Leaderboard

Popular Content

Showing content with the highest reputation on 06/21/24 in all areas

-

This is a companion of the 404 club where watchmakers are encouraged to squeeze every bit of value from those 'less loved' watches they find for less than £10.10..... why £10.10, this was the value and currency voted on by the members who already submit to the existing 404 club, but are finding it more and more difficult to find watches at this price point due to inflation and also wish to open this bit of tun up to more participants. The inspiration for the value of £10.10 comes from the hand position of most of the watches you see in pictures:, example below This is all meant to be a bit of fun and allow you to hone your skills and show off your talent on these watches to your peers here on this forum before attempting to use them on something that will cause tears! So Here are the rules: Watch purchase value to be less than or equal to £10.10 (or equivalent in your currency at the time of purchase) Reasonable shipping and spares are excluded from the £10.10 Before and after pictures are required (if possible) Lot purchases are allowed e.g. lot of 10 watches for £100 = £10 per watch Have fun and don't take it too seriously Over to you!4 points

-

The pallet stones look different, they have different angles on their faces. The pallet fork could be faulty, but there's no more (really less) reason to suspect it over a dozen other things. With the balance out, fork out, wind just a couple of clicks of wind on the barrel; the train should spin freely, and ideally the escape wheel will turn backwards a bit when it comes to a stop Balance back in, if you give it a light puff of air it should oscillate freely, and for a good 15-20 seconds (or more), and do so in both horizontal positions and several vertical positions. Balance out, fork back in. With a little power on the mainspring, the fork should snap cleanly from one banking to the other with a slight nudge. If any of these checks don't pass, figure out why and fix it before proceeding to the next check. Balance back in, wind it up, and observe that it has sufficient amplitude, and runs well in both horizontal positions and 4 vertical positions. If you see that the watch runs well in all but certain positions, that gives you clues as to where to dig further.3 points

-

Unfortunately not, in the past, once a movement became obsolete ( surpassed by newer technology) the cases were scrapped, the gold or silver was worth more than the watch itself. People sold the case, that's why od movements are plentiful but cases are rare.2 points

-

@nickelsilver : Include those steps in your coming book about servicing and repairing!2 points

-

2 points

-

Depends a lot on the steel you're using. In the States O1 is a standard steel used for parts like this. It's an oil hardening steel (the O). There's also W1, and O2 (haven't been able to discern an actual difference between O1 and O2). If you harden an oil hardening steel in water it gets even harder- to the point it may crack at stress points before you get to tempering. In the same vein, if you need extreme hardness you might harden an oil hardening steel in water for something like a cutting tool. In very extreme cases you may quench in salt water brine or even mercury. For most watch parts it's good to harden, then temper to a dark blue. But depending on the steel a light blue may be more appropriate. Also, if not using an oven for the hardening stage, you can be off in temperature enough that you change the metal to a degree that even tempering past light blue results in brittle parts. I also use a little container (ex- CO2 or NO2 cartridge, top cut off, welded to a steel rod), filled with finely ground wood charcoal. Parts at the bottom of that. The charcoal alights, burns out, looks like lava moving around for a while, then calms down. That's when I quench. The charcoal doesn't add any carbon, but it excludes oxygen enough that the parts come out grey. Tempering to color is easy then. The charcoal is ground in an espresso grinder at its finest setting- if you don't want to spring for a commercial level espresso grinder, you can buy it at health food shops and it's even more finely ground. Steels I use are O1, Sandvik 20AP, and Klein Law 100x (same as 20AP minus the tiny bit of lead Sandvik used). O1 is clearly the best for cutting tools, the other two great for parts. Just made some 4th wheel pinions with extra long pivot in 20AP/Law 100x and no deformation in hardening.2 points

-

Absolutely they do, just because ebay doesn't cough up much these days Carboot day today,here are 4 that cost me 12 quid for all. The Sekonda is immaculate, had the back off and very possibly only a service required. Both timex also work, though the 70's style not for long the other has been running since 10.oclock this morning, the dial of that one looks half decent the glass lets it down and the Limit quite poor but case is good and i have the same one in black. I was ten minutes late of picking up a non working Bulova for the same 3 quid, but these are good, I'm especially liking the retro Timex. Yes the 404 are out there, and no postage with these,this thread lives on Andy2 points

