Leaderboard

Popular Content

Showing content with the highest reputation on 06/28/24 in all areas

-

Maybe someone could give you better advice but I would make a support, same size or larger than the dial, drill a hole just bigger than the hour wheel and then push on the hour wheel pivot.4 points

-

2 points

-

I think the best solution here is as Richard has suggested. Get a piece of material with a hole slightly bigger than the hour wheel and carefully drift it out from the front.2 points

-

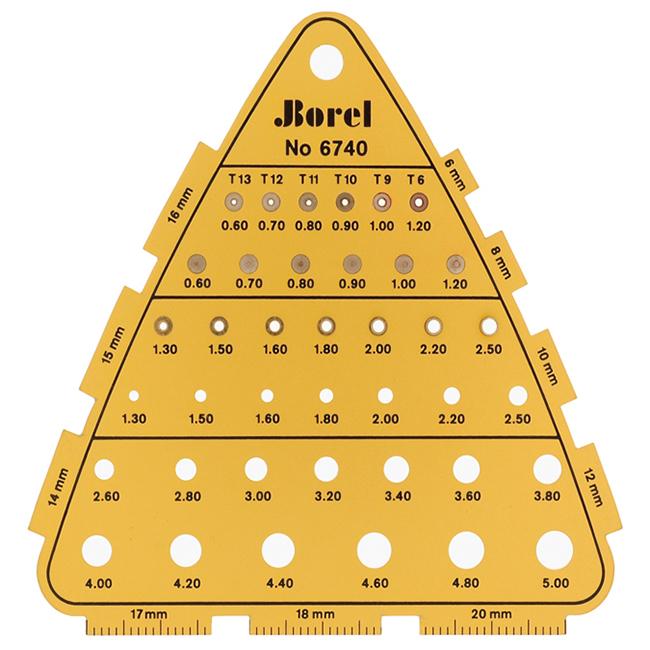

I agree with Mike, those don't look great (I've seen way worse that still worked fine), but that shouldn't keep the crown from going on. I'm guessing the crown has a smaller thread in it. A really handy tool is one of these plates, we always called them "Borel plate/gage", but I see Bergeon has one too. They aren't cheap, but very useful. You have male and female threads to check stems and crowns, tubes for checking crowns (the fit of the gasket) and holes for checking tubes and crown ODs, plus gages for straps.2 points

-

This one cracks me up I never had issues picking up pegwood, but I still think it's a genius solution2 points

-

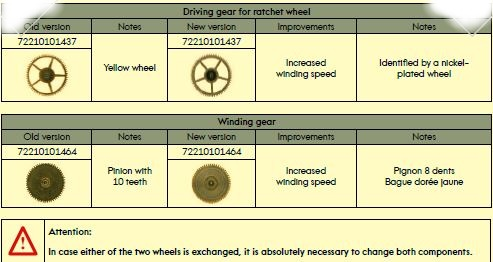

The indication is if I read correctly he replaced the entire unit although he didn't say where the entire unit came from and as to whether is brand-new or used in other words used it may have the same problem plus the bonus problem .To be honest I was really hoping for numbers but I'll work with The number that @oldhippy Has given us which brings up a little problem which is why had asked in the first place but society and get numbers I didn't feel like tracking down of what exactly replaced. One of the unfortunate problems in the universe and watch repair is supplemental information not necessarily available to the world. Like Omega had some upgrades and suggestions for these movements in another instruction sheet. So if you're replacing part number 1464 you're supposed to replace 1437. Notice is a reference to increased winding speed that would suggest that they must've noticed there was an issue with winding and upgraded components. Then a unfortunate problem with Omega is upgrade components usually have the exact same part number with no other designation although here they do tell you what the differences. But a lot of times they assume you're purchasing brand-new parts from them no get the brand-new components.1 point

-

1 point

-

That one is easy Ross, OP means , the watch has not wound any, during the two days that was on his wrist. The question remains, where did the two days of wind come from, 1- Did it come from manual wind through the crown? 2- Or, got wound on Bergeon winder? 3-Manually turning the rotor? Other questions are, does ratchet wheel turn in either direction he turns the rotor? If it runs 2days with manual wind , power isn't prematurely discharged, so IT IS holding power. Was winder module checked, for shakes, worn holes/ jewel holes, and final power transmission to ratchet wheel, the jewel hole of the ( ratchet wheels reduction wheel) might be faulty, or transmit power in one direction only. All holes/jewels holes, arbours, gears, in auto device should be checked. that with broken ratchet teeth, holes barrel arbours fit in !!! We know nothing about the mainplate hole for lower barrel arbour, lower arbour, lower barrel hole, barrel arbour shakes..... etc. The less we know, the bigger the guessing game becomes. Its a simple mechanical machine, not state of the art particle physics or cosmoscience.1 point

