Leaderboard

Popular Content

Showing content with the highest reputation on 06/11/24 in Posts

-

May help if you place something in the hole of the spring (toothpick is good) with one hand whilst you rotate it with the other, then if it jumps out the toothpick will catch it.... may same you hours on your hands and knees looking for it.3 points

-

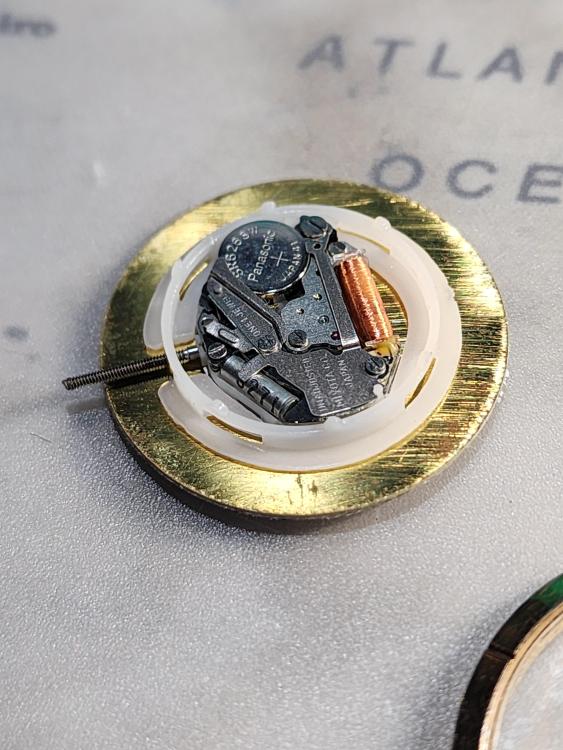

I thought a little experiment was due (as I currently have no watches to work on ) I cleaned a copper plate (scrubbed with soap, wiped with 99.9% IPA, so it passes the "water break test") On test were : (1) a clean section (2) one where I'd wiped with some clean Rodico, (3) wiped with Rodico but then wiped with IPA on a cotton bud (4) clean, then wiped with dried Evostick on pegwood (to see if Evostick leaves any residue) I put on drops of HP1300 and 9010. Unfortunately I don't have an automatic oiler to put same size drops on each section. So the drop size did vary a bit. After 30 minutes - all the dots look similar. Maybe the Rodico section have spread a touch? Looking under the microscope at an angle, there is definitely less surface tension on the Rodico drops (the drop is flatter) for both HP1300 and 9010. See pics below. All other drops look similar. (Maybe I should have done multiple drops) Conclusions. a) The Rodico wiped section did seem to effect surface tension on the oil droplets. b) After using Rodico, a wipe with IPA seems to remove the residue. c) Evostick does not seem to leave a residue d) I desperately need to get a watch to work on, so I stop doing silly experiments3 points

-

The place I worked we were longines agents. I had all their equipment all there service manuals. We were also agents for Rotary. Longines are in a different class. Rotary were bog standard. Again I say they are different and have no connection. Don't believe all you read on the internet.2 points

-

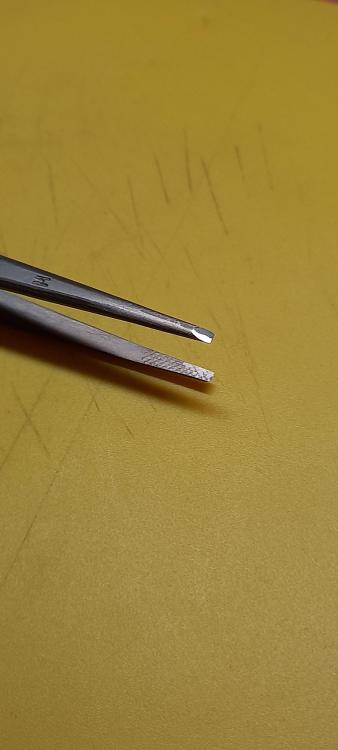

Some of the basics apply to just about about everyone but yep definitely a personal choice for the finer points. What i found with handling bigger parts with narrow tweezers is that the surface grip is low and the part would often slip and move around while it was being positioned so i try to use the wider brass 2mm for as much as i can even screws to i certain size. Titanium is definitely worth a go , i bought these a while back but have only just begun to try them out, i made the tips really wide and then use the edges for lifting screws out. i really must be more aware of what is in my photo shot you're all lucky i have underpants on2 points

