Leaderboard

Popular Content

Showing content with the highest reputation on 06/08/24 in all areas

-

This is just to say a heartfelt thank you to everyone who hangs out on this forum. I was browsing one of the bigger watchmaking Reddit subs today and was struck (as usual) by just how comically bad the advice tends to be over there, and how poorly researched or formulated so many of the questions are. What a difference here on this old fashioned web forum. I've been around here about two years now and every time I arrive with a question, I get a bunch of thoughtful responses from experienced hobbyists and working professionals, without any snark or condescension. For years, I was a major contributor (still on some global leader boards!) on the computer programming site Stack Overflow; the techies here know what I mean. That place is famously unkind to new members and non-professional programmers, with required adherence to a bunch of strict community customs and no tolerance for questions from people who just don't know yet what they need to ask. In fact, a lot of others in my specific areas of specialty over there really disliked me for wanting to take time to tutor novices. It's such a different world here. Any little watchmaking hurdle, no matter how commonplace, begets a stream of really helpful advice that solves the immediate issue and then anticipates the next one. It's been great for skill building. And without the peanut gallery of redditors who mostly don't have a clue what they're talking about. Thanks so much to all of you.9 points

-

Been there. Worn that Tshirt. I now have loads of watches, in bits. I made the mistake, as many do when starting, of obtaining cheap watches. I will learn to repair them I thought. Should have started my course ealier and learned that if a watch is working, you can do a service. If is is broken, unless you have massive skill, it will still be broken. You need replacement parts. Hey another watch that is broken will do. Not. Hence all the bits. I learned from Mark's course. I can now do full sevices easiy. Everthing except Shellac repair. Deep repair is specialist.4 points

-

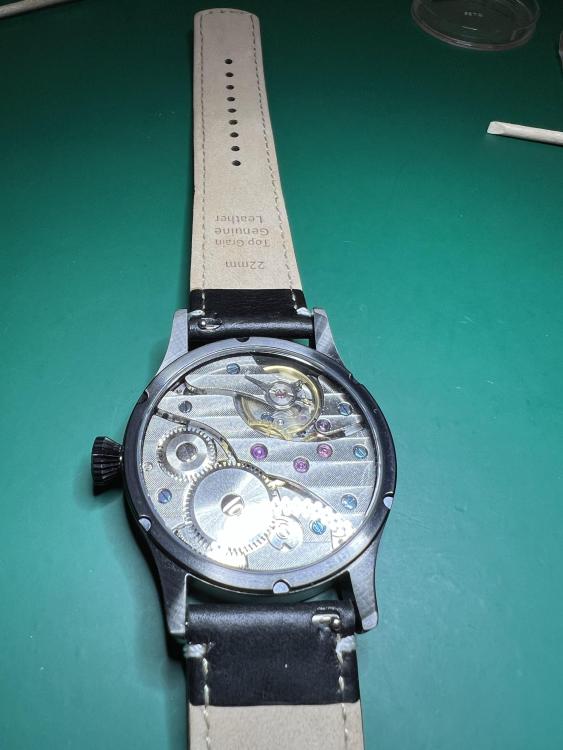

As I am a complete beginner in watchmaking I started by breaking the first movement I attempted to disassemble (I made posts about that it is an ST 36 I still use for practicing). I got a second ST 36 and I managed to disassemble clean lubricate and reassemble this one without apparently breaking anything. I decided that I wanted to make that movement part of a watch so I got a case, band, dial and hands from AliExpress. So today, for the first time, I kissed a movement put a dial and put some hands. Here’s the result. even something as simple as that, I almost ruined it. And of course, completely my fault. I was trying to fit the movement from below and couldn’t figure out how to make it work. It actually is supposed to come from the top and the top of the case unscrews. I almost done the top of the case by trying to pride it open, as I thought it was snapping on. Now, as I write this post, I checked on the item description, and it is clearly indicated that the movement should go from the front and the top of the case unscrews. Anyway, pretty happy with the result. I think I could cut the stem half a millimeter shorter. But that scares me a bit. Maybe file it instead of cutting it. I don’t think I can be that precise with pliers .3 points

-

Thanks. It's been a work in progress. I knew absolutely nothing about cameras or lighting when I started recording my escapades. It has gradually improved over time. I don't broadcast the channel here. I just like to come here to visit with like minded folks, pick up a trick or two, and provide help when I can (which isn't often considering the amount of collective knowledge on this forum).3 points

-

Hi Murks, One way is to use pin vise to hold the stud. Another way is to put the stud in place in the cock3 points

-

A microscope is essential in my opinion. I started out with a tiny Leitz head, single power (had to change eyepieces to change magnification) on a boom that swung it out of the way. When I got this little Leinen I found this Olympus, about the same size as the old Leitz but switchable 1x/ 2x, so 10x 20x with 10x eyepieces. It's on a post mounted to the lathe base, swings out of the way in a second, and can be repositioned over the work "by nose" as needed haha. A lot of folks put zoom scopes on booms over the lathe; it's fine too, but I prefer this compact scope personally.3 points

