Leaderboard

Popular Content

Showing content with the highest reputation on 06/29/24 in all areas

-

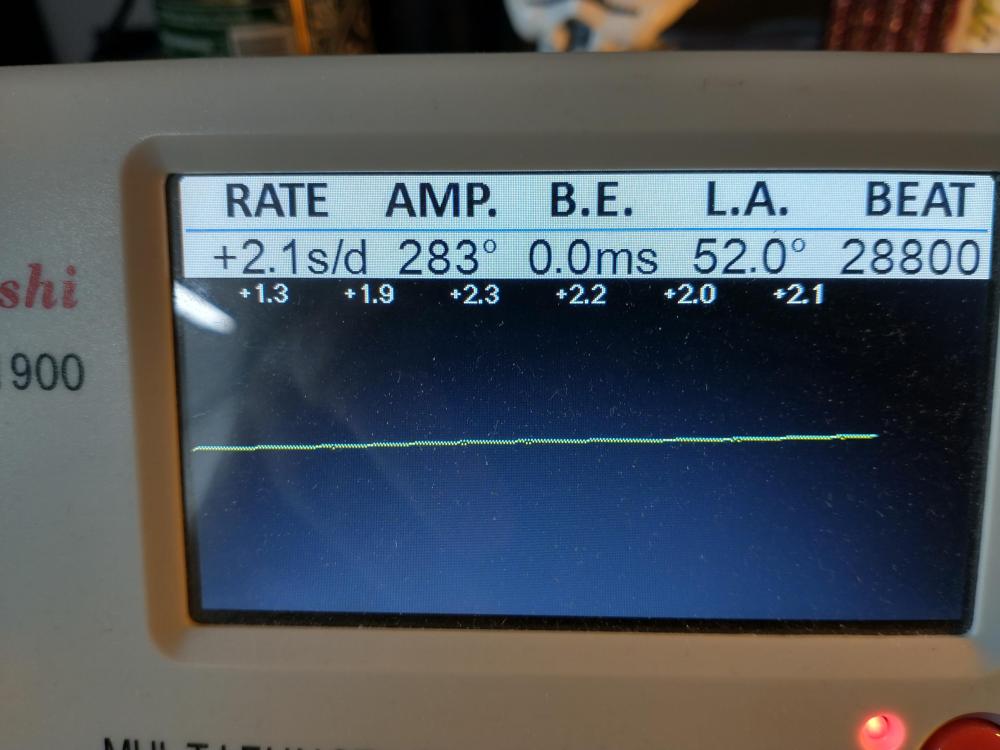

I worked out a simple formula to work out how much to turn a collet. great video by Mark explaining well and showing how to set the impulse jewel between the banking pins and in the middle of the horn/notch of the pallet. If the watch is running at 300 amplitude and it is a 18,000 beats per hour, then in every second the balance would turn 5 revolutions, or 5 tics, which would equate to 1500 degrees of travel. So, 1500 degrees of travel of the balance happens in 1 second, or 1000 milliseconds, so every millisecond equals 1.5 degrees of travel. If the movement is out by 3 milliseconds the collet needs to be turned 4.5 degrees (3 milliseconds x 1.5 degrees = 4.5 degrees) If the watch runs at 270 degrees, the maths would be changed accordingly and a smaller travel in degrees over the space of one second would occur7 points

-

Always fun when @JohnR725 or @praezis gives us a little snark. It is truly a great day when we get them both on the same thread on the same day!2 points

-

What I was getting at was if somebody didn't have the free version where would they find it? Then the other amusing problem is even though the browser I'm using is a Mozilla product it isn't always recognized so the last time I clicked on the link that I had to download the free version it comes up as a blank page. Although out of curiosity right now I did check and it looks like Mozilla Firefox works just fine and it comes up. It just isn't friendly towards all browsers. so for those people looking for the free version it's available here https://c.web.de/@337134913998293880/YuEh_TobSjaCfyBDix_1gg2 points

-

Hi, thanks for the welcome and the movement info. Yes I probably should create a thread for this, just wanted to add something besides “hi” to the introduction.2 points