-

This is a supershock spring. Rotate until one of the arms reaches the notch in the setting then lift out the spring. The cap jewel may be held in with dried up oil. If you are finding it difficult to remove place a drop of lighter fluid on the jewel and let it soak in to loosen up the oil.2 points

-

I have a couple of very expensive Dumont tweezers in steel alloy, No3 and No5 for very fine tasks. But my main tweezers are cheap No3 brass ones from Cousins "Swiss style". https://www.cousinsuk.com/product/brass-tweezers-cousins-swiss-style They are cheap and don't come perfect. I spend some time very regularly to dress them. Like this they work very well. Brass is so soft and wears so quickly that I didn't want to spend so much on Dumont or big brands...2 points

-

Hi Dave, Sorry, but You have gone wrong too far here. The banking pins on the photo look wrong as they are too thick and at least one of them is on completelly wrong position. Bending them will not help, may be some filing may open enough free space for the pallet fork, but it has to be done with understanding the interaction fork/ balance and fork/ escape wheel. So You need to learn the escapement action in details. The pallet fork is something that can not be replaced by size. There are too many sizes in it and their combinations are endless number. You need pallet fork from the same calibre, so You need to find out what calibre it is. Then You will need to source a donor movement. Still palet stones adjustment will be needed to accomodate the pallet fork from donor. Thus, it will be much easier to repair the donor than what You have... The other option is to make new staff for the pallet fork, but it needs lathe work and skills2 points

-

Maybe this has been discussed, but why not both. Keep the 404 thread going as is and start the 10.10£ club in a brand new thread! Problem solved for the purists loyal to the 404 and a new cool thread as well!2 points

-

Thank you for your help. I had to pop the bezel off. It was easy... then I tried to loosen the stem. I pulled on, apparently to hard, and I think it broke. had the tilt the guts out and slide out the stem. I think I am going to find a similar watch and swap the dial. I put a hurtin' on that case and the crystal had a crack. Live and learn. I appreciate all of the help you provided.1 point

-

Haha, this is a friendly forum but sometimes we really need to say " you screwed up " No malice, just sometimes we just need to be direct.1 point

-

I rather like the third quote that I have from @nevenbekriev for which unfortunately I have to agree. A whole variety of actions have been taken based on the perception that there was a problem or just visually it look like there might be a problem It sort of tickled me as well, like saying you've really screwed up but in a diplomatic and kind way.1 point

-

Here is the info on Longines. As I said not related. The only thing they both have is Switzerland. https://en.wikipedia.org/wiki/Longines1 point

-

You=angel, when I gained access to your email. Rgds1 point

-

I rather like the third quote that I have from @nevenbekriev for which unfortunately I have to agree. A whole variety of actions have been taken based on the perception that there was a problem or just visually it look like there might be a problem? one of the things that I always like is background history so the watch was completely assembled all the components were there. what was the condition of the watch did it run for instance? Did it just need cleaning before all these interesting repairs took place. Then grandmothers watch sentimental value to anybody in the family? Always best when starting off in a new field to not to work on things that will get you in trouble with the family just in case. one of the problems for people new to watch repair is the failure to grasp where movements come from. Sometimes there made in-house by the company stamp on the plates but usually they're basically an OEM component purchased by a company. then the company name? Just because a name is on the plate doesn't actually mean that's the same company that originally held the name. For instance the Elgin watch company all that exists of the company is the name. Watches made in China with the name so it's a valid name it just isn't the same watch is that Elgin made way back when. There are all kinds a Swiss companies that people have started back up again and talk about their proud history of but the really not the same company all that's left is the name which is very unhelpful in watch repair the escapement is a very interesting location in the watch and unfortunately a extremely critical location. Everything here is critical changing anything conceivably means the watch will never run again. So for instance visually you now have street banking pins but are the in the exact location there supposed to be? Then attempting to find a generic pallet fork to replace the one that is damaged will lead to failure. actually another option would be just to replace the staff. Until we identify the actual maker of the movement we won't know much of anything but typically on watches there are some generic components. Mainspring is can be ordered by size. Or pallet fork staffs at least you use to build a buy new ones so we just need the dimensions of the staff and if you're really lucky we may build just replace the staff itself without making a new one. Making a new one is rather tricky as they typically are really tiny. just now checking two of the sources that I would look at I'm not seeing a 555 listed?1 point

