Leaderboard

Popular Content

Showing content with the highest reputation on 06/20/24 in all areas

-

My mentor told me that just by changing batteries, watch straps and crystals, one can make a fairly decent living. But if you want to stand out from the crowd, you must do things that other people can't. Hence he does a lot of specialized stuff that other watchmakers don't do. And recently he has started subcontracting the routine service and minor repairs to me, so that he can concentrate on doing what he likes to do.2 points

-

If you are good at your work the word will soon get around. Word of mouth is the best form of advertising and it is free. I was lucky I worked for a jeweller and served my apprenticeship and improving which was 7 years. After a time my master retired so all the equipment was passed on to me and it pretty much everything and a vast amount of stock. So I started out with my own business and had a great little earner. One thing I did was contact the main high class makers such as Omega Rolex that sort of class to get their price lists, I didn't need to contact Longlines as the shop was already a service agent, I just let them know what was happening and they were fine about it. Just showing a customer the price list of what Omega would charge and telling them my price I ended up making enough to keep my wife at the time and me very comfortable. But I was more interested in high grade clocks, which again was a good step. Your best bet is to start with friends and family then you have to decide which road to take. Do you want to just keep horology as a hobby or do you want to make it as you main income. If it is for you as your main income it will cost a lot of money to start. I never had the internet when I started so much of what you have said would never have been a chose for me.2 points

-

There is a 7th option. Search online in your area for watch repair. Then go to those jewelers and see if they are shipping them out and would like to keep the watches local. That was the route I did and I get way more watches than I could have imagined. The repairs aren't always cool vintage omegas and nice movements. You get a lot of really terrible quality quartz that you have to reinstall the hands on or replace the movement on. I do a lot of crystal replacements. Luckily the jeweler does the battery and band replacements so I don't need to bother with those. But then you get vintage Rolex's sometimes and I currently have a vintage King Seiko that is just beautiful. Lots of variety.2 points

