Leaderboard

Popular Content

Showing content with the highest reputation on 06/18/24 in Posts

-

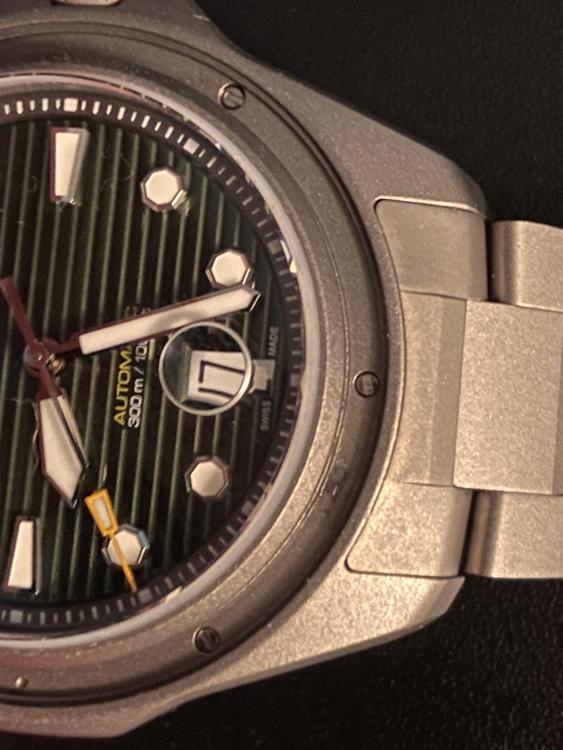

As it turns out that other article was in fact correct. See the attached images. When I removed the metal ring, I found six screws in the groove below them. I suppose that concludes the mystery of how to open this watch. I’ve decided (for now) to heed the advice of my wife and those of you here who say it’s a bad idea to open this brand new watch and mess with it given that I have no experience repairing watches. I suppose the final question I have for you all is what process should I undertake to gain the skills required to have confidence to work on this aquaracer. The first thing I wanted to do with this watch was attempt to regulate it and slow it down a bit. However, I also have ambitions of swapping out what I suspect is a standard grade SW200-1 with a top grade version. I also think it’d be really cool to figure out how to give this watch a display case back. What things should I make sure to do first before graduating and allowing myself to tinker with this aquaracer? Thanks again for everyone’s help!5 points

-

The name on the dial is not listed in vol 1 or vol 2 of watch and clock makers of the world. This dates around 1780 to 1910 looking at the spandrels because they do not have any cherubs. Spandrels are the four corner pieces on the dial. Also the dial is one piece very old ones the arch was attached to the main square. Also the makeup of the dial gives me the period of date. The trunk door is long and not short and wide which is another time scale. The case is very heavily decorated but crude, there are many differences between the left side to the right which indicates a country maker for the case certainly not a first class cabinet maker. The style of the hands also fit in to the time period as they are made of steel and not brass. I f I can be of any more help just ask.4 points

