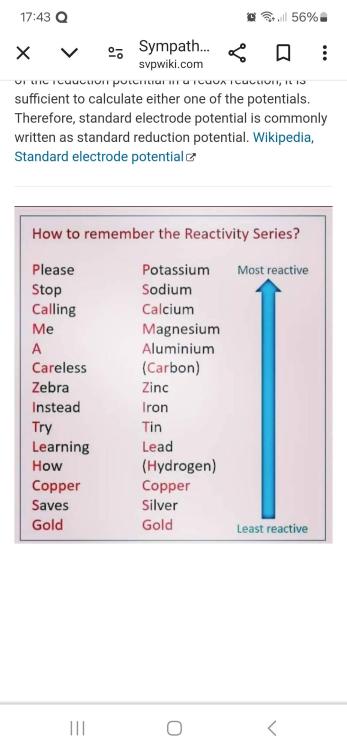

Leaderboard

Popular Content

Showing content with the highest reputation on 06/26/24 in Posts

-

Hi guys, I had a videographer in my workshop last week whilst I was teaching the ladies from Mr Jones Watches, here in London https://www.instagram.com/p/C8mWgjnohG8/?img_index=1 He made a short film of what I do and thought I would share it with you5 points

-

4 points

-

Don’t forget “rare and Unique “ I seem to remember it mentioned somewhere that this style of tool was a factory tool to facilitate rapid trimming of stems in a batch. Tom3 points

-

Hi Frank, I have only omitted one sharpening of the drill bit in the middle of drilling, sizing the string to fit the hole (2-3min) and time for hardening of Locktite - 5 min.3 points

-

This is a really cool forum with a lot of very interesting, like minded people from all over the world, and yet it's microscopic. Sounds like @Nucejoe (Iran) spent some time very near where I used to live here in Colorado decades ago. @JohnC's (Canada) brother worked/s in the same lab as my best friend up in Boulder. @AndyHull (Scotland) shares my enthusiasm for cheap thrills and technology. @SparkyLB (Florida) shares my enthusiasm for woodworking, and we've exchanged many texts on the subject. @LittleWatchShop (Texas) gave me some good advice on patent matters for the tech I'm trying to turn into a business. And finally, a huge, massive thanks to @gpraceman (Colorado). He lives down the hill from me about 20 minutes away. We met for burgers and beers a while back since it's somewhat rare to find people on here that are actually close by. I started a car club (theme is social wrenching), and he came out with his awesome BMW Z4M to help me and a group of car enthusiasts modify my Jeep. Lately, he's been coming up to my house pretty much daily to help me with some major home repairs in preparation for the baby we're having in the next week (hopefully Sunday, and no sooner!). I've made real life friends on the internet before, but while the variety of people here is probably the most broad in many aspects, the quality is simply outstanding. Kudos to @Mark and the moderators for setting up this thriving community! Thank you all!2 points

-

Jon A pleasure to have seen you, and to have you in part of my life. The industry will not die as long as life is breathed into it. You are a breath of fresh air. On a personal note. You have already given me much advice and encouragement. Regards Ross2 points

-

Hi after doing what’s been advised, there are also assorted lots of pocket watch hands on eBay at times .that may be an option. But first get a micrometer or vernier gauge and measure the relevant posts.2 points