-

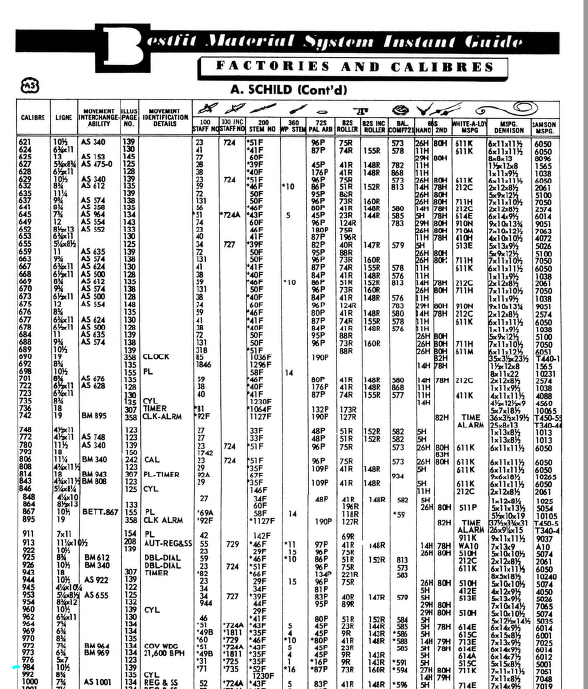

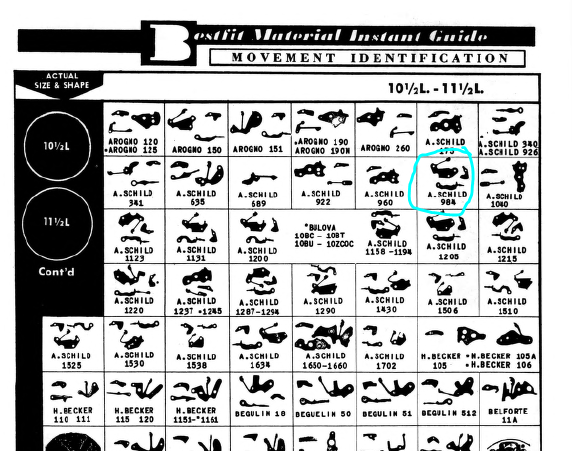

the reason why the brand the name on the dial possibly the name on the movement is not important is often times they did not make the movement. The reason why companies such as bestfit came into existence was that you could conceivably have 100 companies using the exact same movement all having different numbers on their watches but because it is one common movement they would list out the parts so you could cross reference and find the parts anyone have the stock hundreds of parts for hundreds of different watches when in reality only have one watch. the problem with vintage and I'm assuming since you differentiated vintage wristwatches and vintage pocket watches his vintage. Watch companies unfortunately do not stock parts for ever and that would be assuming that they ever had parts at all. Depending upon how vintage watch company may have never of had spare parts. So identifying isn't really an issue because you're never going to get parts other than generic parts that you do by measurement such as the mainspring. here's a website I like to use for looking up parts but you do have to identify the watch. http://cgi.julesborel.com/ let's use this as an example for parts. then we come to hear or get a parts listing and you can click on the parts see what cross references to http://cgi.julesborel.com/cgi-bin/matcgi2?ref=AS_984 one of the things we're looking at the list found above the also see several different escape wheels because the watch came in variations even if you identify the watch you do have to be careful about variations or if the watch was made over a considerable length of time there will be variations because of that so if you order a part you may still find it doesn't fit because it's not the right part for your variation. Like typically escape wheels and pallet fork arbors the pivots can be either conical or straight or a combination of them. Oh and thinking a pallet fork arbors that actually is a generic component because when you click on the other parts found at the site above you will find a Crofts references to about 20 watches but let's see what happens when you look at the pallet fork arbor it across references to a lot of things because basically pallet fork arbors are generic components. In other words the watch companies themselves typically didn't make the mainsprings the pallet fork arbors and possibly other stuff may be perhaps? http://cgi.julesborel.com/cgi-bin/matcgi2?ref=[^}D_Ks I see that you've already been here but the pointed out anyway the pocket watch database is a nice site except it actually has thousands of mistakes for reasons I'm going to skip over. Plus it only has listings if parts were available. Basically wristwatch pocket watch a vintage new no parts are available there is no listing and typically know nothing at all sort of. For instance like modern Swatch group if you have access which you don't you get parts and technical but if you're on the outside you get nothing https://pocketwatchdatabase.com/ oh bestfit book? let's use the same example again. Oh and the PDF the bestfit books had earlier versions which are nice because they have vintage some vintage that may have been dropped for the newer one because after all why carry all the references that the parts are available bad for us by the way. The newest or the last volume that was printed is over 800 pages it's well worth looking through your PDF/book from time to time because it's too much to remember in any case let's work the problem both directions suppose you're looking for parts? Both directions would be if we had a part number or movement number of like a shield 984 in the book. The book existed before the electronic version so if we had a caliber number you can look at up and find out what your part numbers are or suppose you are 100% sure there is the other way another way is on page 139 we can look at the fingerprint system. This is where you know the dimensions of the movement you can go to the section and providing you can clearly see your setting parts sometimes frustrating in this group when people won't give us pictures the setting parts and identifying becomes really difficult having to guess what they look like in the fuzzy photos oh and if you're really desperate in the bestfit book and other sites will often times list the staff and stem by size you can measure yours if that's what you're trying to replace and see if anything will match. But typically on anything really vintage conceivably other than generic there will be no spare parts as there were never spare parts in the first place. Depending upon vintage how vintage they are the spare parts if they did exist no longer exist. So yes repairing watches especially vintage can be a problem because getting parts is definitely an issue often times on eBay a set up active searches and had to wait a whole year for something to materialize.2 points