-

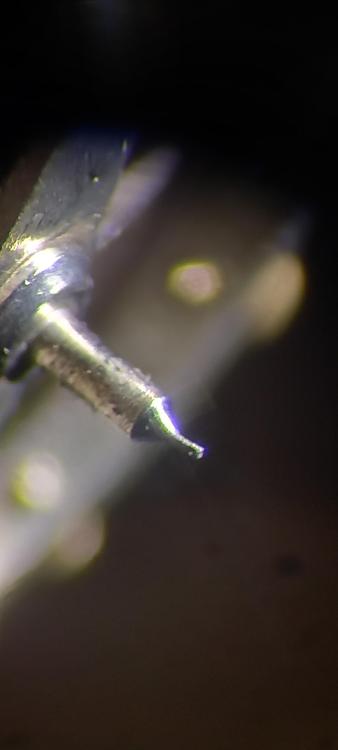

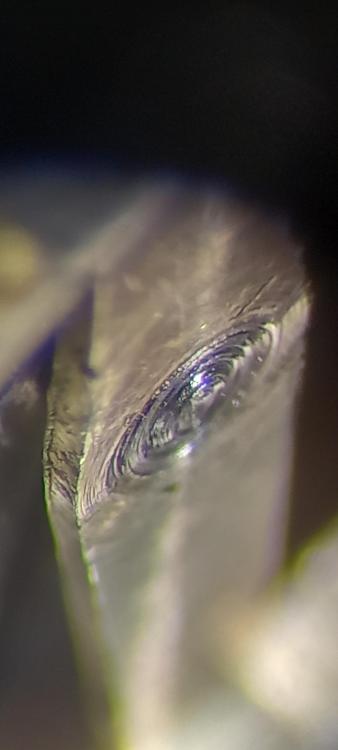

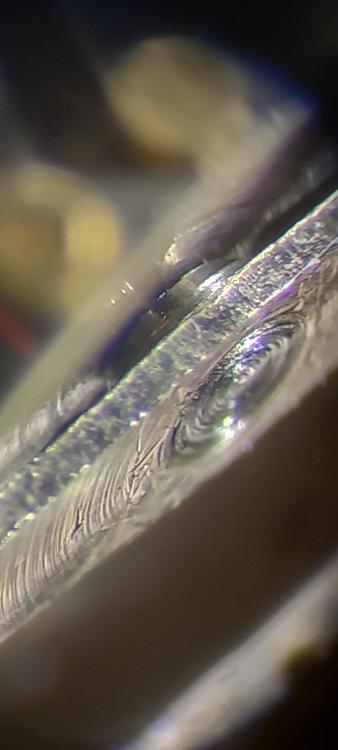

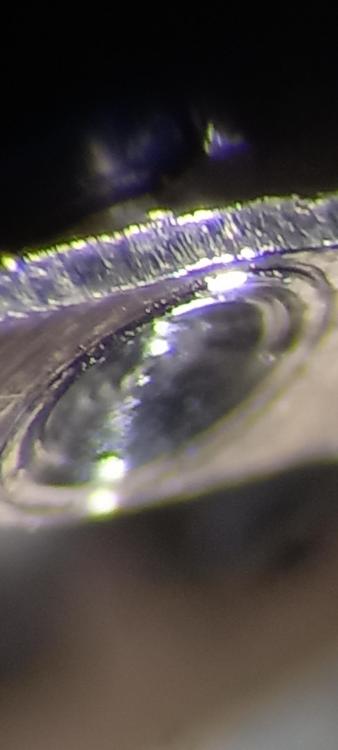

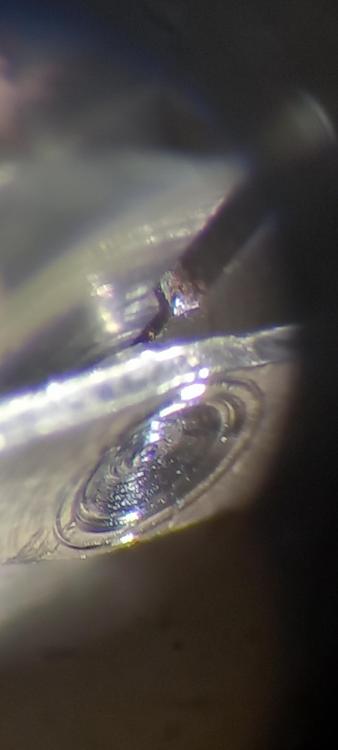

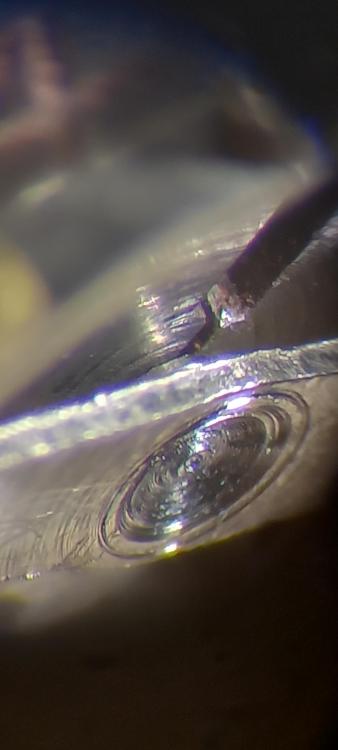

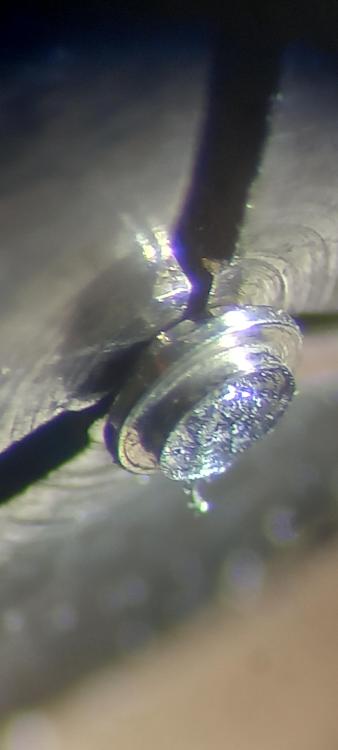

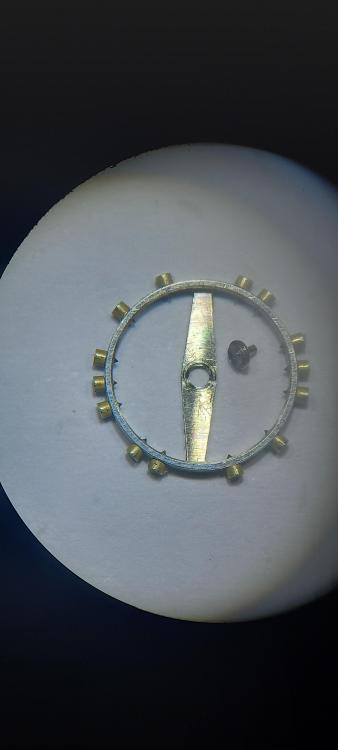

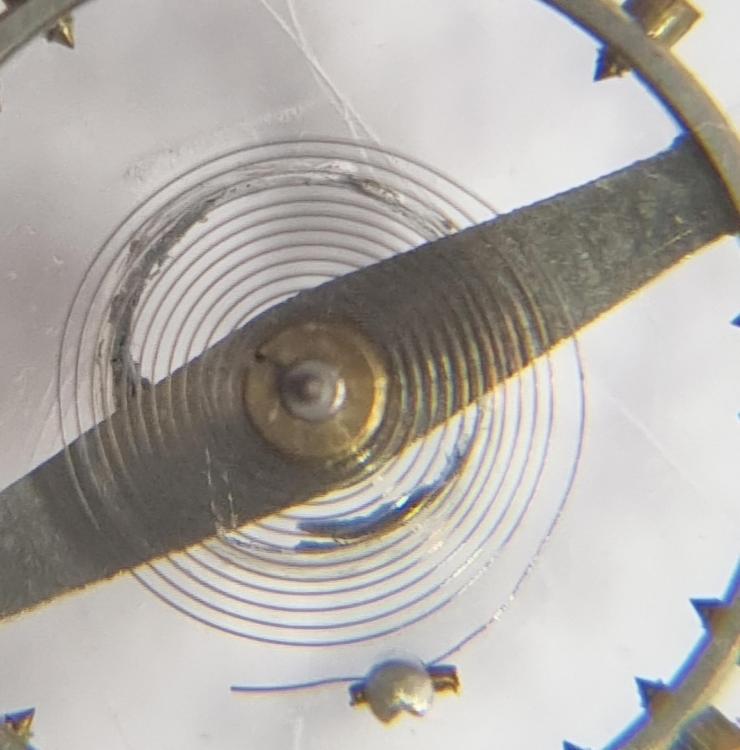

Here is my first attempt at cutting a staff from a balance wheel. I wanted a comparison between cutting the rivet and cutting the hub off. Starting with the rivet was definitely harder than i expected, the rivet was thicker than i imagined and went quite deep into the rivet seating of the balance wheel, its easy to see how a staff hole gets deformed this staff rivet was thick. Thoughts are , difficult to work out where the rivet seating is and it's angle, i caught the balance wheel center right towards the end and the rivet seating is probably a slightly different angle. Cutting the hub away seems like a better option after this experience.3 points