-

I don't anything would penetrate enough to make it worth while and you don't want to be getting oil on the dial.1 point

-

Hi Rich, I use CNC graver bits like this to make cutters for lathe work - both hand or crosslide support https://www.ebay.co.uk/itm/156187467226?itmmeta=01J1FXE1XJ8S5VFNX495C27PTK&hash=item245d7f9dda:g:lQUAAOSw0~1mL7fg&itmprp=enc%3AAQAJAAAA0K9BuIOgX2fZEaHQYQk59Qd5cMC4Sw6bSbBFrSxGDSOD29%2BYZPmZMySDVV71JxNJAnKV7lMkAwKsZJAonq2%2FEm3cF3zZ%2BATwZspxIQVG3FLdlXRLIlL0Cjy8dpkadqDrqM43nxrtd2IYJEE5G2qSXOTLA6WqOpmEAlwzyQoD0PYogDORtM%2BBtURyKZxeKIAWgqoaMwLeckAjMrFtCqjxA%2FWD5GAlPy%2FSlnrDNIqKvsePszv5JOGc5gF9D0kQ3DRbs6SuDIUCZQXuMrLEyaY4R8o%3D|tkp%3ABk9SR_KeuP2LZA1 point

-

1 point

-

That usually means the wrong thread. Was the 'different stem' the same as this stem? The threads look fine to me. (What's the movement?)1 point

-

@Neverenoughwatches This has already turned out to be a very valuable thread which I also believe could save us a lot of money. Thanks for starting it!1 point

-

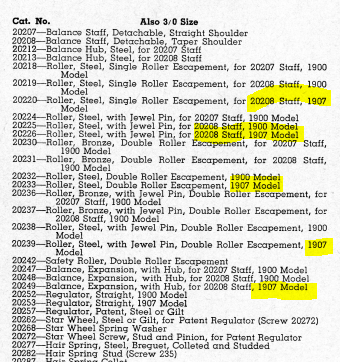

Extremely important when replacing balance staffs to have detailed measurements of the old staff to verify with detailed measurements of new staff to make sure they're actually the same staff. As you've discovered classically with American pocket watches for the most part almost all balance staffs will have variation in pivots size and other times still have other dimensional differences all with the exact same part number. Typical with Waltham lots and lots of variations. Looks like it is the 20208 Balance staff. But ideally it would've been nice to have the original to measure to see what dimensions are not quite right because oftentimes even aftermarket staffs will have variations which is why it's nice to keep the old balance staff. Then if I go look at the staff table in the book as was pointed out up above and as usual there are pivots size variations. Which is probably why your staff does not fit the jewels as you have the wrong size pivots.1 point

-

Different folk use different names for parts, most often the part's function, and sometimes to describe what it resembles regardless of it's function ie .castle wheel, anchor. I particularly like all the old traditional names, they seem much simpler yet more descriptive. This one is also sometimes referred to as a set bridge with jumper spring. Setting parts bridge cover with integrated spring. Personally i think Its a good idea to learn all the variations inc. foreign names, French and German especially since parts and tech sheets are often Swiss.1 point

-

You could use a stem extender or adapter. When fitting a new crown to make sure it screws in correctly file the end so it has a bit of a point.1 point

-

Same as Hector the correct size of die will feed on easier. Although you cant apply it in this case ( shutting the gate after the horse has bolted sorry about that and the pun ) but a popular trick that is used to straighten out the end threads of a bolt after it has been cut is to have a nut threaded on before the cut, the nut is then spun off. For future you can use this method by trimming off the blind end of a crown and have that threaded on before cutting the stem. Cutting it back to the root portion of the thread will help it to enter better. How thick is the crown ? If there is plenty of thread in it you might get away with a little trimming on the stem, add something in to the crown hole afterwards to stop the stem bottoming out past the required length you need. Make sure whatever you pop in the crown is small enough to come out in case adjustment is needed. Bit difficult to do at this size, but another idea is to clip on a halved nut and back it off the stem Get yourself a screw thread polisher for shaving the ends1 point

-

If you have a die of the correct thread, you could use that to freshen up the threads on the stem.1 point

-

Oh man, @Jon (and also @Neverenoughwatches)... so cool I've been dreaming of having a lathe, but it's a bit out of budget and I don't even have space for it..1 point

