Leaderboard

Popular Content

Showing content with the highest reputation on 06/17/24 in Posts

-

Why? Why do I still forget the setting lever screw EVERY TIME? I need to write it on my work mat or something.4 points

-

Just speaking for myself, I started buying relatively inexpensive watches that I liked the look of on eBay and fixing those up. I learned something new with every one. Then it turned out I really started enjoying Bulova movements and 70s styling, so it moved my focus in that direction. I got into Bulova Accutrons because my mom gave me her late father's, which she bought him new in 1973. Before I worked on that, I found some eBay movements to practice on until I could get my confidence up. So I guess my advice is start looking around for things to fix that you would enjoy, without the pressure of working on a family heirloom. Having watches around that you've fixed and can pop on your wrist is super rewarding and will help keep you interested.4 points

-

Yup. I now have a label on the microphone of my Timegrapher that says in big letters, 'DEMAGNETISE'.3 points

-

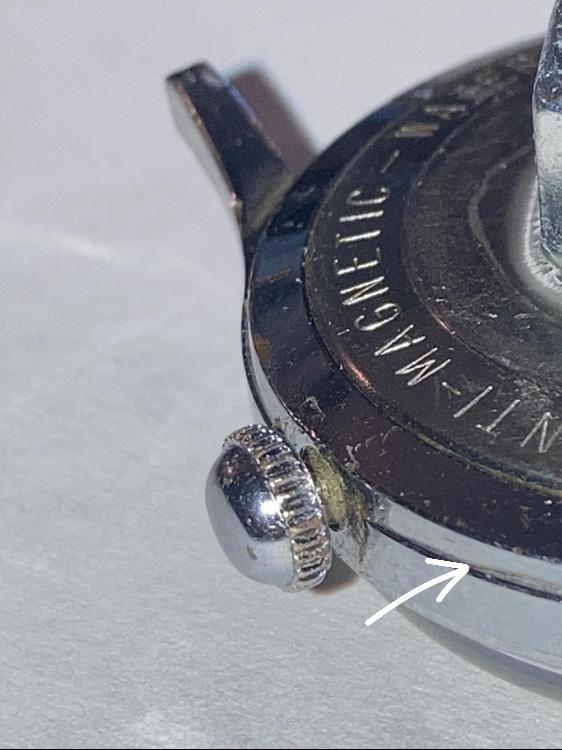

The mystery has been solved. Geotex was correct. As I had mentioned, I had ordered a bezel removal tool to see if that would work. While I was attempting to remove the bezel, the already cracked crystal cracked some more and fell off. As I was shaking out the loose pieces from the dial, the dial tipped and came halfway out of the crystal opening, stopped only by the split stem still being place. At that point I decided to fully commit to the side-cutting plier approach to popping off the crown and stem. One good firm prying move and it came right off. see attached pics. That was last night. The watch is now fixed and awaiting a new crystal and band. The case is in fact, a one piece case. The crumbling crystal revealed a near perfect beautiful dial. I’m keeping this one. Thank you to ALL for your time and advice!3 points

-

This is what I love about the forum, not everything strictly to do with watches. On a previous post I researched and found that "bombe" is convex in French.2 points

-

As there are more wheels than balances in a movement, I would say yes. Frank2 points

-

Need a bit more height to fit under the basket yet, might be tomorrow evening's mod if i get chance. Mum was hard work yesterday, i needed a rest day today of doing absolutely nothing . The jars are 95mm square 180mm high and 75mm opening , i think the basket is either 60 or 65mm. The drill and stand was a fiver the volt regulator was 16 quid and the 3 jars 6 quid for the 3 , the new square ribbed jars are 3 quid each, i bought 4 in case i never see them for sale again. I just like this set up its so simple and not hard work at all. If i could figure out how to post a vid of how easy it is to use. I'd love others to come up with something similar and save a shed load of cash. I'm always on the lookout for stuff like this, it's not even ingenuity, it is literally just cobbling something together that works , its that simple. If the drill burns out which it may do in a couple of years then i switch it for another, i think i have 3 that fit that stand. I have a plan for using a room fan motor, far quieter and those induction motors run forever plus they have 3 speeds and are as cheap as chips. Haha I'm on a mission to convert folk into my way of thinking . My solutions are not diy just yet, current is elma wf pro and IPA , but i really like the way paraffin cleans ( kerosene ) it is similar to lighter fluid in composition,but has little to no evaporation rate. Brake cleaner does a great job of rinsing it off. Those 2 together by hand cleaning imo is the best cleaning i have had to date and i have tried a fair few so called degreasers. I owe the paraffin idea to @Waggy he mentioned kerosene a couple of weeks ago so i thought a solution experiment was in order.2 points