-

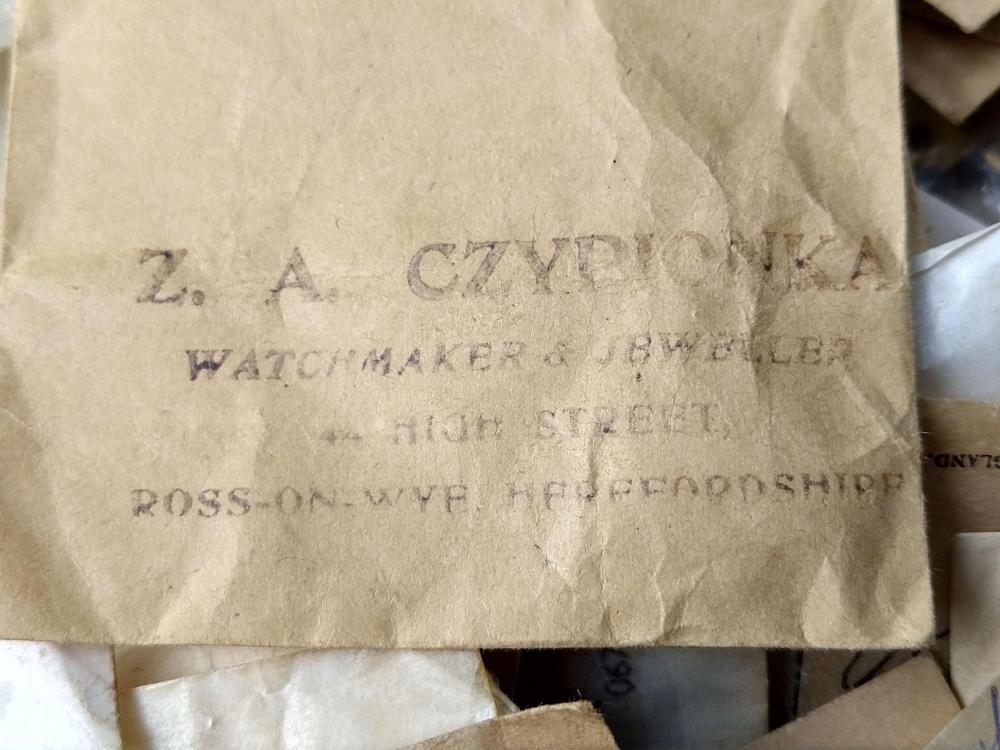

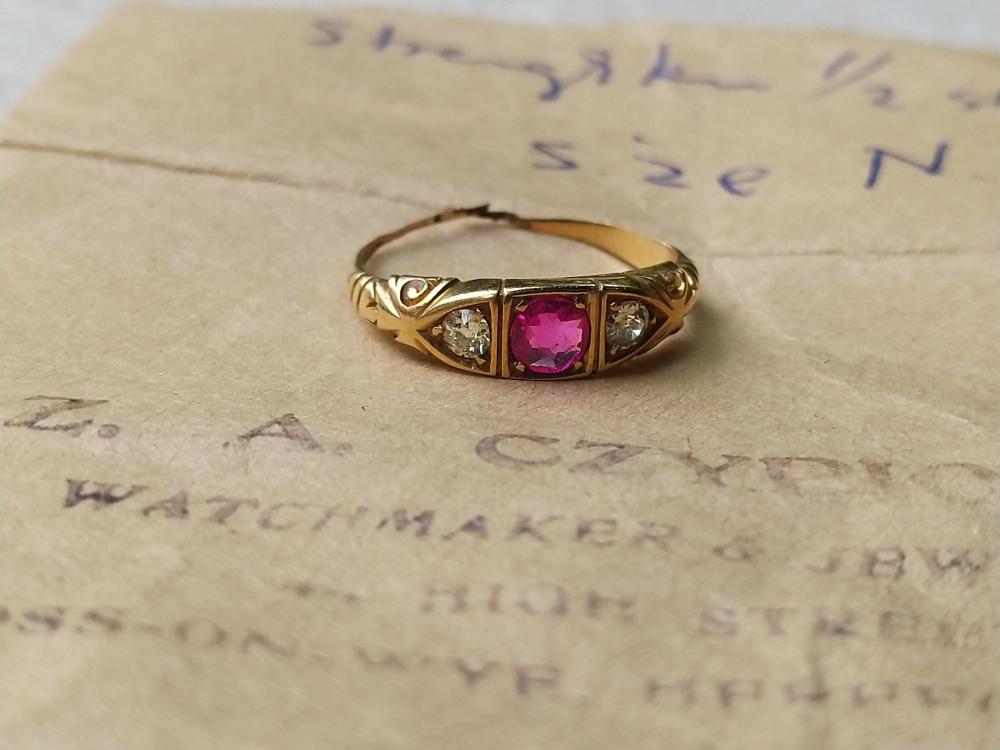

Dear Clock- and Watchmakers, Black and Locksmiths, It seems my en-devour with treasure hunting continuous. My watchmaker carrier started by finding an Eterna Dirty Dozen watch in the dirt. Dirty. I bought a bag of old watch parts and in one of the envelope to my surprise there was a ring. A gold ring with stones. It was a job, a job to strengthen the ring but still keeping the size, size M as it became very thin due to wear. The job went to Mr Czypionka Zygfryd Antoni who was a watchmaker and jeweler from Ross-on-Wye. 44 High street if I am correct, but I am not sure about the number the number on the stamp is not completely clear. Then a bit of a research and turned out that Mr Czypionka Zygfryd Antoni was a polish immigrant who got his citizenship on the 27th of May 1960 as you can see it here on London Gazette page: https://www.thegazette.co.uk/London/issue/42122/page/5719 He is on page 5720 and the list goes up to 5729. Among the immigrants there were 7 Hungarians. Forgot to mention that I am Hungarian so that why I have an interest in it. We are after the WWII, communism was already introduced to the eastern block, certain people became enemy to the state and we are less than 4 years after the Hungarian revolution which produced even more enemies to the state so many flee. Not sure why Mr Czypionka Zygfryd Antoni left though. H.Samual says the stones on the side are diamonds and the middle stone is also a natural stone, but they cannot tell me what it would be without sending it to examination for the cost of £60. I might just do that because of this story. Summary from London Gazette: NATURALISATION List of Aliens to whom Certificates of Naturalisation have been granted by the Secretary of State and whose Oaths of Allegiance have been registered in the Home Office during the month of June, 1960. The date in each case is the date of naturalisation. Czypionka, Zygfryd Antoni; Poland; Watchmaker ; Everstone Farm, Peter stow, near Ross-on-Wye, Herefordshire. 27th May 1960. The foregoing list contains 639 cases, viz.: Austrian 6, Belgian 2, Czechoslovak 14, Dutch 9, Egyptian 1,Estonian 8, Finnish 2, French 4, German 49, Greek 3, Hungarian 7, Iranian 1, Iraqi 1, Italian 22, Latvian 20, Lithuanian 12, Palestinian 1, Polish 402, Roumanian 6, Russian 7, Spanish 6, Swiss 1, Turkish 1, United States of America 6, Yemeni 1, Yugoslav 16, Uncertain nationality 21, Other nationality 10. Total 639. Of these two relate to Uncertain nationality and one American of British origin. The 7 Hungarians: Abraham, Imre ; Hungary ; Coal Miner ; 4 WarrenTerrace, Peterson Road, Wakefield, Yorkshire. 19th May 1960. Bertalan, Jeno Janos; Hungary; General Fitter and Welder; 47 Harrington Street, Derby. 5th May 1960. Brosan, Margit {known as Marguerite, or Margaret Brosan) ; Hungary; Company Director (Property Management); 187 Willesden Lane, London NJW.6. 22nd April 1960. Kutassy, Zoltan ; Hungary ; Coal Miner ; 33 Elmfield Road, Rossington, near Doncaster, Yorkshire. 10th May 1960. Marek, Anna Cecilia; Hungary; Housewife; 6 Tetherdown, London N.10. 31st May 1960. Schnierer, Gyula (or Julius Schnierer) ; Hungarary, Carpenter; Springslade Lodge, near Broadhurst Green, Hednesfprd, Staffordshire, 18th May 1960. Von-Tucka, Constantine Victor Ludwig; Hungary ; Area Manager (Constructional Engineering) ; 21 River Bank, Laleham Road, Staines, Middlesex. 11th May 1960. My best regards, Lui the treasure hunter (and finder)3 points

-

A 1oz should be about right for most work. I had 4 all different as I was also a clock maker. I also had a box wood mallet.3 points

-

Indeed... We have been married 25 years. It wouldn't be the case if I hadn't followed that advice. BTW I am done editing the video (mostly adding text and removing pauses and my hairy harm going in front of the lens because my part tray was on the left and I am right handed. It is now uploading and will soon be attached here I just watched an assembly video of that movement (HMT0231) and I did notice the ratchet wheel screw being reverse threaded. Here is my first watch video taken using the microscope.3 points

-

I have one piece of advice for you here and it's really important to learn it fast. Whatever happens just agree with your missus, if you want to live a long and happy life, she's right, she will always be right and you will never be right , even when you know you are right. You now owe me big time3 points