-

3 points

-

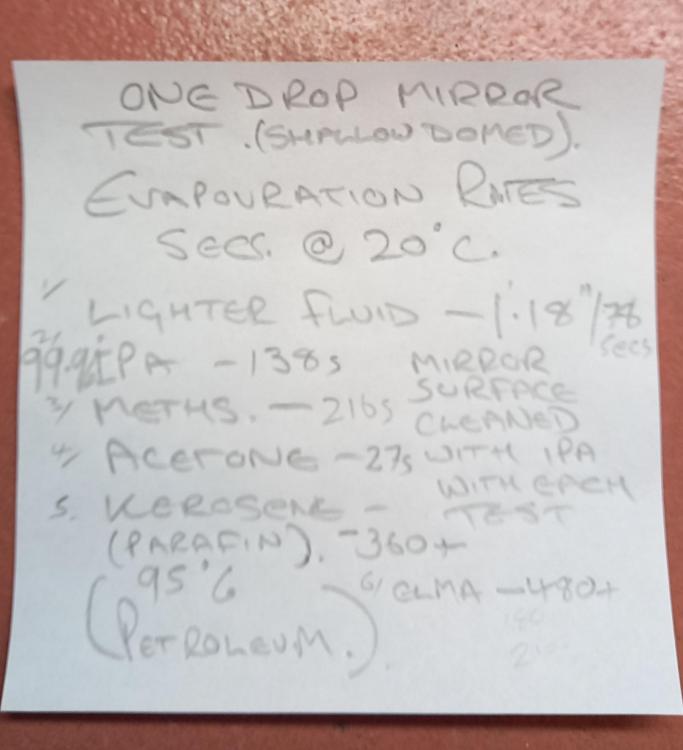

Here is an evapouration test of 5 solvent type fluids in common use for cleaning watch parts , and for a comparison a proprietary cleaner. The list in order of testing and result is as follows 1. Lighter fluid 2. IPA 3. Methylated spirits 4. Acetone 5. Kerosene 6. Elma ammoniated. This maybe helpful in determining how good their cleaning ability is. The testing was kept fairly strict as far as a diy approach can be. A cupped mirror was used to place a single drop of fluid at it's center and timed until the drop completely evaporated or i ended the test, the mirror was throughly cleaned with IPA and dried between each test. Each picture is in order of the test starting with picture 3. My thoughts and notes are pic 3. The lighter fluid left quite a thick layered stain. 4. IPA was less stained. 5. Meths was very light on staining but left a thin outside ring and droplets at the center that would not evaporate ( possibly contamination in the meths ? ) 6. Acetone was by far the fastest evaporation rate leaving again light staining but a heavier outer ring stain. Pic 7. Kerosene which was interesting, very low evaporation rate but a high wetting nature that climbed the whole of the mirror walls in 6 minutes, even with heat from a hairdryer the kerosene would not evaporate. Pic 8. Elma ammoniated which did not evaporate or move at all for 8 minutes and pic 9. needed extra 5 minutes of heat to dry out completely . Pic 10. Is the mess from the dry Elma fluid when i tried to clean the mirror. Make your own conclusions from these results.3 points

-

2 points

-

You have a good understanding of how watches work Ross and like the rest of us you will continue to grow and get better the more you work on them. Each week we learn something new, another idea, a better technique.2 points

-

You could actually make your own wooden pushers, drilled turned and shaped on a dremel type tool. I'll knock some up next week and add them to the thread.2 points

-

one of the interesting problems of watch repair is the lack of technical information and specifications. Such as the strength and power curve of a mainspring is never actually specified anywhere. yes we get physical characteristics physical size but what about the metallurgy of the spring itself? Or as you specify incorrectly new versus old style. for instance as I typically do pocket watches I typically have to take the mainspring out of the package and use a Winder to get the spring end because the end has to hook before the spring can be popped out. This means I get to see my mainsprings and the trend is quite troubling. the troubling aspect is these are all brand-new white mainsprings that often times have a slight yellowish color to them? These springs basically tend to look set and other words no S-curve at all. The one last week opened up to about 5 inches in diameter and looked set. The worst case previous example would been a spring that curved around the arbor but basically went straight out with no curvature at all. then there's the other bizarre springs a 12 size Hamilton it had a spectacular S-curve sort of. The top part was a single turn in the bottom part was multiple turns and actually resemble the figure 8. This watch still had spectacular amplitude the next day. So I'm finding of vast array of differences of the curvatures of brand-new Swiss mainsprings. Some of the best mainsprings I see for American pocket watches were both Hamilton and Elgin had their own alloys of steel and they tend to be some of the very best. Versus the unknown factor of wherever the modern mainsprings are coming from. So there's more to mainspring specifications than the numeric measurements unfortunately. I really think you need to get a stronger mainspring and get as close to 360 as you can be as you will be very happy. It tends to fall on deaf ears on this group but did you know what watch companies are concerned with? There concerned with happy consumers and happy consumers are concerned with timekeeping as they don't have timing machines. Then if you're properly timing your watch and looking at it for evaluation you need to look at it in more than one position. Because typically people who wear wristwatches move their arms around. So ideally should look at dial up dial down and at least one crown position typically crown down. then you look at your timekeeping 24 hours later and see how that looks. I don't suppose those of the same sellers that are selling Museum timepieces? I'm always amused a people that are selling a museum collection of some museum that closed in some bizarre country at very strange and interesting prices for basically total garbage. Then master watchmaker isn't a specific legal title as far as I know. So conceivably in some parts of the planet if you grasp what a pair of tweezers are a you don't poke your eyes out the first day you considerably are now the master watchmaker. Then on eBay the definition of servicing is always amusing as to what exactly does that mean anyway? Not just Ukrainian sellers but all kinds of people claimed the watch is in a variety of conditions which are rather vague. I've even seen people showing the timing machine results and often times I would be extremely disappointed with what I'm seeing but seemingly they think we should be very happy with what they're showing for the recently serviced watch. personally if I'm buying a watch off of eBay I would be very happy to know that it's never been serviced by anybody and definitely never serviced by whoever selling the watch.2 points

