonderful the numbers look and that really isn't adequate. But typically on those YouTube channels no one notices all the other strange and bizarre things they are doing either.1 point

-

Cuare’s reply covers the Chinese winder set and their capabilities very well. An alternative to getting calibre specific sets like these is to slowly build a set of quality Swiss winders. They are sold individually, so you could buy a Bergeon handle and the 2 correct diameter and wind direction winders you need now initially, and buy the other sizes as you need them over time. If you come across a movement you lack a winder for and feel you won’t likely use that size winder often, then just buy a replacement mainspring, because they come already wound and ready to be pressed into the barrel You can usually sidestep the need for having both left and right winders in each size by reversing the wind of the spring as follows - wind the spring into a slightly undersized winder, push it out into the correct size winder to suit your mainspring barrel (thereby reversing its direction), and finally press it out into the mainspring barrel. Best Regards, Mark1 point

-

Hi, They are calibre specific, BUT you can use them on other calibres if the arbour and barrel size are similar and the hand is the correct way, Eg: left or right hand wound. I have a similar set. The one labeled "8200" I use on most Seiko's but not all, I have done Seiko 7005 7009 7019 7S26 with success. Being cheaper you can modify them to suit, eg drilling out the centre hole so a larger winding arbour will fit in a different barrel etc. They are not as easy to use as you see on the Youtube videos, some will escape during the process, I still hand wind manual movements but I use mine for automatic movement. See attached file which will shed some light on what winders have which arbours L/H or R/H and barrel sizes. Your Welcome CJ HJ-Mainspring-Winders.pdf1 point

-

Hi Nevenbekriev, Thanks for your reply. I’m a hobbyist and my understanding of escapement theory is incomplete and rudimentary. But I do understand that preparation is necessary before static or dynamic poising can begin, such as cleaning, polishing pivots and pinions, properly oiling, adjusting the regulator pins, setting it in beat, ensuring the outer coil is concentric and regulator pins are ok. To adjust a cheap unadjusted movement to a state of “adjusted to 5 positions,” I think the success would depend on the movement. With a Timex pin pallet escapement it probably can’t be done, however with polished pivots in jewel settings, a Breguet overcoil, a beat adjust and proper oiling, dynamic poising of an unadjusted watch could have some benefit. There seem to be a few “sleeper” movements out there, i.e. a good movement that was cheapened and cased in base metal to compete. Bulova did this with their Caravelles. Conversely, there are some jewelled watches out there with pin pallets; and the Chinese picked up very good Swiss tooling but the product QC is hit or miss. I suspect some of those unadjusted movements could be improved, while a Timex probably can’t, much. interesting topic!1 point

-

Finally got back to this project. Lighter fluid was the winner here. As soon as I dipped the spring into it, the turns separated like magic. Dried it up and the balance spring now looks perfect so it seems it was a residue of some sort either from the B dip or the crud it was trying to remove. I'll use what B dip I have left on jewels since I haven't had a problem on those yet, but I think once it's gone I won't be using it again and will stick to good old wholesome solvents.1 point

-

I'm a teetotaler. Many members of my family are alcohol intolerant. When I was a baby, my parents gave me a teaspoon of Woodwards Gripe Water and I turned cherry red and passed out for a day. They rushed me to the doctor the next morning and he had a good laugh. Those were the days when baby formulations contained alcohol. I remember watching a darts competition where one of the contestants said that a certain level of alcohol is needed to calm the nerves and stop the shakes. I wonder if that works in watchmaking.1 point

-

I've never touched my life without alcohol . I'm your complete opposite Ross1 point

-

Radium is very dangerous if it gets into your body. This can happen by ingestion, inhalation or contact with broken skin. Radium lume dust is more mobile than flakes, and therefore more likely to find its way into the body unless the right precautions are taken. The greater the dose of radium absorbed into the body, the more danger it poses, whether it’s in the form of dust or flakes makes no difference once it’s inside you. The radium present on a watch dial won’t kill you outright. Once absorbed, it is chemically very similar to calcium, and the body treats it like calcium and stores it in your bones. From there within your body, it’s alpha particle radiation plays havoc with nearby cells’ DNA, causing mutations as cells divide. The end result is often cancer. Some watch brands used radium into the 1970s, so if you are working on watches with lume that were made before 1980, you should assume that the lume contains radium unless you’ve proven otherwise with a Geiger counter. Geiger counters are now cheap enough that anyone working with vintage watches would be wise to buy one and learn how to use it. The absorption of a tiny quantity of radium can potentially have life changing impacts upon your health. Best Regards, Mark1 point

