Leaderboard

Popular Content

Showing content with the highest reputation on 06/04/24 in Posts

-

9 points

-

4 points

-

Alcohol is a polar solvent, which isn't very good for cleaning grease. Benzine (lighter fluid), hexane etc. are non-polar solvents and are far better for grease. Essence Renata is heptane, which is also non-polar.4 points

-

A lot of these companies will not guarantee work on old watches. Don't get out what one just tells you. If you are able to remove the back and take some photos of the movement and the dial it will be easier for us to advise you. Nearly forgot. Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.3 points

-

I switched to naptha a while back for that very reason, i only use alcohols for rinses now.3 points

-

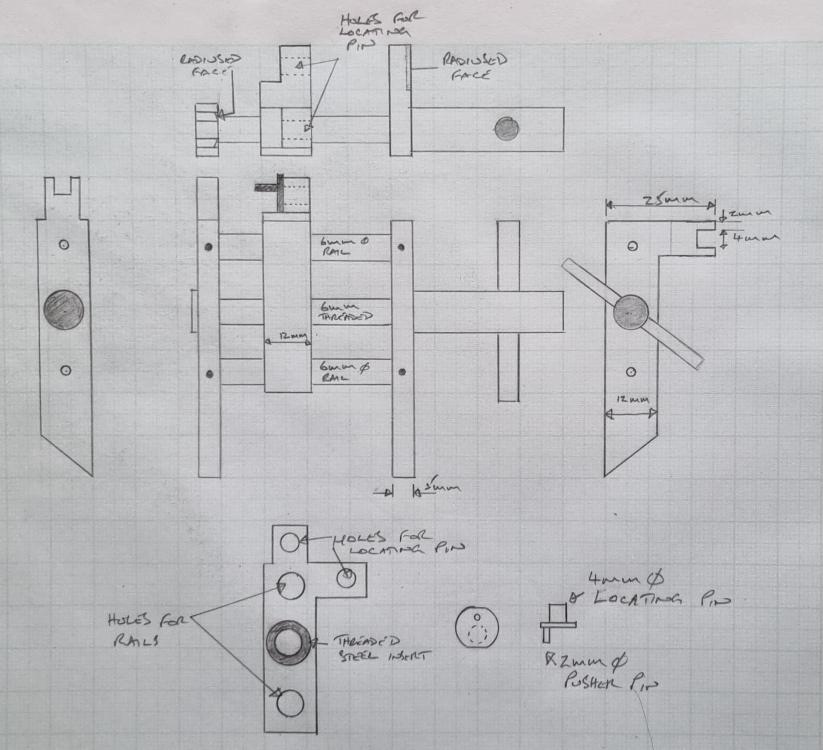

leave it with me, I'll see what I can do As promised I think I've included the most relevant dimensions but the paper is 1mm squared and the drawing is 1:1 so most of the information is there just by counting squares, but let me know if you need more detail. I have omitted the base for clarity. The frame is some aluminium alloy but the two guide rails, the threaded bolt, the threaded insert for the bolt, and the pusher plate are all steel. The pusher plate can be installed in either of two locations depending on whether you're installing or removing. Important to note that it has flats on it to lock its orientation to the frame. Also that the axes of the pusher and locating pins are different. Hopefully the drawing and the photos in my earlier post will give you all the info that you need. Have fun2 points

-

Acetone is a pretty good solvent degreaser for metal parts, and is rather safer than either naphtha or benzine, as small amounts are naturally produced and metabolised in the body. Just keep it away from most plastics & finishes! (OSHA limits for a eight hour exposure: Acetone 1000ppm, Heptane 500ppm, Benzine/Light naphtha 350ppm, Naphtha 100ppm). Naphtha (the 100ppm one) can contain trace amounts of Benzene, which is a carcinogen. [I used the US standards as Naphtha is not generally listed in the UK documents & I wanted all data from the same source].2 points

-

The joke is that I actually have a fully licensed AutoCad 2023 installation on my work computer which I use on an almost daily basis. Sometimes though it's just nice to break out the pencil an paper, and to remind the technology that I'm not as dependent upon it as the world of tech likes to think.....1 point