-

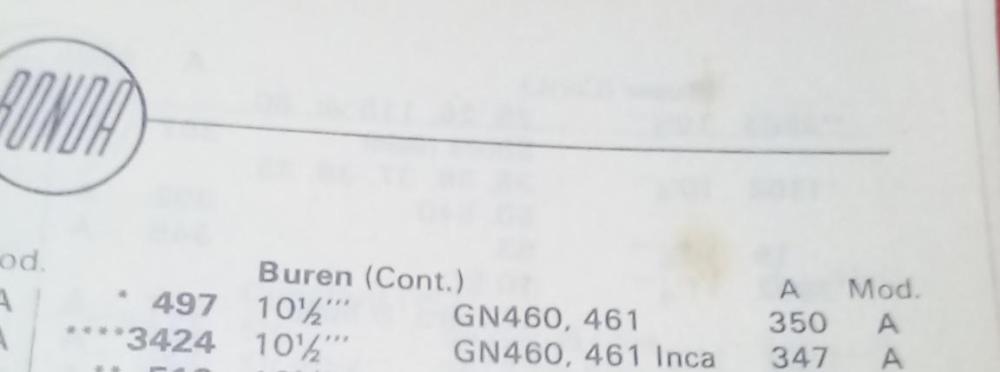

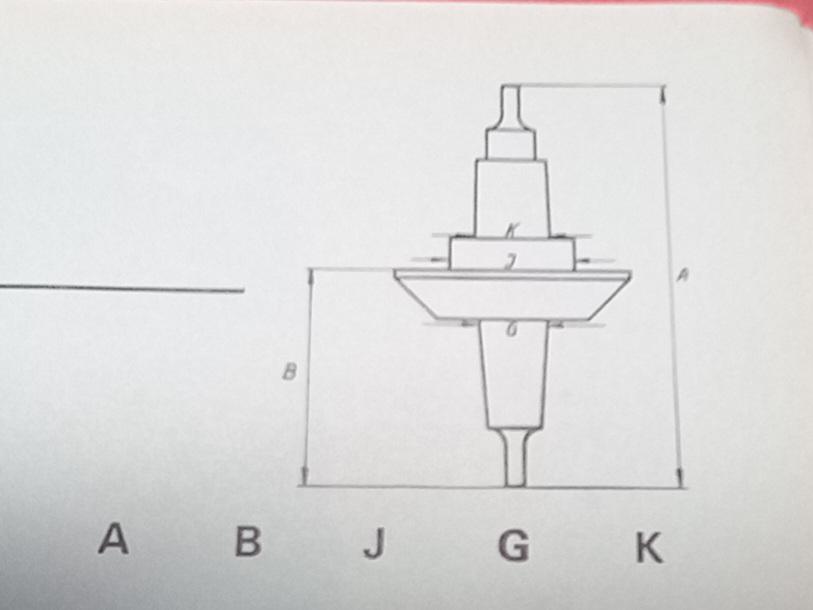

The freebie is up and running, so heres the deal with the staff i used . The balance setting is standard and since i only had a staff for an inca, thats what was getting fitted. From the photos can be seen that there are 3 dimensions that are off, the inca was .03 short for height .02 low from the wheel seat and .01 short above it plus the roller seat was 0.1 too narrow, confirmed with some measuring. Problems that might be difficult to get over . But what the hell, i wont know if it works if i don't try it, worse case i have to move a couple of jewels .As it happens the staff was tight, probably some movement modification earlier in its life ? which there was as the plate under the cock had been gouged . I didn't like the idea of adding to the damage so a paper shim gave me the extra height needed. The roller went on just fine given that it should have been a slack fit. Which is all making me think now that these parts are for an inca version staff, who knows ? But the roller, wheel and hairspring all have correct clearance and all interact exactly as they should. In DD the roller sits at the right height in the fork slot and the gaurd pin is bang center height of the safety notch. Nice when something unexpectedly works. So for a movement that was just chucked in the bottom of a tub of bits resulted in a well running Buren 461 2 hand, related to the Buren Grand Prix and Buren Dirty Dozen. Just needs a stem, crown and case.2 points

-

Welcome to the forum, enjoy,. Yes that is a crystal press also handy for fitting tight friction fitted case backs2 points

-

Hi there, May be You received aggressive answers because You initially asked aggressive question, claiming that Oris service is scamming You. Well, they don't. They just earn their money and they don't care if You are not happy about that. What they do is not fair, but it is legal and You can't do anything to prove it is not. The main problem is You will not get the crown and the tube because nobody but the ones who scamming You have it. They have arranged things this way to earn more money because they can, and actually making big money is not always fair thing ... You options is to rework the watch to conventional, not screw down crown type or to cut new, bigger thread on the crown and make new tube that fits this new thread. Or search for some similar OEM crown and tube... The other option is to buy Q&Q watch for $20 and be happy, one can replace such watch every time He decides. Actually I have chosen this way.2 points

-

I filed all of mine very short, just a little longer than the thickness an average mainspring. It can wind both ways and can be released just by turning the arbor the opposie direction.2 points

-

You will see that I have repivoted useless broken balance. It is just to show that repivoting is possible and how I think it must be done. I made the video because a friend asked me to. The right way is to turn new balance staff thow2 points