-

Hello to you all! I'm a jewellery maker and I volunteer for a local charity shop - taking care of all their jewellery donations. They get a lot of watches too, so I started changing quartz watch batteries and once the back was open I just had to go further... I'm gaining a new skill and the charity is gaining more income - win-win! I'm still an absolute beginner and haven't learnt all the terms yet, but I've already seen that this will be a fantastic place to pick up tips and learn new things. The shop gets everything, from modern ten-a-penny to beautiful high quality vintage/antique watches, so I'll be looking to learn on the expendables before I move onto the good stuff. Looking forward to learning and share as I can. Thanks, in advance! Zelda1 point

-

1 point

-

Cool when your done with you mentor you can give HIM away to me1 point

-

I dont have any personal friends who are watch nerds so I have to share my joy with y'all If you saw my other thread I had bought a Elgin Sportsman to start learning on after getting fairly proficient with my practice movement. I ended up stripping out some threads in the main plate and abandoning that project. I was able to clean it and get it running again so I learned a ton. Next up, a Gruen Precision that I got off ebay. This project took forever and after realizing the balance was no good and buying a donor movement I was able to get it back in working order. I dont have a time grapher yet but I've been wearing it for 2 days and its keeping pretty dang good time! - Disassembled, cleaned and reassembled / lubed the entire movement. - Pressed in a new crystal - Replaced the strap - Replaced the crown (the old crown was just destroyed) One thing that really killed me was that I scratched the dial with my hand levers. I was just rushing because I was frustrated (had to take the hands off a few extra times because they weren't flat) lesson learned. Next up is a Seiko that I also got on ebay. This will be my first automatic, and my first date complication. Super excited and so glad I found this hobby!1 point

-

I think the lume may of been added by a tinkerer, it looks a bit sloppy.1 point

-

The problem is that this movements were not produced with the modern level of standartization, there for parts from one didn't fit well to another, even if they may look the same. May be it doesn't concern the winding stems, but yet there are not spare parts for such movements in supply companies, not even clear calibre identification possible. And where calibre identification is possible, there are no Ronda numbers for the balance staff or the winding stem for this calibers in the data bases.1 point

-

The movement is FHF, something like this. But it will not help much to find stem. Sometimes making one is easier1 point

-

Hi @Roll1ex, welcome to the forum. It's considered good practice to introduce yourself to the forum in this thread: https://www.watchrepairtalk.com/forum/23-introduce-yourself-here/ But no worries. I don't have the spec sheet for the 15xx movements, but when I look at the 31xx information, it stands out that the endshake of the rotor should be between 0.01 and 0.03mm. That is LESS than the pallet fork and the lowest of all endshakes in the movement. Not exactly sure what you mean by that. The rotor itself is a unique part which doesn't have different heights. If you mean the height at which it is installed vis-a-vis the automatic bridge, then yes, that can be adjusted a bit via the two jewels that hold the rotor axle. Height differences vis-a-vis the bridge can also be caused by the strength with which the new axle is hammered/riveted into the rotor. And yes, that can be compensated a bit via the jewels. This would probably indicate that the axle isn't perfectly perpendicular to the rotor. That could explain why the weight is closer to the rest of the movement at 9 o'clock -- it would then be furthest at 3 o'clock. That would be bad news. A new axle should then be installed... and properly this time. As I wrote already, there is margin for adjustment via the jewels. As for the spring clip, the 15xx movements only seems to have one spring clip thickness (part 7911 - https://www.cousinsuk.com/PDF/categories/2878_Rolex 1530 Pages 6-10.pdf). The later 31xx movments have several versions with different thicknesses. But there is a good chance that the clip is worn (=thinner than it should) and should then be replaced. But, in conclusion, if the rotor hits the caseback in one particular postion, then my first suspicion is that the axle wasn't punched in at a perfect 90° angle. That must first be re-done correctly. No other fixes will be solving that problem. Furthermore, if the rotor "dings" against the caseback when the watch is shaken (but not in other situations), then there is likely also an issue of endshake (more an issue of the jewels) or lateral play (more likely the sping clip). PS: by whom? Independent or RSC?1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)