Leaderboard

Popular Content

Showing content with the highest reputation on 05/28/24 in Posts

-

...but not too hard like me on a first attempt (see the crack?) : Mind you, getting a full replacement rotor in NOS condition (you don't want to buy a used one with already worn axle) will set you back several hundred dollars. PS: here is a nice video on the rotor axle replacement. As @Jon said, it's definitely doable. I was just stupid..3 points

-

2 points

-

Hahaha, true! I agree. Yes. Put a thin sheet of transparent plastic film on top of it and work "through it". It'll make it a lot easier and you won't loose the spring. Start with one leg, then position the second leg at the widest part of the circle/chaton to slip it in. Then slide back the two legs to insert the head.2 points

-

1 point

-

Out of curiosity I don't suppose you want to share the prices? Yes it would be cheaper to get a Chinese clone but this is not a Chinese clone this is a Swiss 6498 and the last time I looked brand-new movements are extremely expensive. I see the answer has materialized before I Finished this I'm still curious genuine Swiss because as I said the last time I looked they were rather expensive. Although taken a quick look at eBay it looks I can get a movement For approximately $130. Otherwise I'm seeing silly prices starting at $400. This is the unfortunate problem of anything that is well watch repair Somebody in there before you that didn't grasp what they were doing and now you have to pick up the pieces. It seems be unfortunately the world of the watch the more pieces of the stuff you have to deal with. I suppose it's a miracle that in the watch runs at all. On the other hand the number of amateur parts destroyers of watches versus the quality of watches well that's probably a good thing that there only a tiny percentage of1 point

-

New movement. I have told him that it will be an old watch but a new movement. He is happy with that.1 point

-

Yes thats possible, that pivot could well have more friction when sat in the dimple, might be enough to stop the balance. If the dimple is deep enough and the staff pivot has worn down as well, which it most probably has then the staff could end up riding on the underneath of the balance jewel at it's shoulder height and stop the oscillations. When the spring is removed it is only held at one point , at the collet on the staff, in this situation the spring is free to take on it's own natural shape. When fitted to the movement the spring is then held at 2 points, the collet and the stud, 3 if you include the regulating pins. In that situation the spring is being pulled from its natural shape if the 3 points are not correctly adjusted to match the spring's shape, usually just at the stud can bring things into alignment. Bunching up of the coils more often makes the spring oscillate faster, in effect taking the active timing point from the regulating pins to the bunched up coils , closest to the collet.1 point

-

Hi Arron. Disclaimer: I am a hobbyist and not a watch repair professional, so take my advice for what it's worth. 1. I would say no. At worst it could lower the amplitude some. 2. It does from the top, but from the side it looks all wrong. It looks to me like it would foul the rest of the hairspring and cause it to stop oscillating. The Breguet overcoil should sit roughly parallel to the rest of the coils but on a higher plane. Yours looks bent in the opposite direction. 3. If the balance spring is bent near the stud it could push the whole spring off-center once the balance staff is in its jewels. 4. Unless it was very severe, then no.1 point

-

Ok, good luck with the repair! We are all jealous if you received the machines originally as gifts... Sorry about the steep price of the replacement part. You will also find that the glass jars with the embossed L&R logo fetch a pretty price as well. However, the very first L&R jars didn't have that detail but had the manufacturer mark of "5371" on the bottom and these have the same lid threads and squared-off bases. They sell for less but are still "original" and if you can find them they will fit the same lids and wall wave breakers while more securely sitting in the machine base than some of the modern replacement jars that have been suggested.1 point

