Leaderboard

Popular Content

Showing content with the highest reputation on 06/09/24 in Posts

-

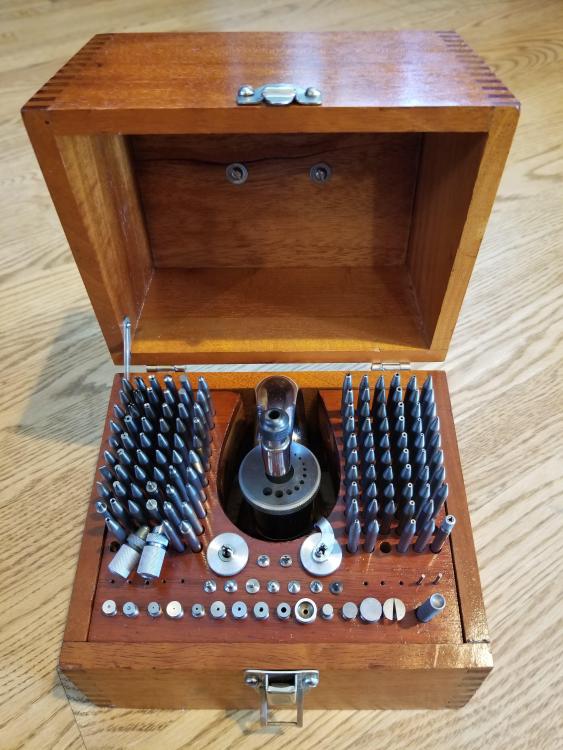

Several months back I came across this K&D 600 Series staking set from an old jewelry store that no longer services watches. I finally got around to restoring it. The case top had a crack running through it, by the handle. I cut that part off and replaced it with a new piece of mahogany. Sanded and stained the wood. Cleaned up the hardware. De-rusted all of the stakes, stumps, etc. and cleaned and lightly oiled them. Disassembled the frame to clean, lubricated and re-blued some of the parts. It turned out better than I expected.4 points

-

My watchmaker friend once told me that you can swap reversing wheels between SW200 and ETA 2824 but NOT the whole bridge, just the wheels. I asked him that about parts interchangeability because I was working on a Maurice Lacroix with a rusted SW200's ball bearing. He said that he doesn't know about the bearing but I try swapping anyway, first I put the whole ETA rotor on the SW200 and it worked perfectly, so I punched the rusted bearing on the Maurice Lacroix rotor out and replaced it with ETA's. Since the bearing gear connects directly to the reversing wheels I say the wheels must be swappable. Don't know about 2892 and SW300 though, I never asked my friend about that. I wish someone out there with parts could spend their time to try swapping parts between various ETAs and SWs then make a compatible list, we the community would really appreciated it.3 points