-

I have ordered an 8n24 from a Chinese supplier on Amazon. It looks like a genuine part. I will update when it arrives and I have fitted it. Many thanks too all who have helped me with this1 point

-

1 point

-

1 point

-

'Gun metal' in watches has nothing to do with the metal for guns. It is about the oxidation finish, which was the same as in weapons made of steel. Actually, this is the cheapest type of watch cases, as they were made of regular iron sheets, but they got popular and modern at the time, as were good looking. There are alot expencive watch makes that used gun metal cases along with the silver and gold ones.1 point

-

I have a very similar one (also Cousins, also German, but 0.6 to 2.0mm). I'm happy with it and I once did a decent job (I think! time will tell..) on a barrel bridge to reduce sideshake of the barrel. Sure, if you are an extreme perfectionist, you could argue that holes get better=straighter by having smoothing broaches with the least possible taper. That means, to have many! But really, for Seikos you will be fine with that set from Cousins. PS: have fun! It can be quite a bit of back and forth until you get the right hole size. Take it slow and don't get frustrated. But when you do get it right, it's a great feeling. OH, a tip!! What I did to help me get the hole size right was to measure the barrel arbor (at the respective position for barrel or bridge) and then use a sharpie to draw a line on the smoothing broach where it had the correct width. That saved me a lot of time.1 point

-

That is definitely a possibility. Even with a proper timegrapher, you sometimes need to adjust the "gain" settings to get a proper reading depending on the thickness of a case. Still, I wouldn't rule out magnetism. Also sounds plausible to me. The Chinese blue demagnetisers are cheap and worth getting (IMHO).1 point

-

I think the metal cap for want of a better word is soft iron to protect from magnetism. It is also the only thing holding the movement in the case.1 point

-

Yes, gum netal, which actually means iron. It is thick enough to be grinded in order to remove the rust pits and then polished, but it will need blackening oxidation in the end for protection from getting rusty. The watch has nothing to do with the railways, it is the same like the 'squirrel' candys - You do not really expect to find a squirrel inside...1 point

-

OK, sometimes it really happens without problems at all. You can take a covex oilve 120/12 stone from Molnija 3602.1 point

-

1 point

-

The back when new would have been the same colour as the rest of the case as you can see very dark gun metal is a very dark blue/black and would not be shiny. So unless the owner intends to match it how it would have been when new which I don't think it can. It should be left as it is.1 point

-

Naphtha covers a number of different hydrocarbons, including what is commonly called lighter fluid, aka benzine, and then some seemingly more nasty ones. Some talk with CAS numbers in this thread: I'm quite sure the naphtha I got in that post was the bad stuff, definitely not something you want to be around much.1 point

-

I also find the red oiler in this set the most versatile size, but for cap jewels, I’ve found that the finer, Bergeon ergonomic oiler, 7013-N, gives me greater control over the amount of oil I’m depositing and gives me a more consistent drop size. The yellow oiler is great for use as a probe - nudging pivots into place etc. I’m about to file one down into a tiny tool to move the collet in adjusting beat. Very handy, just too chunky to use as an oiler.1 point

-

Yes all broaches are tapered, without the tapered length they would not broach evenly and the tapering does vary. Minimum to maximum broaching out sizes are quoted per broach.1 point

-

It was already mentioned in many mainspring threads here : There is an optimum length/thickness that gives the maximum run time. The mainspring will occupy half of the inside barrel space then. Longer or shorter (same thickness of course) will need more than or less than half barrel space: less run time! Frank1 point

-

I would have assumed that a longer spring (within reason) would have provided a longer run-time. It would be interesting if you (or someone else) could elaborate a bit about that. I'm intrigued. Or, perhaps a joke that I don't get1 point

-

You might want to look for "thickness gauges". They are used for measuring things like paper or leather etc. They are spring loaded like the feintaster. If you file a small section out of one of the anvils, you can measure balance staffs the same way as you can with a feintaster. They are cheap as well (found these for €10..).1 point

-

Correct but we only see at X1 magnification. Not visible to the human eye.1 point

-

I also use autosol rich, cases definitely, as with all polishes it does abrade surfaces. At x10 fairly noticable Polinum and Polinoxx are the finest finish I've come across up to now, brilliant stuff1 point