-

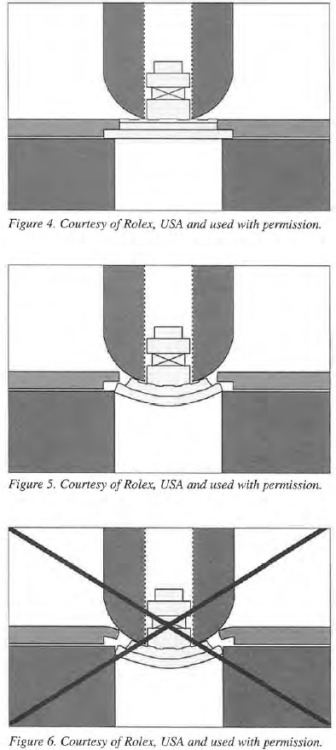

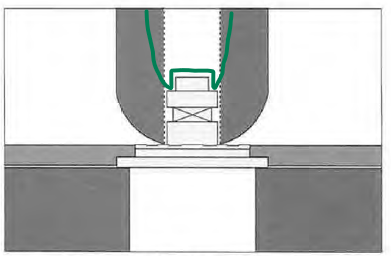

Yes, I have the set of punches and they are 4.6mm. And my staking tool (Boley) has the standard 4.7mm. It does, unfortunately, produce a little bit of play... in my attempt to use it, I wrapped a layer of aluminum foil around the stake to reduce the play. I think that worked ok (I failed for other reasons). A professional (Rolex trained) watchmaker told me that I don't need to worry about the play because it would somehow not matter when you actually hit the stake (with the axle and rotor flat on the anvil.... but I wasn't convinced. There are specific punches for each calibre. I doubt that they are interchangeable. This is indeed meant to be done that way. In my case, no damage was caused at that stage. I don't think you need plastic protection. The attached (as PDF file) article from the Horological Times is brilliant and goes into a lot of detail, see pages 10-14: 2009-03-web.pdf One screenshot from the article is below. NOTE: If you don't have a punch that fits as perfectly as shown in the picture above (and if you want to reduce the risk of hammering too hard and consequently hitting the rotor with the punch as the axle breaks away), you can use a punch that just fits over the top of the axle like drawn in green in the picture below.1 point

-

Lol yeah not a great movement then. I think the arbor is pressed onto the lid on those. I seem to remember quite a big clumsy looking thing and awkward to get in position. So maybe the arbor hook is not catching the mainspring eye deeply enough, other shocks might also cause a release . Lol you are funny Rich, not quite a Basil Rathbone fan then.1 point

-

Thanks for all the input. I too thought that a slip between the winding and sliding pinion would not cause the mainspring to release its power. Here is my hypothesis as to what is going on: The watch has an EB 8800 movement (pin pallet - no pallet stones) where the barrel lid doubles as the barrel arbour. When the winding pinion slips a shock of pressure goes through the crown wheel and is transferred to the ratchet wheel. This shock lifts the lid of the barrel and that causes the mainspring to slip inside the barrel (possibly at the hook end) No more slips from the winding pinion and the problem has gone1 point

-

1 point

-

Something I've never thought about before, yes we give the watch it's power by winding up a manual watch but the real initial transfer of energy comes from us . Energy released from our fingers using muscle tension to overcome the resistance of the mainspring to coil up. So we are in effect transferring our energy to our watches. Now there's a wierd thought, if only that tranfer of energy could be measured from our phyical loss of it to the gained energy of the coiled mainspring, thermal energy to kinetic energy Stress on the bearings though, i wouldn't want to try that.1 point

-

Yes, I don't understand either. I can only think the winding it by the ratchet wheel force is being applied at an angle and holding whatever us slipping in place.1 point

-

the two points of energy release would be the click and the pallet stones, providing the barrel and train is in good order and transferring that energy between those two points. If nothing can be seen to be visually unwinding within the train then you would suspect it's something hidden within the barrel. I do find it hard to understand that colin managed to fully wind-up the mainspring using tweezers on the teeth of the ratchet wheel that is some hellish tension to hold on. If i had to guess it would be either the bridle slippling off the barrel wall ledge at a set point of tension or the arbor hook disengaging from the mainspring. The ledge/ bridle lip has worn or the inner coil of the mainspring is not tight enough around the barrel arbor. Can't be the winding pinion teeth as the energy is provided but not locked here .1 point

-

I had a similar thing on a Citizen, turned out that one of the jewels on the pallet fork was tipped up ever so slightly, so it would hold the wind most of the time, but then (apparently at random it seemed) the escape wheel would slip over/under the stone and the watch would rapidly unwind. Just a thought1 point

-

A worn winding pinion wouldn't release the power, as the click is holding the crown wheel.1 point

-

Guys, thanks for your help! According to the advice of a colleague @nevenbekriev, I managed to straighten the spring. Surprisingly, it turned out completely flat. Like new. And the watch after that, for the first time since it was with me, started running late. That's great news!!! The rotation of the weights is about 190/200 degrees. In the past 12 hours, it was 4 minutes late. I still have enough room to speed it up. Looks like everything will be OK. Thank you very much for your help!1 point

-

No hex wrench needed there. Screw driver in case of AS1475 or just push the poinst down in case of Poljot2612.1 point

-

Well, what is written here can't be explained with the wear of the winding/sliding pinion. Probably it is some kind of delusion from You side. But it prevented the people from pointing the reason of what is happening. Otherwice, this kind of wear is one of the common problems of winding works in watch movements. It meets often in old or cheap movements, or particulary in negative stem system pocket movements where not proper adjustment of the sleeve that guides the stem is done.1 point

-

Watch this video. Alex demonstrates the procedure very well. I also recommend oiling through the jewel hole.1 point