-

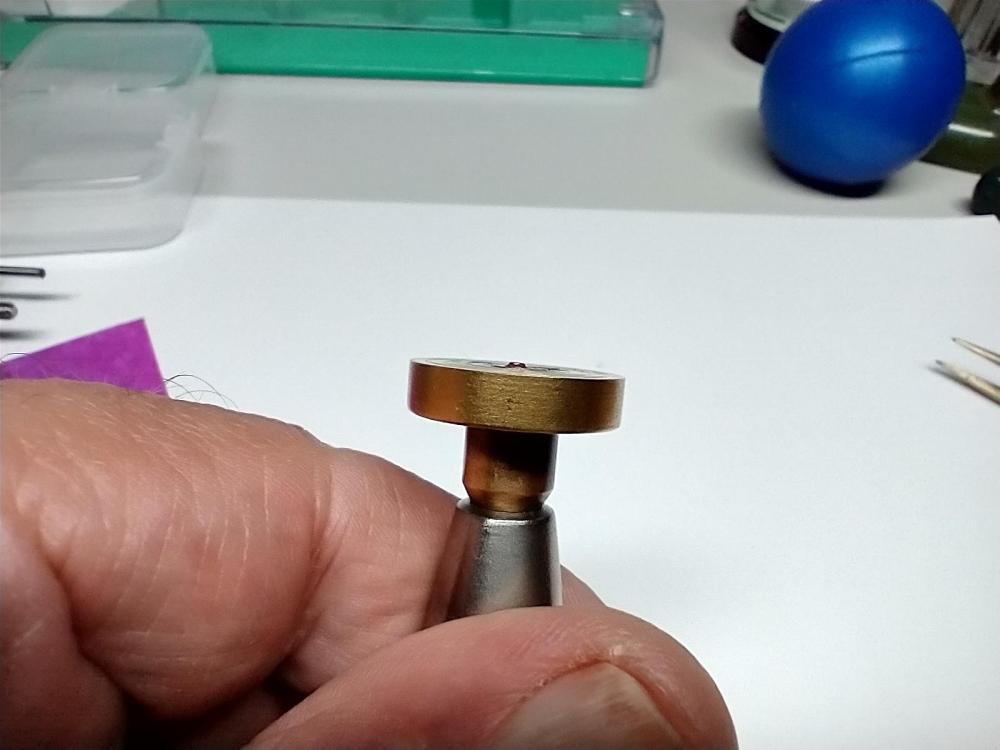

Hi guys, Some of you who have been stuck down the rabbit hole of watchmaking know that a fair part of it is finding a solution to a particular problem, especially when it come to vintage watches and all their idiosyncrasies. And, to find the solution, some unorthodox approaches and methods are employed. I find a good watchmaker will find a way to overcome. So, I'm servicing this Tissot 784.2 and find the centre wheel jewel is toast. The flat side of the jewel which the centre wheel sits on is intact, but the oil sink/dial side is crumbling and half of it is gone. It might last this way for some time, but maybe not and I'm guessing more on the latter. When I pressed it out, it fell apart. I teach my students there are two golden rules of watchmaking. Rule one: You are like the S.A.S. with servicing. You are in and out with no one knowing you were ever there. Not leaving gnarled screw heads and scratched bridges, etc. Rule two: Always think and consider the next watchmaker who is going to work on the watch. Don't leave obvious problems, or bodge something together, knowing it will create problems for the next watchmaker who works on the movement. If rule one is adhered to, rule two covers itself. The point I'm making here is, I could have left the centre wheel jewel and it might have lasted, but that's leaving the problem for the next guy and not very SAS. For some reason Seitz have discontinued the jewel size I needed (Sods law!), so I found one in a scrap movement that was the correct inside diameter. 0.8 mm to take a 0.79 centre wheel arbor. The outside diameter of the replacement jewel was 1.5 mm, so I had to ream the centre hole a little bigger from 1.19 mm to 1.49 mm. The problem was the jewel was 0.4 mm deep, so sat proud on the dial side and stopped the cannon pinion from seating properly, as you can see from this photo. I needed the jewel to be 0.27 mm deep like the cracked old one. Now, synthetic jewels are made from aluminium oxide with some colouring thrown in. Aluminium oxide is what is coated on wet and dry paper and as I don't have a diamond honing wheel, I decided to glue a piece of 400 grit onto a blank 8 mm collet and glue the jewel to a faced off wax chuck. Make sure the jewel is off-centre. Then I used my 8 mm lathe to hone the jewel from 0.4 to 0.27 mm. I can only use a GIF, so here it is... Then I lay another jewel that is 0.4 mm deep next to the one I'm honing and compare how much has been honed. I use a feeler gauge between the wax chuck and the wet and dry to gauge how deep the jewel is, so when I remove the jewel from the chuck using acetone, I know it is pretty close to what I want and found on my bench micrometre that I had honed it to 0.275 mm, so 0.005 mm bigger, which I'll force myself to live with. I was pretty impressed by the accuracy of doing this by eye with no CNC or even micrometre gauges whilst honing, just a rudimentary feeler gauge I made. Then I pressed in the jewel with a jewelling tool and set the correct end-shake for the centre wheel and ensured the cannon pinion sat correctly without touching the centre wheel jewel. There was no real need to polish the face of the jewel, as it isn't an acting surface, but could have done using the same method with different diamond micron pastes to get a mirror finish. The whole process probably took me close to an hour to figure out and work. Obviously the next time, it would be half as long. The diamond wheels would have made the job a lot quicker, as the wet and dry was wearing out making honing more difficult. I think with a diamond wheel, this could be done in a matter of minutes. A lot of the time was taken soaking the wax chuck in acetone and gently teasing the jewel away from the chuck. Because the jewel is so slim it is also very brittle and will easily break if this stage is rushed, so it's a matter of being patient and letting the acetone do its work and wipe away the melted superglue and gently prying it off with your fingers, not tweezers. You can't gauge how much pressure you are putting on the side of the jewel if you use tweezers. I could have saved myself time and effort by making a brass bush to fit, but I didn't like that idea I had robbed a jewel and broken one of my cardinal rules, which was more 'Dad's Army' rather than S.A.S.! It's a very similar way I hone down brass bushes, as parting them off on a lathe can't get total accuracy on the depth, so I finish them off like this. Now I've been successful using this method, I'm going to invest in some different grade diamond wheels for my lathe. These kind of skills and problem solving, I teach here in South London in evening first and second year courses. I hope this gives you ideas of overcoming obstacles and another reason to buy a lathe!2 points