-

Whatever method or level you decide to take it too, can I suggest when you get there you put 3-4 thin coats of renaissance wax on it and buff it well. This will give a good protection against finger marks and oxidising in the future. Tom1 point

-

That looks familiar! I was recently given one with a very similar state case - but yours is not as bad as mine! I was advised the one I have had a gunmetal case and was supposed to have a blued finish - the inside back cover, the blue-black, is what the outside should be. To see if it is gunmetal or pewter, see if a magnet is attracted when near it, but I'd remove the movement first and demagnetise afterwards. This is the one I did, as much an experiment as a definite solution; just don't use the boiling part, as this did not do anything useful other than wreck the old pan I used. The cracks in an enamelled dial can apparently be made invisible with denture cleaner, though I've not tried that myself.1 point

-

Buckle before polishing Buckle after polishing I don't think I've ever heard of or seen anyone polish a buckle, but I thought "Why not?". This time I kept a high speed on the mop and applied only a light pressure against the metal surface with the engraving "Mondaine". I did this to avoid rounding off the engraving and I'm pretty sure it helped. A high speed on the mop creates significantly more heat in less time so you have to be careful not to burn your fingertips. I am still looking for good protection for my fingers. The pin for the buckle was way too small to hold with my fingers so I clamped it in a vice. It's a bit scary if such a small and hard piece of metal flies away when the wheel spins at 7500 rpm (over 125 rounds per second) so not without safety glasses which should be used regardless. It could be that the original polish on the buckle was satin-brushed and I have a couple of mops for that too. It's easier to satin brush because you don't need to use any polishing compound, but it's nice when it shines1 point

-

I got it off ali, link below, it's listed as 7 day delivery to the UK, it took six, it was tracked all the way, the shipping company must have been on steroids. https://www.aliexpress.com/item/1005005679514184.html?spm=a2g0o.detail.pcDetailBottomMoreOtherSeller.12.145a5455x35xN6&gps-id=pcDetailBottomMoreOtherSeller&scm=1007.40050.354490.0&scm_id=1007.40050.354490.0&scm-url=1007.40050.354490.0&pvid=1ab7382b-111a-4cd4-abab-9bf54c20c43e&_t=gps-id:pcDetailBottomMoreOtherSeller,scm-url:1007.40050.354490.0,pvid:1ab7382b-111a-4cd4-abab-9bf54c20c43e,tpp_buckets:668%232846%238114%231999&pdp_npi=4%40dis!GBP!24.03!22.79!!!29.76!28.22!%402103890117174285697985147edb92!12000033989266123!rec!UK!162015786!&utparam-url=scene%3ApcDetailBottomMoreOtherSeller|query_from%3A1 point

-

Small screws and springs always get hand washed in a weighing bottle with a little agitation from a fine artist's brush. (Seeing as I am a professional artist, I got loads of old brushes about, so there's that.) Only those super heavy yoke springs that look like they came off the suspension of a '53 Ford go in the basket.1 point

-

Interesting observation. I generally use Essence Renata or washing benzine, i.e. solvents similar to lighter fluid for any manual cleaning tasks. I'm happy with it.1 point

-

Update. Clock is assembled and running like a champ! Previous clockmaker replace the convex glass with a flat glass. LOL It did not allow the bezel to close. Yesterday, I was driving home from Bryan Tx and passed through the little town of Kyle. The wife was driving so I was on FB marketplace. Up popped a little Smiths-Enfield clock for 20 bucks. It was on my way, so I got it. Next day, I stole the convex glass from it and put it on my ST 124. The donor's dilemma!!1 point

-

My personal preference is to use the finest one (red in your set) for 99.9% of what I do. I can always add more oil if necessary, but it's harder to remove too much. I use the largest oiler to transfer lubricants from their bottles into my oil cups.1 point