-

Hello friends, here's an update on this "interesting" barrel. First, a bit off topic, my technique of applying breaking grease (I have 8217). I apply a dot, then smear it gently in the direction where the bridle will slip. Rather than ending up with a couple of dots, I rather have a thin film all around. I see the risk that inserting the mainspring from the retaining ring would actually push down the dots to the bottom of the barrel and away from the wall. This risk is reduced when the breaking grease is already thinly spread out along the wall. Anyways, more a side-note.. Now back to the main topic. After inserting the mainspring and arbor, I use the basic barrel closing tool to click on the lid. As a matter of precaution, I use the tool upside down: I put the barrel on the flat bottom of the tool and use the concave side to push down the lid. I'm thinking that it may ever so slightly compress the lid (like inserting an acrylic crystal into a bezel with a press). May not do anything, but felt smart Once the barrel is closed without any problems, I burnish the edge of the barrel wall towards the lid again. You can see the process in the two pictures. No image of the final product, but I tell you: it looks nice.2 points

-

Always nice if you give us a picture of the watch in the discussion to avoid confusions? My confusion is I'm reasonably sure that the Hamilton 980 is supposed to have 17 jewels? Yes that's not a good sign at all Unfortunate not all watches have back spin. But even without the backspin the gear train still should turn very very easily which this one does not sound like it is.1 point

-

That's a clear indication there's too much friction in the wheel train. Ideally, when the train stops you should be able to see the escape wheel spin a tiny bit backwards (counterclockwise as seen from the side opposite the dial) as already mentioned by @nickelsilver. The cause may be something specific or the cumulative effect of several errors. When I get this kind of problem, I test by adding one wheel at a time. Start by checking that the arbor in the barrel spins completely freely. To test, you first need to remove the mainspring. A few years ago I started a thread that became very instructive for me. Maybe you can benefit from it too.1 point

-

See, You give too little information. I asked many things and still have no answer. So I can only guess. Speaking of this, I red once again everything in the tread and saw something, which can be interesting. As I understand, the old staff which has broken roller side pivot (only one broken pivot) measures 402 in lenght. One broken pivot will shorten the staff by about 30, so in every case, You original staff was no longer than 440. As the 588 staff which is long 475 fits and even there is big axial free play, this will have to mean that the balance that was in the movement actually is not original one, but just put by the previous owner in the movement to ease selling it to You. This means that the roller is not from this movement and in such case, it is no wonder that it touches the main plate. Do You know how to check if the roller can work together with the pallet fork correctly?1 point

-

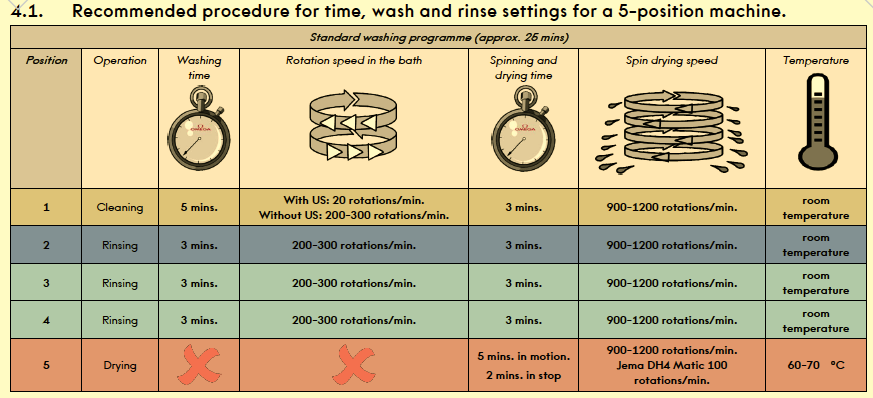

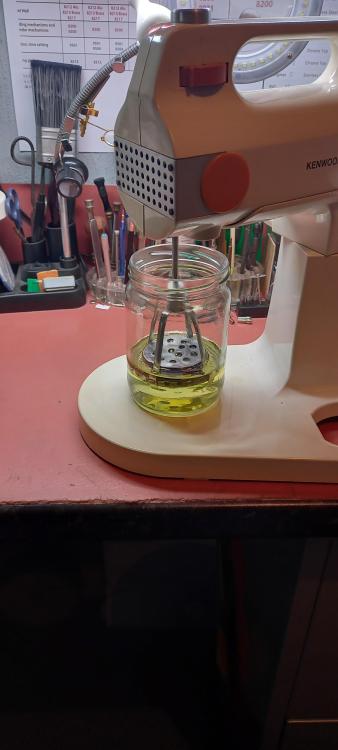

Just think how much speed would be saved by spinning at these faster rates especially when you need to understand where the speed is actually used. Probably not recommended for the cleaning because spinning that fast even with the outer wave breaker probably not one drop of fluid would touch the watch centrifuge action would push the fluid out probably over the top of the jar and make a big mess so you may have to slow down there. But for drying your running 10 times faster is that mean we can shrink the time that you have to spin dry afterwords this could be a considerable speed improvement to cleaning a watch. One of the amusements with the Swiss cleaning machines are my understanding is only the extremely expensive vacuum assisted machine can you actually program the RPMs everything else is a knob and you don't actually know how fast it's going even though. Which is why the above chart becomes amusing because if most cleaning machines don't actually have an RPM how which set the RPMs anyway? Square versus round one of those endless debate items? But while you're at it what about changing direction? In other words your spinning in one direction to fluids at some point time probably even with the way breakers will spin with the watch and then you stop suddenly the fluids will crash into your watch parts aggressively cleaning even better than you spin the other direction. Don't remember where I saw YouTube video one of the machines is going back and forth that seem to me to be very aggressively going back and forth another experiment for you to try1 point