-

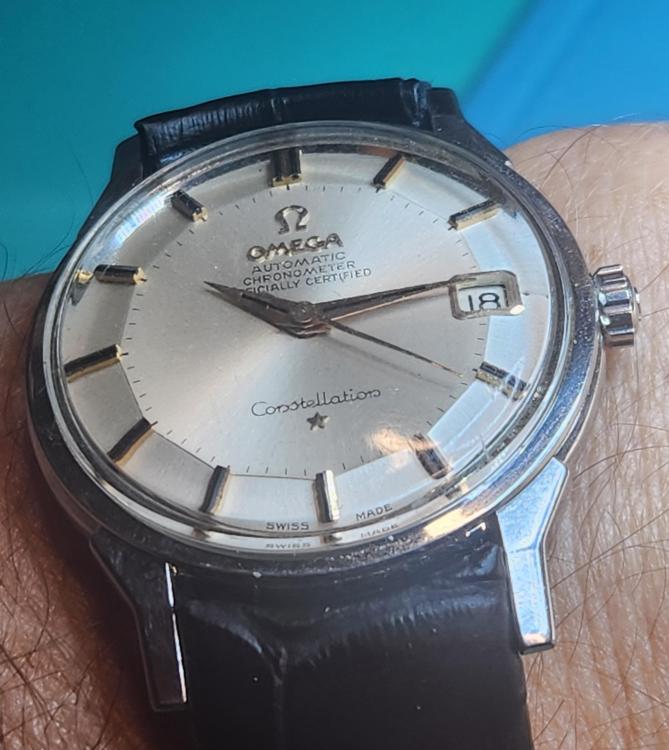

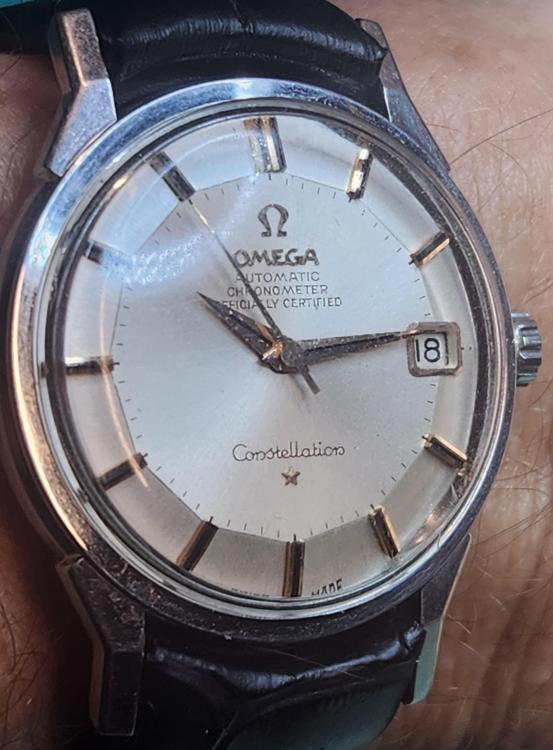

For me it is my 3 pieces from my Gramps. We all will be passing at some point and these will likely stay with me until then. Of the 3 the 1964 Omega Constellation pie pan chronometer is top pop. However I think never say never. It needs an original crystal, the small hour marker next to the date window, and a replacement strap and buckle, but otherwise nice. Here it is on a curved-end strap, not original to the design but looking to see what might be visually appealing.2 points

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

Yes Mike I still use that by selecting all, it takes a few mins to load everything up. Be nice to have it stored though in case it disappears completely. Thanks Andy This is the best one Melissa, the guy who set up and owned the original passed away last year The original was way better set up and so simple to use.1 point

-

Absolutely they do, just because ebay doesn't cough up much these days Carboot day today,here are 4 that cost me 12 quid for all. The Sekonda is immaculate, had the back off and very possibly only a service required. Both timex also work, though the 70's style not for long the other has been running since 10.oclock this morning, the dial of that one looks half decent the glass lets it down and the Limit quite poor but case is good and i have the same one in black. I was ten minutes late of picking up a non working Bulova for the same 3 quid, but these are good, I'm especially liking the retro Timex. Yes the 404 are out there, and no postage with these,this thread lives on Andy1 point

-

1 point

-

1 point

-

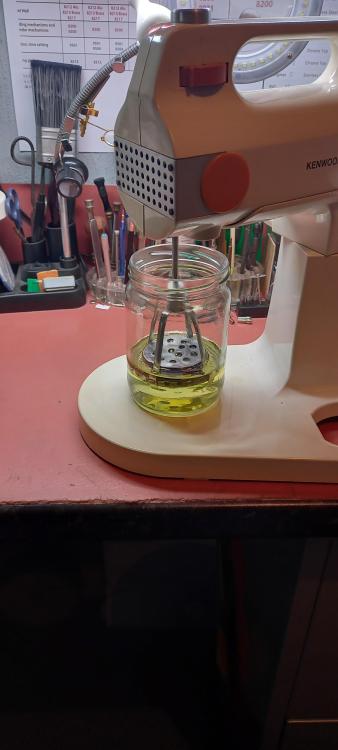

A little update. The shaft going straight through the lid was not very optimal construction so I glued a ball bearing to the lid. It gives stability and I also switched the shaft coupler to a flexible version. That way it doesn't really matter if the motor isn't perfectly aligned with the glass jar. Did some dry runs and now I can go really high rpm. I dared to go full rpm with the basket holder only. 2000 rpm that is allegedly. Maybe I'll next contemplate getting those square jars.1 point