-

In the Ebay link above, you get 1ml of 9010 for 16 pounds. 2ml, in factory sealed bottle, from Cousins, is 17 pounds. They do have Kluber P125 in small quantities, which is interesting. But a lot of it really is false economy. I think a lot of people just assume that oil is extraordinarily expensive across the board from every supplier- it's often not just more expensive from these re-packagers, it's literally the same price for half or less quantity.2 points

-

Interesting experiment @Knebo. Thanks for sharing! It also tells us that if we want maximum performance we should replace the reversing wheel with a new one which is the recommendation of ETA. I never do that as long as it's working fine but with this new knowledge, it's something that can be consider as an option.2 points

-

Just to add to the initial poster. I am new and have been in this forum since I started a couple weeks ago and everyone has been incredibly helpful and nice. Thanks2 points

-

Getting there. Finally got the toothache problem sorted. Pain should be gone in about 3 days. Then I can get back to watches. Looking so forward to it. Only going to do services for a while. Just to get my mojo back.2 points

-

So, I did an experiment. Not a fair one, I'll warn already. I compared the performance of the automatic works with: a) old (but functioning) reversing wheel, cleaned and treated with V105 b) new ETA reversing wheel, taken as-is from the blister Test 1: signs of rotor spinning when manual winding --> both performed fine, but the new wheel was better (super smooth) Test 2: With the automatic works fully assembled but not installed in the movement, held vertically, let the rotor swing from a 90° angle. --> new wheel the clear winner As I said, not a fair comparison because I'm comparing an old wheel (functioning, but potentially with slight wear) with a brand new one. But still, I think it's sufficient confirmation that the potentially-old ETA wheels sold by CousinsUK are still in perfect condition despite their age and don't need new lubrication.2 points

-

This is just to say a heartfelt thank you to everyone who hangs out on this forum. I was browsing one of the bigger watchmaking Reddit subs today and was struck (as usual) by just how comically bad the advice tends to be over there, and how poorly researched or formulated so many of the questions are. What a difference here on this old fashioned web forum. I've been around here about two years now and every time I arrive with a question, I get a bunch of thoughtful responses from experienced hobbyists and working professionals, without any snark or condescension. For years, I was a major contributor (still on some global leader boards!) on the computer programming site Stack Overflow; the techies here know what I mean. That place is famously unkind to new members and non-professional programmers, with required adherence to a bunch of strict community customs and no tolerance for questions from people who just don't know yet what they need to ask. In fact, a lot of others in my specific areas of specialty over there really disliked me for wanting to take time to tutor novices. It's such a different world here. Any little watchmaking hurdle, no matter how commonplace, begets a stream of really helpful advice that solves the immediate issue and then anticipates the next one. It's been great for skill building. And without the peanut gallery of redditors who mostly don't have a clue what they're talking about. Thanks so much to all of you.1 point