-

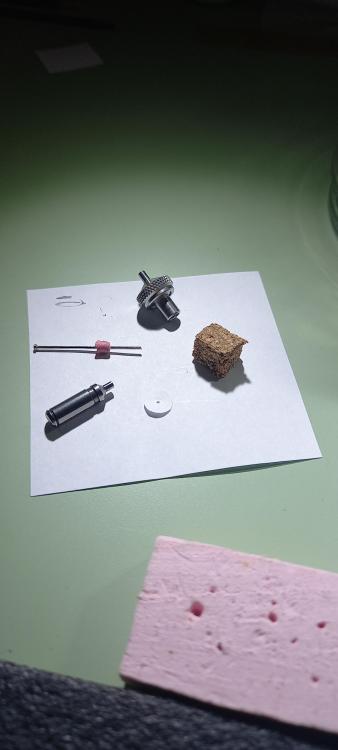

Eyup watch people, just thought i would share a little technique i came up with this morning to sort out a floppy minute hand on a Smiths 542 diving watch. The pictures are pretty much self explanatory, but i will do a quick run through of how i achieved a good adjustment. The tools, bits and bobs used are all shown and the only description needs to be the concave pusher that squeezes the tube's size down. To begin, stuff a piece of sponge into the bottom of a correctly sized stump to suit the head of the hand, this is to hold in place the pin that is pushed through from underneath. Next press a piece of paper ( paper punch ) that will protect the hand face finish, over the needle. Cut the needle as the tapered point will interfere with the hand centering. Use a piece of cork to hold the hand up until the chosen concave pusher engages the tube. Check the hand centering then press away, i didn't go crazy not wanting to damage the jewel tool, just short firm presses little more than you expect to exert when pressing a jewel in. Job done and lucky no broaching required. ,2 points

-

@spectre6000 I think “low cost, low risk watches” would work as a title with the advantage of being inflation proof. TOM2 points

-

A few years ago when I got initially transfixed by Mark's videos (having just stumbled onto them) I told my wife I know what my old-man-hobby is going to be! But I only made it into my forties before I couldn't resist any longer. If you are who I think you might be (and have an Oklahoma accent to go with your Location) I have seen your work and you are doing amazing stuff now.2 points

-

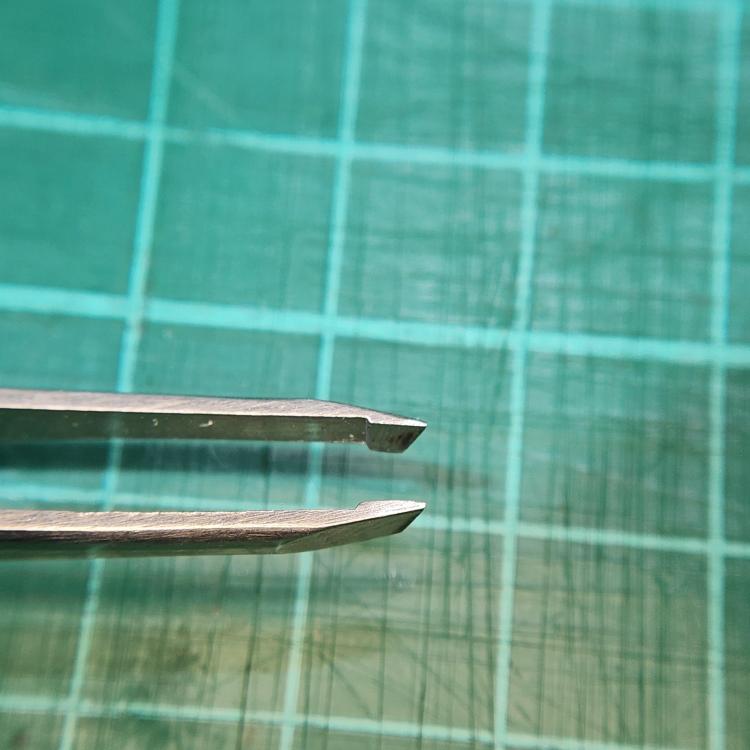

As with many videos: long-winded and waste of time (imo). A polished and slippery tip is less than optimal. I use rectangular Degussit stones (the Seitz one is nearly polishing, takes too much time for my taste) exactly as Nev shows. Frank2 points

-

Well said. I've found if I am searching for answers to a problem I've encountered, many times there's already a thread about that topic with good advice offered. I've thoroughly enjoyed being here, and more than got my money's worth in taking Mark's courses (I wasn't complete beginner but I thought taking a few courses from a trained professional might be worth it - and it certainly was!) and then continuing my growth with the help of this friendly and knowledgeable forum.2 points

-

2 points

-

2 points

-

I used to do the same and had the same issue, but I had a cunning plan...... "as cunning as a fox what used to be Professor of Cunning at Oxford University but has moved on and is now working for the U.N. at the High Commission of International Cunning Planning." I now use the same setup, but I place an old glass crystal from a ladies watch on top on the spring inside the mesh basket, this prevents the spring from standing up and it cannot now slip through the mesh:2 points

-

1 point

-

Thanks @tomh207 indeed it made sense that one is better off with a too long than too short stem as it can be shortened but not lengthened. I think I’ll reopen the watch and as you mention creep toward the correct length of the stem. I’ll also regulate the watch a bit. Compared to before I disassemble and reassembled it it the amplitude seem correct but it acquired a small beat error and where it was before running at +5s per day dial up and -? (Single digit don’t remember which) sideways it is now running at -4s dial up and a -7s sideways. I think I must have moved the regulator a bit inadvertently.1 point

-

When you get to the final adjustment of the stem always take it slow with a file. It is a good practice to cut it conservatively and sneak up on the final fit a tiny tad at a time. Tom1 point