-

So, balance jewel is set correct. Before removing the cap jewel, push on it whilst keeping an eye on roller table, see if this lifts the table any. The aproach I said before, lets the dome of end stone enter oil sink of balance jewel, thus you get max lift on the pivot/ roller table. Good luck.1 point

-

The Elgin is an Elgin 477, they call it a Grade, not a Movement. https://pocketwatchdatabase.com/guide/company/elgin/grade/477/parts1 point

-

Horolene clock cleaner is what I recommend and Steel wool extra-fine 0000. That is what I used on lacquered plates and parts. Depending how bad the parts are and what I see it is bad will depend how long you need to soak the parts, its a trial and error. Make sure all the parts are covered in cleaner if not it will leave a tide mark and you will have a hell of a job to remove it. You can then rinse in warm water and dry with a hair dryer. I hope you have a clock mainspring winder to remove the springs and put them back in. You might need the bushing tools and the bushes for worn holes, also a clockmakers lathe to tidy up pivots, needle files and an assortment of emery sticks. A bottle of Windles Clock Oil is the best you can get and clock oiler. A chime is not the best way to start. A simple timepiece is the place to start then a strike and then move onto a chime. I can help you get it back together in fact there are a few on here that can also do that1 point

-

1 point

-

Yes watch repair has lots of interesting unique challenges. One of things you want to do with your bestfit book is scan through and look at it the entire thing from time to time refresh your memory on all the things that are in there that you keep forgetting about. Oh and in addition to the book they have the online version which brings up something interesting and often under looked. I see in your profile you don't have a location so depending upon where you live on the planet this may or may not be of use to you. You notice at the link below there's a reference to your local material house? Scattered across a lot of locations on this planet were once local material houses and a lot of them still exist to this day. Everyone gets used to cousins because it's only online. Sometimes it becomes challenging to even find a phone number for them if you have a problem. But one time they were physical local material houses where is a watchmaker you could physically go there and get parts or call them up depending upon how far away you are or that you staff fax machines the days when that was popular so a lot of those material houses arts on line and they still have parts and can order parts for you if they like you? Okay liking isn't quite the right term. At least in the US a lot of material houses will only deal with people in the trade in other words you have to have a business license. Some of this has to do with tax reasons in other words if they sell you a spare part wholesale no sales taxes collected because it's collected on the final repair, just. But some of those material houses could still sell you supplies because typically whoever buys the supplies are the final user. It would be really nice if on that webpage of the list all of the remaining material houses because yes there very helpful if you need a bestfit part as you can just reach out to them and they will do the hard work and find one for you. Because the other problem is even if they were online not everything is online because as you're beginning to grasp there are heck of a lot of parts out there and they can't really list every single part in existence as it would be very impractical. So basically the only things that get listed online are the things that are sold in any quantity. http://bestfitmaterial.com/1 point

-

Yes it's a 250V 0.1uF X Rated Interference Capacitor for reasons as above.1 point

-

1 point

-

It's probably a K2 rated capacitor which will be connected across Live and Neutral. It's there to stop the motor acting like a small transmitter and interfering with the neighbours' radios. The machine will work without it and the wretched things often let out the magic smoke when they're getting on a bit. It's value probably 0.1uF (also sometimes written 100nF). Try searching RS or Farnell etc and see if you can find a replacement/equivalent.1 point

-

1 point

-

I have a sneaky suspicion that L&R Rinse #3 might be deodorized kerosene.1 point

-

It does Hector, it absolutely stinks, i wear a cloth covid mask which dulls what you can smell while the lid is off. It dissolves grease and grime like butter melting in a hot pan, I've been hand cleaning recently in a small tin, last night a load of grime from a mainspring just floated to the surface. It has a greasy feel to it but that disappears with IPA or brake cleaner which i have started to use. It wouldn't surprise me if something cheap like this is the main ingredient of some proprietary cleaners. I wonder if that comment has just blown wide open the doors of the watch cleaning industry . I think I'm right in saying both Benzine and Paraffin are two different products of naptha processing. Benzine i think is light distilled naptha not unlike light fluid and evaporates fast, where paraffin is much heavier and takes a long time to evaporate. The experiment i did a week or so ago shows how different they are , the paraffin wets surfaces quickly probably why it cleans so well.1 point

