Leaderboard

Popular Content

Showing content with the highest reputation on 06/05/24 in Posts

-

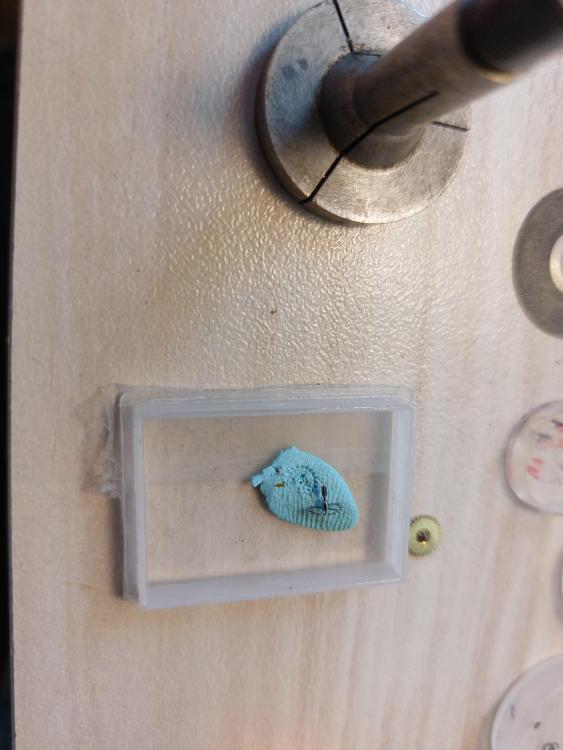

Yes, Chajka (Чайка)1301 . The click spring can be made of spring steel wire. No annealing needed for such steel. Such wire are the springs for violin and guitar, but this spring is thinner than the thinnest violin string. Spring from another movement can be reshaped, as suggested. Such movement can be obtained for less than 50 p in Russia, but I am not sure if this is an option now. The broken piece of the barrel screw can be unscrewed with hard sharp pointed tool. The screw is not tightened now, as the head is not there, so it should unscrew without resistence.3 points

-

Why heavens to Betsy, Scott did you wimp out mate ? 10.10 pah, and you already had a 404 in toe. I'd be ashamed to call myself a Yorkshireman if i ever stooped so low. Talk some sense into these people Rich , ffs moderate will ya mate .3 points

-

OK I'm going to call this.... and the winning combination is...... £10.10 So the value to be equal or less than £10.10 or equivalent in your currency, exclusive of reasonable shipping charges and/or spares. To start the ball rolling here is my first posting as a 10:10, this is a Buler that I picked up in October 2023 for the sum of £3.00, apart from the strap and cracked crystal, all is original: Before shot: And the movement: All went smoothly with no drama, so the whole thing took about 5 hours, here is the final result: The date is manually set (not quick set... hence the wrong date)3 points

-

I do the same. There is no being too careful! Yes, the results were not good. Using a water based organic material such as coffee with a solvent based lume is a recipe that ain't gonna work in my book. It is counterintuitive. I use various powder pigments to dull down the colour with the lume. Thanks for the link to the pigment you use @mikepilk2 points

-

Unfortunately the periodic table is complete, so either something like radium which is bad for your health and isn't available any more or tritium, witth it short half life, as far as brightness is concerned.2 points

-

There are not many companies making tritium lume watches; all the current ones use miniature gas filled tritium tubes, as far as I know. That means the ones with glowing digits rather than indices tend to be larger sizes. Ball make both lower and higher end ones: https://www.armourlite.com/isobrite-t100-naval-series-tritium-watches https://www.ballwatch.com/global/1/collections/roadmaster---94/marine-gmt-ceramic---dg3030b-s1cj-bk---2639.html Traser make more mid-range ones: https://www.traser.com/en/collection/our-collection/outdoor-watches/ There are some others, but those give a range of examples. Tritium fades quite quickly over time; it's half life is roughly 12.5 years, so a 25 year old watch would have 1/4 the intensity compared to when it was new. If it must be tritium, then I'd only get new or very nearly so - no vintage ones.2 points

-

Thanks, that's really useful @Jon. The green lume I have looks pretty close to that. I have ordered some vintage tinting paste. I'll try the basic green with just a hint of the tinting paste to tone it down a touch. BTW I like the burn marks left on the card by the hands2 points

-

OK. So, let's get organized a bit. This is a fun thing, so nothing too serious. We'll either need a new, separate thread for the new 10:10 limit, and it'll need a name: 404 Club Reboot, 404 Club Reloaded, 404 Club Lite, 404 Club 2000 (like the old sci fi flicks), 404 Club Remix... 10:10 Club ... and keeping under the original 404 limit goes into ... 404 Club Prime, 404 Club Alpha, 404 Club Classic, 404 Club Elite, 404 Club Ninja, 404 Club Hard Mode... OR Continue under the original thread with the new 10:10 limit, but if you snag one under the original 404 limit, you get to (must!) post your find with an image of a gold star. Any gold star image you find on the internet that you want to post. Thoughts?2 points