-

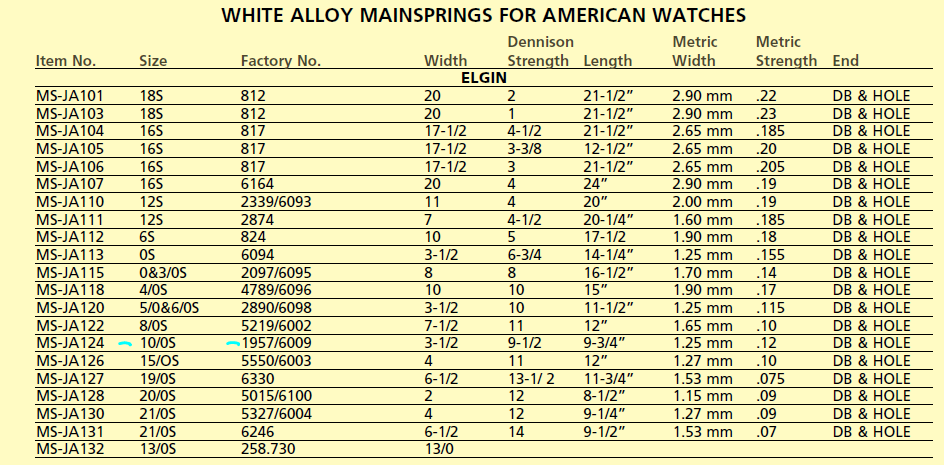

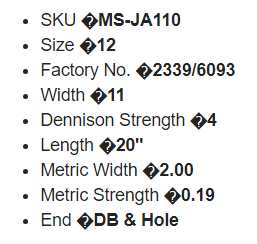

My suggestion would be if the Hamilton does just need a spring then look at this one first as the easiest to fix. As advised by JohnR725 the Hamilton spring should be a 718440 https://www.ofrei.com/page2031.html Just removed a lot of rambling!!1 point

-

Thanks chaps for the advice. I think what I'm going to do is Horolene and steel wool the small plate I've already spoiled (as my earlier picture shows), and give it a dose of Mohawk as per Dell's excellent video (I've also 'liked and subscribed' Dell ). The main plates look clean but I'll give them a careful bath in paraffin or something that won't attack the lacquer after I've done (attempted to do), the re-bushing required. Er... unless either of you think that's a really bad idea! Dell, thanks for the video showing how to find the original centres. I now understand the principle and will do some practice on an unidentified clock plate I've found amongst Dad's effects before risking anything on the Smiths Enfield. O.H., I probably didn't mention that I'm an amateur, but well trained, watchmaker so, in terms of broaches for example, it'll be nice to use some of the larger ones I've never had to use before I do have a good selection of ready made bushes but will be able to turn any that I don't already have on my lovely IME lathe. I suspect the real fun will begin when I have to get everything synchronised ultimately! Thanks both for your interest and encouragement. Martin1 point

-

That was a nice video. Good to see you using a mask. I have just subscribed to your channel. What I have used drys in around 2 minutes.1 point

-

1 point

-

Are you sure it's a 555 as it's very unusual to have 2 circuits for the same movement? Edit After a little digging is yours a Heuer 185 which should have the 555.232 which is a 2Hz movement? Further Edit After further digging the circuit with the M379 chip is from the 555.232 and Borels may have them. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=|[[H[KZ1 point