-

Great question! I think it is both. Being an heirloom but is also, in my opinion, one of the most iconic wristwatch design of the 20th century. Omega was arguably at its peak. This has the 561 chronometer movement, one of Omega's finest. I like the stainless steel case and crown with the rose gold hands and RG and black onyx hour markers. The dog leg lugs are just such a great design element as well. I could not ask for a better example of the era and am fascinated about the whole '60s and into the '70s time period when the quartz crisis came on and this piece just predates that very important time period in watch history. So not only personal history but historically significant as well, the iconic design and a fine movement all speak to me. I am lucky to have the opportunity to caretake this piece as I think it is really a timeless piece. Not the only model or maker in the watch world of course but really a part of the lexicon of watch collecting and watchmaking.1 point

-

My recommendation would be to spread the word with family, friends and colleagues about the repairs. I think you're right in ruling out dealing. The parting out can also be a minefield as you've first got to sort out what parts are at fault and what then can actually be sold for spares. If you're going to do this then you'll probably need to pick a maker / movement and stick with it. Best of luck with whatever you do.1 point

-

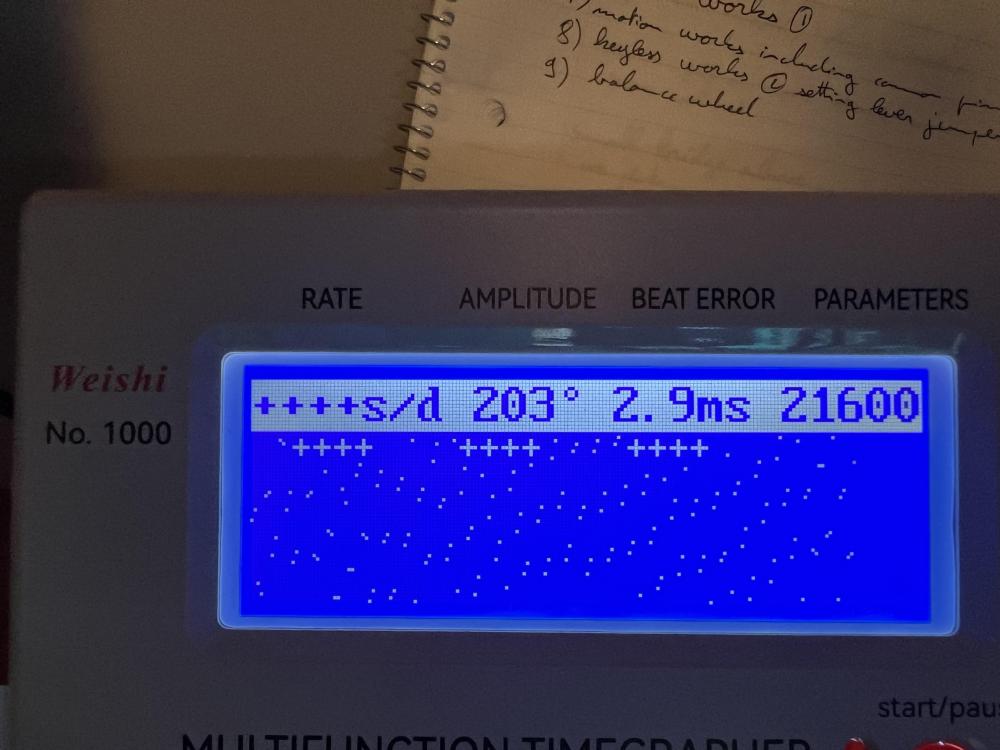

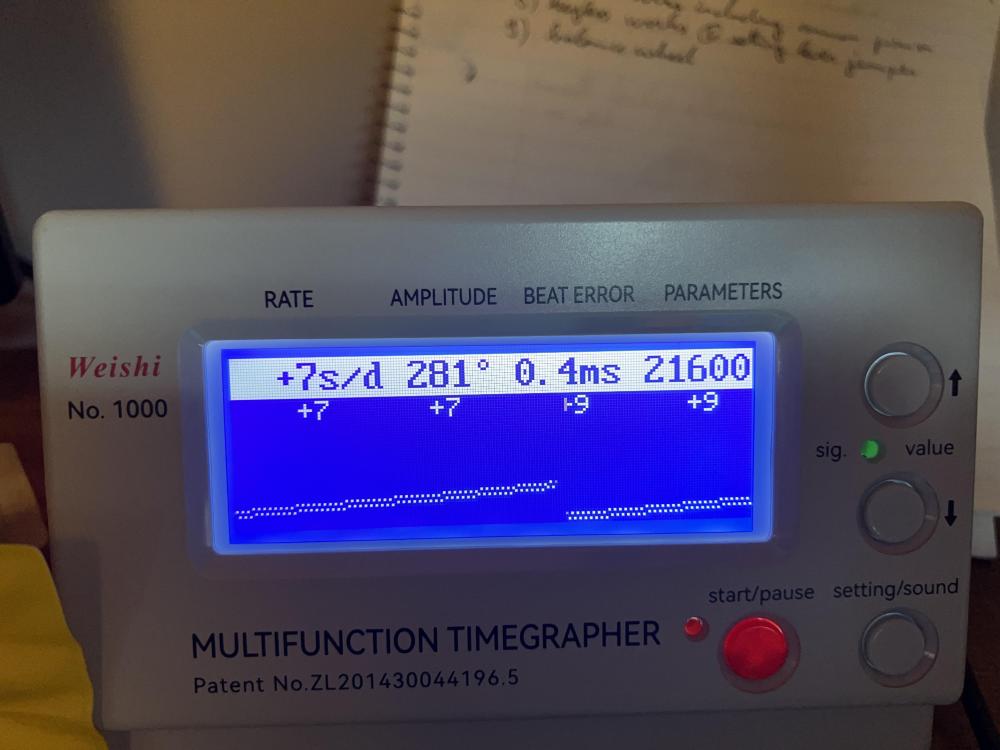

Back to the original topic (I went back and posted what I could about the 6T15 in the other thread but not making much progress. I cleaned the ST36 and reassembled and attempted to lubricate it. I have a video of that but it will need editing before I can upload it. I am also trying to have a second angle from my phone and some voice but I am not sure I’ll have the time and capability to put it together nicely. Anyway here is a recounting. 