-

2 points

-

Same here. I watched it several years ago and I concluded that she concluded nothing.2 points

-

Thats the nature of the game dean, i spent 2 hours yesterday lining up an impulse jewel with a friction fit staff and roller in one, polishing the heck out of the pivots and straightening the pivots only for one of them to break on me at the last hurdle. If not looking directly down at the jewel hole it can look off center from the cup, thats not to say i haven't seen them come poorly manufactured this way. There can be a thousand and one reasons why amplitude is low and incorrect endshake is just one of them. If you have plenty of money then the Horia tool, the clone version is ok for what we pay for it but thats about it, the pushers and stumps surfaces are a bit rough but can be improved. Are you crazy ? This is watch repair, if you aren't now then you soon will be, we all are, welcome to the club2 points

-

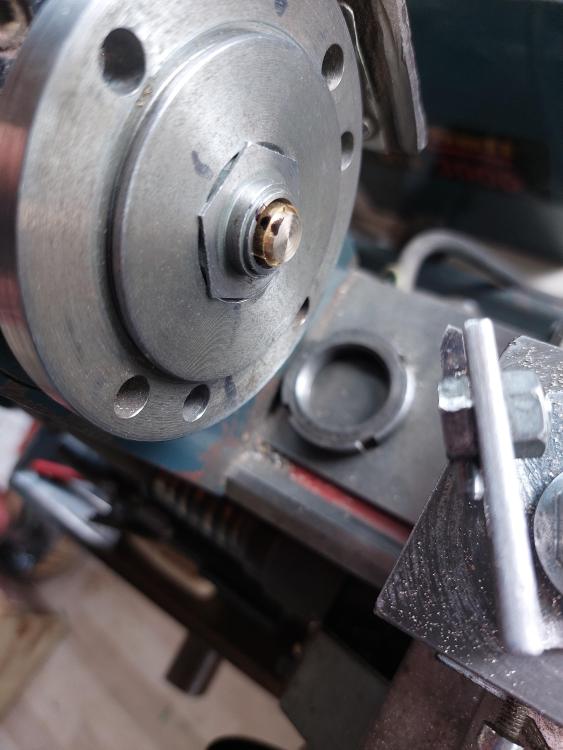

Shellac is what I used. Baloon chuck... Could work, but here the pivot is verry lo above the pinion shoulder and I am not sure if i will protrude enough from the hole of the chuck. It depends on the chuck. But I don't have one... Here it is crusual to make the pivot centrical and this is what I came to in my practice that really works.2 points

-

I tend to do the same, but I'm not very strict about it, given the very shallow taper of the broach from end-to-end and the 1 or 2 mm of hole you are broaching the height difference of the broach over that plate thickness is vanishingly small, I could do the trigonometry, but haven't had enough coffee yet this morning, therefore in reality I don't think it really matters if you do from one side or do 50:50..or...? I tend to do from one side, and if it needs more I try and remember to do the next bit from the other side, if I can't remember which side's turn it is I don't worry about it using the reasoning above.2 points

-

2 points

-

The joke is that I actually have a fully licensed AutoCad 2023 installation on my work computer which I use on an almost daily basis. Sometimes though it's just nice to break out the pencil an paper, and to remind the technology that I'm not as dependent upon it as the world of tech likes to think.....2 points

-

I have a very similar one (also Cousins, also German, but 0.6 to 2.0mm). I'm happy with it and I once did a decent job (I think! time will tell..) on a barrel bridge to reduce sideshake of the barrel. Sure, if you are an extreme perfectionist, you could argue that holes get better=straighter by having smoothing broaches with the least possible taper. That means, to have many! But really, for Seikos you will be fine with that set from Cousins. PS: have fun! It can be quite a bit of back and forth until you get the right hole size. Take it slow and don't get frustrated. But when you do get it right, it's a great feeling. OH, a tip!! What I did to help me get the hole size right was to measure the barrel arbor (at the respective position for barrel or bridge) and then use a sharpie to draw a line on the smoothing broach where it had the correct width. That saved me a lot of time.2 points

-

Yes all broaches are tapered, without the tapered length they would not broach evenly and the tapering does vary. Minimum to maximum broaching out sizes are quoted per broach.2 points

-

for under $20 that is great pickup. Not the traditional split stem. the crown just unscrews.1 point

