Leaderboard

Popular Content

Showing content with the highest reputation on 06/07/24 in all areas

-

3 points

-

In years to come the owners will say they can't hear it because they have gone deaf.2 points

-

My worry is that coffee or other "edible" pigments will be hydroscopic, and encourage mould and rust to form. This happens to some degree with older lume anyway, but I think small amounts of acrylic paint or pigment powders might be a safer option.2 points

-

I've been reading the replies your getting apparently working on one Seiko automatic that you haven't finished yet makes you an automatic expert so you have nothing to fear. Especially because the people who posted all the comments about no need to fear anything will help you straight out whatever happens just in case it should happen. But don't worry based on the replies watch repair is super easy no skills required. To be honest normally I don't care what people work on if you want to start with a Rolex I would encourage it I'd typically no longer will make any suggestions at all of people skill level. But if you don't feel comfortable Your the one doing the work they are not they have experience and they forgot what it's like to be in your position. If it makes you feel better finish the Seiko first or anything else you need to do to make you feel better about moving onto the next watch. Ok, I'll admit that @JohnR725 has a point here. First and foremost, YOU decide. And YOU have to be comfortable doing it. It's also good advice to finish the automatic Seiko before going to the next watch. In defense of the "encouragement" posted above: when I serviced the Tissot 783, it was actually my second automatic watch and it was only about one year ago. So I didn't forget how it feels being in your position. Without a doubt, there is a learning curve. But I, personally (!!!), found it quite doable. It was a simpler auto system than some ETAs, Omegas and Rolexes that I worked on afterwards. But very important: this is only gentle encouragement. Nobody here is "pushing you" to try. And that said, I fully support your decision to...2 points

-

1 point

-

This is just to say a heartfelt thank you to everyone who hangs out on this forum. I was browsing one of the bigger watchmaking Reddit subs today and was struck (as usual) by just how comically bad the advice tends to be over there, and how poorly researched or formulated so many of the questions are. What a difference here on this old fashioned web forum. I've been around here about two years now and every time I arrive with a question, I get a bunch of thoughtful responses from experienced hobbyists and working professionals, without any snark or condescension. For years, I was a major contributor (still on some global leader boards!) on the computer programming site Stack Overflow; the techies here know what I mean. That place is famously unkind to new members and non-professional programmers, with required adherence to a bunch of strict community customs and no tolerance for questions from people who just don't know yet what they need to ask. In fact, a lot of others in my specific areas of specialty over there really disliked me for wanting to take time to tutor novices. It's such a different world here. Any little watchmaking hurdle, no matter how commonplace, begets a stream of really helpful advice that solves the immediate issue and then anticipates the next one. It's been great for skill building. And without the peanut gallery of redditors who mostly don't have a clue what they're talking about. Thanks so much to all of you.1 point