-

https://en.wikipedia.org/wiki/Rotary_Watches https://coron.et/new-1minute-reads/longines-record-whats-the-story1 point

-

I bet you collect the shavings to weigh in, being a tight Yorkshireman. Hehe.1 point

-

I ordered from Cousins... The shipping is orders of magnitude more than the gaskets.... but then again, this is Watch Repair1 point

-

1 point

-

1 point

-

Hi, I'm Rory, a watch enthusiast that is mostly interested in vintage watches. I am still learning basic watch repair concepts and have enough tools to do basic repairs and crude "servicing". I am also very into 2d printing and like seeing ways that it can be used in conjunction with watch repair, such as cheap custom movement holders etc.1 point

-

1 point

-

I'm pretty certain that Rotary never made their own movements. I have only ever seen AS, ETA, and Peseux movements inside Rotary watches, and some Chinese in more recent examples.1 point

-

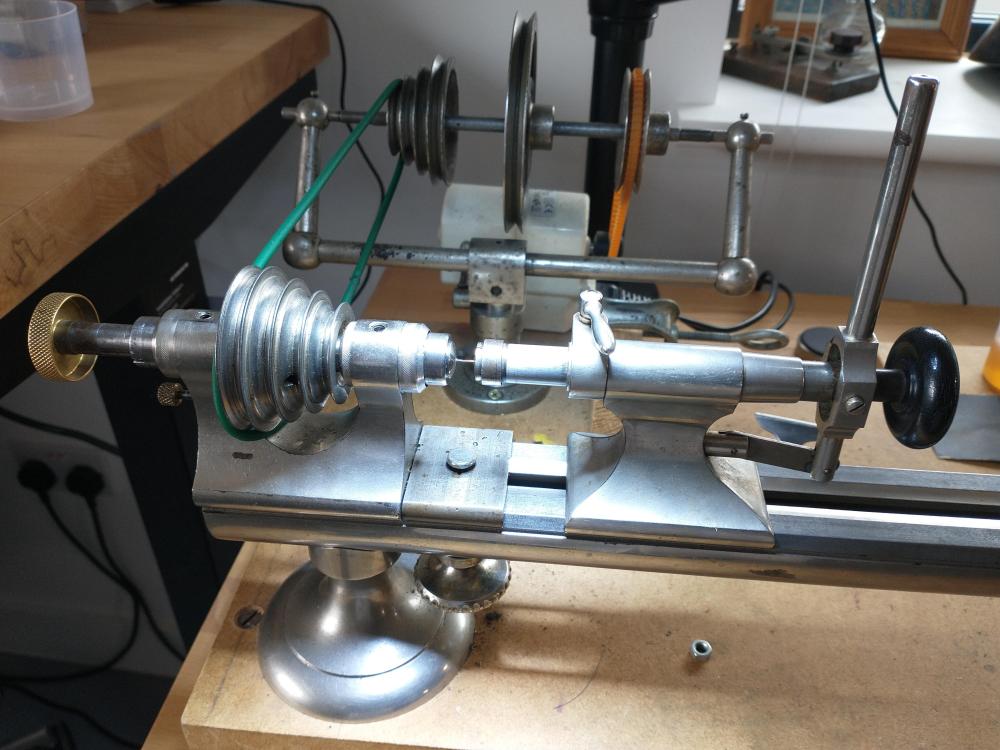

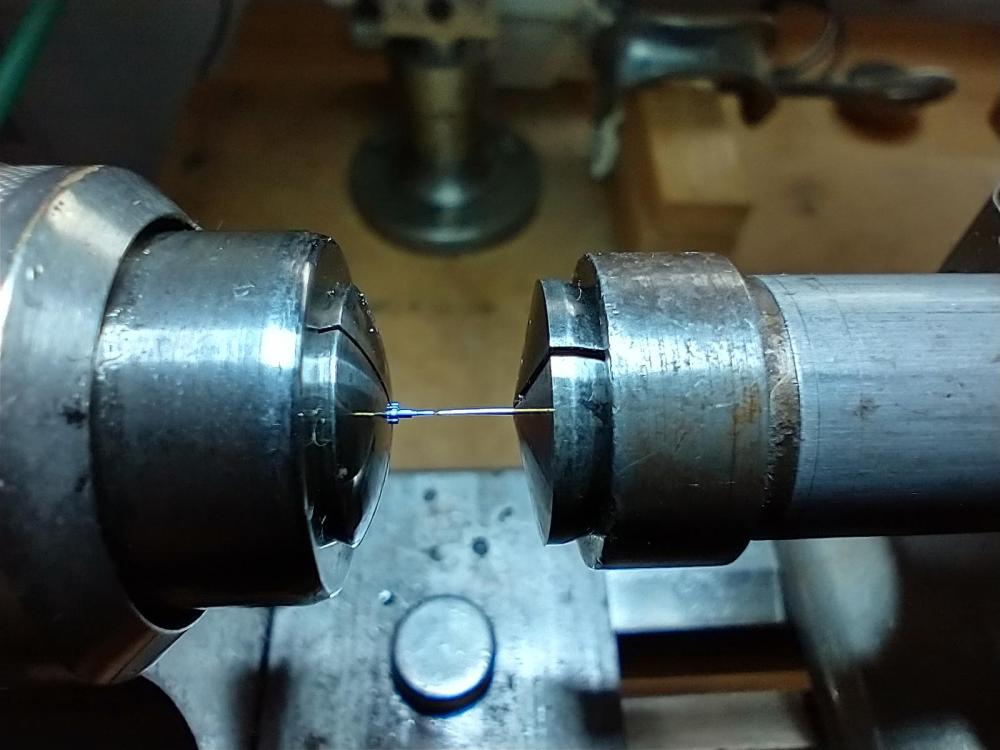

It's always worth investing in a tailstock that takes collets. I've got several tailstocks based on these two designs. One with collets and one with runners. The students last night were using them on a few WW bed Boley Leinen lathes to straighten pivots after removing the arbor and pinion from the wheel. They held a brass taper pin in a collet in the tailstock to have a guide to straighten the pivot/arbor in line with, as you can see in the first photo. The runout of the headstock is about 0.005 mm, which is pretty darn good for this old girl. I use airline oil to lubricate it, which is ISO 22. You can buy it from Amazon or many other places (Toolstation). Great for honing screwdrivers and tweezers