-

One of the problems with anything resembling older watches is people not always doing things correctly. So yes there is a possibility that somebody shortened the hairspring which is why you're going fast and perhaps they even did that to fix the beat error which would not be the correct way to do it. Sometimes on some vintage watches there can be a little bit of hairspring stuck through the stud but that's usually more vintage. In any case if the stud pinned hairspring doesn't look right it probably isn't right. So underpinning giving a length will slow the watch down and then you'll have to rotate the collet to adjust the beat.1 point

-

Always learning and new knowledge to pick up 8lackie and the list of tools to make the work easier is an endless one. Stick with it , you will aquire more of both over time, no rush.1 point

-

Thats another strike for the youtubers then, thats where i had heard about it.1 point

-

I'm not a fan of adding extra power to a vintage movement because it causes extra wear. Extra wear equals worn sooner equals less run time1 point

-

1 point

-

1 point

-

You can add MWC, Marathon and Nite to that list, they have also sold T100 tubed watches as well as the more normal T25 tubes. The tubes at very best will only last about 20 years but these three and Ball do replacement services. Tom1 point

-

@8lackie, we need to know the particular place the spring breaks - the internal end for example, and when exactly it breaks - when winding in the winder barrel, when transferring to the watch barrel... The problem in using too small winder barrel is that when transferred, the spring unwinds rapidly to the bigger barrel size and the shock it takes is really big.1 point

-

In my experience, trying to swap "clone" parts onto the real McCoy has caused me issues. But my clones were of the chinese variety, so this may work for you. As far as NOS, when something has factory applied oil, its safe to assume the oil is dried up since it hasn't been moving. I would do a lubeta dip(or make your own) and call it a day.1 point

-

Right you are! Preschool was an ordeal, and now I know why. Point taken. Ever onward!1 point

-

1 point

-

1 point

-

Thanks T & A. No banking pins on this one but I applied the underlying principle you expounded in ensuring by adjusting the collet so that the pallet fork swung equally either side of what I judged to be the centre line & this worked !1 point

-

I think we need a bit more to go on 8lackie. But honestly you have probably already answered this. The second question answers the first question. At pre school we learned to put different shaped blocks into holes of the same shape, round block into square hole X square block into square hole _/ . At watchmaker's school, i suppose that practical exercise continues at a much much higher level , parts need to fit very precisely. And in watchmaking very precisely means working at measurements in low numbers of microns . My point is, a mainspring meant for a 10mm barrel may not fit in an 8mm mainspring winder and if it did fit its unlikely that it wil be happy about it ( or otherwise feels very happy and secure and does not want to leave without a fight ) Please rate if you found this information helpful or otherwise sarcastic .1 point

-

The difference is likely insignificant, on a thicker material than a lid a bit more so. Theoretically you would end up with a peak in the center of the hole if you broached from both sides, which i suppose once that had worn away would leave a cylindrical hole. That possibly could be taken into account of when to stop widening the hole. In all circumstances the the finished fit is the narrowest part of the hole and will eventually wear to the widest part of the hole which is one reason why its not a lasting repair. Dont be tempted to polish up the opening as the soft brass can potentially be charged up from any compound used. Ideally a broach with as shallow taper and smoothest cut as possible to finish with.1 point

-

The method of doming the washer to remove it, then flattening it out again to sit tight after replacing the o-ring works well. No mangling involved. You will struggle to get the right size of o-ring through the gap. I'm not saying it's impossible, but the potential for damage is great.1 point

-

1 point

-

You can always broach from both sides to make the hole more even. The plate and brigde holes i broach for a tighter fit than the barrel and lid. These are not part of the unwinding only the winding as the arbor is fixed by the click and only moves when winding up. As long as they aren't so tight as to stress the winding mechanism, the important bit is to get the friction right in the barrel so as not to rob power right at the source.1 point

-

That is definitely a possibility. Even with a proper timegrapher, you sometimes need to adjust the "gain" settings to get a proper reading depending on the thickness of a case. Still, I wouldn't rule out magnetism. Also sounds plausible to me. The Chinese blue demagnetisers are cheap and worth getting (IMHO).1 point

-

I think the app is misinterpreted the noise because of the extra case construction Tom1 point

-

Yep, basically the same principle as for watches with a Swiss lever escapement. The position of the hairspring collet needs to be adjusted/rotated on the balance staff such that the impulse jewel sits perfectly at rest between the banking pins when there’s no power to the pallet fork. On some escapements, there’s an actual beat adjuster, but I’ve never seen one on a clock.1 point

-

thank's guys, I figured it out in the end. Was quite rewarding to see it work correctly. I did wonder how it triggered the half hour, but I noticed that the width of the slots on the count wheel allow for it to drop into the same slot twice, once for the hour and another single strike for the half hour. What I didnt realise was that I had to align those things you mentioned, oldhippy, as I'm fitting the wheels and levers to the plates. I understand it now, I think the next time will be much easier.1 point