-

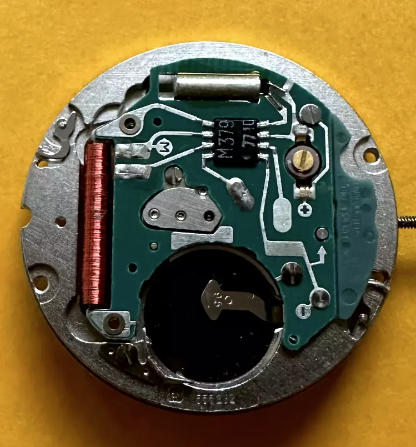

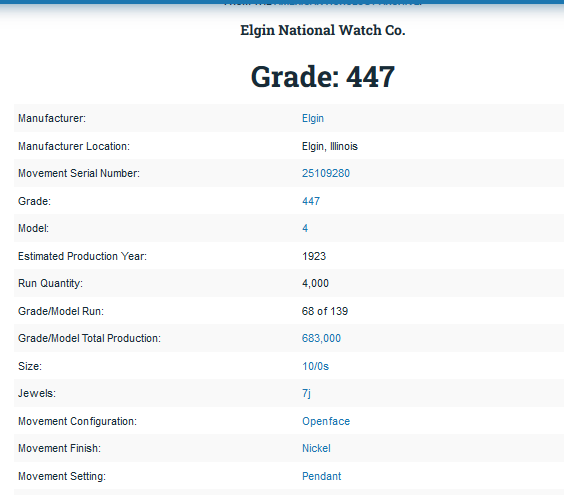

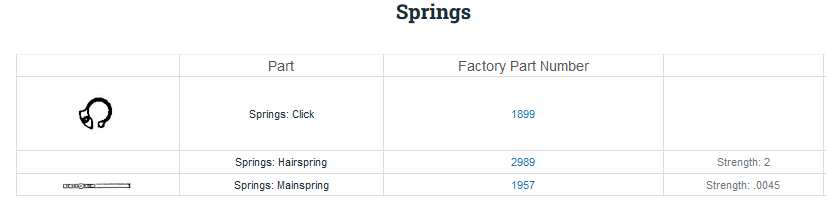

did you look at your picture of your Elgin? I circled something for you it has letters as because it's an American-made watch if you look at pocket watch database you'll see Elgin national watch company.. Then your grade numbe is 447 not the number that you quoted is really important to get the numbers right if you want to get the right parts tthen when you're on the pocket watch database side if you look on the left-hand side one of the categories is parts.. Then from the parts section llego Springs and also about the image we see the mainspring. then notice in the bottom of the image there is your mainspring part number 1957 strength .0045. the. But it looks like that's going to be a problem because well mainsprings are always going to be a problem. Which is why the other way always do this is take the mainspring out and measure what it is and then we can look on the listings and verify the spring in the watch is the same size and we think it is. Looks like it's been upgraded to a new part number and as usual you're only going to find one spring if you go with the modern as they don't make all the springs they once did but looks like this is your spring I'm confused here as this is not a 12 size watch? proper diagnostics I think is needed. In addition typically changing escapement components in vintage watches is a bad idea because they were adjusted to each watch. Plus I see your watch has movable banking pins I wonder if anyone's ever move those? We really need better pictures to see what were looking at.. Then look at the parts list another problem typical with vintage watches looks like there were two separate pallet forks for this watch. in other words it was made by the Hamilton watch companyanother US watch company. then I just can't do a couple of quick copy of pace and not inform you where all this came from as it's way past my bedtime and I don't have time to explain. Other than typically with mainsprings take out the old spring and measure it as things work out a lot better if we can compare the old with whatever we think were finding oftentimes especially with a vintage there could be possibly validity of variations. Then with both Elgin Hamilton they had the original steel Springs and often times they had newer alloy Springs with different part numbers and of course aftermarket would have different numbers tthen I'm assuming this is the correct spring then we discussed this somewhere on the group because the type of end of spring is this or both of these have you will be extremely unlikely to dish of the spring and you're going to have to the hand wind it in or get some mainspring wagers which would be preferred and then there is a procedure.. Simplistically wind most of the spring into the wind your belief a little bit out the end dish of the whole thing in the barrel which is actually quite easy to do if you're holding a Winder and observe what you're doing it like the end in place into its slot hold it down and pop it out and as I said we have pictures somewhere to explain this when you get your springs. Because otherwise if you try to shove the spring in the end is never going to catch and that will be a problem tthen you go to eBay and search for both springs you might be lucky and find the original Elgin or Hamilton spring and yes even though their vintage usually the originals are much better than the aftermarket especially lately where the aftermarket's seem to not be there best.1 point