-

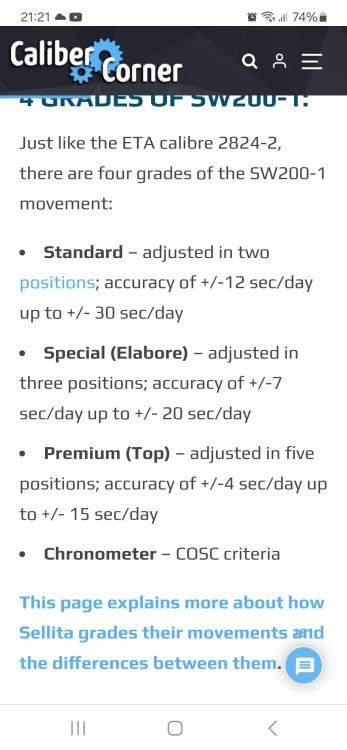

Some of the skills that always could use improvement for an amateur watchmaker/hobbyist would be: Crawling on the floor with a flashlight and a magnet. Staring in bewilderment at a cleaning basket wondering why 18 pieces went in but only 17 came out. Removing a barrel bridge multiple times because you forgot to install the hack or the setting lever the first time. Memorize the expedited shipping rates from Cousins. Arriving home 5 minutes before the wife so you can stash the eBay packages before she asks "so NOW what did you order?" Seriously, while the ST36 and NH35's are low risk movements and can provide a decent amount of basic skills, I would see if you can get your hands on a higher quality movement. There is a world of difference in working with an ETA2824 or Sellita SW-200 vs. a Sea-gull ST2130. I would look at your last project and ask yourself what your weakest skill or failure was in doing it. Then do it again ... and again until you feel comfortable with the process. You will eventually get to the point where you won't accept "good enough".2 points

-

I really don't want to be responsible for any damage to the watch but the screws could be under the bezel spring.2 points

-

Can you get a top view with power off, balance at rest? The hairspring could be off center just enough that it is touching something when running (center wheel, stud, regulator). Thing is, on older stuff in particular, if you find a balance complete there's about a 99.99% chance the hairspring of the new balance will need some adjustment to work correctly. Also, not much use getting concerned with the rate until you get the amplitude up.2 points