-

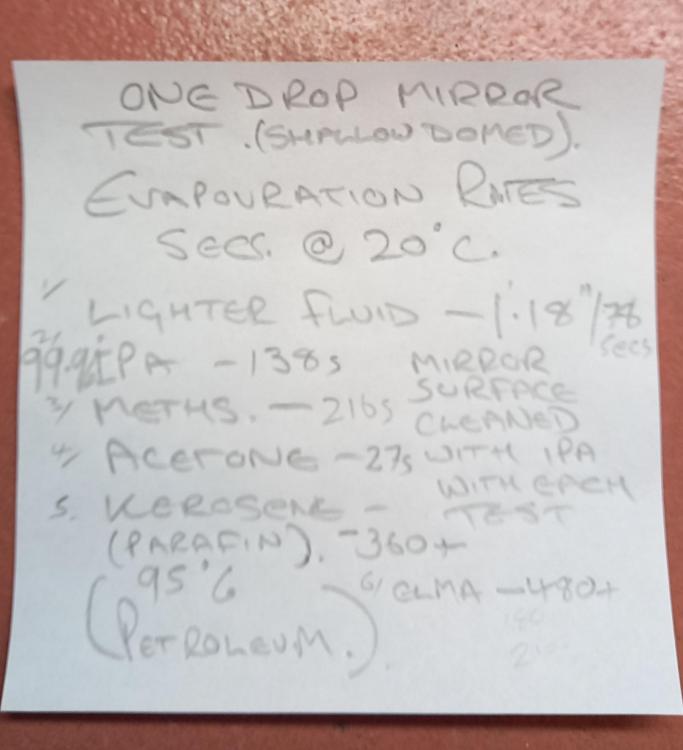

Here is an evapouration test of 5 solvent type fluids in common use for cleaning watch parts , and for a comparison a proprietary cleaner. The list in order of testing and result is as follows 1. Lighter fluid 2. IPA 3. Methylated spirits 4. Acetone 5. Kerosene 6. Elma ammoniated. This maybe helpful in determining how good their cleaning ability is. The testing was kept fairly strict as far as a diy approach can be. A cupped mirror was used to place a single drop of fluid at it's center and timed until the drop completely evaporated or i ended the test, the mirror was throughly cleaned with IPA and dried between each test. Each picture is in order of the test starting with picture 3. My thoughts and notes are pic 3. The lighter fluid left quite a thick layered stain. 4. IPA was less stained. 5. Meths was very light on staining but left a thin outside ring and droplets at the center that would not evaporate ( possibly contamination in the meths ? ) 6. Acetone was by far the fastest evaporation rate leaving again light staining but a heavier outer ring stain. Pic 7. Kerosene which was interesting, very low evaporation rate but a high wetting nature that climbed the whole of the mirror walls in 6 minutes, even with heat from a hairdryer the kerosene would not evaporate. Pic 8. Elma ammoniated which did not evaporate or move at all for 8 minutes and pic 9. needed extra 5 minutes of heat to dry out completely . Pic 10. Is the mess from the dry Elma fluid when i tried to clean the mirror. Make your own conclusions from these results.1 point

-

Regardless all the conversation till here, I will ask HOW exactly did You try to let the wind of the spring down? I meam I doubt that You are not aware that this is not possible by just detouching the click in automatic watches...1 point

-

My favorite was an all in one round tube with the fixed tungsten graver I could do most of my work just with that one. If you google graver handles and click images you will see many types. I couldn't get on with those round stumpy types, long and thin was best for me.1 point

-

After a long delay, I finally got the shock springs reinserted! I taped down the small bridge that held the jewel to my steel riveting anvil so it wouldn't move around and that helped a lot. The spring on the main body was easy in comparison. I purchased 25 springs from H&W Perrin in Canada ($9 with shipping) and found a good fit for the one I lost. Alex has great videos, which helped me with the spring. This Westclox with a Seiko movement is fighting me every step of the way. I'm sure it was never serviced. Almost every screw was frozen and needed a good soaking. The transmission fluid/penetrating oil combo worked best. The good news is that everything is in great shape.1 point

-

Have a look here. https://www.facebook.com/TimelineWH/videos/the-fusee-chain-maker-the-worst-jobs-in-history-at-sea/1778730682206168/1 point

-

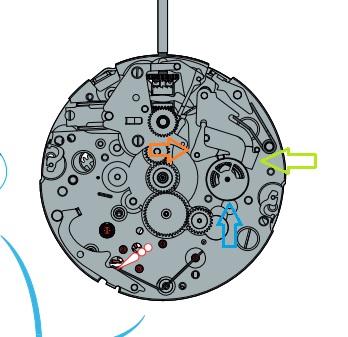

The hour counter wheel does have a clutch, which slips whenever the chrono is stopped. In the image the blue arrow is the hour counter wheel, the green is the hammer for resetting to zero, and the orange is the brake. The hammer is pivoted on an eccentric that goes through the watch and is moved by the cam; the cam movement causes the brake to be pulled away or come in contact with the hour counter wheel. When the chrono is stopped, the brake is in contact. When you press the lever to zero, the hammer comes down and pivots the brake away while zeroing, then when the hammer comes back up the brake comes in contact with the counter again. The spring that holds the hammer back is what is actually applying pressure to the counter wheel through the brake. If that is disengaged then the counter will run- but it will run all the time. In this case it could be that the clutch wasn't lubricated and is too grippy to slip when the chono is off. The brake surface that touches the wheel is toothed, but it could still slip. On older 775X movements, the brake was smooth, and slipping was a common enough problem that they went to the toothed version.1 point

-

Last night's experiment coming up later today, i bought some Kerosene. Tested 6 fluids that are in common use for cleaning and a couple of interesting findings.1 point

