Leaderboard

Popular Content

Showing content with the highest reputation on 06/06/24 in all areas

-

3 points

-

9 size guitar string is 0.22mm, 10 is 0.25 and 11 is 0.28 as I remember. The violin thinnest string is 0.2. I often use these for repivoting... The Chaika click spring should be 0.12 -0.153 points

-

Hi. Watch repair is as much about collecting tools as it is repairers as nearly everything needs a tool to do but as long as you enjoy the hobby go for it. Have a look at the watch repair site , the courses run by our administrator Mark Lovick.3 points

-

The way the hairspring is sitting I wouldn't be surprised if the first coil is touching the stud when running. Easy 60+ seconds.2 points

-

The pack the part is in is oxygen free so it stops or rather slows down oxidation of the lubricant on the part. It is already a 'dry' lubricant, so is unlikely to dissipate like greases and oils. If the lubricant on the reversing wheel(s) has gone over time, you'll soon know when winding the watch and seeing the rotor spin as well. if that is the case, remove the reversing wheel, clean and lubricate. No biggie!2 points

-

Thanks! I must indeed have stumbled on an older version (two actually) and neither of them mentioned this oiling point. But it seemed to make sense and great that I can now see the latest doc to confirm. Yes, they are pre-lubricated. But how old is this lubrication if it's still original ETA parts?? Could be 10-year-old stock that Cousins is still selling... I'm worried that the pre-lubrication has dried out. That being said, it seems to work fine (no spinning) --- for now. Not sure if it'll wear out quickly, though (if the pre-lubrication wasn't good anymore).2 points

-

front loaded case - lift crystal. lift dial ring. at the 3 hour there is gap to insert tool. Timex recommended a flat screw driver. but I use needle nose pliers that are filed down to fit into the space. Grab the stem and twist the crown off. actually this is the same as the 1960 Marlin2 points

-

2 points

-

The mainspring would be my prime suspect, once you get to it, installing a new mainspring is fairly simple. But in getting to the spring barrel you are about 50-75% of the way through a complete disassemble, so you may as well go the 'whole hog'. I don't know your experience level, but if you are just starting your journey I would get some more experience under your belt before risking a service on this watch, a good excuse/motivation to get started in the hobby. Other than that you could maybe find a watch maker in your location and get them to do the change out if you aren't ready to take it on yourself yet. Just looking at the watch it looks like it is about due a service, difficult to be sure from a picture, but maybe worth biting the bullet and get it serviced, or bide your time and do it yourself when you are feeling confident2 points

-

2 points

-

Those case #'s are from the 3rd and final iteration of the Benrus waterproof design. They had some other case designs in their final years as the quartz crisis came on, but by that time US legal restrictions made them change to advertising only as water "resistant.": There is no gasket, glue, sealant, crystal ring or separate bezel, just a tight fitting flexible crystal meant to fit the machined groove on the case and be installed (and removed) from the front with a crystal lift or wrench. There is a gasket in the crown. Their waterproof guarantee always included the disclaimer that the case, crystal and crown needed to be intact for this functionality. Not sure how these did on a pressure tester, but it was good enough to secure multiple government contracts for a series of military watch models. Most of the civilian cases cover the joint in the split stem, so you can't manipulate them to slide in and out from the side (as you can with some of the military models), you just have to trust the system and yank on the crown! I enjoy working on that era of Benrus watches. Their ETA movements are reasonable to service, they have parts that can still be sourced, and most were tritium lumed so the dials have nice patina without radium burn marks.2 points

-

I'm not a fan of adding extra power to a vintage movement because it causes extra wear. Extra wear equals worn sooner equals less run time2 points

-

1 point

-

I'd be interested to know a bit more about what you mean it was "loose" and "adjusted".1 point