-

1 point

-

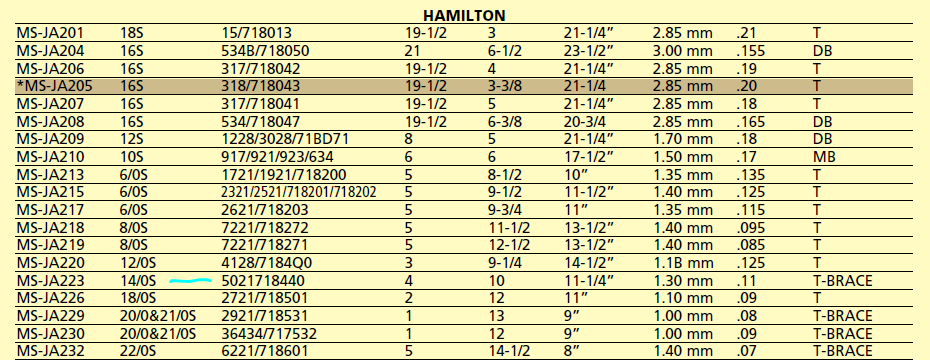

Thanks Andy yes i can solder, mostly plumbing, i can just about silver solder,not always pretty though. Is it important for the machine ? my room is in the far corner of my house, miles away from any neighbours and i dont watch TV and only me in the house anyway. I got impatient and finshed off the mini mesh basket carrier and soldered a mixer whisk to a stud connector bolt. The machine as far as i could google is a 1/10 hp that equates to 75watts which means i can run it on a fan speed controller that can manage 300 watts. The machine works a treat and the controller keeps things quiet when working in the room. This is what diy appliance conversions are all about, one cleaning machine and one part dryer. Total cost a whopping 19 quid. Breakdown = carboot mixer £5, 2x cousins cleaning baskets £3 , 1x carboot hairdryer £1 , 1x carboot microphone stand £2 , 1 fan speed controller £7 , and about £1 for the bolts connectors etc. Lets round it up to 20 quid just for the hell of it. The plastic tub and green dust cover is just for storage. Come on guys if you haven't got the cash for a cleaning machine and dryer then knock something up, if i can do it anybody can do it.1 point

-

https://www.replateit.com/ I've seen other people recommend them on other websites and their prices seemed very reasonable so I figured I would give them a shot.1 point

-

1 point

-

Actually thinking about it - the pawl to be replaced was clearly not hardenend, that's probably why it wore in the way it did, maybe the idea is for the pawl to wear rather than the ratchet wheel. As people like photos here is a (soft) one that I have made up But I like the charcoal idea for hardening other parts without scale built up, will have to try that. The surplus place often has old coffee grinders. For steel we have the UK/US terminology differences, I've been using gauge plate and silver steel (maybe drill rod in us terms). But I'll see if I can get some O1 round.1 point

-

Hi all, I do some repairs at our local repair café, one of them being wristwatches. This normally involves fitting new strap pins, batteries, etc. Now I need to identify movements, learn how to replace stem and crown pieces, etc. Hopefully you will put up with me and my forthcoming questions, thanks in advance.1 point