-

Had a rethink on my tweezer use yesterday, i must have 3 dozen old Dumonts , Bergeons, precista and various other good and cheap tweezers. So decided to scrap using my current choices and am now down to just 2 non brand makes. A very cheap Cousins brass pair that i dressed and polished to 2mm wide tips and a pair of antimag steel that have wide sides that i found amongst the pile and dressed these to fairly sharp tips and polished the ends leaving the handle which should have some friction built in ( who has had some tweezers slip right through their grasp and land right in the middle of a movement ? ). Working with them both yesterday on a Smiths diver was such a nice uncomplicated change, 95% of disassembly and reassemble is possible, the brass for turning the plate and fitting bridges plus some other concentrated gripping use and the steel for everything else. For repair adjustment and cleaning a few others take over, like a steel forked tweezer for pinning a stud, a thick tipped brass for turning a boot reg pin, very thin 4mm wide steel for barrel and mainspring work and obviously hairspring tweezers. There should be "for you" just the right amount of tension between the 2 blades, too much and you drop stuff when you lose concentration for a moment, too little tension and you will notice your fingers tremble much more as you try to resist the closing up on fine work, your finger muscles are attempting to match the tweezers tension output at low levels of tension , which is quite difficult.1 point

-

My first guess would be a friction spring, something that helps hold it in place when not being driven? If I'm understanding the diagram for that movement correctly, the lower centre hand is on item 52 in the drawing, "Hour counting wheel " - and that appears to be an assembly with a spring friction clutch included, between the driving wheel and hand / reset cam? It's shown in the calendar works assembly drawing, page 22. Or is the "reset" actuator supposed to remain solidly against the cams, and there is some slight loss of pressure on that somewhere, an eccentric screw or pin that needs adjusting? I've never worked on one of that style so I'm not 100% on the chrono disengagement or reset. I'm looking at the ETA 7751 technical manual, linked via this page: https://shopb2b.eta.ch/en/mecaline.html?p=31 point

-

Have we had " Tight Timers " "Dollar Dials " " Low dosh Discoveries" "Canny Cases" "Ticker Thrift finds " "Chrono Catches" "Wristwatch Hit" " Way-hay Watches " "Stingy strap-ons"1 point

-

Just found this amazing item on AliExpress. Check it out! SG$2.71 | RONDA stem 1002 stem 1003 stem 1004 stem 1005 stem 1006 stem 1009 stem 1003 movement stem 1005 movement stem 1009 movement stem https://a.aliexpress.com/_mt6jK34 Check out AliExpress.1 point

-

Thanks for all the replies. I think I will keep the watch untouched until I feel more confident to complete a full service. I had hoped to get a bit more use out of the watch before having to service plus it pains me to leave something 'broken' in the drawer and not get in and fix it. While I have no idea of its service history (no service marks inside the case back) it was running pretty well (tested with a phone app only) and certainly performing OK 'on the wrist' hence consideration of the mainspring fix. I have to wonder why the spring might have failed (previous bodging by another owner kinking the spring? over winding because the bridle is not slipping for some reason?) so that may be a sign that service was required regardless of its performance. What are the possible causes of a mainspring break? Anything that might suggest about the condition of the rest of the movement?1 point

-

I thought of "Precious Finds for Pocket Change". Or maybe "The Penny Pincher's Post"?1 point

-

I knew I this will bite me. I apologize for my laziness, I speak English poorly. What I meant was, I performed a barrel end shake inspection, which showed that the end play is a bit excessive, was a bit "loose". The excessive play was coming from the outwards bent barrel top and bottom faces, which had to be "adjusted", strengthen flat.1 point

-

Haha tight arse from Scotland by any chance ? Lol right on the nail Rob but then is any price above free to a Yorkshireman a bargain ?1 point