as well. https://www.amazon.co.uk/SILVERHOOK-SHAL1-ISO-Airline-Liter/dp/B00H8OJ228/ref=asc_df_B00H8OJ228/?tag=googshopuk-21&linkCode=df0&hvadid=310737079185&hvpos=&hvnetw=g&hvrand=8446584936607870183&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9045907&hvtargid=pla-565058627185&psc=1&mcid=c78243a34ad337cba6caab83f5da302c1 point

-

1 point

-

Thanks for that, very helpful. But naturally, the more you learn, the more questions you have! Cousins have domed crystals in any diameter and multiple thicknesses. The gasket is still in my watch, and with a vernier, if I push a bit, I measure the inside diameter as 36.0mm. So, knowing nothing, that seems like it would be a reasonable interference fit, but is there a better way to figure this out? And how best to determine the correct thickness to use? Is it OK to re-use the gasket, or should I buy a new one? I probably have a bunch more questions, but that'll do for now1 point

-

What you describe sounds perfectly reasonable. I can't disagree with anything. I guess we come to a point where it's really about personal preference. Personally, I use my brass tweezers dressed to about 1mm for almost everything. From plates to screws and jewels. I rarely find them bent. But I do have to dress them frequently. Then I use thicker brass tweezers (2mm tip), e.g. for inserting the barrel arbor or sometimes for thicker springs. And No5 steel to manipulate shock settings (not grabbing, but just pushing with the 0.1mm tip). Wide and thin carbon tweezers for dials and hands (or jewel picker-uppers), respectively. But this is all personal preference, I think. Most approaches seem to be fair game as long as we're not scratching bridges with steel tweezers.1 point