-

You wouldn't happen to know the service history of this watch would you? Or would you have A timing machine like how well is the watch running when it is running? From time to time watches need to be serviced it's not enough to just change the mainspring and you're good to go. I've been reading the replies your getting apparently working on one Seiko automatic that you haven't finished yet makes you an automatic expert so you have nothing to fear. Especially because the people who posted all the comments about no need to fear anything will help you straight out whatever happens just in case it should happen. But don't worry based on the replies watch repair is super easy no skills required. To be honest normally I don't care what people work on if you want to start with a Rolex I would encourage it I'd typically no longer will make any suggestions at all of people skill level. But if you don't feel comfortable Your the one doing the work they are not they have experience and they forgot what it's like to be in your position. If it makes you feel better finish the Seiko first or anything else you need to do to make you feel better about moving onto the next watch. Oh and minor reminder here this is an automatic watch and you will require breaking grease if you want your automatic mainspring to work correctly1 point

-

Ep. 4. Well, it runs... After putting everything back together (including installing a new mainspring), I put the movement on the timegrapher. I was not impressed with the amplitude, so I started checking and noticed that the mainspring barrel was too loose. I disassembled everything again and adjusted the barrel. I also noticed that the new spring is of an older style, whereas the previously installed one was of a newer S-shape style. If I had not adjusted the barrel, I would have never known that the spring was different. I checked with Cousins, and the spring seems to be the one I ordered. However, Cousins does not specify the exact type of spring you order, other than whether it is Automatic or Non-Automatic. After barrel adjustment, the amplitude went up, and the result I would say is nice. Will check on it again after 24h. Should I keep this mainspring, or should I be looking for another replacement?1 point

-

I am not certain that it is assembled correctly. I will remove the hack and see what that changes/doesnt change. Thanks for the advice guys.1 point

-

1 point

-

Oh dear, please excuse my brain-fart. Thanks @praezis for the peer-review Of course, you'd need to ADD weight to the balance wheel to slow it down. Ironically, I was only doing the exact thing two months ago. Watch too fast, added timing washers. I can post pics on demand.1 point

-

I have one of these tools. Used it a couple of times and didn't like it. The problem is that when the power is dialed up high enough to pop the cover off, the cover usually flies across the room and then rolls under some furniture. The blade then continues to move forward due to the momentum and the hardened blade then punches a line into the lip of the case. This line would affect the seal of the gasket, making the case non-waterproof anymore. I've switched to using a Seiko-style case knife and find that this design allows the user to exert more wedging force due to using a pushing action. Even very tight casebacks can be popped off with this tool.1 point

-

I agree with @Jon, the Tissot 79x are pretty straight forward and well-designed movements. If you can handle Seikos, you can handle this one, too. Unless you have never done any calendar works. If you want to go down this route, you are lucky in the sense that the mainspring barrel is easily accessible WITHOUT removing the train wheels/bridge (you could maybe even leave the balance on, but then take extra care). See below. When you get to that point, make sure you gently "shake out" the barrel instead of roughly yanking it out and potentially bending the center wheel. You might also find this thread useful (783 is the 784 without calendar):1 point