-

Or a design flaw whereby the friction fit impulse pin over time starts to ping out of perpendicular from slamming into the fork. Doesn't help you, but it would be interesting to sample about 10 of them at various ages.1 point

-

1 point

-

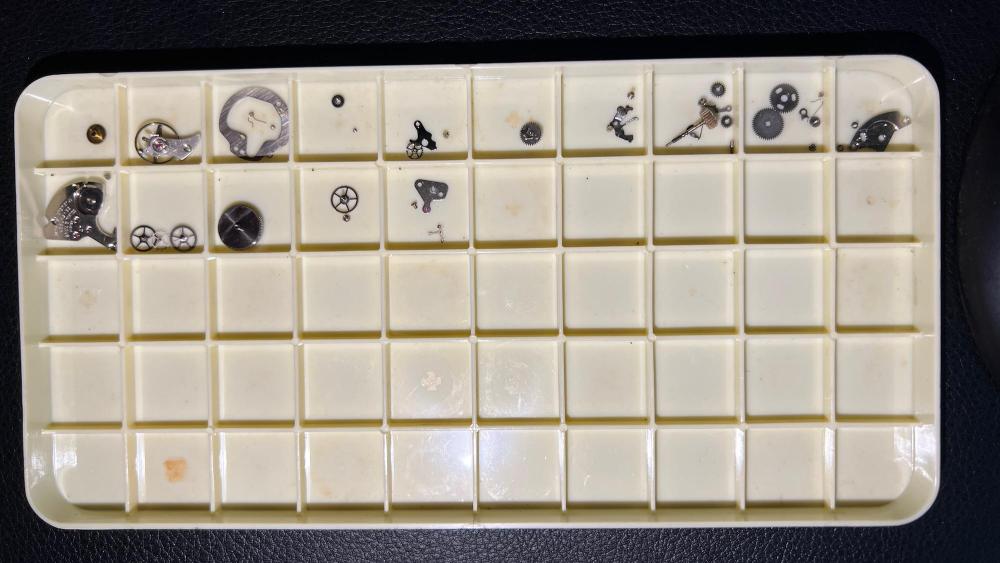

I totally agree with @Mercurial's points on starting with a known-running watch, and the ST36 being larger and easier to service. That said, my first repair was an Elgin 345, which taught me an awful lot about non-interchangeable parts. My next one was a very similar Caravelle, and I have to say I really love those Bulova movements and have done many since. They are very nice to work on, and as you noted parts are readily available. For the most part you can get away with the phone camera's zoom, especially for assembly/disassembly pictures. One piece of hard-learned advice: take more than you think you need. Unless I know for a fact that screws are the same, I keep them segregated with the parts they were holding on. Right up until I bump my parts tray and mix them all up, at least. You can see here how the automatic works are in one compartment, the train bridge in another, keyless works in another. I like to keep the balance and pallet fork in the center with their associated screws--I clean them separately and want to make sure they're kept safely away from other parts. I heard a great phrase on someone's Youtube video that stuck with me: "good screw discipline." Yes, definitely a 4x or 5x loupe. With a 10x you get much shorter working distance (you have to be around 1" from the work) and shallower depth of field. I know it's a little spendy, but a stereo microscope is hands-down the best purchase I've made. Honestly if I had only loupes to work with I might not have stuck with the hobby. It's such a pleasure for my rapidly aging eyes and back. I've even figured out how to tilt it so I can use it to install hands and work with my staking set. Having both eyes also helps with depth perception. Hope that helps, and good luck!1 point

-

Hello and welcome to the forum. Just follow Richard’s instructions, pictures are always useful in determining problems. Cheap watches are usually pry backs and some can be very tight.1 point