-

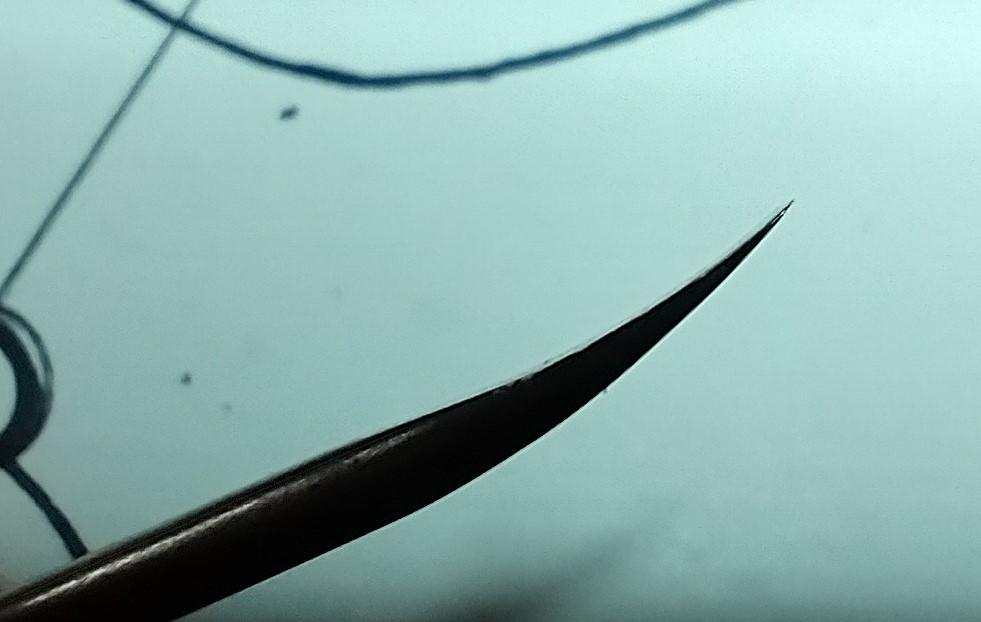

If you've got some tool steel rod, something like 2 mm, shape the end like a screwdriver and beat it flat on an anvil with a hammer it will work harden the tips and they will be really slim. Finish them off on some wet and dry and you've got some really good slim hand removers. I use mine I made for things just like this. They will find the smallest gap and open it up. I buy my tool steel from these guys https://www.groundflatstock.com/ Brilliant for making tools and parts. always good to have a supply of 2, 3 and 5 mm rod. I buy tool steel sheet from elsewhere to make things like yokes and setting lever springs. Great as collet removal tools as well! They chip every now and then but I just hone it back. I've been using these for over seven years now2 points

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot. I don't want to seem rude. You have very little experience and to tackle a ladies Omega is not recommended until you have at leased serviced Gents movements and get to understand them, they are bigger so it will be easier for you to work on. Omega watches are high grade movements and you could damage the movement beyond repair. I would put it to one side until you have more experience.2 points

-

Welcome to the forum. You're probably best starting a new post in the relevant section of the forum requesting help and giving more details on the fault. In the mean time if you've not already got them, here's the details for your AS 2066 movement. chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.cousinsuk.com/PDF/categories/645_as2060,1,2,6,4,6.pdf2 points

-

So no problem as long as you understand what needs to be done. Very good! I started the disassembly yesterday. With a few exceptions the screws looked untouched so maybe the watch has never been serviced. I have the principle of treating all watches regardless of value and brand in the same way but hand on heart, I took extra time and was extra careful to dress my screwdrivers and tweezers. This level of quality is beyond anything I have experienced except possibly a couple of Omega movements. In general, it is easier to handle high-quality movements because all the parts fit together so perfectly, especially during assembly. Just screwing the case back on and off feels almost a little sensual. It almost makes you blush and look over your shoulder The fit is exceptionally precise! In the long run, maybe sometime in the fall, I plan to create a service walkthrough. Therefore, I take lots of pictures of which I may then use a third. If there is interest in taking a look at the status of the movement, you can click on the link below where I will gradually post the raw material. On Thursday, the family goes on vacation so the continuation first in the second half of August if all goes as planned. https://1drv.ms/f/s!AnVrKJ9agkNWkoFMtyD2O4kPIs66Jg?e=oMRKbn2 points

-

I use them 15 years, have figured nothing beter. Just a pieces entirely made of tungsten carbide. I thought small price is not bad feature at all...2 points