-

This is how i fit the brass hairspring pin in the stud. Assemble all of the balance and install it in the movement, fit the movement into a movement holder. Slide the hairspring into the stud and fit the brass pin using fine tweezers. I stand the movement holder on it's side so that the movement is in a vertical position, this gives better access to the stud hole. Voilà1 point

-

1 point

-

I have an Eakins microscope which looks pretty similar to yours. The only thing I needed was a C-mount adapter. I got mine on ebay, it looks like the one below (but is a 0.35X, not 0.5X) That just drops into the trinoc port and is held in place with a grub screw and then the camera screws onto the top part. I also use a 0.5 Barlow.1 point

-

Take a rod that is bigger in diameter than the nut but is smaller than internal diameter of the outer bearing ring. File a slot in it.1 point

-

Or they don't care or are blissfully unaware! Good quality oils and proper oiling techniques are the most critical aspects of a service. Attached is a link where I allow myself to be uninhibitedly vicious! https://www.watchrepairtalk.com/topic/26353-whats-your-favourite-youtube-watch-repair-channel/page/2/#comment-218905 I even commented one of the videos with: "I really don't mean to be rude, but you're drowning that movement in oil. It's not going to run well or for long. You really need to do something about your oiling skills, or lack thereof."1 point

-

1 point

-

Without checking the old youtube , i seem to remember it's Weekend watches, I'll send my PR invoice in the post Adam Haha i was close its weekend watch repair, I'll send a discounted invoice instead1 point

-

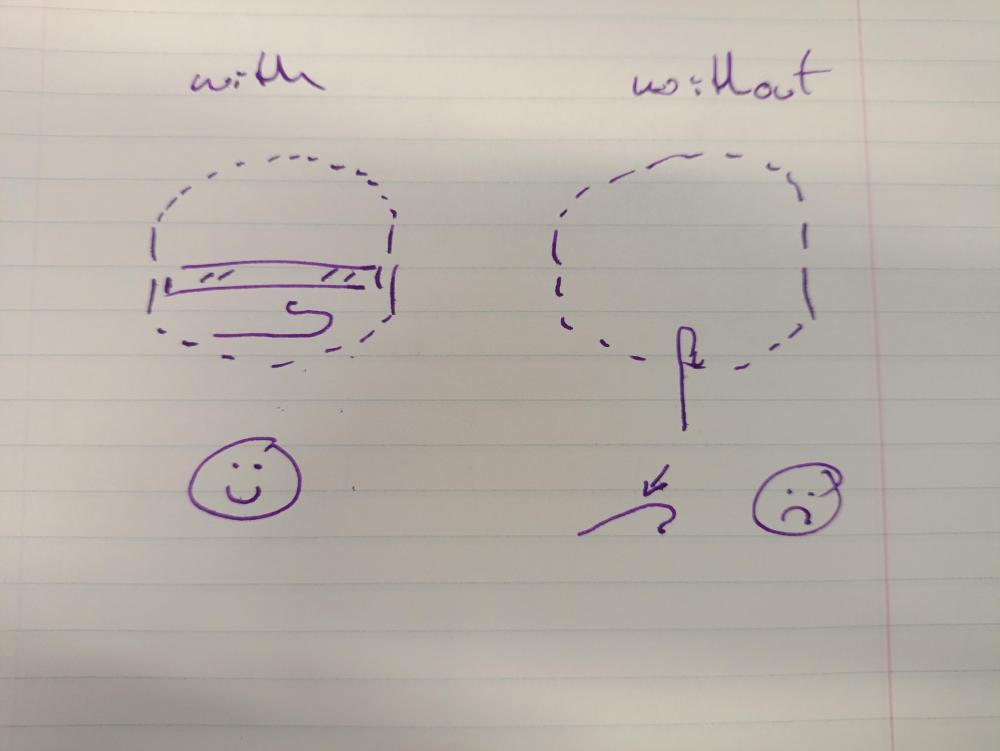

Yeah he coffee filter does need something to stop it flopping around, if i use one i sit it inside a small cut down plastic funnel. Thinking of buying a s. steel coffee filter, i refuse to use my v60 coffee funnel . I always clean screws by hand anyways. I find the "with" option always results with a smiley face1 point

-

1 point

-

Eyup Tom, yes i looked at those yesterday, i have them in my basket already, not expensive either. The pusher i used is a seitz so yes they do fit the 4mm clone, it was the biggest one seitz make so would not do an hour hand. It was just another idea of doing it. I've done a few on a staking tool before and this way would work there just as well too. It made it a one handed operation by keeping the hand in place and added a little hand finish protection, instead of trying to hold a hand on a stump with paper inbetween and drop the stake into position onto the tube. Life is hard enough as it is You could just use a flat full anvil if you have one for your tool or a metal plate laid over the clone's stump hole or even just free hand on a flat staking block. This just had a bit more control and i fancied a Saturday morning play ( that had a totally different meaning 20 years ago ) . No doubt i will get a slap from the missus later for that comment1 point

-

No that makes sense specs, personally i like some of the cheap stuff, in part it was designed so that anyone from any walk of life could have a watch on their wrist. But essentially you are correct this thread is about the hunt for real gems, I'm sure we are all more thrilled after opening a parcel and being faced with something really nice that reveals itself, than a bag full of cheapos.1 point

-

..and how critical EACH oiling point is. Absolutely. And many don't even show the oiling properly. They probably know this it's a minefield.1 point

-

Thanks for the tips, @Jon and especially for the video demo. I’ve struggled with this and knew there must be a better way. I’m always fearful of the potential for inflicting damage, but the method you show allows for better control in the process. Great tip too about dulling the blade with 400 grit paper. Big thanks.1 point

-

My favorite was an all in one round tube with the fixed tungsten graver I could do most of my work just with that one. If you google graver handles and click images you will see many types. I couldn't get on with those round stumpy types, long and thin was best for me.1 point