-

There was a thread recently here on WRT (April or early May?) with ideas to keep the various parts sorted, so you may want to search for that. As mentioned above, with experience you will begin to notice the different traits of various screws as they relate to their function and it'll be easier to sort out, especially if you practice with a particular movement or movement family. I use a divided watch parts tray with lid when I'm working on something new to me. Each subsection of the movement is taken apart and the related bridges, springs and screws are placed together. I can then take a photograph before removing the large parts for cleaning. By referring to the picture you can easily reunite the parts during assembly after performing any needed manual cleaning of the screws and springs.1 point

-

1 point

-

I have often to reshape stones, for example when I need to replace 'rolled over' or burnished type stone with a modern one. The other case is when a wider pallet stone has to be sized to tight fit the slot in the pallet fork. The tool that does this jobs is this kind of diamond disk. Grit 1000 or 800 is perfect for the honing. If the stone height is to be resized in the way Jon did, this will be enough to put the disk (the big one) on the table top diamond side up, put the stone on the disk, press it with finger and move it forward-reverse for a while on the disk surface, then try the height. If one is carefull and take measures not to grind the surface bent, this will take no more than minute to resize the jewel. The same way I use to resize the pallet stones. If a stone edge have to be rounded, then I turn on the top of a rod a 'nest' to receive the stone and glue there the stone with shellac, then while the whole thing is rotated, use the disk as a file to shape the stone.1 point

-

I'm not saying for a second that the truly "cheap" watches aren't worthwhile (I have plenty of them too). Hopefully that's not what was conveyed. I just don't want to make it the primary focus any more than making finding a Rolex for $5 the primary focus. Anything anyone finds under the threshold they feel is worth the cup of coffee cost of entry is worth it in my book. I want the name to convey that, and not just "cheap" as that leaves out a big chunk of the fun of it. Cheap, yes, also diamonds in the rough, once in a lifetime finds, watches to learn on, and probably some other angle I'm missing. Something like "I skipped a trip to Starbucks for this!" (which sounds way too much like a clickbait listicle title) that doesn't make any judgements on the watches themselves, simply notes the price paid was low.1 point

-

Yes- and even cheaper straight from the maker (and 30% off on top of that right now, 240 Euro) https://www.toolteam.com/de-DE/kaefer-jka-feintaster-40001-t-766312-4031452400014.html1 point

-

It could be the position of the snail wheel. You will need to test on your bench and watch what is a happening.1 point

-

I cleaned the fine springs in my cleaning machine up until one slipped through the mesh parts basket. I managed to find it by sticking a telescoping magnet tool down into each jar. Now, I just clean those separately in a small glass jar.1 point

-

I don't understand the crazy prices on used JKA Feintasters. Cheaper to buy new from CousinsUK and less likely to have issues. I have a micrometer like this or my analog Mitutoyo. Having the little table to set things on is nice. My Seitz set has mostly unmarked pushers. Some are marked but that's likely because the watchmaker that I bought it from has multiple sets and was able to give me a mostly complete set by stealing some pushers from a partial set.1 point

-

1 point

-

From the UK I bought cheap tiny vials of 9010, 9104 (HP1300), 9415 and 8217 from ebayer dondy0114 in this listing: https://www.ebay.co.uk/itm/276048651571 They came in their tiny containers exactly as pictured and I can see no contamination under my cheap "20x" eyeglass. I've done a few watches and have no reason to doubt the authenticity, but also no way to check it! The seller speaks of taking care over expiry dates. As a mere tinkerer I'm confident enough. And although it might work out at three times the price per ml, the tiny amounts are enough for a few watches per year almost indefinitely! So it's a good buy for someone like me.1 point

-

1 point

-

Take a rod that is bigger in diameter than the nut but is smaller than internal diameter of the outer bearing ring. File a slot in it.1 point

-

Probably just tight, try a one sided razor blade and work around the back.1 point

-

I adjusted the depth of the oscillating pinion, and I think I have it right. The dog bone spring I hadn't thought of I think now I'm more familiar with the movement and how it works I might strip down the Chronograph module, clean it all again, and re-build. Maybe get it running better second time round.1 point