-

Unitas Was the original Swiss manufacturer now of course it's made by Swatch group or specifically ETA. I have a link to their website and while I was there I downloaded the tech sheet for you which I'm attaching. Oh and as this is the newest version of the tech sheet it of course has the etachron regulation system which Yours being the older version does not but otherwise everything else is exactly the same. https://shopb2b.eta.ch/en/6498-1-6498-1-5.html Nice that you're the first one that's there it's always bad with other people been there before you as they can get very creative with things that will cause problems. Then don't think of this is a pocket watch think of it as a large wristwatch because that's basically what it is. It's why it's the classic choice for training watch repair. Although usually for training and watch repair we recommend purchasing the clone eight by the Chinese as it's considerably cheaper than the Swiss version that you have. But otherwise this is basically just a really large wristwatch very nicely made and they typically run very very well. ct_6498-1_fde_482382_10.pdf1 point

-

A few comments based on your queries: - Reversing during use is a normal function meant to improve cleaning and shouldn't hurt anything. When the field reverses it functions as an electrical dampening brake until the rotation stops and then starts the spin in the opposite direction. Of course, it would only be recommended to be reversing at the relatively slow speeds you'd be using with a loaded basked submerged in cleaning fluids. - Those rings aren't part of the L&R equipment, but you may find them useful. They are shims that are used to hold a crystal while you pick it up with a crystal lift, and a set of these accommodates many different fixed diameters (in mm) as listed on the rings. - You should attempt to find the resistance rating (in ohms) of that rheostat, either through careful examination for more markings, perusing old manufacturer information or by direct measurement from front to back contacts along the full slider track (if the resistance coil is intact). You don't have to get one that is exactly the same, and you can add a fixed power resistor in series to help adjust the "fit" if you can't dial in the sweet spot for operation, but attempting to match the original values is best. You do need to have a wattage rating of the same or higher so the speed control can handle the amount of heat that must be dissipated during use. - There are a number of very useful threads here in the WRT forums dealing with L&R repairs, and this has included discussions of rheostat speed controls as well as electrical schematics for many models, so you should do some searching and you may find the info you need. While repairing an L&R open frame Junior I was able to source a 50 watt 800 ohm rheostat from Surplus Sales of Nebraska (their item number RWA-A-29418-5). It is now listed as sold out, but next to that listing on their page is one with a slightly larger body rated at 75 watt 750 ohm which might work for you, or you may be able to find something else on their site: https://www.surplussales.com/Potentiometers/Rheostats/PotsRheost-3.html I just returned from an international trip but sometime in the next day or so I'll also go look at my other L&R machines and spare parts bin to see if I have any Rex rheostats to check out, in case yours is broken or shorted out.1 point

-

Thank you Richard. Not sure why it does not run. Maybe old oil? It has never been opened before. I am the first. The balance moved OK. The pallet fork moved side to side OK. However, although the watch accepted a wind, the train did not move. All of the pivots and wheels appear correct. No damage. I have noted that the jewels and pivots are completely dry. There appears to have been no lubrication at all. No wear on any jewel or hole. Maybe it stopped because of that. I hope so. Possible the owner di not do anything when it first stopped. As I said, virgin interior. I am using brass tweezer to make sure there is no scratches, and am being extra careful with screw removal. No scratches or deformity as of yet. Want to keep it that way on assembly. Already pegged. Tomorrow I will do a full clean and be ready to begin the reassembly. So looking forward to this.1 point

-

Hi Rich, Yes, You can polish the arbor pivots and the barrel holes, but it will be beter to burnish them. The normal reason one will do it is if there is bad surface by the manufaturing or signs of degrdation of the surface due butting from no lubrication or hard particles for example, and it is done to prevent the bearings from fast wear when working in such state of surfaces. Othervice, do not expect significant change in amplitude because of the polishing. This is what I think, but You can try before/after with no change in other conditions and make own conclusions.1 point

-

Alex has a video showing how he polishes the barrel holes and arbor.1 point

-

Your varying lines look weird I'm used to seeing normal graphical display versus whatever this is showing? Then it be interesting to see your timing 24 hours later that will really give you a clue as to whether you need servicing or not. A lot of watches even vintage pocket watches you can wind them up tight Then they will look pretty good on the timing machine but 24 hours later they'll totally crash and burn. Fortunately the Rolex is sealed up you don't have a presentation back. Because rotors with worn and/or broken axles can actually Rob on the plates and not good at all. Shouldn't affect the running of the watch but visually it won't be as pretty as it used to be. I needed to go find the timing specifications and your slightly out of beat. You can have a maximum of 0.8 ms in any of the positions. Then the clue to servicing would be 24 hours where you have to have a minimum of 200° in any of the crown positions.1 point