-

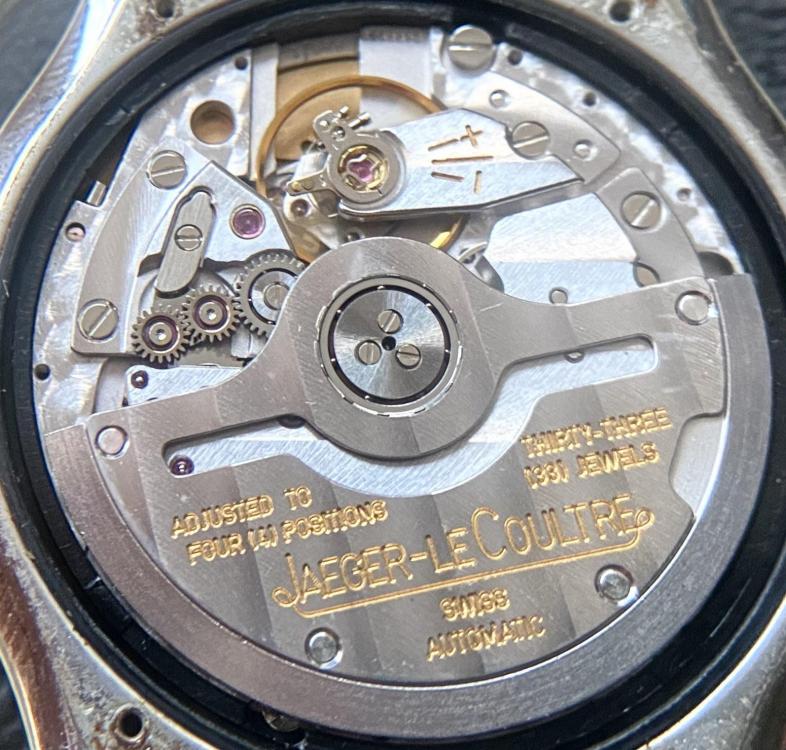

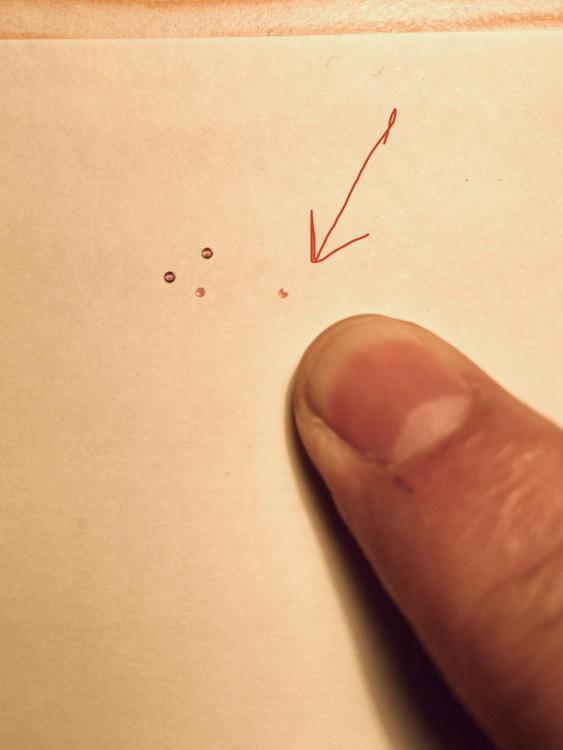

My JLC Heraion with caliber 889/1 needed a service. Having gained experience with several other (cheaper) watches I decided to try it myself. Being totally aware that I wouldn‘t get any spareparts if something might go wrong I was willing to let it serviced by JLC (about €800,-) if an accident should happen. Preparing my work I found a technical guide for the partially identical 928/2 at cousinsuk and a workthroug by the WatchGuy (AP Royal Oak with JLC 889/1). I designed a movement holder with a free CAD program and 3D printed it with my Ender 3. This holder supports the movement much better than my vice type holders. I didn‘t put me under time pressure in any way and just worked on the movement when I felt totally relaxed. A week later I had successfully disassembled the movement. Some screw hads unfortunately showed that I was not the first being inside this watch. The jewels of the fast reving wheels were totally dry and clean (!) showing that modern oils don‘t gum up but do eventually evaporate. I successfully cleaned the parts in pharmaceutical petroleum ether 40/60 and One Dip. The escape wheel and the pallet fork got epilamed. What happened to be the most challenging task was handling and oiling the super tiny capstones (0,9x0,12mm). One of them slipped out of my tweecers. My heart stood still for a moment. After hours of searching I gave up. I suspect the tiny particle landed on my clothes, skin or hair where it couldn‘t be seen. After some research I found that it is a standard KIF 508 which I could order with Boley. This time I was lucky For oiling the combined stones (fixed cap) of the escape wheel I found help in this forum. Meanwhile the watch is ticking healthy again and shows good results on the time grapher.1 point

-

1 point

-

Thanks for the quick response. @Neverenoughwatches if you can solder and want a replacement then just PM me your details and I'll get you one in the post.1 point

-

Not sure if these deal with the public but it at least gives you the details you need to look elsewhere. https://www.jewelerssupplies.com/elgin-mainspring-12-size-MS-JA110.html Edit It's still always a good idea though to measure the existing spring and confirm the figures. You may also want to check this forum post.1 point

-

It is (or was) a "RIFA" X cap by the look of it - they are renowned for catastrophic failures! Search google for "rifa capacitor explosion" and you will see vast number of mentions of these. Or see this for brief example: https://en.wikipedia.org/wiki/RIFA_AB#Legacy I would advise adding a modern 0.1uF X cap to limit interference emission from the brushes.1 point

-

In the last 15 years I have worked mostly on fusee movements. Mostly verge, but english lever too. I have found that problems in the ratchet works in the fusee is common for such movements, so I have done many of them. I can not refer to something written in a book, but what I have found is that the ratchet pawls are not hardened. This is may be because the riveting in place, if they were hardened, then the degree of riveting needed would be not possible without breaking. I make this only parts in the watch movements from ordinary nails as material. The nail is harder than soft steel because of the plastic deformation in time of it's ptroduction and is just what is needed for the purpose.1 point

-

That is a metallized film capacitor, probably polyester or polycarbonate. My 50 year old Kenwood Chef blew it's motor run capacitor many years ago. Sounded like an explosion. Scared the heck out of my mum. I replaced it with an oil capacitor and it has been running fine since. I've had quite a bit of experience with blown EMI suppression capacitors. Just clean up all the burnt bits from the pcb and replace it with a X2 rated capacitor. If the pcb is burnt, scrape away all the carbonized bits, as carbon can conduct electricity and short the circuit.1 point

-

Selenium was the original rectifier material and did have a terrible smell.1 point

-

1 point

-

Adapt a router, I'm sure that 12 - 24, 000 rpm wouldn't cause any damage at all.1 point