-

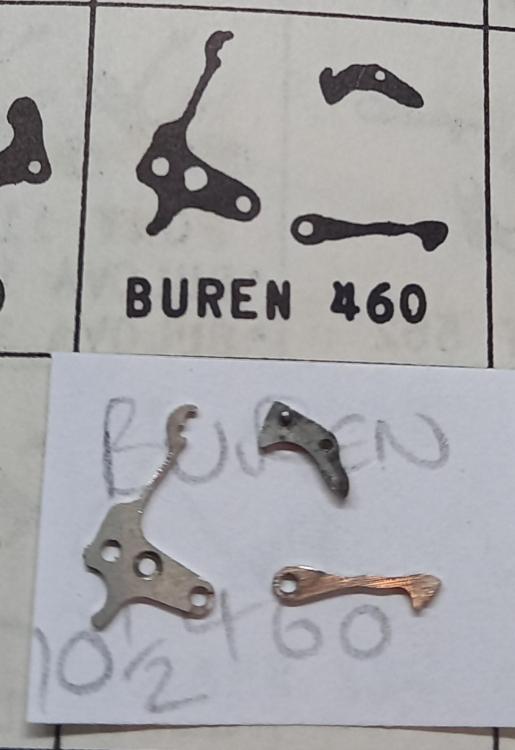

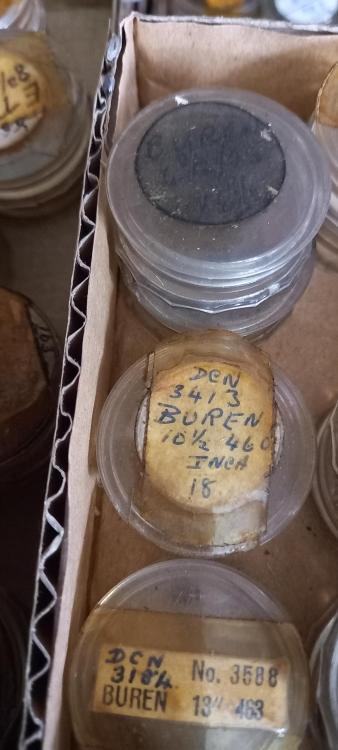

My Inspiration experience for a new thread. Here is a little job lot of a few nic-naks i made an offer of 18 quid for a few days ago. A few handy items inc. a Smith screw back remover which was only my reason for buying ( they dont call me " eagle eyes " for nothing. Also a nice old retracting pencil, a split/ wooden container of cylinder punches , a wooden screw top ( the fine thread is amazing) diamantine pot,a bakelite glass lens loupe and some other useful odds and ends. And hiding at the bottom of the plastic tub was a movement. So while having a break from figuring out my next move regarding the barrel arbor re-pivot, i thought an investigation was in order. This is the surprise bit, down comes Bestfit from the shelf above and gives me a Buren 460. Striped down and potentially only a re-staff is required, checking the balance stock i find a 460 inca, 3 of the dimensions are off by 10,20 and 30 microns and are undersize for what i need , a few more packets to check may turn up something, keeping these chubby pinkies crossed while i search.2 points

-

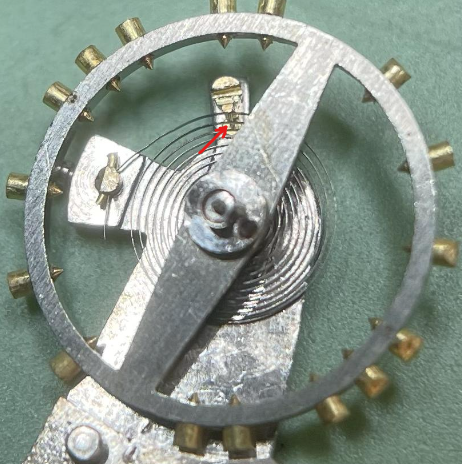

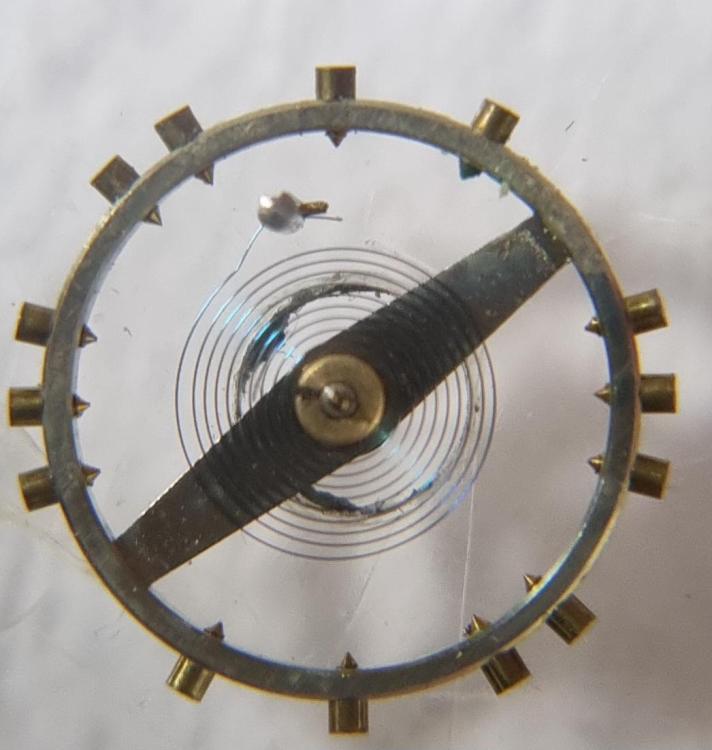

Yes its incorrect, thats what throws the coil out of center. @DanB terminal curve is at a radius equal to the distance from balance jewel hole ( or balance pivot) to midpoint of the regulator pin-boot. The coil should remain concentric and unaffected by moving regulator pin along the entire length of the terminal curve, here's how it usually looks. Good luck.2 points

-

Difficult to say from these pictures. But here are a few observations. here, it looks as if there is a possibility of the second coil (counting from the outside / the one that is within the regulator pins) could touch the regulator pins as well when the watch is running. See red arrow. That could effectively increase the rate of the watch (shorter effective length of the hairspring). Have a close look with your loupe/microscope when the watch is running. ...but on this picture of yours it almost looks the opposite. Very hard to say. Have you looked from the side to see if the hairspring is flat and not touching anything? Lastly, on this picture, you can see that a previous watchmaker has tried to increase balance endshake by creating bumps in the metal under the balance cock. So you know that the watch has been through some things. Possible that someone has replaced the balance staff or even balance complete (in old watches, this can often lead to timing issues when the hairspring is is a bit shorter that the original or the balance wheel a bit lighter). Either way, you'll learn a lot from this one! Good luck!2 points

-

Swiss EB 8800. AND thanks again for your help! In a completely unrelated matter, a friend of mine asked me if I could get his pair of 50 year old political novelty watches running. He had a set, Richard Nixon and Spiro Agnew. The Agnew one was actually a sort of big deal in the early 70s. Interesting story. Anyway, I open them up (two days before getting the Sovereign watch open) and what do I find? Two EB 8800 movements. What a coincidence. None of them needed parts. Just a cleaning and lubrication. They’re all running now.2 points

-

2 points

-

2 points

-

Yes, that's a good idea. Fault-finding (and maybe fixing) is the biggest skill. And actually quite fun. hahahaha, %2 points

-

I would start by finding the faults I introduced to this one. You can learn a lot from your own mistakes.2 points

-

Expat in Argentina. Forced into "retirement" - too old, too foreign. Been watching a ton of videos and I have always loved LOVED pocket watches since I saw my first one. I might get into wrist watches - wife wants to see if I can fix her grandmother's watch, it'll be a while before I am comfortable with that. Found an inexpensive tool kit here, not the best of tools, but starter stuff. I am never shy about asking for help, a master in my trade - and have always learned from apprentices, zero ego. Thanks for having me.1 point