1) I didn’t remove the mainspring or clean the barrel as I didn’t want to risk kinking it I have successfully manually rewound one but I’ll keep my practice to the already broken watch. 2) I still have not taken apart and oiled the shock protection and cap jewels. I’ll get to it but I am a bit afraid of manipulating such tiny pieces I’ll practice more off camera first. With that said after the disassembly I cleaned all the parts except balance assembly and pallet fork (and click spring + yoke spring). The cleaning is done by putting the parts in small brass and mesh baskets writing down which part went I which basket and which were not cleaned and which compartments they are stored in (that latest is not really needed with the st36 as all parts are easy to recognize and the screws are big enough that I put them I the baskets on the Slava movements it was needed to keep track of which screws are which when they were too small to go in baskets I used an ultrasonic machine to clean the parts I do 3 20mn passes with the parts (in their baskets) in a mason jar first 2 passes are in 2 different jars of lighter fluid and the 3rd pass is with IPA. Then dried them by keeping them in the baskets and using a hairdryer to avoid condensation (I found that this is actually not working well as a drying method and I should take them out of the baskets first I think ) The balance and pallet fork spent 10mn in a jar of Hexane. Then reassembled the movement this went mostly ok with some fumbling which you’ll see in the video when I put it up. The put it on the timegrapher and here is the horror I looked better at the balance assembly and found that the coils of the hairspring were sticking to each other (even after demagnetizing). I realized it had to do with the cleaning and drying so I gave the balance a quick 10s IPA bath (I know shellac) and dried it using the hairdryer. Result was the coils looked good. Here is the timegrapher result after this. So I am pretty happy.1 point