-

You wouldn't happen to know the service history of this watch would you? Or would you have A timing machine like how well is the watch running when it is running? From time to time watches need to be serviced it's not enough to just change the mainspring and you're good to go. I've been reading the replies your getting apparently working on one Seiko automatic that you haven't finished yet makes you an automatic expert so you have nothing to fear. Especially because the people who posted all the comments about no need to fear anything will help you straight out whatever happens just in case it should happen. But don't worry based on the replies watch repair is super easy no skills required. To be honest normally I don't care what people work on if you want to start with a Rolex I would encourage it I'd typically no longer will make any suggestions at all of people skill level. But if you don't feel comfortable Your the one doing the work they are not they have experience and they forgot what it's like to be in your position. If it makes you feel better finish the Seiko first or anything else you need to do to make you feel better about moving onto the next watch. Oh and minor reminder here this is an automatic watch and you will require breaking grease if you want your automatic mainspring to work correctly1 point

-

I have one of these tools. Used it a couple of times and didn't like it. The problem is that when the power is dialed up high enough to pop the cover off, the cover usually flies across the room and then rolls under some furniture. The blade then continues to move forward due to the momentum and the hardened blade then punches a line into the lip of the case. This line would affect the seal of the gasket, making the case non-waterproof anymore. I've switched to using a Seiko-style case knife and find that this design allows the user to exert more wedging force due to using a pushing action. Even very tight casebacks can be popped off with this tool.1 point

-

The auto mechanism is pretty easy to work out on this movement. Once that is removed with the rotor, then it is nothing that you can't handle. Here's a similar movement with some pics. This is with the rotor removed, by pulling back the retaining clip/spring This is the auto mechanism This is the automatic click There is a strange part that keeps one of the wheels in place that is held down by a screw as you can see in this photo. Turn the screw anticlockwise to allow the wheel to be removed as the slim piece of metal with a cut-out disengages from it and when assembling turn the screw clockwise so that slim metal retaining piece engages with the side of the wheel.1 point

-

Wow i could have used this a dew years ago VWatchi! What a thorough walkthrough. When I did a 2890-2, I don't remember there being such a difference in some of the oiling of the train of wheels. I just do 9010 on them all. I do have a question for you and for anyone else. I noticed that some of your parts have oxidized after cleaning. I have that issue sometimes and I'm not quite sure what causes it. I just did a Rolex 645 and had this issue on a lot of the pinions on the wheels. It seems to have definitely robbed me of some amplitude. I use an ultrasonic for all my cleaning, in addition to hand cleaning. Water and Liquinox. Then distilled water and a rinse in IPA. Sometimes it happens, sometimes it doesn't. Id like to be able to tell when it will happen so I don't lose amplitude. Does anyone know?1 point

-

I wish I had space for a large polisher . I have to make do with a Dremel type tool, but am very happy with the results. It's just a question of how much abrasive and the pressure. Depending on how deep the scratches are, I'll start with 600 grit and work to about 1000 or 1500. Then I used hard felt wheels with Dialux white. For final polishing (Dialux white) I find the small chamois wheels excellent (they are ideal for polishing gold too). I realised that looking under the microscope for scratches when final polishing was a mistake, only the naked eye matters. And a couple of wears and micro scratches will be back. I have only had this problem once or twice. I think it might be something to do with the crystaline structure. As Nickelsilver notes, you need to change direction. Once I figured that out, I didn't have a problem.1 point

-

Next time run the clock with power on and activate the strike and chime trains if fitted and note the positions of the warning wheels, stop wheels, lifting levers, gathering pallet etc and make a note. As I'm still in training i still make small diagrams of each movement I work on and write a small descriptive explanation for each component, this i do at the back of the book with the job number and towards the front i list all the bushes that have been changed. on each arbor Assembly, helps massively and you soon realise that all works basically work the same, its just the manufacturers that add little bits to improve ( make life harder in some cases ) movements.1 point

-

This is a common problem, miss-readings when the watch is cased, especially if the movement is not held rigidly in the case. When testing cased watches in my Weishi 1000 (you cannot adjust the gain), I put the crown against the outer metal post of the holder, as the stem and crown can transmit a clearer sound from the movement. Even so, I have some watches (like a Seiko Divers watch)where I cannot get a sensible reading from cased movement.1 point

-

I just got a Timex Macguyver field watch for under $20US. From photos, condition looks pretty worn, but I'm happy enough because all my past attempts at buying one of these ended when I wouldn't go over $75. And it will be my first watch with a 2 piece stem, though not my first plastic monobloc Timex. (the weird UFO Fun Timer series has a little threaded nylon plug in the back to reach the stem screw instead of a split stem)1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)