-

You should consider titanium, reasonably cheap and material seems to be the best of both worlds between brass and steel, see my writeup above - just a suggestion1 point

-

My company (JRW) now has a trade account with Boley. The chuck adapter, on its own, looks like it would cost around £170 after taxes and shipping; ouch..1 point

-

If you go to(see link) it lists calibers by ligne and also gives the staffs measurements. Measure the movement in lignes then measure the broken staff and cross reference https://www.balancestaffs.com/longines.php1 point

-

1 point

-

I find that a caseback knife of the above design is best. The conventional caseback knife is prone to slippage and scratching up the cover, as you have discovered. This Seiko style knife is used with a palm grip, with the handle sitting in the middle of your palm. The blade is wedged into the crack between the case and the caseback. You may have to experiment whether to use the blade with the bevel facing up or down. I find that facing up works 90% of the time. The blade is pushed into the crack without any levering action. This is not a tin can, do not lever the cover off. You are basically using the bevel to wedge the cover off. This method prevents slippages and damage to the caseback. If you are worried of hurting yourself, use a glove on your left hand. The only time I use a levering action is on watches with the tiny lip on the caseback that is specifically designed to be levered off. Sometimes cheap watches have incredibly tight casebacks that can only be taken off with more advanced opening tools. Hope yours isn't one if them.1 point

-

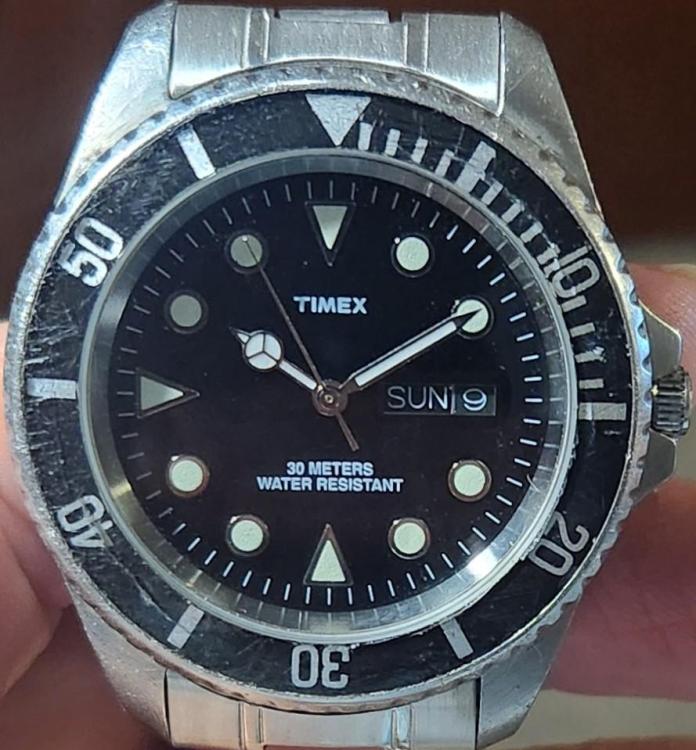

You can see what is left of the crud around the edge of the crystal where the small gap with the bezel held it in place until it hardened. The case is all SS. The bezel does not rotate but I am not scuba diving either....had to use the trick @JerseyMo describes about grabbing the winding stem with pliers and removing the crown to get this movement out of the case. These worked perfect with the offset. All in with the battery, crystal with End pieces and shipping (last 2 items from Cousins UK) £10.99.1 point

-

Hi Colin, If the reverse wheels are lubricated as needed, then another possible reason is they are weared. The wear is in the bearing table/pinion and may be in a manner that the table of the wheel can be tilted on the pinion and thus may rubb on the table of the wheel that connects the both reverse wheels pinions or somewhere else. Another kind of wear is when big radial free play of table/pinion bearings is present, in such case the mesh of the wheels is not normal and may cause friction.1 point