-

Prices do seem all over the place for the watch, strap and just the clasp but there is this from Germany. https://www.ebay.co.uk/itm/135005273120?itmmeta=01J0TJMP138Z4QERY8F2Z9H0MS&hash=item1f6ef0fc20:g:69wAAOSwUAxmDvzv&itmprp=enc%3AAQAJAAAA8DvqNkSKObfbadJvfcq8GmK3UkPIamYTZrvEDC175AS9DGqMVWNYYsJYGulbYTnwbl9Sk%2FclIgnO5RO1MI8Y6oj4XLBD0uaexfXBnom3b%2FrzLBQA1pGCRggV3lMJJTNinEw5%2BIY4GfkSFrLgvN%2FDBtTbTnmDxLekau4jj3A9H%2Fl0VMFGN7vPmYuiNVCzdXnu6lc%2FdBXcQ576lHPbRlt4%2Bms1sUjwCqb8B01YDlEiKg56xFltJEbO8Ffj23pmY9byQ6klouX9XEN2a45nebe2LU%2BNz63ZJC20HmdfrAikrG4Nkrb%2FvnM7hRYh2ln0xPTLTg%3D%3D|tkp%3ABk9SR4jh0tKGZA1 point

-

I just got a bottle of kerosene from a hardware store. Surprisingly, not many hardware stores stock this stuff anymore. I tried it on the clock that I was working on. It really works well as a pre-cleaner. All the treacle and tar just dissolves in kerosene. The only drawback is the smell but it's heck of a lot better than turpentine or petrol. Maybe the next time I'll try deodorized kerosene, which cost 5X more.1 point

-

Hi. The bestfit books one and two were put on the site a while ago by Old Hippy for members to download, as far as I know they still exist. Do a search on the site for reference. They can also be purchased from. Cas Ker who have the copyright Correction copyright is Wm Macawcompany. If you search the term. Mediafire it should bring up the original links as posted by old hippy.1 point

-

1 point

-

1 point

-

Best Fit catalogues, but not everything listed, welcome to the wonderful world of watch repair. If you supply the movement diameter and photos of the bridges and keyless works, if it's listed someone will find it for you.1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

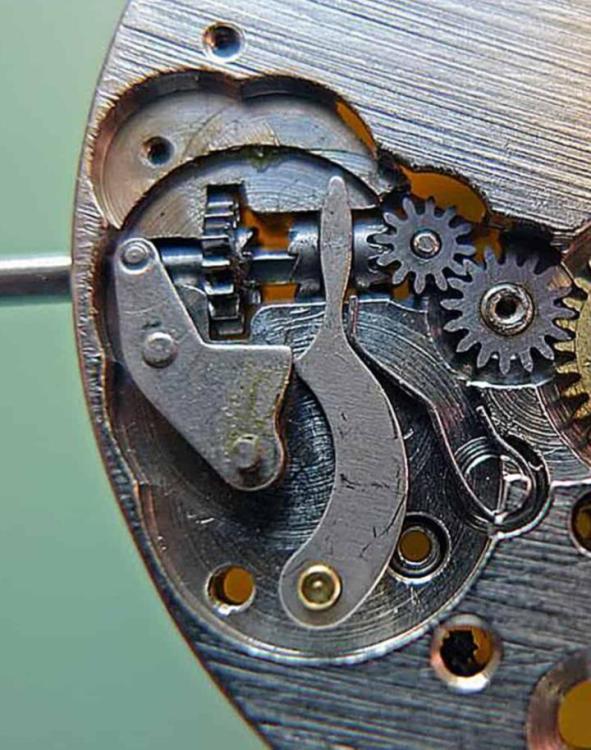

It can vary, look at this photo . Pulling the stem into setting mode the yoke spring gets tensioned and when the setting lever screw is loosened (traditionally in this example was called the pullout piece screw for obvious reasons ) to release the stem too much the yoke under pressure against the pullout can jump underneath it and not always re-position as it has lost interaction with the pullout piece's slider and the two parts can bind up and get stuck in misalignment causing maybe an unwanted dial off situation to re- align things. It doesn't always happen but it can do, in winding mode there is less pressure on the two mating sliding surfaces so the problem is far less likely to happen. Again it all depends on the keyless set up, but this one is a classic for it , if you are not careful, i make a mental note of how many turns to make on the pullout screw to just release the pullout from the stem also avoids you completely disengaging the screw . I now look forward to an onslaught of abuse for calling the setting lever the pullout piece, i think it suits better in this example of releasing a stem so there ppbbbbbbbtt.1 point