-

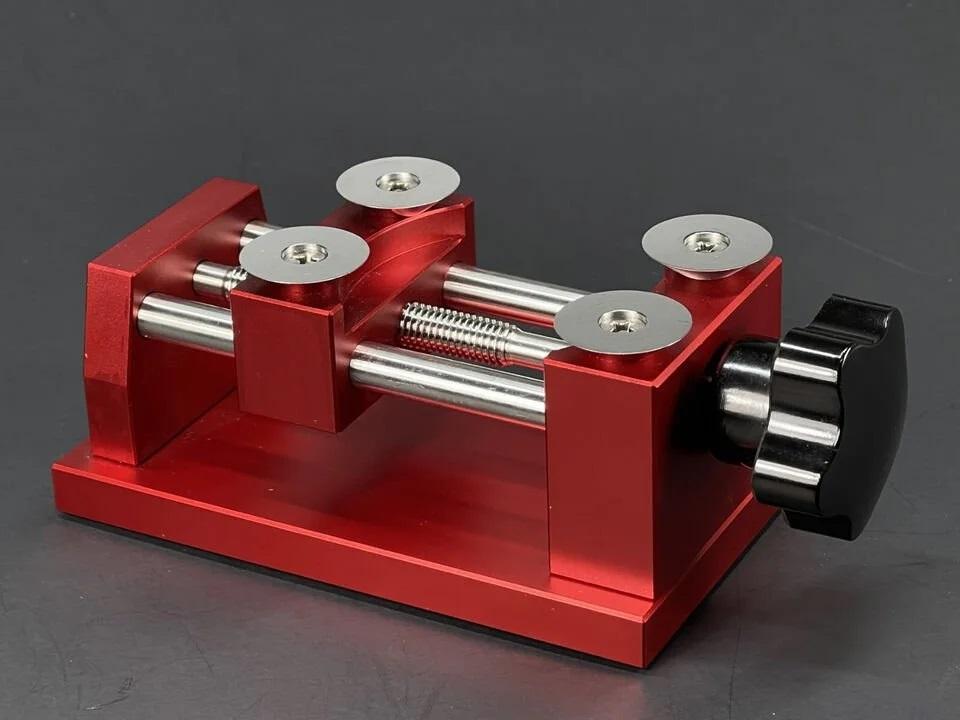

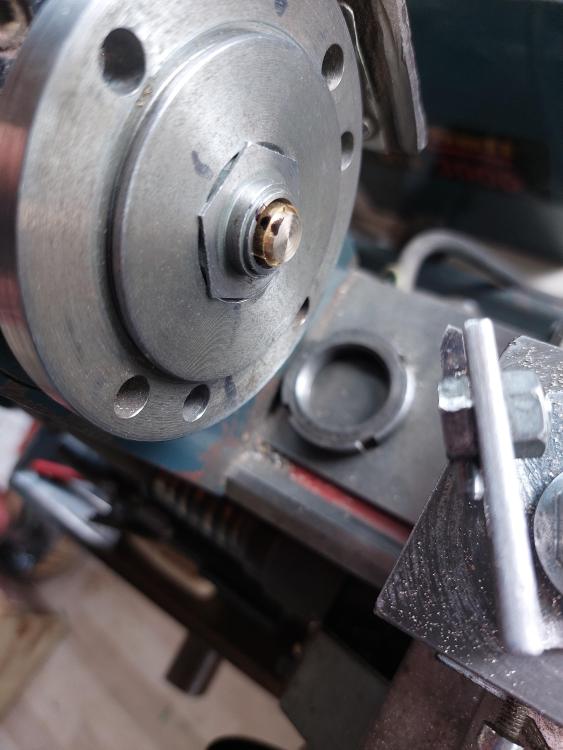

An update to my post above, i got this type of bezel remover yesterday, absolutely perfect, the build quality is very good, no slop or play, perfectly aligned, no manufacturing defects, i've tried it on a couple bezels and it just works how it should, it's a solid bit of kit, i'm more than impressed. The scores on the door say it's a 10 out of 10 from me. What a difference in build quality from the first bezel remover i got, i slagged the first bezel remover off as chinese junk but this one makes up for it.1 point