-

Had a rethink on my tweezer use yesterday, i must have 3 dozen old Dumonts , Bergeons, precista and various other good and cheap tweezers. So decided to scrap using my current choices and am now down to just 2 non brand makes. A very cheap Cousins brass pair that i dressed and polished to 2mm wide tips and a pair of antimag steel that have wide sides that i found amongst the pile and dressed these to fairly sharp tips and polished the ends leaving the handle which should have some friction built in ( who has had some tweezers slip right through their grasp and land right in the middle of a movement ? ). Working with them both yesterday on a Smiths diver was such a nice uncomplicated change, 95% of disassembly and reassemble is possible, the brass for turning the plate and fitting bridges plus some other concentrated gripping use and the steel for everything else. For repair adjustment and cleaning a few others take over, like a steel forked tweezer for pinning a stud, a thick tipped brass for turning a boot reg pin, very thin 4mm wide steel for barrel and mainspring work and obviously hairspring tweezers. There should be "for you" just the right amount of tension between the 2 blades, too much and you drop stuff when you lose concentration for a moment, too little tension and you will notice your fingers tremble much more as you try to resist the closing up on fine work, your finger muscles are attempting to match the tweezers tension output at low levels of tension , which is quite difficult.1 point

-

The Marshall Peerless lathes are a little different from most watchmaker lathes. On most, the head and tailstock locate on the bed on the angled sides of the bed (as do many other larger yet still "small" lathes). On the Peerless, the location is done in the slot in the middle of the bed, which also has angled sides. On many watchmaker lathes, the slide rest uses the aid of a part called a "shoe". The shoe fits the angled sides of the bed, and the slide rest has a recess that fits the sides of the shoe. This is honestly not the best arrangement, as there are two sources of wear and so alignment issues: the fit of the shoe to the bed, and the fit of the shoe to the slide. The former can be corrected (with a lot of work), the latter not really. It's possible that Marshall made a shoe for their bed, but I don't recall seeing one. Some makers made slide rests that locate against the front surface of the bed. Levin, Derbyshire, Marshall, and in some cases Leinen all made slides like this. The advantage is it eliminates the two wear points above. The slide goes on, slid up against the bed, and tightened. Easy. I believe Pultra also locate against the front of the bed, and there are certainly others. This is the style you want. This is a Marshall slide rest, top and bottom And an American Watch Tool rest top (with shoe) and bottom AWT later shifted to the simple locating piece like the Marshall/Levin- and went on to become Derbyshire.1 point

-

That time period does appear to be the start of the real boom of the hobby. I was a little later starting, but since 2 years ago the prices seem to be increasing at least quarterly. Tools especially, a lot of sellers have noticed the demand and hike their prices up to ridiculous sums . A lot of stuff at these hopeful inflated prices don't sell and end up being listed for months on end. Buy if they ever do ,and if it becomes just a "rich man's" hobby i doubt it will happen if folk have plenty of money to burn then they have better things to do than tinker with watches.1 point

-

Just did a basic search on google and they have come up with Marshall slide rests.1 point

-

I have a microscope over my lathe. It can be swivelled out of the way when needed. I find a microscope’s superior magnification more suitable especially when cutting small items such as balance staffs1 point

-

You can convert them to be more universal. I drilled out the arbor hole in some of the winders to accept larger arbors, using the generic Bergeon sizes as a guide. I did add the Bergeon #6 and #8 arbors (you can buy these separate from the winders) to give me 3.0 mm and 3.5 mm arbors respectively, as the largest in the Chinese set was 2.7 mm. That gives me more flexibility in which arbors I can use with which winders. Mainspring-Winder-Size-Charts.pdf1 point

-

It was already mentioned in many mainspring threads here : There is an optimum length/thickness that gives the maximum run time. The mainspring will occupy half of the inside barrel space then. Longer or shorter (same thickness of course) will need more than or less than half barrel space: less run time! Frank1 point

-

1 point

-

I'm not a fan of adding power to a vintage movement. I would go for the original specs or even slightly weaker.1 point

-

I dont have any personal friends who are watch nerds so I have to share my joy with y'all If you saw my other thread I had bought a Elgin Sportsman to start learning on after getting fairly proficient with my practice movement. I ended up stripping out some threads in the main plate and abandoning that project. I was able to clean it and get it running again so I learned a ton. Next up, a Gruen Precision that I got off ebay. This project took forever and after realizing the balance was no good and buying a donor movement I was able to get it back in working order. I dont have a time grapher yet but I've been wearing it for 2 days and its keeping pretty dang good time! - Disassembled, cleaned and reassembled / lubed the entire movement. - Pressed in a new crystal - Replaced the strap - Replaced the crown (the old crown was just destroyed) One thing that really killed me was that I scratched the dial with my hand levers. I was just rushing because I was frustrated (had to take the hands off a few extra times because they weren't flat) lesson learned. Next up is a Seiko that I also got on ebay. This will be my first automatic, and my first date complication. Super excited and so glad I found this hobby!1 point

-

I've been intrigued by everyone's input here...so I decided to give this a shot. I bought the"typical" Pearl watch-machine basket and trays, for about $65. The trays are good,..the housing is a nightmare ! Thought it would take the mixer off my bench at anything above about 200rpm. The housing is cast of course,..and it's not "true" at all...so the harmonic vibration was insane. So,..I bit the bullet and bought the Elma housing and top. Not the baskets though, as the Pearl one's fit the Elma. Saved a bunch there. The basket and lid came to about $80 with shipping. The opening in the Elma top is 8mm, and the shaft that came with my stirrer is 6mm. I bought a piece of steel tube, 8mm O.D., and 6mm I.D. Cut off about an inch of the tube, and drove the rod into it. Gives a really snug fit.... Lightly champfered the leading edge of the 8mm section, then lightly tapped it into the top of the Elma lid. Spins like a dream now So... I have about $240 total into this including jars and steel mesh for the wave breakers I'm pretty happy Best to you all Randy1 point