-

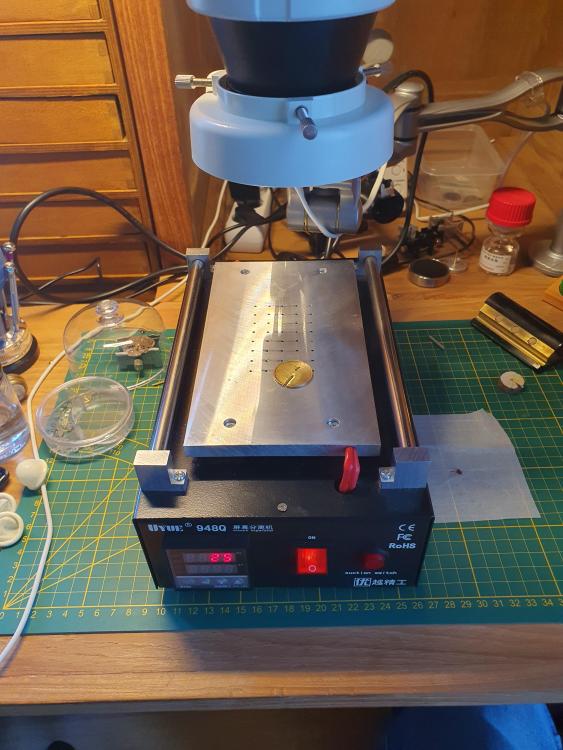

Haha ok so let us begin . Yes the oats tin is a temporary modified heat reflector/ retainer until i find something more..... lets say " the part " looking. No not mcgyvered but an A Team special reconstructed spinney thingymabob whirlygig device. The speed of both the drill and hairdryer are controlled by a very sophisticated and complicated piece of apparatus called a " SPEED CONTROLLER " at the extortionate price of £15.99 . No i dont need to hold anything the drill is in a cheap drill stand ( cost £5 for both from a carboot sale ) the travel on the press is 85mm which is enough to lower and raise the basket in and out of the cleaning jars. The " speed controller " is just a voltage regulator and usable on just about any electrical device to control the speed of a motor or heat output within the full range of a domestic AC electrical supply. Shellaced parts i hand clean and dry separately, i dont risk them at all, shellac will start to melt at around 65 °. The timer , yep an old Smiths timer, i think that was a quid and the white appliance is a food dehydrator, i rarely use that now, i think parts need to be dried quicker than that can achieve. I think thats covered everything. Feel free to ask anything else. Besides the basket you are looking at around 100 quid in total for everything you see here including the ultrasonic and the dehydrator. The ultrasonic i also rarely use , combined with an ammoniated solution ( elma wf pro , which i desperately need to use up and not buy anymore ) and it's cavitation action it is too bloody aggressive imo. I also have something even more diy-ish, simpler, cheaper and more portable that i like for cleaning right next to where i work on my bench. What do you need for cleaning ? A solution that cleans and rinses well that leaves no residue and a device that spins your parts round and around through the solution with some added method of agitation, there are a multitude of ways to achieve that and it does not need to be complicated or expensive, trust me . What you are paying for mostly with the average proprietary machine ( I don't mean 1000's for automated) is mostly a little bit of convenience, i bet i could swap my jars out as quick if not quicker than something like these machines you are looking at. Ps . I'm also impressed you managed not to laugh, i would have2 points

-

Hello, if you have seen some of my posts since I started in this forum you know that I am new to watch making and I have had my share of mishaps but I think here is an accurate statement of where I am: 1) I think I can disassemble and reassemble an ST36 correctly without damaging the hairspring or loosing parts (most of the time) 2) I think I can clean a movement which is reasonably dirty (a new movement or one like the 6T15 I worked on which has 15 year old lubrication but no actual dirt or water ingress). 3) I have an idea of how to lubricate a simple movement but not practiced much and I am pretty sure I am messing it up 4) I made a watch out of an ST36 and parts. I messed up doing the same for an NH35 as I cut off the wrong dial feet (I swear I checked which I needed to keep and then somehow cut those off). Here are the different things I did to learn (mostly in order) Learned to disassemble and reassemble the ST36 and broke the setting lever screw and messed up royally the hairspring in doing so. I have had some success correcting some of the hairspring mess then made it worst when trying to completely correct it. I have put repairing hairspring aside for a bit Disassembled and reassembled a cheap Chinese skeleton 2650G movement with center second Disassembled and reassembled a cheap Chinese Date, automatic and center second movement DG2813 ( mostly a Miyota clone for the base movement and automatic works but different for the date) almost successful but lost the spring for the date jumper Disassembled cleaned reassembled and lubricated a 15 year old 6T16. Nothing lost nothing broken but the movement is working worst than before with a crazy timegrapher reading. This came from a watch I haven't put it back in yet Disassembled cleaned and gave up on reassembling 2 junk slava 2414 movements coming as part of a set of broken soviet movements So finally here is my question. What do you think I should work on/practice next? In term of available movement I mostly have a new ST36 and a new NH35. I was thinking about practicing more with the ST36 trying to correctly clean and lubricate it. I also thought, now that I have a working microscope camera and I should have a reader for the SD card soon I can not only take pictures but videos. If I filmed the process and posted it would it be too much to ask for comments on what I should do different/better and what I am doing correctly? I could try to do that with the NH35 too but with the date and automatic works it will be more complicated and I only have Moebius 800 and Molikote DX so no lubrication for the barrel.1 point

-

As repairers and enthusiasts, we always want to see the movement or we simply want to figure it out well in advance of the inevitable service that will happen sometime in the future! We often forget that Sellita's (and ETA's) movements are made in different grades. In an Invicta we can count on their simplest grade, and in Caliber 5 their finest, so your numbers have me a bit puzzled, within spec though. Most important is that it gains or loses roughly the same number of seconds per day. I always get a little concerned when I read comments that disdain and dismiss watches like Tag Heuer's Aquaracer with "the fact that it only has a simple movement from Sellita" when in fact it has a movement of fantastic quality. Well, I felt like a Master Watchmaker and owner of the world! Seriously! Then after six months or so I slowly started to realize I had only scratched the surface. After another six months, I knew for sure I had only scratched the surface. Nevertheless, working on watches is a wonderful way to waste your time!1 point

-

Personally I think your timegrapher microphone is waaayyyy too big to demagnetise Ross1 point

-

Gut feeling is the pin spacing is fine- don't mess with it. There are other issues to address before adding others.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