-

I remembered that when Lititz Watch Technicum's YouTube channel existed, they had a video about polishing. As I recall, many experts thought that video was among the best on the subject of polishing. It's a real shame that their videos are no longer available and I've been in touch with them regularly to see if they can get these videos back. Unfortunately, it seems that these videos are gone forever. The last message I received from them on 21 January read: "I'm sorry, but not yet. In a nutshell: the school is scheduled to be shut down next year - a new school is bring opened in Dallas, Texas. Because of that all video access is blocked. If a decision is made to not close the school, then at some point the videos will likely be made available. We just do not know that yet. So, just check in again in a month or three; sorry I can't be more specific than that." Well, as I recall, there was a section in the video that was about how to preserve the edges of a watch case, that is, how to avoid rounding off the edges when using a mop wheel. I don't remember all the details but what I do remember is that it's about keeping a high speed on the mop wheel and keeping a light pressure on it. I didn't think of this when I was polishing the case back but the next time I'll try it and see what difference it makes.1 point

-

In another life, I was a crew member of a nuclear powered submarine for 2+ years. On my first deployment one of the nuclear twidgets who worked on the reactor came into the senior petty officer berthing area with a geiger counter. After taking a couple of readings, he zeroed in on me. My watch with radium lume was setting off the compartment radiation counter. My watch was confiscated and placed in a lead container for the duration of the patrol. I was told to take it home and not bring it back aboard afterwards. I was also told that the radiation emitted wasn't in the least dangerous to me but that it posed a pain in the butt for the on-board radiation monitoring system. I'm assuming that he knew his subject matter. In any event, I sold the watch and bought another so that I could have a timepiece on my wrist while working aboard.1 point

-

The actual dose you receive from working with lume is probably relatively insignificant, even if it comes in contact with your skin. Ingesting or inhaling lume on the other hand presents a somewhat greater risk, particularly if you do so regularly. If you were to remove and store all of the lume from every watch you ever encountered, and then swig the resulting concoction, the acetone would be a more immediate hazard. Here is a chart of relative doses that brings some perspective to things. https://xkcd.com/radiation/ It is factually correct to state there is no such thing as a safe dose of ionising radiation, but since you are being bombarded with the stuff naturally, the additional risk of working (sensibly) with lume is relatively low. Flying from LA to New York is more risky I would suggest, and even then, the risk is pretty low.1 point

-

For vintage watches that the hands may have radium lume on them and they are not painted I just drop them into a small jar of acetone and let it dissolve the lume. I then remove the hands and tip the acetone (about 20mills only)into my jar of spent cleaning fluid which is left in the corner of my shed to evaporate down and then the heavier parts like turps that dont evaporate are stored in a container to go to my local council recycler that takes oil and paint thinners. The little amount of radium in it is of no risk as I don't touch that many old watches and it means I don't have to worry about dust coming up from the hands when I remove the old lume. I do take care even with the movement and case and ensure I wash my hands after dismantling them for cleaning and usually wear finger cots too.1 point

-

Be aware that even if the dial no longer glows, it is still probably radioactive, since the half life of Radium is around 1600 years, and other transuranic elements are probably present with similar or longer half lives. The hazard is relatively low, but you should still take care. If removing old lume, wear gloves, and a mask, and keep the old lume in a paste form by using some form of barrier material, water, while it may leave marks is probably OK. Something oil based may be better, and any solvent that evaporates rapidly may transport the particles into the air. The amount of material involved is pretty small, and the radioactivity present in a single watch dial is not a huge amount, but it should be treated with respect to avoid ingesting it. Skin contact, while ill advised is less hazardous, if you do get it on your skin, wash it off with plenty of water and soap or hand cleaner. In this sense, it is similar to things like asbestos, lead and mercury, all of which you are likely to encounter in the environment naturally, and all of which present a small, but not insignificant environmental hazard. There is an interesting article on Wikipedia -> here <- particularly the section on safety. The hazard is greater when the material is on a more industrial scale. This article might be of interest in that respect. https://www.bbc.co.uk/news/uk-scotland-edinburgh-east-fife-34862223 In summary, treat with respect, but don't get too paranoid, just exercise suitable caution. Slightly off topic. If you are interested in detecting radium and other radioactive particles, you can obviously buy a suitable detector, or if you like a challenge, you can build your own, using a geiger tube, or even a pin diode. Google keywords "open source geiger counter." or "pin diode radiation detector" I have a bunch of old pin diode based dosimeters in my junk pile, which I intend to convert into counters when I get a bit of spare time. See here for more -> http://www.stm32duino.com/viewtopic.php?t=33221 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)