-

At Long Last the Fight for Parts Supply is Going to the High Court Cousins battle with the Swatch Group is now heading to the High Court in London. However, after the ruling in Switzerland, the case in London commences with arguments that you might not be expecting. Anthony Cousins explains the details below:- It has been more than a year since I last updated you on our legal battle with the Swatch Group to overcome their refusal to openly supply spare parts. Doubtless some of you will think that we have gone quiet because we have given up, but nothing could be further from the truth. When we started this process, I made a commitment to keep fighting until we won the day, or had exhausted every available means. That fight has continued and has now reached a significant milestone. In December of 2021, the Commercial Court of Bern gave a verdict that ran contrary to the most fundamental principle of British and European Competition Law, which is that no matter can be decided without consideration of the impact upon UK consumers and competition in the UK. We supplied the court with overwhelming evidence to show that watch owners are suffering substantially higher prices for servicing and repair, are waiting significantly longer for their watches to be returned, have an extremely limited selection of locations where they can obtain service, and are frequently obliged to have work done to their watches that is not necessary and that they do not want. We also asked the court to engage independent expert witnesses to advise them on how British Competition Law is applied and decided. The Bern Court refused to consider any of that evidence, declined to employ any expert witnesses, and determined that Swatch was “objectively justified in changing its supply chain. In so doing, the Bern Court did not consider at all any of the evidence we provided on the impact of Swatch’s cessations of supplies on UK consumers and competition in the UK. As we reported in August of 2022, we appealed against this ruling to the Swiss Federal Supreme Court (FSC), pointing out in detail why the interests of consumers and competition are always paramount. Our experience of the FSC has not been good. Twice before the Bern court ruled in our favour, and on both occasions the FSC changed the Swiss Civil Code and found in favour of Swatch. Although our arguments were entirely correct, it came as little surprise when in September of last year, the FSC refused our appeal and found again for Swatch. It is outrageous that a foreign jurisdiction thinks it can alter the basis of a UK law, without even asking for any opinion on this from this country, and at the same time ignore a wealth of factual evidence that has been placed before it. I have no doubt that the Swiss judicial system is not a suitable forum to give rulings on British and European law, but explaining in detail why is an issue for another day. However, for you as the reader to understand what actions we have taken subsequently, it is necessary that you understand some basic points about why the Swiss had the right to rule on British and European law in the first place. Brexit had not happened when the case started back in early 2016, and an agreement existed between the EU, Switzerland, Iceland, Norway, and Denmark, called the Lugano Convention. This treaty deals with how cross border disputes between parties in the different countries should be managed in the courts, and in simple terms stated that all the signatories to the convention recognised each other’s judicial systems as being equal, and gave each other the right to rule using whichever country’s law was applicable. In our case this meant that a dispute between a British company and a Swiss company about a matter of British (and EU) law could be dealt with by either country’s courts. When we first wrote to Swatch about taking legal action, we told them that we would be taking them to the High Court in London if they did not resupply us within three weeks. To avoid that, they brought a claim against us in the Bern court without, however, telling us that they were doing this. But this did mean that the proceedings were supposed to be dealt with using British and EU law, not Swiss law. I am not going to detail the whole case again here, but for what follows to make sense, there are four significant points I must explain about how this relates to the Lugano Convention in our case. Firstly, the UK was (when the case began) bound by the Lugano Convention because it was a member of the EU, but when Brexit happened half way through our case, the UK was no longer part of the convention. The UK government applied to join the convention, and whilst waiting for a decision from the other members, held that any case started under Lugano rules would continue to be bound by them. Over a year later, the EU was still refusing to agree that the UK could join the convention, so the rules applicable in our case became somewhat less clear, and indeed before the final appeal was heard at the FSC, the Swiss courts declared that the convention was no longer applicable, and the final appeal was conducted under different rules. Secondly, all EU members use the same wording in their competition laws that appears in the EU Treaty, the only minor and required difference is that where the EU Treaty says ‘in the EU’, the UK Competition Act says ‘in the UK’. As part of the Brexit process, although the basics of UK Competition Law stayed the same, Section 60a was added to the Competition Act which allows UK law to deviate from EU law, so the two cannot be considered to be the same. Thirdly, under the terms of the Lugano Convention, if a matter is decided in one country then all the others are bound by it, and the courts of those other countries cannot review or overrule the decision, or hear the matter again, even if they are certain that the foreign decision is wrong. This is part of a wider legal principle known by the Latin phrase “Res Judicata”, which loosely translates as “This has already been Judged”. The point of this is to prevent a matter being repeatedly litigated, and to avoid conflicting judgements in different countries. Fourthly, under the terms of the Convention, the only action another member country can realistically take, is to refuse to recognise the foreign decision if it is ‘contrary to public policy’, but this has to be something other than the law applicable to the decision concerned, for example if one of the parties right to a fair trial was breached. As highlighted in the point above, it is not possible to argue that the Swiss courts did not apply Competition Law correctly. That would be ‘reviewing’ the case, which is expressly forbidden. Keeping these four points in mind, the actions that Cousins have now taken can be understood. When Swatch wrote to us in 2016 to say that they had lodged their claim with the Bern Court, there was a delay whilst we were waiting for the papers to be served on us. In that time period, we lodged our claim at the High Court in London in the expectation that the proceedings in Switzerland would not be admissible. Normally, a claimant has only three months to serve the papers on the other party, but because of the extraordinary nature of how the Swiss proceedings played out, we applied to the High Court for extensions to that time period, and in the end were granted a very exceptional ten of them. This meant that when the final FSC verdict came in, we still had a live claim that we could use. After lengthy consultation with our UK legal team, we identified two ways in which we believe the UK courts have valid reason not to recognise the Swiss decision, which in turn would allow us to bring the case again in the High Court, and have a British Judge decide a matter of British law concerning British markets and British consumers. Firstly, both the UK and Switzerland are signatories to the European Convention on Human Rights (ECHR), and it is contrary to public policy for the terms of that convention to be ignored. A crucial part of the ECHR is that parties in a legal action ‘have the right to be heard’. For this requirement to be met, it is vital that any evidence offered is considered by the court hearing the case. This did not happen in Bern. Secondly (as I explained above) after Brexit, UK Competition Law had the right to deviate from that of the EU. The Bern court did acknowledge the addition of Section 60a to UK law, but continued to regard UK law as being the same as that of the EU, and made its judgement on that basis. It is therefore true to say that UK Competition Law has not been applied at all, so it is not correct to claim that the matter has already been judged. In July this year, we served our High Court claim on Swatch (UK), and had the High Court start the process of serving on Swatch Group and ETA in Switzerland. The process of serving on foreign companies takes a few months, but Swatch UK received the claim within two days, and were required by the rules to enter a defence within six weeks. As we expected, Swatch responded by stating that this matter was already decided, and they applied to the High Court to have the claim struck out. We objected to the application on the grounds that I have explained above, and after some debate back and forth, it was agreed that there would be a one day hearing before a Judge in the High Court in order to decide whether or not the Bern verdict should be recognised in UK law. In simple terms, if the Bern decision is recognised, then there is little else that we can do. However, if the Bern decision is not recognised, then our current claim will continue and a longer hearing will be timetabled at which the evidence will be considered, and a ruling will be given under British Law. We are very confident as to what that ruling would be. On Monday of this week the administrative team at the High Court processed possible dates for the hearing, and it has been confirmed to us this will be the week commencing 26 February 2024. Whilst I am sure that there will be much interest within the watch repair world, this case has far greater significance. The Bern decision is not confined to watch parts, but covers wholesaling and other forms of distribution of any product in any market. If that decision is recognised, then small businesses in every sector who can not compete with the buying power of their larger counterparts will find themselves either out of business, or under the direct control of the manufacturers, and the big loser in the end will be the consumer. I never imagined when all this began that Cousins would end up fighting to uphold the basic principles of UK business law, but if that is what we need to do in order to preserve the right of our customers to continue to offer their services to UK consumers as they have done for Centuries, then that is what we will do. I will keep you updated as matters progress. Regards, Anthony1 point