-

1 point

-

A little update. The shaft going straight through the lid was not very optimal construction so I glued a ball bearing to the lid. It gives stability and I also switched the shaft coupler to a flexible version. That way it doesn't really matter if the motor isn't perfectly aligned with the glass jar. Did some dry runs and now I can go really high rpm. I dared to go full rpm with the basket holder only. 2000 rpm that is allegedly. Maybe I'll next contemplate getting those square jars.1 point

-

Hi @Knebo The same with the service guide for the JLC889! I followed the recommendation for the ETA2892 with a similar bearing. Interestingly Dr. Roland Rannft proposed not to oil these bearings at all. He argued that the oil compromises the function by catching dirt particles and a ball bearing could live without lubrication. I grew up in Konstanz at the Swiss border1 point

-

Yes it's a 250V 0.1uF X Rated Interference Capacitor for reasons as above.1 point

-

It's probably a K2 rated capacitor which will be connected across Live and Neutral. It's there to stop the motor acting like a small transmitter and interfering with the neighbours' radios. The machine will work without it and the wretched things often let out the magic smoke when they're getting on a bit. It's value probably 0.1uF (also sometimes written 100nF). Try searching RS or Farnell etc and see if you can find a replacement/equivalent.1 point

-

The Hamilton 980 is exactly what it says it is. https://www.emmywatch.com/db/movement/hamilton--980/#:~:text=The Hamilton 980 watch movement,relatively low for American conditions. Ill have a look at the other for you later unless someone else has responded in the mean time. The Elgin can be traced by it's Serial Number as below. https://pocketwatchdatabase.com/search/result/elgin/251092801 point

-

Great question! I think it is both. Being an heirloom but is also, in my opinion, one of the most iconic wristwatch design of the 20th century. Omega was arguably at its peak. This has the 561 chronometer movement, one of Omega's finest. I like the stainless steel case and crown with the rose gold hands and RG and black onyx hour markers. The dog leg lugs are just such a great design element as well. I could not ask for a better example of the era and am fascinated about the whole '60s and into the '70s time period when the quartz crisis came on and this piece just predates that very important time period in watch history. So not only personal history but historically significant as well, the iconic design and a fine movement all speak to me. I am lucky to have the opportunity to caretake this piece as I think it is really a timeless piece. Not the only model or maker in the watch world of course but really a part of the lexicon of watch collecting and watchmaking.1 point

-

Cousins doesn't sell top grade (at least not to me), and their price for elabore is considerably more than I paid for the top grade from the eBay seller... If you can find a source that will sell me a top grade movement (both the 7750 and the SW200-1) at a reasonable price, that's probably where I'm headed next. The seller hasn't responded. If I don't hear from him by Saturday, I'm going to file a claim with eBay. I've tested the movements, and sent multiple messages. Not much else I can do.1 point

-

Thanks guys. I did originally think of laying the movement on a drawing pin and pressing the face down but I then thought of a better solution, that is if you have a 3D printer. There is another thread on here where a guy (Thank you) has designed a modular 3D movement holder so I thought just print out the insert and make the inner diameter the same size as the dial. I used some flexible TPA filament and it worked like a dream I can lay the movement face down and press the pin, with no problem Sorry I'm trying to upload some photos but for some reason now my photos are corrupt1 point