-

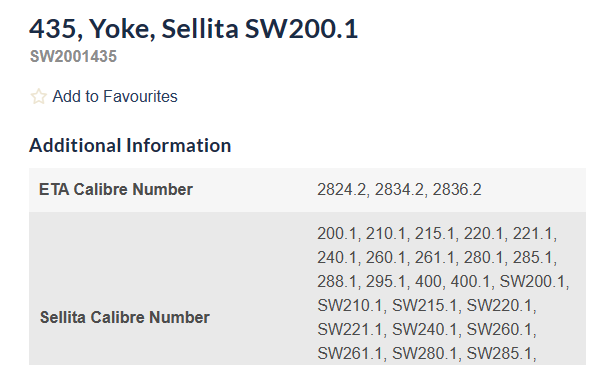

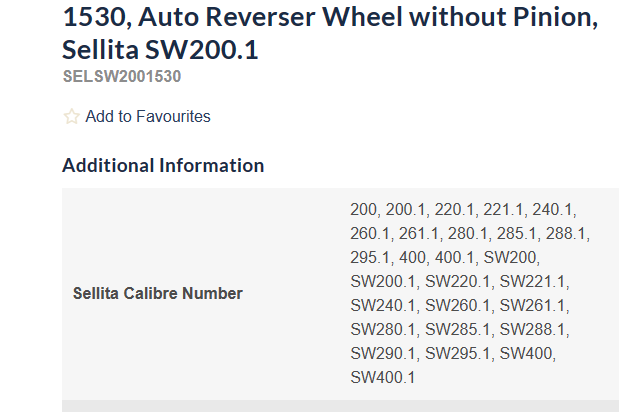

oh thanks for this! I also noticed that Cousins would mention the compatibility between ETA and Selitta for some parts, but not for others (incl reversing wheels), see two sceenshots below: I would not apply V105 w/o first properly cleaning them. Yes, my instinct here is the same. Either clean+V105 or use as-is from the blister. an addition from a different thread, posted by @Jon: see here for context: https://www.watchrepairtalk.com/topic/25027-eta-2892-a2-service-walkthrough/?do=findComment&comment=2520431 point

-

There are two good cross-references you can check, and I already did. https://www.emmywatch.com/db http://cgi.julesborel.com/?_gl=1*1c1sjug*_gcl_au*OTE2ODU1MjI1LjE3MTc2NzkyMzM. None of these cross-references shows that the ETA and Sellita calibres are interchangeable in this respect. I'm not sure though as it could be that the databases haven't been updated. I would not apply V105 w/o first properly cleaning them.1 point

-

Thank you for your kind words! It's from ETA's technical documentation. Surprisingly, you can still find the latest versions of these documents for many, but not all, of ETA's calibres here: https://shopb2b.eta.ch/en/ I assume it's only a matter of time before these documents are removed. I've meant to download all of them but haven't gotten to it yet. As a backup Cousins has most of them, but not always the latest versions. I don't think there's any need. As far as I know, they are pre-lubricated. The only reason would be if and when the rotor starts spinning when you hand-wind. Yes, as seen in their documentation that's what you're supposed to do.1 point

-

@mikepilk I have the more than £20 horotec one which looks identical except for colour. The red cap is what you would use to adjust the power. I have automatic centre punches which are the same thing from a base mechanism point of view. I use this as the next level caseback removal if my case knife collection won’t handle it. Tom1 point

-

There are all kinds of guitar gauges For example these are: 8 = 0.008 inches = 0.20 mm 11 - 0.011 inches = 0.28 mm And so on.... Note: Gauge/1000 = inches Inches x 25.4 = mm Maybe too thin in the case of the click spring, but worth keeping in mind for future spring makes..... my son goes through set of strings a month, so lots of spring material in my spares draw.1 point

-

1 point

-

I have said it before, my anecdotal evidence dispels any fear of radium in the quantities we deal with in the watch world.1 point

-

I buy the Elma cleaners as Cousins sell them in 2.5L containers (£29.45+VAT). The L&R are only sold in bigger 3.8L containers(about £47+VAT). I use about half a jam jar of fluid and change after 5 watches. It's lasted me years and is similar in price to buying naphtha, but it cleans much better. So for anyone still using naphtha/lighter fluid, I recommend switching. It's a bigger expense up front, but they will last you a long time, and you will notice the cleaner/shinier parts.1 point

-

That makes good sense...... thinking of a good name..... The Cost Conscious Challenge Operation Skinflint Cheapskate Challenge Polish The ??1 point

-

404 Club Part Deux, 1010 Club Or to take the value out of the equation (as inflation will eventually make the value limit go higher): Budget Watch Club, Bargain Watch Club, Dirt Cheap Club, Club Thrifty1 point

-

I've run across a "STAUER" tritium watch that seem pretty bright. I'm looking at a Marathon as well. I had hoped a Radium dial watch would still work but I think all the old Seikos with radium have burned up the luminous material by now. The Ball watches, maybe $1000 , um wow certainly better than Rolex but 3 times the price of a Marathon, couldn't be worth it. (for my worst case scenario we're hunting, rainy, no chance to charge a lume watch, someone is injured at night. I want a watch I can check pulse, hold pressure on a wound for 10 minutes , mark a tourniquet etc.) (and it still works after I've shot my 12 ga. and fell out of a tree). I am having so much fun investigating, collecting and repairing watches !! Not ready for prime time but watches are cool.1 point