-

True, not all terminal curves have a bend ( the last circle of the coil might be its terminal curve as well) as long as the coil remains level ,concentric and unaffected as regulator arm is moved through entire length thats needed for regulation. Rgds1 point

-

Bottom photo hole looks battered. I think you'd expect to see no refection where the olive shape is , the light would bounce sideways of it instead of up. If you tilt the jewel i think you would see it.1 point

-

1 point

-

1 point

-

in other words it be nice to know what the problem really is before taking a cause of action. then there is the other little problem all the pictures of the balance wheel out of the watch especially associate with the regulator pins look a bit suspicious but this picture in the watch looks decent? which brings up my complaints of it's hard to tell what a balance wheel is doing outside of the watch because typically it's leaning and not in its natural position like it would be inside the watch where the problem is in the way.1 point

-

1 point

-

Yes, but its really hard to tell if it is an regular/straight hole or an olive hole. Guess I need a microscope for that. The domed are easy, but not the other ones.1 point

-

1 point

-

1 point

-

Personally, I would be wary of re-pinning the stud and make the hairspring longer to compensate for the watch running fast, because it is more than likely the balance that has had weight taken from it when the poise screws have been shaved and removed weight from the balance which naturally will increase the timing, thus the index being all the way to one side to slow the balance down, Re-pinning the hairspring is going to change the pinning up point (where the spring passes between the regulator pins), but may also change the vibration rate of the spring slightly, which isn't the correct way to slow things down, unless it was incorrect to begin with, but to know that for sure you'll need a hairspring vibrating tool. This method will increase the timing, but I doubt it will run exactly at 18000 BPH anymore because of re-pinning the spring where it shouldn't ideally be. Adding timing washers is the way forward to alleviate this problem and slow the timing down, I believe. Having plenty excess of hairspring after the stud isn't a problem as long as it doesn't touch anything.1 point

-

Thanks for the reply Knebo. Nice catch about the bumps under the balance cock. I've seen those on the main plate in other watches but not as was done here. I'll do as you suggested and see what comes of it.1 point

-

Very interesting @Neverenoughwatches and great pictures!! Bummer for me, though, as I don't have a lathe. And it makes me put into question if I'll ever be able to replace balance staffs properly. Until now, I thought punching them out would be alright (even if many have argued against it already in this forum).1 point

-

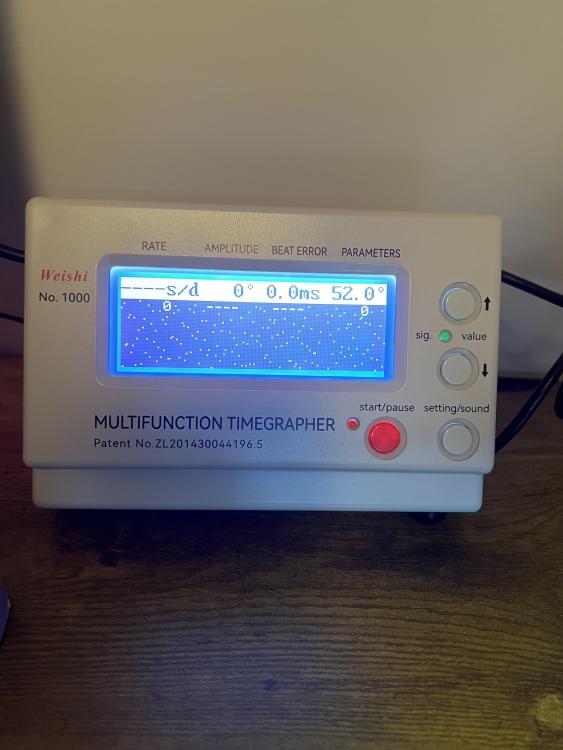

Not a bad idea but I'll need help with that. I have no idea what is going wrong. I just have the timegrapher picture which makes me think escapement problem and this video I took of the escapement working I should really post that on the other topic though For now though I"ll follow up the plan and clean then reassemble and lubricate the ST36 then check it on the timegrapher.1 point

-

I didn't mean that literally but you could of course not know that. I was thinking of Jerry Seinfeld who recently said: "The secret of life is to waste time in ways that you like". If true, it is shameful considering the price. I do not think it is true. On the contrary, I think they are using Sellita's premium grade but it would be interesting to have it confirmed or denied by a reliable source. So do I1 point

-

The easiest way to tell what grade the movement is by inspecting it with special reference to the balance. Standard and elabore as a pair share the same balance which has different shaped spokes compared to the ones used in top and chronometer. It could be standard, elabore or top, unlikely to be chronometer grade as that is often marked on the dial. Tom1 point

-

Ha, like OH I have 4; just weighed my most used one and it's 30 grams with the (lightweight) handle, so right at 1 ounce. There's a smaller one, and two larger. Again like OH the biggest one gets used for clock work and comes in at 55g.1 point

-

Interesting movement! These appear to be similar ones on ebay, in somewhat better condition, if you need spares? https://www.ebay.co.uk/itm/294082407812 https://www.ebay.com/itm/335367737161 This video shows how to make a simple and reasonably safe rust remover - the recipe is in the video description. I've used it on various things with great success!1 point