-

I’m Allan from the Central Coast of NSW in Australia. I’m retired and having fun working on recovering old watches. Hope to get help from other knowledgeable people on this forum.1 point

-

Being a Yorkshireman like you Rich, I don't like to waste £££ on bits of Bergeon plastic when it's not necessary. I had a very cheap (and nasty) cushion, threw away the middle, and in the ring put some 15mm thick packing foam. It's perfect for the job. Soft enough not to cause damage, and wipe clean. I don't like the idea of gel cushions, as they can catch hands/pivots etc and cause damage.1 point

-

OK, looks like the only reasonable option left is to shorten the hairspring a little. Is it pinned to the stud or it is glued?1 point

-

Yey i win , they dont call me Tommy the tool tinkerer for nofin, I'll pm my address, how soon can i expect it to arrive ? Haha, just realised my mistake Think Rich think before you press submit reply1 point

-

Jumping in here, you are upset about the way the whole industry works, I get that and I do agree to a point. I would not call it a scam though, if I have a service with parts you can only get from me then you either pay my price or don’t, it is literally as simple as that. as has been pointed out the movement is pretty standard, 3rd party crowns will have a close match as will case tubes. Find the parts, buy the tools and fix it yourself or find an independent watchmaker who quotes you a price that is acceptable to you. this forum is a respectful and supportive place to be if you want to be involved and learn about watchmaking, we even support the drive by folks who post a question, get an answer and are never seen again. Tom1 point

-

Definitely some kind of guillotine, for cutting pins OH ? Might not be watch related but the new one looks similar and I've seen vintage ones that almost match up. Obviously its completely useless so i think the OP should send it my way and i will dispose of it responsibly .1 point

-

1 point

-

Ok so the cheap carbide drill do work just not when used in a hand vice. You will need carbide for drilling spring steel. But they will drill more than spring steel, just read this i posted a few weeks ago. There's a first time for everything, broken pivot on a barrel arbor, granted it looks quite small and feeble, in a plate jewel as well EB 8021N . Been running like that for a while looking at the wear on the plate. Typical all cleaned and ready for assembly, new balance staff fitted trued and poise checked. Check all the watch parts people before you start cleaning and find the irreparable repair first . Looks like me and the lathe will be getting reacquainted tonight https://www.watchrepairtalk.com/topic/29807-broken-barrel-arbor/?do=findComment&comment=252636 Now i wouldn't want to risk an important part as these drills are very brittle and if broken inside the part you aren't going to retrieve it. But for drilling off the screw holes for handmade setting levers and such things then i think they are ideal. Anything with a blind hole will be risky, just bere that in mind.1 point

-

As most people do, I've tried the 'cheaper' drills - and found them pretty useless. Now I buy 'Dormer' brand from Cousins. They are a well respected brand. They cost a bit more, but compared to the three cheap ones you break drilling a hole, they work out cheaper. For saw blades, I bought Cousins own brand. I don't have anything to compare them with, as they are the first I've bought, but I've had no problem cutting brass and steel. BTW I assume you will be annealing the spring steel ?1 point

-

Thanks for the congrats, everyone! Anyone coming through the Denver area, feel free to hit me up. I'm en route to all the ski resorts from DIA! I bet dollars to donuts gpraceman would join us to boot.1 point

-

You need the same number of screws on both sides and they must be the same that means weight, length and thread.1 point

-

Oh B...... Not fair. Found one . Can't get it as my bride has correctly informed me. No room. Need for new liquids. The use would be 'as well as' and not 'instead of'. I get excellent results as is. Ah well. Converted but blown out of the water. If I did, but I won't. The only thing I would make different is a semi circular holder for the jars to be set, and to allow them to swing under the basket winder as a normal machine does. Don't you just love DIY. Even the dreams?1 point

-

You would need to measure the relevant pivots with preferably a bench micrometer like a Feintaster. Then cousinsuk have hands for pocket watches I’m sure a lot of other material houses do too. https://www.cousinsuk.com/category/hands-pocket-watch maybe look here for examples? Tom1 point

-

You will either have to find the caliber, maybe under the balance wheel or behind the dial, to look up the correct sizes or measure the pivots that the hand attach to.1 point