-

1 point

-

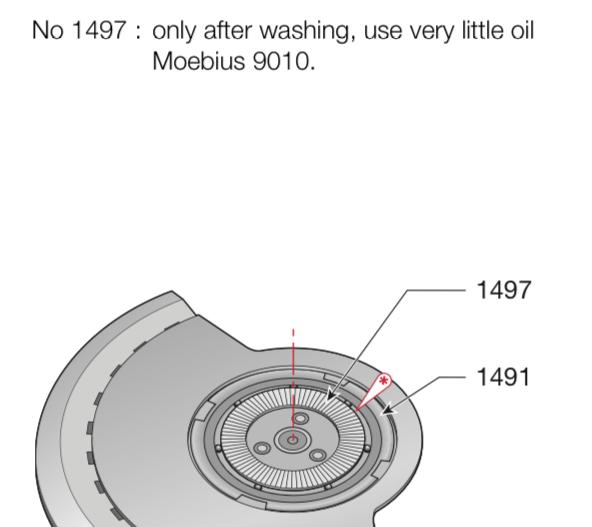

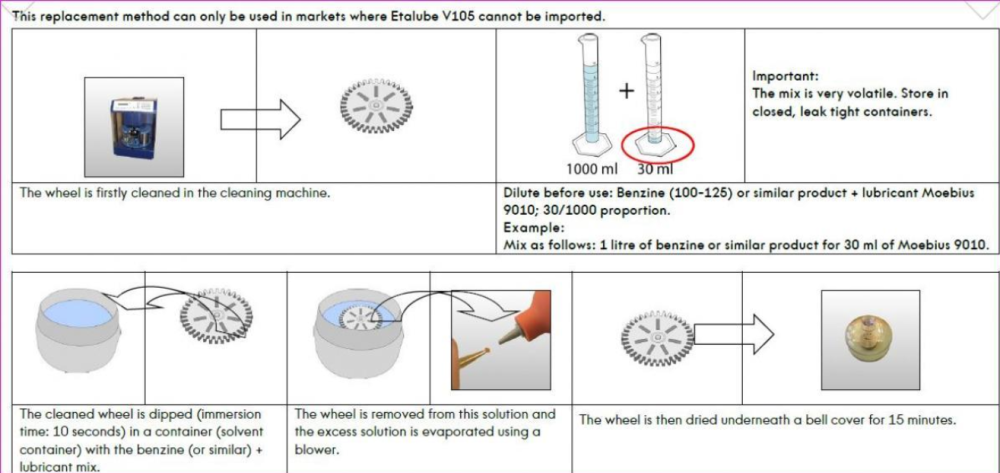

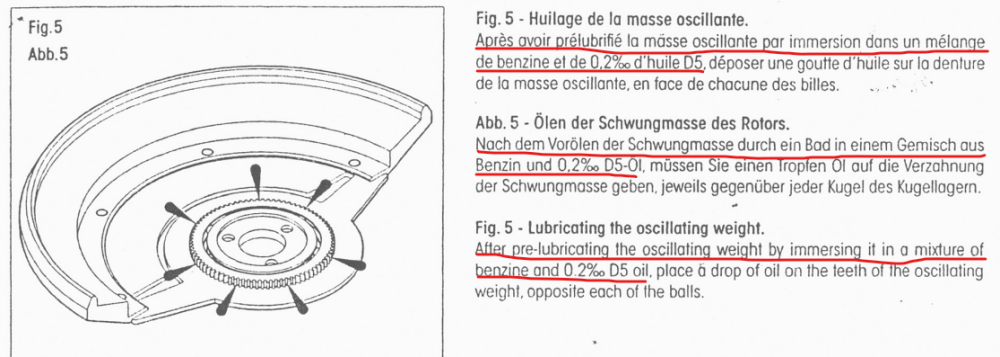

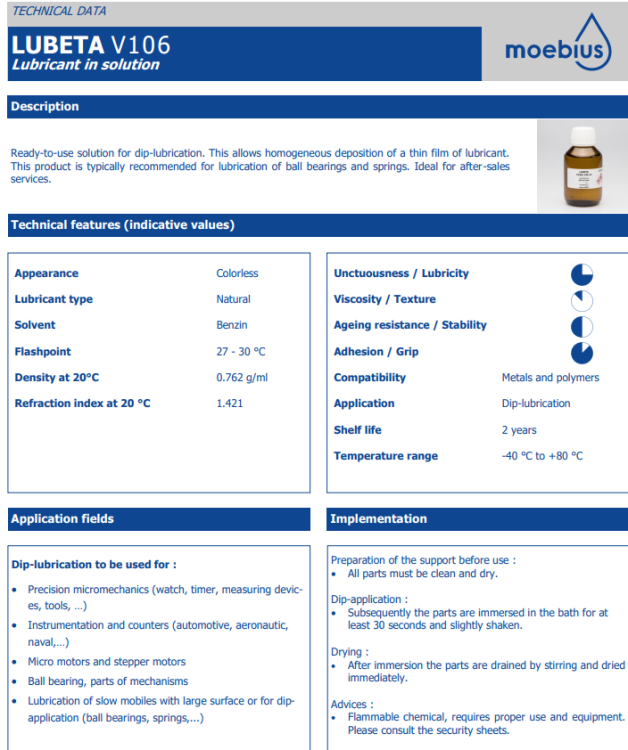

Hello friends, connected to some questions I raised in a thread about JLC cal 916 (see here: https://www.watchrepairtalk.com/topic/29824-jaeger-lecoultre-calibre-916-memovox/?do=findComment&comment=253043), I'm starting this topic about Moebius Lubeta V106 for oscillating weight ball bearings -- not to be confused with V105 for reversing wheels. Does anyone know more? As in, what it consists of? I'm asking because Lubeta V105 can be "recreated" by mixing benzine and 9010. (image credit @mikepilk) I wonder if Lubeta V106 is also a basic mix like that.... and stumbled on the service guide for the JLC calibre 918. Interestingly, the "create" an immersion lubricant with benzine and D5 oil. Could this be what V106 is??1 point

-

Hi The tech sheets for your interest. Along with JohnR725s information should give you the answers. 8597_Omega 9300, 9301, 9900, 9901.pdf1 point

-

Not sure how much you use the old ranfft archive but bits are already starting to disappear.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)