-

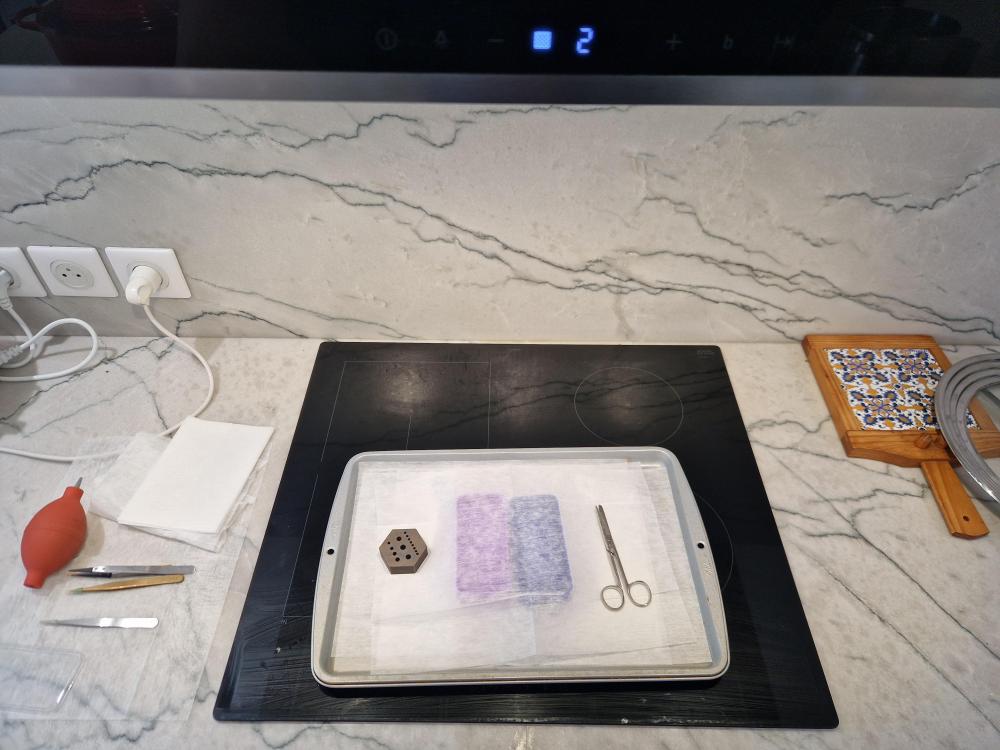

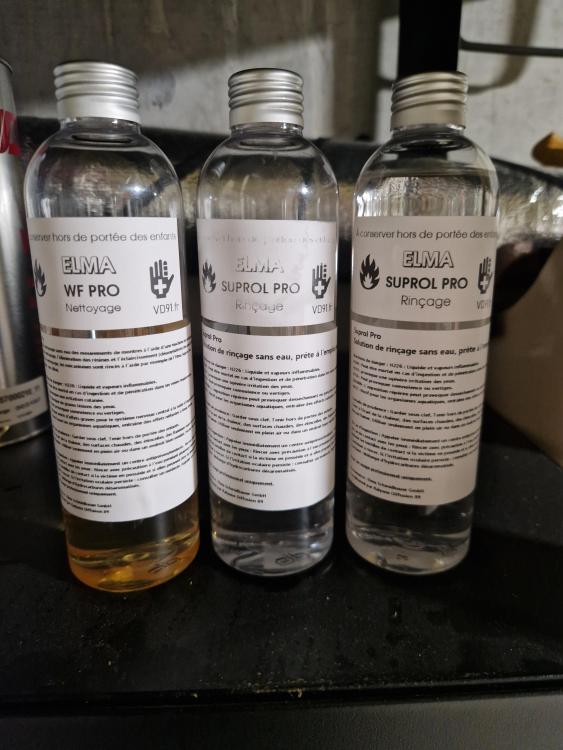

Alright... while I still hope for some answers, I'll continue my walk-through. For now, just a quick post about the cleaning procedure. I did peg all the jewels and cleaned off dirt, oil etc with Rodico. Pivots cleaned with EVE pin polishers (only briefly to remove dirt). Then parts go in a couple of cleaning baskets (round brass ones) and inside of stainless tea filters... inside the Elma waterless cleaning (one 10min cycle) and rinsing liquids (two 10min cycles) in the ultrasonic. After the cleaning, I put the parts in storage trays, cover them with a type of cellulose "paper" (that lets through the air, but protects from dust). And put that in the oven at 57°C (not too hot to avoid melting the shellac on the roller jewel).1 point

-

Your first few posts need approving, not sure of the number after that no approval needed.1 point

-

1 point

-

1 point

-

The HMT are great to work on because they are so plentiful and varied and rock bottom cheap. But the movements have a couple of weird things that will cause you to break your first unless you heed: 1) the ratchet wheel screw as well as the crown wheel screw is left hand thread. They are never marked with 3 lines but they are always left hand and you will break one if you don't watch. 2) the mainspring also winds the "wrong" direction. Left hand, more common on Japanese movements. But yes I agree buy a couple of them. A lot, probably most are weird frankenwatches with terribly painted dials, but there are also plenty of interesting originals.1 point

-

I really like the Tag Heuer aquaracer, particularly the model that my wife got for me. It was a watch I had wanted for quite some time. I know that online and on some forums people like to trash the brand for whatever reason, but the adjustable bracelet and the general look and feel of the watch are just great. It’s very lightweight and very comfortable due to the design and the titanium material. I also think it looks great. I also don’t understand why many look down on ETA and Sellita. They are movement manufacturers and make great or at least good movements. The only thing that surprised me is that Tag used the lowest grade of movement for such a nice watch. I would have expected a higher grade given the price and also the quality of the rest of the watch. However, it hasn’t soured me on the watch at all. On the contrary, it’s given me the challenge of swapping in a top grade movement once I feel capable of such a task. I'm not sure where I read it, but I do believe I read that they used the lowest grade. I could be wrong though, so if anyone finds better information on the movement, let me know. On their website all they say is that it’s a “caliber 5”, which provides hardly any information at all. I also aspire eventually to create a custom sapphire case back to put on the watch, but that will be more challenging given that it will need to be custom manufactured somehow. I don’t ever plan to sell or give up the watch, so resale value doesn’t matter to me. I just look forward to one day turning this watch into the finest version of itself, at least according to my own tastes. Perhaps I’ll even add my own custom finishing or engraving to the movement to view through the see through case back. Whether or not any of this is feasible is another question, but it seems like a fun goal to pursue during my lifetime. It’ll give me a fun reason to learn watchmaking at the very least.1 point