-

NOS radium lume that has been protected from moisture/humidity is much greener than I would have expected, based on some well-wrapped example hand cards I’ve come across. Very similar to 1st generation “cold” lume and other glow-in-the-dark items from the 70’s and 80’s.1 point

-

1 point

-

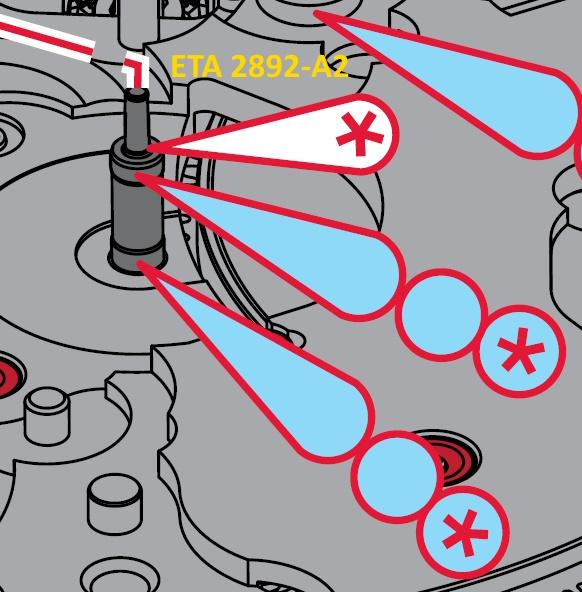

One of the things that I find interesting with a vintage new old stock hands still mounted in the paper is the effect of the radium on the paper. In the image I snipped out you urge you can see it but maybe it's the lighting because usually the paper looks much more brown if it's been under radium hand it has a nice light burnt look.1 point

-

Unfortunately the periodic table is complete, so either something like radium which is bad for your health and isn't available any more or tritium, witth it short half life, as far as brightness is concerned.1 point

-

You can add MWC, Marathon and Nite to that list, they have also sold T100 tubed watches as well as the more normal T25 tubes. The tubes at very best will only last about 20 years but these three and Ball do replacement services. Tom1 point

-

I have a very similar one (also Cousins, also German, but 0.6 to 2.0mm). I'm happy with it and I once did a decent job (I think! time will tell..) on a barrel bridge to reduce sideshake of the barrel. Sure, if you are an extreme perfectionist, you could argue that holes get better=straighter by having smoothing broaches with the least possible taper. That means, to have many! But really, for Seikos you will be fine with that set from Cousins. PS: have fun! It can be quite a bit of back and forth until you get the right hole size. Take it slow and don't get frustrated. But when you do get it right, it's a great feeling. OH, a tip!! What I did to help me get the hole size right was to measure the barrel arbor (at the respective position for barrel or bridge) and then use a sharpie to draw a line on the smoothing broach where it had the correct width. That saved me a lot of time.1 point

-

When pegging and doing a pre-clean on very dirty movements I always use naphtha. As mentioned above, IPA isn't good solvent for oils and grease.1 point

-

1 point

-

Inflation is still alive and well, so I don't think that we will see prices coming down anytime soon. Seems that many people picked up this hobby because of the pandemic. That was my case. Of course, us newbs needed cheap watches to work on, and tools and supplies. So, I'm sure that helped drive up the prices as well.1 point

-

It was already mentioned in many mainspring threads here : There is an optimum length/thickness that gives the maximum run time. The mainspring will occupy half of the inside barrel space then. Longer or shorter (same thickness of course) will need more than or less than half barrel space: less run time! Frank1 point