-

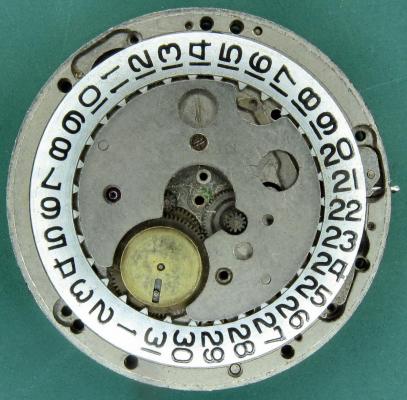

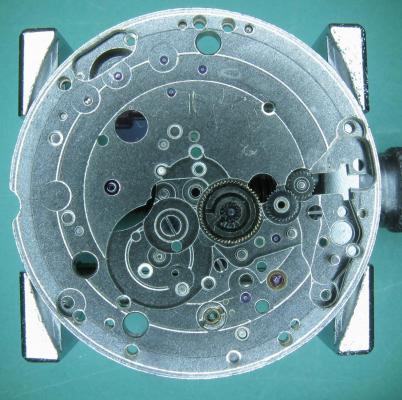

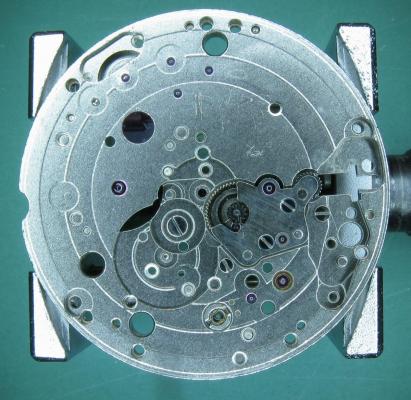

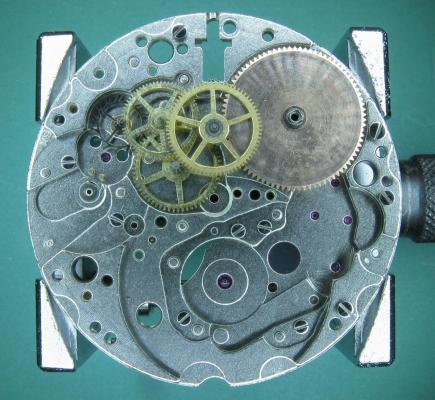

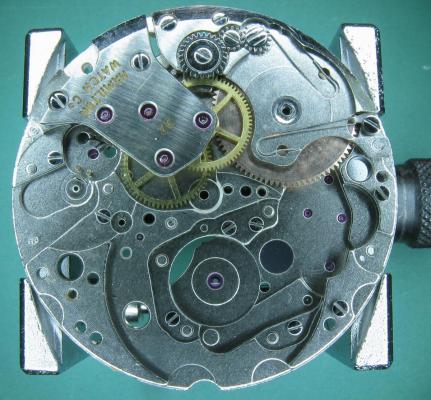

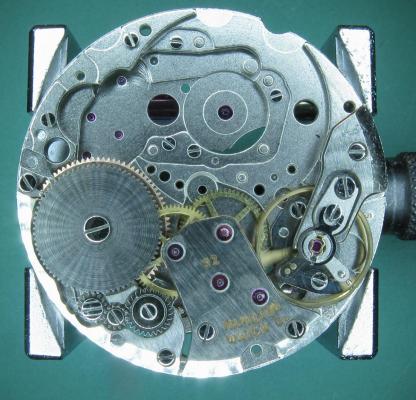

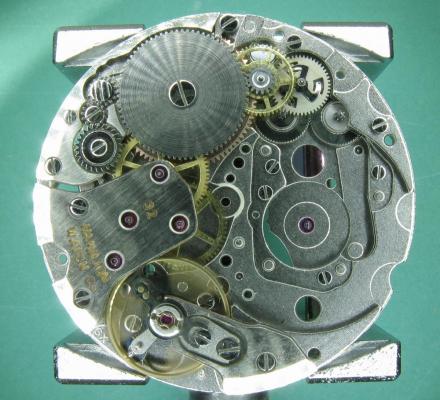

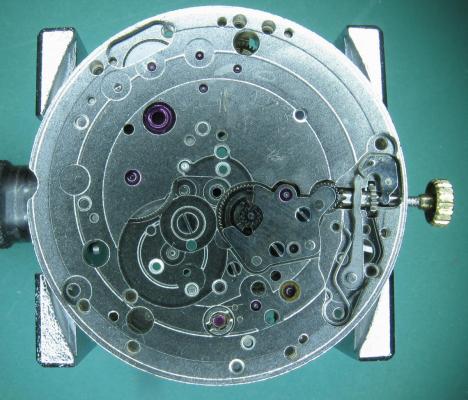

This is what I got up to over the Easter break. It was a project that I bought as a box of bits for a few quid about 4 years ago because although I had no idea what it was (the listing didn't say), it looked interesting and I fancied the challenge. It turned out to be a Hamilton Intra-Matic Westminster which the previous owner had tried to "fix", got as far as dismantling, and given up on. Cosmetically it was in good order but mechanically was not good. The rotor pinion had lost its bottom pivot, as had the second wheel (centre wheel in a more conventional wheel train). And because it had spent some time rattling around loose in the box of bits the hair spring was in a poor state, and what had me really stumped when it came to working out how it all went back together was a large and rather complicated looking wheel and pinion assembly for which I simply couldn't find a home. Any way, it was put to one side until I could track down a donor for the parts and to hopefully show me where the "spare wheel" went. The movement is a 30 jewel Hamilton 92 micro-rotor, which is a re-badged Buren 1281. Unfortunately (for me) this has been used in a number of higher end autos and also as the base movement in some big name modular chronographs because of its thinness, which means that they tend to hold 3 figure values even as spare parts donors so it took a while for me to track down a suitable candidate at the right price. However, I did manage in the end to nab one for just over £30 and it arrived at the beginning of April, so the fun could begin. No strip down on this one as the Hammy came to me fully dismantled, here is the donor as I got it. It's a Buren 1281, a bit grubby with some missing screws, and the minute hand pinion has seized onto the centre post. I later discover that the canon pinion (which is actually on the second wheel pinion) is loose and I reckon that someone had diagnosed the loose canon pinion, had tried to correct it by tightening what they thought was the canon pinion, which was in fact the minute hand pinion, onto the centre post, over did it, and caused the whole thing to seize, hence spare parts movement on eBay!!! I stripped out the second wheel (complete with