-

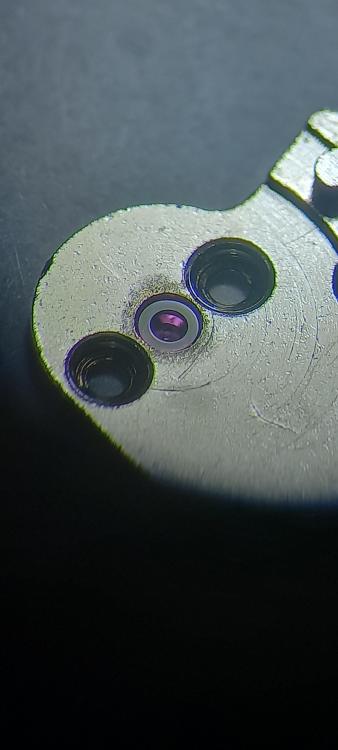

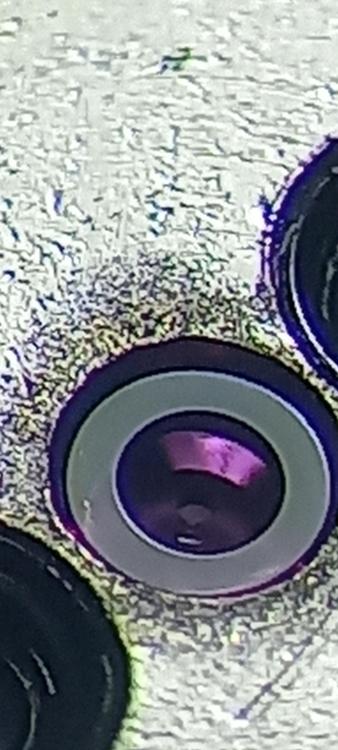

Here is an example of how well the Kerosene is cleaning, these pictures are of a fixed balance jewel that I have just replaced on a cock. After pressing the jewel in I pegged the jewel and surrounding metal, as we know this spreads any dirt and grease present which is then wiped off the pegwood onto some tissue paper, but still leaves a thin film of grease on the watch parts to be cleaned off. A 20 second hand brush clean in Kerosene then placed on tissue paper and folded over the part to soak up the fluid plus a few blows from a puffer. Then rinsed in IPA hand brushed and again dried with tissue paper and blown. The pictures of the jewel are as it was left after cleaning, the whole cleaning process was completed in under a minute. The jewel looks spotless and polished.1 point

-

If you provide the dimensions of the movement and photos of the keyless works, someone may be able to help, if not then it's a guessing game. As you have discovered, many different sizes for all dimensions. Chemical Engineering for me, we have a few Electrical Engineers on here, amongst other Mechanical Engineers.1 point

-

The pins may have been bent on purpose. Altering banking pins opens a (very large) can of worms. Setting them correctly takes some effort, and reading up on what is required, as you will find if you search the forum.1 point

-

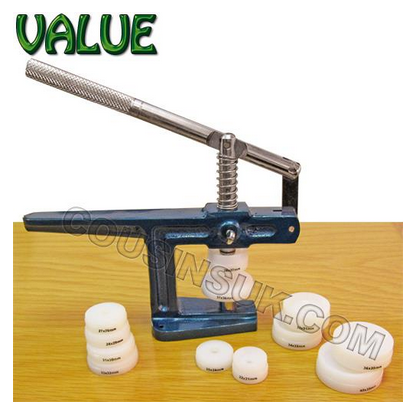

Disclaimers: I have never touched a Skagen. I'm going by pictures I've been able to find online, so this is kind of generic advice to someone new. Also I'm in the US, so apologies on the mixed currencies in my reply. Well a brief online search shows generic Skagen glasses priced at $25 on Esslinger, and real Skagen ones from £25-42 on Cousins UK. Add in the cost of tools, the watchmaker's time, skill, and the monetary liability of working on your watch, and £85 looks pretty reasonable. That said, as you noted there's a satisfaction in doing it yourself, so it's not always about saving every penny. Crystal replacement isn't too difficult, and flat or domed doesn't make much of a difference in my experience. You will need tools to open the case, remove the movement, clear out any old crystal bits, and then press in a new crystal. For a crystal press, I use one of these, about £45 at CousinsUK. Some people like the lever style. This one is only £14.15 at Cousins. It looks like a snap-back case, so you can use the press to close it back up, too. To open it you'll want a case knife of some sort. I use this type most of the time. And then you'll want to have a nice pair of tweezers, and probably a small screwdriver to remove the stem, most likely in the 1mm range. You'll also want a spring bar tool, so you can remove/reinstall the bracelet. This is a nice one for £8.95. Hope that helps your decision!1 point