-

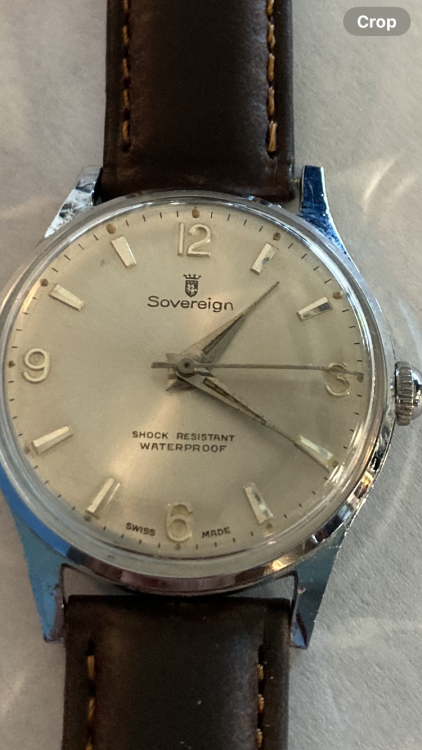

Swiss EB 8800. AND thanks again for your help! In a completely unrelated matter, a friend of mine asked me if I could get his pair of 50 year old political novelty watches running. He had a set, Richard Nixon and Spiro Agnew. The Agnew one was actually a sort of big deal in the early 70s. Interesting story. Anyway, I open them up (two days before getting the Sovereign watch open) and what do I find? Two EB 8800 movements. What a coincidence. None of them needed parts. Just a cleaning and lubrication. They’re all running now.1 point

-

Thats what i like to hear fella , someone with some blood in their veins . " TAH- DAHAAAA "️️ There's never a decent imoji when you want one If you questions , which I'm sure you will have. 1. Yes i could well be one card short of a full pack. 2. Yes I'm serious this IS my actual set up 3. Dont forget what i said about laughing at it. Fire away I'm all ears, eyes...........whatever1 point

-

I've been getting boxes to store the tools I already have. The Chinese jewel press came without any kind of box or case, so I started looking for something to suit that and ended up with some to take the bigger tools like the old open frame clock & pocketwatch mainspring winders & small winder kit, Jacot tool case etc. Old or antique wooden boxes can be cheaper than modern plastic stuff on ebay, and I prefer wood for these old or delicate tools. So, I ended up with three boxes: This one is just a bit wider and around the same height as my Boley staking set box, and will fit the jewel press with it bit sets, plus the Rex roller remover set: These two are rather larger, 14" & 16" wide, just basic plywood with corner bracing: They have all been abused, misused and bodged over the years! The smaller one turned out to be an antique travel writing slope! The original hinges and lock have gone & the tray appears to have been put together with bits of the writing surface, plus the original red & green baize being cut up and stuck in fragments in the base and on the underside. Sad. I've managed to find some hinges similar to the originals & a lock that may fit, plus ordered some felt and baize for the underside and linings. The outer surface is quite good, just needing a clean and polish. It started out nearer like this, another generally similar one on ebay that's not quite so far gone: The larger ones are just plain boxes; the latches and handle fittings are rusted but nothing special and easy to replace, plus some cracked corner joints. The worst butchery was at the back edge of the lid on the medium size one - someone had nailed it with carpet tacks! After removing those and re-gluing the back, all the nail holes are visible with glue showing in some of them. I'm often amazed at the levels of bodgery on some things. This has also had an initial clean up, with white vinegar and a melamine sponge - it's several shades lighter now, than when it arrived. Once the structural repairs are done & minor defects patched up, I will give them a refinish with shellac, if that seems compatible with the original varnish.1 point

-

Guys, I will suggest to do as watchmakers do when they make balance staff for unknown movement and no original staff in it to make measures at all. First thing to do is to determine the size A. This is done by putting the balance cock in place and measuring the distance between tops of the top and bottom cap jewels. Then measuring the thickness of the cap jewels and subtracting the sum from the distance between tops gives the size A. For measuring the size B it is needed to fix a 0.15 - 0.2mm plate on top of the pallet fork cock with some rodico, then measure the distance from the top of the plate to top of the bottom cap jewej and subtract the thickness of the cap jewel.1 point