-

1 point

-

I think the pallet fork stump is used for punching out the staff of a pallet fork. The slot is to prevent putting pressure on the guard pin. The tube is used to pick up the stakes from the holder. Especially useful if you have fat fingers. My set is missing this, so I have a short silicone tube to do the same job. I have 2 balance staff removers and one of them has the tip of the punch broken off. If you have a lathe, it shouldn't be too difficult to make a new punch.1 point

-

Hello and welcome to the forum TZIllustratedGlossary.pdf dictionary_ebauches_sa.pdf1 point

-

Hello and welcome from Leeds, England. We're all willing to help on here.1 point

-

1 point

-

That looks like normal behavior to me. That movement only winds in one direction, not both, so when the rotor turns anti-clockwise it winds the main spring and so is fighting against the mainspring tension. As a result it will turn under its own weight but it won't free spin. When it turns clockwise though it has no resistance and so can spin freely.1 point

-

1 point

-

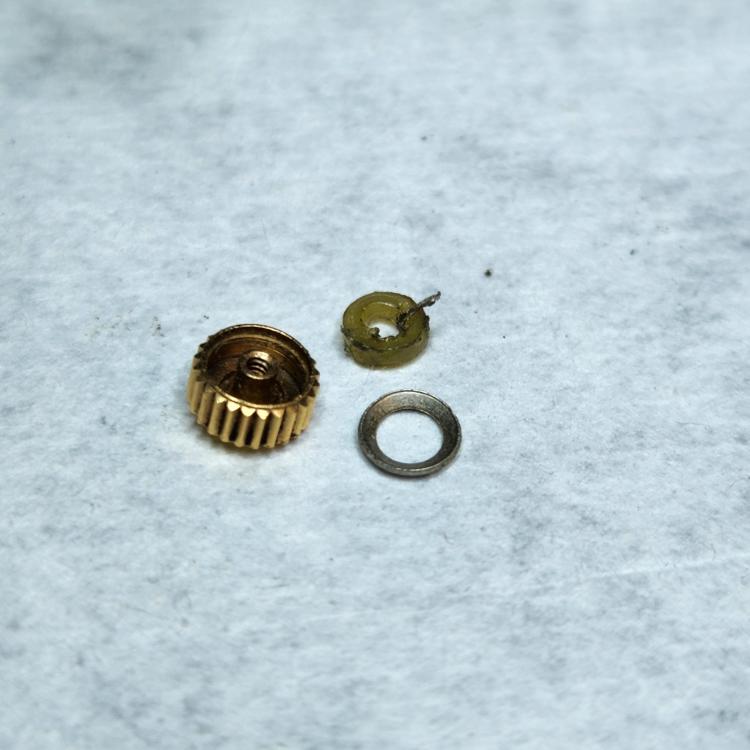

Recently a new member asked how to remove the oring from a waterproof crown. He was redirected to an old YouTube video where the washer was forced out by stuffing in multiple orings into the groove in the crown until it bulged the washer out. I always thought that method was a waste of good orings. So I toyed around with the idea of pushing in the washer with a domed staking tool. I first had to soften the old oring by soaking it in acetone for about an hour. Then I selected a domed staking tool with a centre hole just slightly larger than the hub of the crown. The washer is quite malleable and was easily domed in until the rim was smaller than the lip holding it in. The next task is to find an oring of the correct size to replace the damaged one.1 point

-

Hello Mark. I'm completely new to you, your site, and a complete novice as well. Not enrolled yet. I like the content of your site and the friendliness of the members. I ran a site of my own for many years and installed Adsense. Members, be aware that Mark receives and income from the 'clicking' of the adverts. Be very careful about causing Mark a problem. Don't click every advert each time you visit. If there is something that may interest you, by all means 'click'. Adsense keep a record of 'Clicks'. Some of my members tried to help and give me more income. They 'clicked' every advert, every time a visit. Asdsense stopped my 'click' income for 3 month. When it came back on, members did 'click' each visit, but limited 'clicks' allowed the income to grow. Let's help Mark. I know the cost of running a site. Regards to all Keep well. keep safe Ross1 point

-

In a lever escapement the guard pin and fork horns keep the escapement from unlocking accidentally. In a situation where the watch receives a shock the balance can move away from the fork, which increases the guard pin and fork horn shake. If the escapement is setup so the locks are quite light, but still just safe, when the clearances increase during a shock the escapement could unlock and stop the watch. Not sure why you think lock drop and run to the banking are doubled in a coaxial? The main advantage they say is more stability in timekeeping over time. I personally don't think it is more stable than a good lever escapement, and it is very touchy to work on and delicate as made by Omega; I see it as an interesting escapement but if I had to choose I would take a standard lever myself.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)