-

Thank you for sharing this @Jon , it really shows your passion for watchmaking and teaching. Like others have said I too am grateful for the knowledge and insights you share here and on your YouTube channel. I have benefited greatly from your knowledge and sharing. Tom1 point

-

1 point

-

Great, thank you very much, i figured it out yesterday. Before checkin back here. But thats very helpful either way, thank you for taking your time, and have a great day1 point

-

I hadn't realised this morning that the document did cover the 2851.1 point

-

1 point

-

I enjoyed the video Nev,short and to the point, yey i made a funny . This is something I've wanted to try for a long time, I'm a very long way from turning a working balance staff, so this would be my go to if i didnt have the correct staff. Actually i would have liked to see and hear some info on the dressing in of the pivot to the staff. How about modding a close sized staff.1 point

-

I have the set of 3 and use them regularly. I haven't touched the hooks on mine so they still wind both ways, up to now the hook has always backed out for me. It should be possible to get inside with a bent pin to pull the spring out just far enough at the back of the hook to release it and back it out.1 point

-

Hahaha, the opposite = the one with the least hair. The one speaking broken Spanish at min 42.1 point

-

Nice short video - without endless blabla that most others like to add. I suppose however, a few time consuming preparations and sidework was omitted Frank1 point

-

The hot one with long dark hair , if it is, someone's going to be getting lots of private messages1 point

-

While hesitant to share a video of myself, I took inspiration from @VWatchie's strategy of posting a non-English video. That's me in my day job as an economist.1 point

-

Well, since you mention it I like you have a YouTube channel. I only started it so that I could illustrate my questions on WRT. Then I thought it would be fun to try my hand at some reviews and tutorials. Perhaps I should try to make a one or two minute video just to let people know a bit about who I am. So yes, that is a thought!1 point

-

My master insisted I wore a tie. I wore those big wide flower power ones. Sometimes I used to serve in the shop it gave me extra training in helping customers and explaining what their watch or clock needed.1 point

-

Great video Jon, I'm right in saying that we here are very fortunate to have you in our group and appreciate you giving up your free time to advise us1 point

-

Unfortunately, it is not only watch owners who are denied the right to buy spare parts but also professional independent watchmakers. It is shameful beyond all limits. Of course, everyone should have the right to buy spare parts without any reservations whatsoever. It should work in the same way as it does for cars, but unfortunately, the legal system does not bother to prosecute this practice. Fraud exists but there is another side that is not obvious from the owner's perspective. The symptoms of a problem may be obvious but the cause is quite different. If the symptoms are eliminated, the cause may still exist and the watch will not work properly anyway. This is why repairers are not happy just to fix the obvious fault but need to go through the whole watch to guarantee its functionality. Many repairers have made it a rule never to fix just one symptom to avoid disappointment and claims. I recently convinced a Rolex owner that the movement needs to be serviced and repaired even though the watch is running just fine. It seemed that only the rotor needed an overhaul but on closer inspection, it turned out that the problems were much more extensive. If you want to know more, click on these links: https://www.watchrepairtalk.com/topic/29655-rolex-cal-3135-issues/#comment-251377 https://www.watchrepairtalk.com/topic/29655-rolex-cal-3135-issues/page/2/#comment-2535981 point

-

1 point

-

Just bought this PinVice; 0 - 1.5mm. It has two bits, one with internal rounded fingers and the other bit has the edged fingers. https://www.cousinsuk.com/product/single-ended-round-with-2-collets-horotec?code=P58276 So far I've only been using it to hold a 2824-2 winding stem. Seems nicely made, works well and you get "two" for the price of £8.50 excl. VAT. Depending on your location, members Waggy suggestion seems price-wise okay. However if you live in the economic suicidal European union, by the time I get it in my hands (due to duties and registration fees) it cost me over $34 ....... That's the reason for me buying the Horrortec1 point

-

always nice to have a picture so were all on the same page here. Plus I think the subject has come up before somewhere on the message board? you will note if you look carefully there is an X in the picture saying no lubrication but there is also a another number pointing to the barrel wall. So you need a breaking grease like p125 or the equivalent and no lubrication on the mainspring itself.1 point

.thumb.jpg.e5c1fb6b4b7d697f84de65ced371de30.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)