-

I'm with OH here, long and thin. Over the years I've grabbed any blank ebony handles I can find, kind of classy, but whatever works. In the pic the longest thinnest one is one I still use from school 25 years ago, that's what we were shown to use and given, just 1/4" dowel (6.35mm). I have a few others like that around still too. It's important to have enough graver sticking out that the handle doesn't foul on the T rest.1 point

-

In years to come the owners will say they can't hear it because they have gone deaf.1 point

-

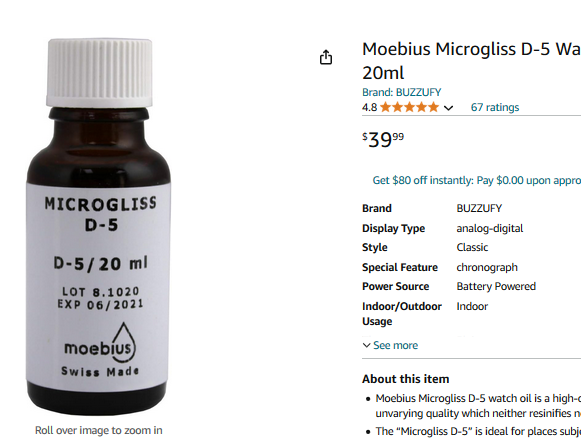

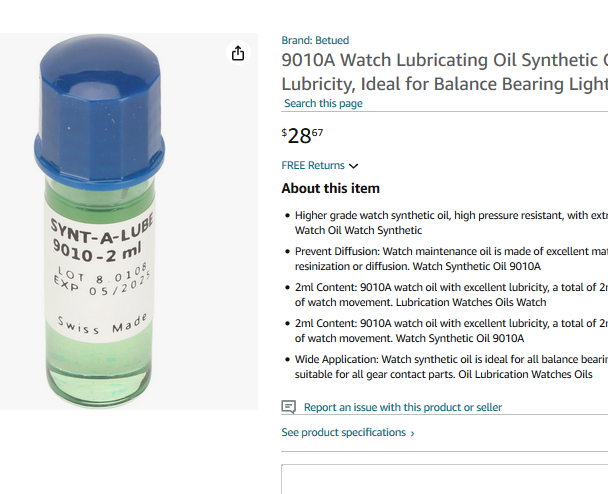

I've seen something similar to this on eBay. Someone seemingly helping you out by breaking up those really expensive bottles into? It brings up all kinds of interesting questions like if you're purchasing oil brand-new in original bottles it has an expiring date. These do not have any such dates so you're going to pay a premium price for oil that you don't actually know how old it is. Then when the biggest concerns anyone has is how does the oil get out of the bottle I'm assuming they use a syringe. So realistically if they wore gloves and a dust free environment you could get clean quantities of the exact amount of oil they claim. Then I remember the seller on eBay helping you out giving you these good deals etc. but are they? For instance I snipped out some images for 9010 and D5. Let's start with D5 if we purchased a 20 mL bottle off of Amazon the cost would beBasically $40 and purchasing our bargain oil in little teeny-weeny bottles were getting 2 mL at a price of? Oh there's a 50% off sale normal price would be and now are getting at a sale price. But let's look at the Amazon price it should be four dollars per 2 mL. Instead the sale price the bargain price $6.93 and the regular price $13.87. Notice a minor discrepancy on pricing that bargain really isn't that big of a bargain. Then we have the 9010 Amazon price varied by quite a bit it depended upon which seller I was looking at. Basically anywhere from roughly $30 for 2 mL all the way up to a bargain for them $50. Now instead a getting to milliliters I could did for the D5 you're only going get .5 mL which would run you $7.50 versus their price of $6.93 at least the sales price so I guess you are saving a few pennies.1 point

-

1 point

-

Hi, Hi, this is a watch hand press, I always want to have a more sturdy way to install watch hands, but I already own a nice set of Horotec watch hand installing tools, so I don't want to buy a watch hand press if I can just design one using the nice tools I have. So I design one, the dimensions are for Horotec watch hand tools, enjoy. Watchmaker Tools - Watch Hand Press Inserting Tool https://www.thingiverse.com/thing:39774111 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)