-

1 point

-

I have often to reshape stones, for example when I need to replace 'rolled over' or burnished type stone with a modern one. The other case is when a wider pallet stone has to be sized to tight fit the slot in the pallet fork. The tool that does this jobs is this kind of diamond disk. Grit 1000 or 800 is perfect for the honing. If the stone height is to be resized in the way Jon did, this will be enough to put the disk (the big one) on the table top diamond side up, put the stone on the disk, press it with finger and move it forward-reverse for a while on the disk surface, then try the height. If one is carefull and take measures not to grind the surface bent, this will take no more than minute to resize the jewel. The same way I use to resize the pallet stones. If a stone edge have to be rounded, then I turn on the top of a rod a 'nest' to receive the stone and glue there the stone with shellac, then while the whole thing is rotated, use the disk as a file to shape the stone.1 point

-

Yes- and even cheaper straight from the maker (and 30% off on top of that right now, 240 Euro) https://www.toolteam.com/de-DE/kaefer-jka-feintaster-40001-t-766312-4031452400014.html1 point

-

I don't understand the crazy prices on used JKA Feintasters. Cheaper to buy new from CousinsUK and less likely to have issues. I have a micrometer like this or my analog Mitutoyo. Having the little table to set things on is nice. My Seitz set has mostly unmarked pushers. Some are marked but that's likely because the watchmaker that I bought it from has multiple sets and was able to give me a mostly complete set by stealing some pushers from a partial set.1 point

-

Or they don't care or are blissfully unaware! Good quality oils and proper oiling techniques are the most critical aspects of a service. Attached is a link where I allow myself to be uninhibitedly vicious! https://www.watchrepairtalk.com/topic/26353-whats-your-favourite-youtube-watch-repair-channel/page/2/#comment-218905 I even commented one of the videos with: "I really don't mean to be rude, but you're drowning that movement in oil. It's not going to run well or for long. You really need to do something about your oiling skills, or lack thereof."1 point

-

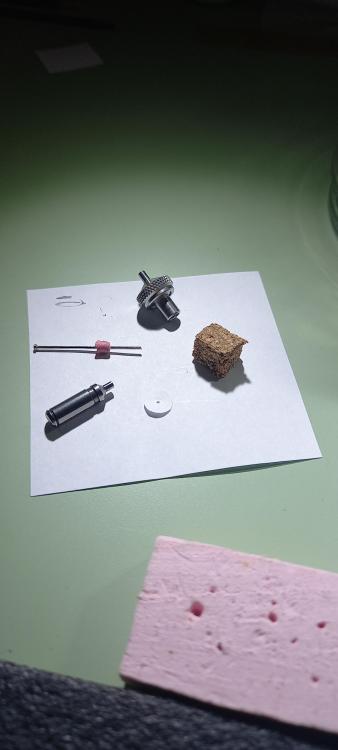

Eyup watch people, just thought i would share a little technique i came up with this morning to sort out a floppy minute hand on a Smiths 542 diving watch. The pictures are pretty much self explanatory, but i will do a quick run through of how i achieved a good adjustment. The tools, bits and bobs used are all shown and the only description needs to be the concave pusher that squeezes the tube's size down. To begin, stuff a piece of sponge into the bottom of a correctly sized stump to suit the head of the hand, this is to hold in place the pin that is pushed through from underneath. Next press a piece of paper ( paper punch ) that will protect the hand face finish, over the needle. Cut the needle as the tapered point will interfere with the hand centering. Use a piece of cork to hold the hand up until the chosen concave pusher engages the tube. Check the hand centering then press away, i didn't go crazy not wanting to damage the jewel tool, just short firm presses little more than you expect to exert when pressing a jewel in. Job done and lucky no broaching required. ,1 point