-

The watch that got me into watches was a Cyma... I had it serviced shortly after I got it, and the watchmaker informed me it was a German issued officer's watch from WWII. Little tangs around the crystal from a battlefield repair via the tip of a bayonet to hold it in staring at me each time I check to see if I'm late for class... Deep dark history on my wrist without even knowing it... $35 on eBay from Ukraine with no hint of provenance unless you really knew what you were looking at... Which I most certainly did not! I just thought it was cool; didn't even know hand wound watches existed prior to purchasing it! This is definitely a thing. I'm an elder millennial, and graduated college right as the Great Recession hit. Of everyone I went to school with, I knew of precisely one other person to land a job on graduation (excluding things like retail and waiting tables). That gave me just enough of a head start to be able to buy a house right before the market went crazy. I have a few friends that have been able to buy houses, but very few. Not many friends with kids, and those that have them are all older (medically, 35 is the start of "old" for pregnancy). It's anecdotal, but it seems to thoroughly reflect the demographics and statistics I keep seeing...1 point

-

Radium is very dangerous if it gets into your body. This can happen by ingestion, inhalation or contact with broken skin. Radium lume dust is more mobile than flakes, and therefore more likely to find its way into the body unless the right precautions are taken. The greater the dose of radium absorbed into the body, the more danger it poses, whether it’s in the form of dust or flakes makes no difference once it’s inside you. The radium present on a watch dial won’t kill you outright. Once absorbed, it is chemically very similar to calcium, and the body treats it like calcium and stores it in your bones. From there within your body, it’s alpha particle radiation plays havoc with nearby cells’ DNA, causing mutations as cells divide. The end result is often cancer. Some watch brands used radium into the 1970s, so if you are working on watches with lume that were made before 1980, you should assume that the lume contains radium unless you’ve proven otherwise with a Geiger counter. Geiger counters are now cheap enough that anyone working with vintage watches would be wise to buy one and learn how to use it. The absorption of a tiny quantity of radium can potentially have life changing impacts upon your health. Best Regards, Mark1 point

-

Excellent post and advice @Mercurial I agree with everything you say. Yes, this is important to understand. The good thing is that you can start pretty slowly and then if your interest grows, increase the number of tools. I wouldn't be surprised if I've spent the equivalent of one or two good Rolex Submariner watches since I started eight years ago. The nice thing is that I appreciate my tools at least as much as my watches. There is something truly magical about using a well-used patinated Swiss quality tool that a skilled watchmaker used for decades. Again, excellent advice, and when you want to go wristwatch size but still not take any financial risks I'd recommend Vostok 24xx movements such as Vostok 2409. Most modern watches, less than 60/70 years or so, seem to secure the impulse jewel with friction only so that should be safe to rinse in IPA (isopropanol, not Indian Pale Ale). I've never handled Radium but Kalle Slaap made an interesting video about it some time ago. As I understand it, it's the dust that can "kill" you. https://youtu.be/Z-A-e8zSoOM1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

Thanks for the tips everyone. I went with the feeler gauge option as it was to hand. Rather than risking the temper I used a mini angle grinder (plus constant cooling) to cut a rough blank, then carbide drills and diamond files to drill and shape the part. I tried scribing the shape on to the part but eventually having scribed a copy as a template I glued it to the blank and worked on that: I changed the design of the detent spring slightly as the original obviously had a stress riser at its root. I couldn't match the exact shape of the detents but their positions are identical to the original. Time to check for functionality and fit: I bent the spring slightly (about 0.3mm at the tip) down towards the setting lever. It functions perfectly and feels smooth with a distinct click from one detent to the other, so I'll polish it ready to fit to the watch when it is cleaned: Thinking of stress riders I polished the cut edges of the spring with metal polish on the tip of a toothpick . It will be interesting to see if it lasts.1 point

-

It's a pretty common part. But you will need to measure it's dimensions. For this you will need a set of calipers. You will need to know it's length and diameter. Then you can order the part. You will probably also need a stem and a crown as well. These parts are pretty universal. You can find them on the esslinger website.they have a considerable variety. Removal isn't too tough. Needle nose pliers.just be careful not to bugger the case. Correction...the stem is not universal..they are particular to the movement and the threaded end comes in different diameters as well..they are known as tap sizes.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)