-

1 point

-

Project update- now completed. I saw another weems where the locking crown was threaded and matched the thick diameter of the threaded case, the end inside was mushroomed so it would lock out before becoming detached. The crown I have had only the internal threads so I hunted for a replacement screw that would fit like the 'original'. A setting lever screw from a scrap movement had a .8 pitch and a head wide enough to wedge into the case and allow for unscrewing of the crown. I wish the screw was longer but it will allow the bezel to be unlocked and turned. The watch is a gift for a young pilot so I'll warn not to unscrew the crown too much. I found a donor movement with the extra long version of the seconds pinion spring so movement is working brilliant... I made the little wedge part from a tiny piece of .015 annealed 1075 steel shim. My work is quick and dirty and wouldn't fly on a nicely finished case but my rough finish doesn't really show under the locking crown and matches the damage on the bezel quite nicely thank you ... I have a bigger version weems on the bench at the moment. There are so many variants of case and movement they feel more like the days of hand made. I'll post the other soon....1 point

-

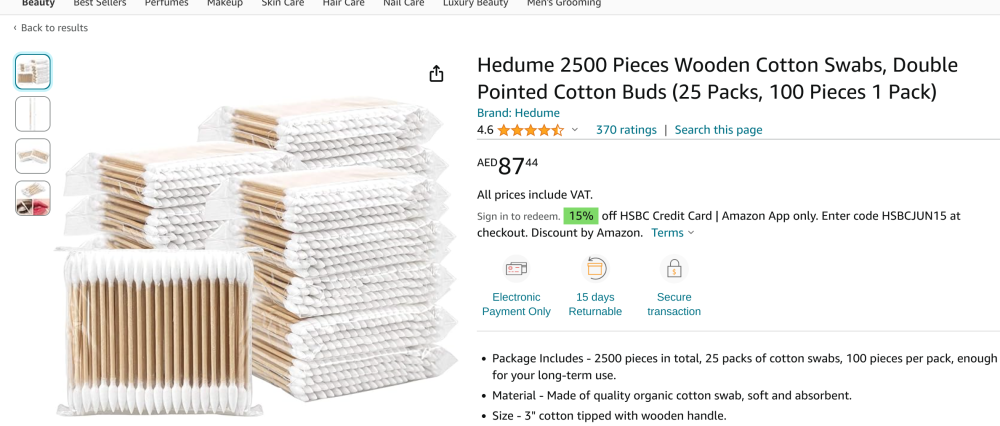

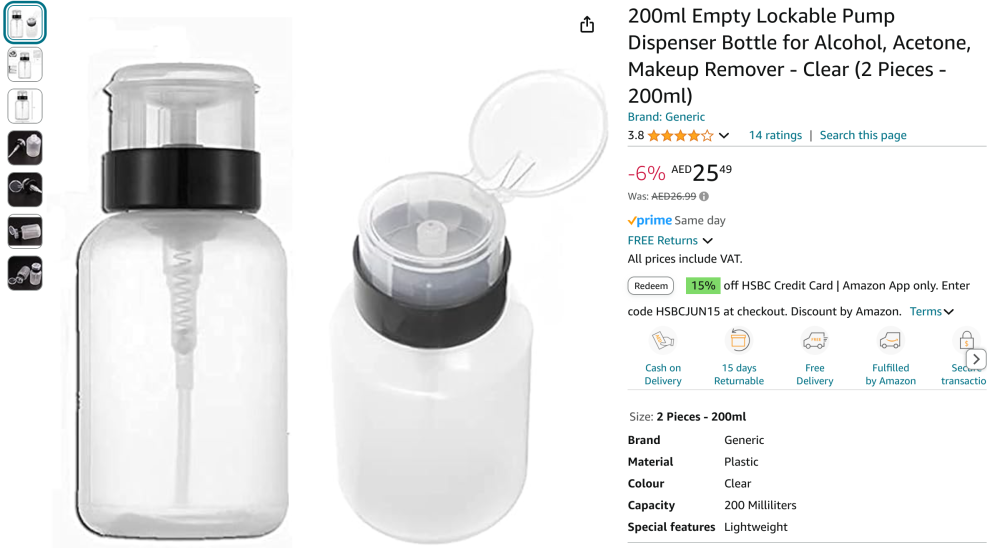

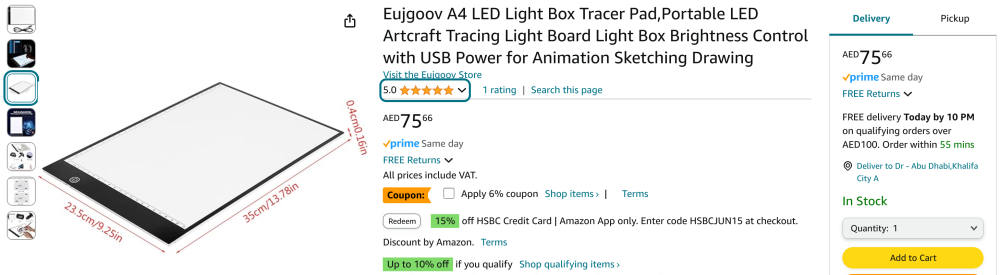

Another idea stolen from Mrs W. The pointed cotton buds allow better cleaning in the nooks and crannies of the main-plate and mainspring barrels etc than the normal rounded ones do. The holder makes it neat and tidy on the desk, and the squishy top dispensers work for IPA and acetone, however naphtha seems to light and it drains from the tube/plunger mechanism before it gets to the outlet. If this watch thing doesn't work out I can switch to a nail salon Note 1 AED = 22p = $0.27 And I use these for small jobs like removing rust from screws or small parts with evaporust, or dissolving out a broken stem with alum etc. Best part is that they are free (Mrs W's eyes roll each time I scavenge the used ones from the hotel dining table) and seal much better than anything else I have bought on Amazon, and the metal lids do not react (swell) with chemicals like naphtha etc. On a roll here..... I got this a while ago too for finding cracked jewels, beats trying to balance the main-plate on top of a torch/phone and focus your scope at the same time. Just put this on the desk top, turn your room/scope lights off, place your main-plate on it and turn it on (powered by USB cable). You then have hands free experience to focus/zoom your scope and poke the plate around to search fro those cracks. There are smaller cheaper version out there (this one is +/- A4), but this was on half price when i got it so couldn't resist a bargain! I also confirmed that these generic Mr Clean magic erasers (Melamine Sponges) are the same as the Bergeon 'pith wood' alternatives OK this is my last one for today.... This is what I mix my lume powder with when doing watch hands, find it much easier and convenient than the resin and thinner that you find in lume kits. just mix it directly with the powder and apply.1 point

-

I saw those great idea scott, i like the meds gel caps for storing small stuff although the big ones have good volume for wheels etc, extremely cheap 1000 for around 15 quid, enough to last most of us a lifetime and they've been used for decades so a proven storage idea. These with a lid on as well if you want to pop a member something in the post and not be damaged.1 point