-

I don't usually do it but I just burnished and polished a barrel arbor a couple of weeks ago. The upper arbor was rusted and pitted, so it was a necessary job. I chucked it in the lathe and used the rough side of the pivot polisher first, then the smooth side. And finally polished it with autosol on a wooden popsicle stick. It still had some deep pits but that was all I dared to polish. I also used a smooth broach to smoothen the barrel cap hole before polishing it with a bamboo toothpick.1 point

-

The rotor replacement is really easy. It's like anything, if it hasn't been done before, it holds a little fear. This Horotec set of punches will do all the rotor sizes https://www.cousinsuk.com/product/oscillating-rotor-weight-axle-punches?code=R15264 The old axles gets staked out and the new one rivetted into place. The trick is to be deliberate in hitting the punch completely upright on the axle and hit it really quite hard .1 point

-

1 point

-

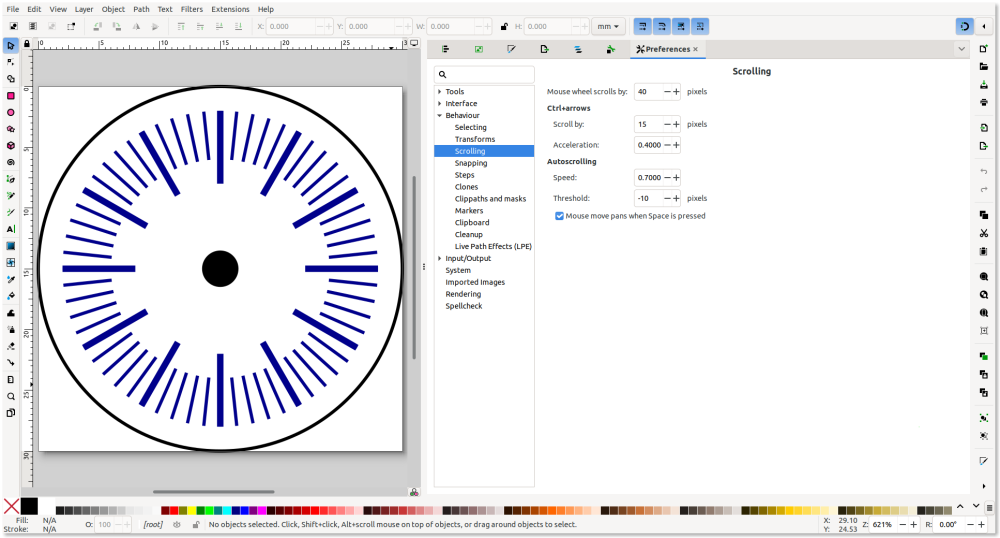

I feel I should call this post "Artificial Intelligence creates a watch dial." I present possibly the worlds first AI generated python code to produce an SVG graphic for a 30mm watch dial. First... I went to ChatGPT and asked it the following question. It responded with the following code... def generate_svg_watch_dial_with_markers(diameter, num_minutes_markers, num_hours_markers, hole_radius): svg_content = f'<svg width="{diameter}mm" height="{diameter}mm" xmlns="http://www.w3.org/2000/svg">\n' # Draw white circle for watch dial svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{diameter/2}mm" fill="white" stroke="black" stroke-width="1"/>\n' # Draw markers for minutes for i in range(num_minutes_markers): angle = i * (360 / num_minutes_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 6) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 6) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:1"/>\n' # Draw markers for hours for i in range(num_hours_markers): angle = i * (360 / num_hours_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 8) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 8) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:2"/>\n' # Draw solid black circle in the center svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{hole_radius}mm" fill="black"/>\n' svg_content += '</svg>' return svg_content import math # Diameter of watch dial in mm DIAMETER_MM = 30 # Number of minute and hour markers NUM_MINUTES_MARKERS = 60 NUM_HOURS_MARKERS = 12 # Radius of hole in the center in mm HOLE_RADIUS_MM = 1.5 svg_code = generate_svg_watch_dial_with_markers(DIAMETER_MM, NUM_MINUTES_MARKERS, NUM_HOURS_MARKERS, HOLE_RADIUS_MM) print(svg_code) I saved this as 30mmWatchDial.py Next a ran the code (using python of course). python 30mmWatchDial.py >30mmWatchDial.svg ... and here is the result displayed in Inkscape. Here is a png of the .svg .. and the .svg saved as a .svg.rtf is attached to the bottom of this post. Save it as .svg and you can open it in Inkscape. Some things to bear in mind when playing with this idea. The free version of ChatGPT can only write short snippets of code, so don't try to get too fancy or you will get incomplete results. Image generating AI will produce arguably more interesting watch dials, like the one below, but they wont be in SVG format. ChatGPT is available here -> https://chat.openai.com/ DeepAI image generator is here -> https://deepai.org/machine-learning-model/text2img Have fun. 30mmWatchDial.svg.rtf Just for fun, here is another AI generated watch. Spooky stuff.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)