No family heirloom so no pressure. I have a watch I would like to be able to service which I own the Seiko Brightz SAGN011 with the 4S27 movemnet I talked about in another topic. It is a pretty complicated watch and the only place which used to agree to service it in Boston is closed. Right now it is out of commission due to a broken bracelet link (which I couldn't find anywhere short of buying the same watch). I'd like to be able to service it but I won't touch it until I am pretty confident. Right now buying broken watches on eBay and hoping to fix them is a bit out of my league I am still at hoping not to break perfectly working movements. I did points 1,2,3 and 5 quite a bit. Not yet the 4. I'll see when I feel confident enough to work on movements costing several hundred dollars. I also read a lot of bad press about Chinese movement and I agree I have very little experience but I have to say I like the ST36 a lot and the video I saw don't really show that it is true for instance what you have below. For instance I keep hearing how Chinese movement come with no lubrication or bad one. That wasn't the case for the 3 ST36 I looked at. It is true on the other hand that I saw a huge quality difference between the ST36 and either DG2813 or 2650G. I haven't played with the NH35 yet but I know I don't like the Miyota movements though. That definitely helps and I shall for sure look at the video and maybe buy a few. The looks are not all to my taste but to work on it doesn't really matter and starting with a running watch with a reasonable investment is great. Disassembly was done during lunch break 30mn almost no incident, the only thing is I forgot to remove the tension from the setting lever jumper before undoing the setting lever screw so the setting lever was ejected from the underside of the movement (but just under the holder and nothing broken). I am climbing this evening so I won't get to cleaning till at least tomorrow but I may get a chance to upload the video1 point

-

There is visibly a circular plate spring where the bezel fits, that appears to just lift out once the bezel is off? It looks like there are holes or recesses under that, which may contain the supposed screws???1 point

-

Ideally the baffles would be on the side of the jars, of course the jars would have to be wide enough to accommodate the baffles and the baskets.1 point

-

i wasn't being serious Rich, as cheap as it was and I've not actually finished with it yet, the drill stand needs a wooden base attaching and the whole thing spinning around so there is more height available for some deeper better square ribbed jars that should provide a bit more agitation. Yep as cheap as it is i would put it against any basic machine, its only one way so i have to find other ways to ramp up the turbulence, but i can't fault the finished cleaning results at all, especially with the switch to a parafin clean , hell that stuff lifts dirt like nobody's business.1 point

-

Nothing to laugh at, if it works, it works. Yes if money was no object a professional automated machine would be more efficient and look the part but for most of us several thousand pounds is too much.1 point

-

Thats just the tip of the iceberg, they have no idea of what is yet to come. When you start grabbing stranger's left hands to turn their wrists to see what watch they are wearing then thats when they need to start worrying. Erm not that i...ah-hem....have done that.1 point

-

John will ask this question anyway: how did the watch run before your service?1 point

-

Good then looks like the plan is a video of tear down and reassembly and lubrication of the ST36. I like the video too because I can show to my family and friends what new crazy hobby I have.1 point

-

Great piece of kit. Is that a tin of oats? I see it looks like to be a macgyvered power drill. Nice. How did you control the speed? Don't tell me you hold it while it does all the cleaning cycles? Where did you get that nice mount and stand for the drill? Why was there a need for a step down transformer for 230V to 143V?? Does the hair dryer not get hot enough to melt the shellac on the pallet fork and such? That's a repurposed oven timer right? What's the white appliance? Cool.1 point

-

1 point

-

I particularly liked that last sentence. In the link I just wouldn't do it1 point

-

Here's the details showing different / additional parts on the 1020. https://oldswisswatches.com/watch-parts-branded/omega-calibre-movement-and-spare-parts/omega-1020/ There are some NOS 1010 1580s still out their but conditions still isn't always that good unless you're willing to pay. https://www.ebay.co.uk/itm/405035477509?itmmeta=01J0JP3XWZ71Q7XKK5W8P6GQHF&hash=item5e4dfeea05:g:5a0AAOSwoThmawTD&itmprp=enc%3AAQAJAAAAwP2liVaOU0W5Ai5GICgxygT5FH%2BGhWU%2FcwXbRGnaG01A7BpJzexk3HtNEy1z8OqdYn15%2FolBYnK56ib5ocROAv6iThYgzfDhGB3Mxbf%2FTAvV7QbIMSynXluugOGn6TgH8VuGkDpiaQ6xCDhMDK7v6uQbvY6CSHiRv8lLMlBYr9Epsr8YEGrB1uyBTozivvAD%2FpTTLNe9H7H4RNGRb0zJvkqxOq0%2FWVr9jGUlxakGo3xbnNpPoGSrbKQoTWuUA8n65Q%3D%3D|tkp%3ABk9SR8zej9aEZA https://www.ebay.co.uk/itm/326153923507?itmmeta=01J0JP3XX34DMANT3JDTFC84QF&hash=item4bf049ebb3:g:FoIAAOSw~iFmYf5j&itmprp=enc%3AAQAJAAAAwPordCvUkW0WyFx4JfQ7A8uKAkExMrRqJ7Cy7QIuoioBkTvYVOEr%2BSTTZRy1CWoD--SoprDCpJrWP%2FDjVakYE5M01iIQy6PIi7%2FuJ90cbUURnIU33LP6RnWkUGYjCt7BkIsfYinKgiwx9NYp6mQlObxkx2uDxErz7WhCcx3ICuooi9omaM0aBXuvsOMMHH%2Fm11ByYIv%2BuOf0NLgLfbWJCDAMTAm5HI0dges3PL6Jp9GtY%2BjqtYFdqNQtKz010MIGQw%3D%3D|tkp%3ABk9SR9Lej9aEZA1 point