-

Eyup Tom, yes i looked at those yesterday, i have them in my basket already, not expensive either. The pusher i used is a seitz so yes they do fit the 4mm clone, it was the biggest one seitz make so would not do an hour hand. It was just another idea of doing it. I've done a few on a staking tool before and this way would work there just as well too. It made it a one handed operation by keeping the hand in place and added a little hand finish protection, instead of trying to hold a hand on a stump with paper inbetween and drop the stake into position onto the tube. Life is hard enough as it is You could just use a flat full anvil if you have one for your tool or a metal plate laid over the clone's stump hole or even just free hand on a flat staking block. This just had a bit more control and i fancied a Saturday morning play ( that had a totally different meaning 20 years ago ) . No doubt i will get a slap from the missus later for that comment1 point

-

Very innovative, there are also a set of Seitz pushers for this very job. I think they would fit the 4mm Horia too. https://www.cousinsuk.com/product/seitz-jewelling-reducing-hour-hand-hole-tools Tom1 point

-

I adjusted the depth of the oscillating pinion, and I think I have it right. The dog bone spring I hadn't thought of I think now I'm more familiar with the movement and how it works I might strip down the Chronograph module, clean it all again, and re-build. Maybe get it running better second time round.1 point

-

Great work. How long did the actual grinding take, and did you use water?1 point

-

I restore torsion clocks and quite a few of the early ones there is nothing in the book so I lower the fork until it flutters ( drops more than one tooth at a time ) then raise the fork by 1mm, the book is only a starting position sometimes it’s ok other times not , every clock seems to be different. everything is important with regards to torsion clocks . Dell1 point

-

1 point

-

I agree with you about the #5, I have a Dumont steel set with the green coating for grip and once I get them in my hand it's hard to put them down until something inevitably pings away. I think the slimmer points of a #5 make them more springy (less stiff) and this is combined with the fact you have less contact surface area means the parts are then more likely to ping away than drop onto the work surface if you loose your grip. Like you, I am quite strict with myself and try my best to use them sparingly. As for material I stumbled upon the titanium tweezers from CousinsUK, their own brand, and they are now my go-to tweezers the quality is excellent and they are almost as non-scratchy (hard) as brass: titanium = 70-74 Rb, brass =60 Rb and stainless steel = 121 Rb. However they have around the same tensile strength as steel (tensile yield of titanium = 480 MPa, brass = 124-310 MPa and steel = 485 MPa) so the time between dressing and risk of deforming the tips is very similar to steel. Also, the tweezers also seem to naturally form a brushed/sand-blasted type surface finish which is good for gripping (both between the tips and finger grip). I did try some cheaper off-brand titanium, but they were thin and I had to repeatedly open-up the tips so they returned to an opening distance that was workable, they felt spongy and cheap. Finally, titanium is by nature non-magnetic so it's one headache you don't have to worry about. In short, I think I have found my 'sweet spot' in titanium, not saying they are a panacea but I would recommend that anyone should try out a good set and give them a chance. I dress the titanium with one of those M40 diamond metal plates which seems to work well. Only when working on a delicate movement (Omegas butterfly wing coatings !!) do I switch to brass, but all the time thinking in the back of my mind I can't wait to get back to my titaniums. I have a set of #7 carbon/plastic tweezers that I use for dials, and date/day rings, so they don't scratch, but find them too clumsy for anything else. In regards to size I use a #00 for most of my work as the stiff tweezers tend to be less pingy... new word! However, when working on the finer parts or on a ladies movement I swap out the #00 for a set of #3c which are smaller version of the #00 and handle the smaller parts without the fear of damaging (crushing) them. I tend to use the #5 for removing shock springs and working on hairsprings, I use my steel Dumont #5 and the Cousins titanium #5 together for hairsprings - I can get a needle like tip on the Dumonts, but find that the titanium ones sharpen to a slightly less needle like tip, but still sharp. I use a set of #7 for holding the shock jewels as the curved jaws hold the jewel/chaton on the same plane so you seem to have more contact surface area = more grip = less pingy, you are also holding the part sideways so not pushing down, so less tiddlywinks. I also use the #7 occasionally just to change things up when working on a movement. @nevenbekriev Wow, just wow, that's impressive!1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.60cd38ae2471f23998527c6f6a3643e4.jpg)