canon pinion which I tightened), rotor pinion, balance and hair spring, and the main spring (which was in better shape than the Hammy one), and then put the parts through the cleaner; the Hamilton 92 parts had already been cleaned. And here we go with the good bit. The Hamilton 92 main plate; cleaned and ready for reassembly. I usually start with the wheel train when I build a movement back up but that's not possible here because the motion works bridge also carries the lower pivot jewel for the second wheel, so the motion works have to go in first. With the bridge in place you can see the pivot jewel in between the minute wheel and the intermediate wheel. The movement is flipped and the wheel train and barrel (cleaned and greased main spring, and braking grease on the barrel walls) are positioned. Train bridge and barrel bridge installed complete with crown wheel and intermediate winding wheels. At this point the end shake on all of the wheels was checked and the general free running of the whole train tested, then the pivots oiled. The ratchet wheel in place, the pallet fork installed and the escape wheel teeth / pallet jewels lubricated. The balance dropped in and off it goes. Then the auto winding reversers and reduction wheels go in. The three armed spring on the first reduction wheel is a ratchet which prevents the rotor from helicoptering during manual winding. Unfortunately it also gives the crown a very gritty feeling when you hand wind which takes a bit of getting used too but it is normal. Bi-directional flip-flop (for want of a better term) gear and auto wind ratchet in place. Cover plate on and the micro-rotor assembly installed. Turning things over again the keyless works go in. Then the calendar works, date wheel, and cover plate. Before the dial and hands go back on. Confirmation on the Timegrapher that all is well. The obligatory wrist shot. And something more formal for the album :-) This is now an absolute favourite of mine and has a permanent home in my collection. It took a lot of waiting to get the donor but it was well worth it. The watch has been running continuously since 11 April kept wound from wearing it when I get home from work in the evenings and at the weekend, and has remained within a few seconds of reference time. And the "spare wheel"..... was precisely that, it didn't belong with the box of parts that this project started out as. I do hope the seller didn't miss it :-)1 point

.thumb.jpg.60cd38ae2471f23998527c6f6a3643e4.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)