-

Known as precise but not accurate , hitting the same mark each day just not the accuracy mark.1 point

-

Some of the skills that always could use improvement for an amateur watchmaker/hobbyist would be: Crawling on the floor with a flashlight and a magnet. Staring in bewilderment at a cleaning basket wondering why 18 pieces went in but only 17 came out. Removing a barrel bridge multiple times because you forgot to install the hack or the setting lever the first time. Memorize the expedited shipping rates from Cousins. Arriving home 5 minutes before the wife so you can stash the eBay packages before she asks "so NOW what did you order?" Seriously, while the ST36 and NH35's are low risk movements and can provide a decent amount of basic skills, I would see if you can get your hands on a higher quality movement. There is a world of difference in working with an ETA2824 or Sellita SW-200 vs. a Sea-gull ST2130. I would look at your last project and ask yourself what your weakest skill or failure was in doing it. Then do it again ... and again until you feel comfortable with the process. You will eventually get to the point where you won't accept "good enough".1 point

-

The mystery has been solved. Geotex was correct. As I had mentioned, I had ordered a bezel removal tool to see if that would work. While I was attempting to remove the bezel, the already cracked crystal cracked some more and fell off. As I was shaking out the loose pieces from the dial, the dial tipped and came halfway out of the crystal opening, stopped only by the split stem still being place. At that point I decided to fully commit to the side-cutting plier approach to popping off the crown and stem. One good firm prying move and it came right off. see attached pics. That was last night. The watch is now fixed and awaiting a new crystal and band. The case is in fact, a one piece case. The crumbling crystal revealed a near perfect beautiful dial. I’m keeping this one. Thank you to ALL for your time and advice!1 point

-

John will ask this question anyway: how did the watch run before your service?1 point

-

Hi all I have always had an interest in old watch's and used to live in New Zealand but from the age of 9 lived in australia. One day when i was about 17 (now 60) my dad gave me his fathers watch that he wore in the trenchs in WW1. It had suffered being in that environment and had a broken glass and didnt work but i noticed it was a rolex. when i was about 20 i took it in to the agent for rolex in melbourne to have it repaired and was told it had a broken mainspring but that they wouldnt repair it/or couldnt? So in the mid 80's i took it to my local watchmaker/jeweler McMasters in errol st north melbourne Victoria for repair. The owner said it could be done....some weeks later i received a phone call to come in to collect the watch and that there was good news and bad news. On entering i was told that the movement and dial had been lost but the good news is that they had put in a new dial with a movado movement !!!! I was a kid of 21 and didnt know what i could do...they still charged me for the repair and i left dumbfounded and dejected... Some years later i was told by a more knowledgable man that my watch/movement was rare and he believed it was simply taken... I have thought about this for many years and now with the internet...and me with more money...have decided to try and find the right movement and dial for the case.. Is it possible to find and buy what i need? im hoping so as id like to pass on the watch to my sisters son who now serves in the airforce (RAAF) The watch is stored away safely but i will get it out and photograph it so that it helps identify what i need....hope someone can help Regards Andy Murray PS my grandfather started off with the artillery and then was transferred to grantham and trained in machine guns...i have his service record,discharge cert and machine gun badge as well as photos etc1 point

-

I think you have a typo - should be $500 not $1500 for a cal 10xx watch in good condition If you look at @JohnR725's link to Julesborel, you can find which parts are common to other movements, then search on ebay. You can pick up parts or scrap movements for these 10xx series fairly cheaply - I did, I have a couple of 1012's1 point

-

If it's a push on back then it could have a notch in it for the stem which would mean the wording position would stay the same across all watches no matter how many times the back was removed. I've never seen a watch of this era, even a front loader, that doesn't have a removable back.1 point

-

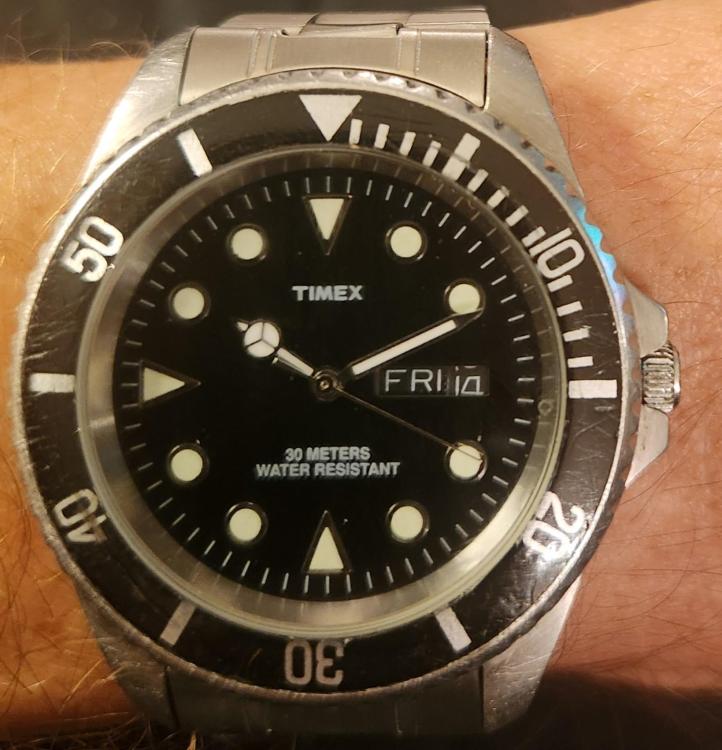

I have a love/hate relationship with Timex. Partly hate the crudeness of the movements but also admire that they keep on going, a bit like dollar watches. I can't fault the look.1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)