-

Maybe you could try a rubber ball or a suction grip opener. https://www.cousinsuk.com/product/suction-grip-dies-with-holder-cousins As a last resort, you could try the glued on nut trick.1 point

-

I know clockboy has the cleaning machine which is the one from India and he has said it is a fine machine giving good results. As you have good contacts and are willing to do the wiring it is up to you. I don't like to boast but all the photos of the machines I have had them or similar. The red one I had for cleaning small clock movements such as travel alarm clocks. I don't think there is much more I can say in giving advice. Good luck in what you choose and do let us know and if you obtain one post photos of it.1 point

-

1 point

-

Try taking the strap off and see if there is a notch for a tool or knife in one of the strap recesses? I've never seen one before but suspect it is a pry-off type, as it seems unlikely the text and logo would always be in perfect vertical alignment if it was a screw-on type?1 point

-

+1 for a stereo microscope. I’ve got one with a boom arm so you don’t have the base plate in the way. I always have it tilted so you get a better feel for height. I found I couldn’t work out how close my tools were to the movement with the microscope lense pointing straight down. I do tilt it straight for hairspring adjustments though as it’s important to see the spacing in the spring and where it needs to be adjusted1 point

-

1 point

-

Armed with the above assurances that the hood should slide off, a further, more confident attempt was made & was successful! Unwound the gut & shortened that on the train side in removing a very weak section (the owner didn't want to wait for new gut!) & the clock re-started & keeps good time. I've now been given another LCC by another friend - he delivered the whole thing not just the movement as I had been lead to expect - & will shortly submit some questions about it. In the meantime many thanks to the colleagues above.1 point

-

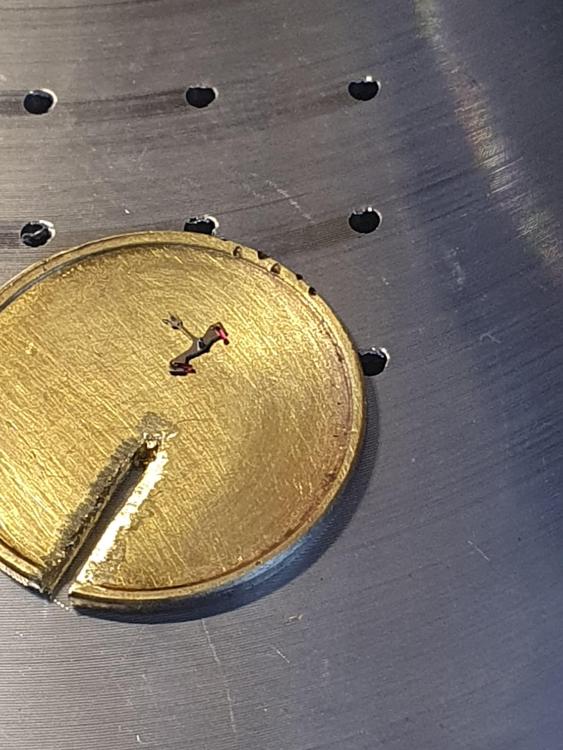

Thanks for your walkthrough @Knebo and what a stunning watch! This is my second time seeing the pawl lever system in a non-Japanese movement. Judging by Kalle Slaap's reaction in this video I thought the only exception was the Panerai P.9000. When you also consider that several other parts of the movement look Japanese, you suspect that Panerai's movement may have been commissioned by Seiko but marketed as Swiss, or Panerai may have simply acquired Japanese watchmakers. Anyway, having researched it a bit more I just learned that the magic lever system was invented by Seiko in 1959 and that several other Swiss movements are using it. I also learned that the JLC 916 was introduced in 1969. About the "broken jewel". I also noticed it looked a bit funny and judging by its colour in the picture I too thought it was a jewel and not a brass bushing. Thanks for clarifying!1 point

-

1 point

-

It looks like it has a knife groove a bit to the right of the crown in that centre detail, as if the whole case splits around the middle - see the first two photos?1 point