-

Yey i win , they dont call me Tommy the tool tinkerer for nofin, I'll pm my address, how soon can i expect it to arrive ? Haha, just realised my mistake Think Rich think before you press submit reply1 point

-

1 point

-

1 point

-

Hi after doing what’s been advised, there are also assorted lots of pocket watch hands on eBay at times .that may be an option. But first get a micrometer or vernier gauge and measure the relevant posts.1 point

-

1 point

-

1 point

-

I totally agree with @Mercurial's points on starting with a known-running watch, and the ST36 being larger and easier to service. That said, my first repair was an Elgin 345, which taught me an awful lot about non-interchangeable parts. My next one was a very similar Caravelle, and I have to say I really love those Bulova movements and have done many since. They are very nice to work on, and as you noted parts are readily available. For the most part you can get away with the phone camera's zoom, especially for assembly/disassembly pictures. One piece of hard-learned advice: take more than you think you need. Unless I know for a fact that screws are the same, I keep them segregated with the parts they were holding on. Right up until I bump my parts tray and mix them all up, at least. You can see here how the automatic works are in one compartment, the train bridge in another, keyless works in another. I like to keep the balance and pallet fork in the center with their associated screws--I clean them separately and want to make sure they're kept safely away from other parts. I heard a great phrase on someone's Youtube video that stuck with me: "good screw discipline." Yes, definitely a 4x or 5x loupe. With a 10x you get much shorter working distance (you have to be around 1" from the work) and shallower depth of field. I know it's a little spendy, but a stereo microscope is hands-down the best purchase I've made. Honestly if I had only loupes to work with I might not have stuck with the hobby. It's such a pleasure for my rapidly aging eyes and back. I've even figured out how to tilt it so I can use it to install hands and work with my staking set. Having both eyes also helps with depth perception. Hope that helps, and good luck!1 point

-

1 point

-

So finished reassembling and lubricating my grandfather's ETA 1080 today and took a couple of pictures of it before putting it back into its case. For anyone interested I assembled the movement in the order shown by these pictures (000A.jpg, 000B.jpg, 001.jpg to 073.jpg). The pictures were taken during disassembly so the parts in the pictures are somewhat dirty. The pictures were intended for my personal use, so some of the text and coloured arrows might seem somewhat cryptical. And finally, a slow-motion video of the balance in motion can be seen here. This watch was last used some 40 years ago or so, so just wonderful to see it tick again! This was my first ETA movement and compared the Vostoks and Poljots I've been working on before I must say the fit and finish is indeed a notch or two better. I really enjoyed doing my first Swiss watch (except for the Unitas 6498 in Mark's watch repair lessons).1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)