-

I'm sure i started a thread for this about two years ago, no eyed deer where that went to ( ok so its a goat, what ya gonna do ? Shoot me ? ) . I'll try again. A new place where we can post wacky ideas that work ( i have lots, they dont always work, but then neither do i if i can help it ). Heres one - so i dont get the typical ultrasonic cleaning thing which goes something like this, parts in a mini mesh basket in a lift out basket in a glass jar in the US. ( see picture 1, yes i have pants on today so lets not get too excited ) This seems like an awful lot of barriers for the cavitations to penetrate before they reach the actual part, 3 in fact. We can eliminate two of these very easily, like so by putting the parts directly into a small tin that will float. A tin with a lid is great , i have a few that i use that float very well in fact. An alternative is one of those tea lights after the candle has burned out. Dome the bottom of the foil to create a keel to stop it tipping over, the watch part also settles in the bottom to give it more stabilty. I use a small US occasionally, next to where I'm working if things just need a quick rinse, gives you a good example of how i do things sometimes, part goes in the foil tub placed in the water then i drip a little cleaner into it. Works a treat though the US could do to be upgraded. For plates and bridges you can also hang them off copper wire draped over the side of a glass jar or tin. A little tip or trick can often save stress when tryin to get our heads around something, like parts that are just not cleaning well enough, that has just a very simple answer to it. More ideas people please, teamwork makes the dream work an all that Another quick one folks, this time for drying parts. I feel this needs to be quick to stop that white ring staining that often happens when the part is removed from an IPA rinse, commonly seen around the jewel holes. This involves 2 pieces of apparatus besides the dryer. 1 x wire egg cup and 1 x half of one of those spring loaded 2 part tea strainers. The wire egg cup allows the warm air to pass through the mesh basket. This basket is suitable for plates, bridges and a few other parts that have enough mass not to blow away , although as you can see my dryer is speed controlled .Obviously if you are drying small parts leave them in the mini mesh baskets that have lids and use a bigger basket holder. Hairdryer is fitted to a small microphone stand.1 point

-

1 point

-

1 point

-

1 point

-

Not at all. Maybe this direct translation has a slightly different meaning in your language. There are surely many many clever people who don‘t use PCTM. Please don‘t take a flippant remark too serious.1 point

-

I don't know if this is a language difference, but in saying 'Clever people use PCTM' is inferring that if you don't use this method then your not clever?1 point

-

Always listen to the voice in the back of your head which says in this particular case extreme caution. Versus jumping in and breaking something that you really don't want to do. Then somewhere in the group we've had the discussion of all the friends whatever who find out what your hobby is and suddenly they have a watch that needs to be serviced. Because conveniently the you're the only watchmaker still alive on the planet at least that they know of. Not that they couldn't find a watchmaker Conveniently they don't because They would then have to make a serious commitment of paying money. On a case like this it was properly tightened the ball definitely will not work but it might it just shouldn't because it should be really nice and tight. If you have the proper hand held ones most of the time that work fine but they can slip and scratch things up. Then I'd be curious to see a picture of the Bergeon Case (as there's probably more than one choice in their catalog I'm curious about which one the Chinese have cloned?1 point

-

I have one and really like it. I clean it in warm soapy water and dry with a lint free rag which makes it good as new again.1 point

-

The ball might work, if not you need a screw down case opener. The bench mounted ones are the best rather than the hand held ones, and the chinese clone of a Bergeon one I got was about 1/10th the price and works great.1 point

-

You can now see why you part a lot of money for these and where that money goes, especially the exceptional engineering. They practically service themselves and results are truly amazing. Here's a 3035 from this week. As you can see from the second to last pic, the hairspring was in a right tangled mess. Either someone had tried taking it out and back in again, or the watch had taken quite a hard tumble. I'm guessing the latter. The last pic is the carnage that someone inflicted on the case trying to get the bezel off! Jeez! That is one deep groove! Even one of the bridges had the part number scratched into it. Classy!1 point

-

Hello fellow members, I am a complete novice with regards to watch repairs, I have replaced a couple of movements for battery watches and I’m fairly good with intricate tasks so I’m considering attempting to replace the mainspring on a small Omega watch from around the 1960’s…. I’m not sure if this is something that would be way beyond my capabilities or whether it’s even worth attempting? I would appreciate any advice with regards to this and if there are any posts or forums etc already available on your site I would love to be directed to them…. I’ve had a quick browse but it’s a bit overwhelming for someone who is not conversant in horology and its terminology. I really need an idiot proof step by step guide if there is one available? Many thanks, N Ford1 point

-

Dial silvering is quite easy if you have a good silvering kit. I have silvered many dials and also wax filled numbers. This is what I used. Works every time with first class results https://www.hswalsh.com/product/clock-dial-silvering-kit-hs14831 point

-

AndyGSI, Thx sir for "reeling me in"! I actually found the correct stem in a box of spares that I had.. Just enough length to set it up. I was unable to verify the PN prior to purchase, but it seems to fit fine!!! Thx for the assist sir!!! John1 point

-

I have quite a few of these little compartment boxes, that Chinese electronic component kits, screw kits etc. are supplied in. They mostly have some or all dividers movable, so the compartment sizes can be adjusted to suit the items you are storing: (The original components are only ever used for prototypes & test rigs, as the quality is often dubious - but good value for that purpose, and often cheaper than the boxes alone, if you try to buy those!) OK! Not bad, the currency prefix was too small to read...1 point

-

I usually store the dial, date and day rings and any hands to keep the set together, I think they are too thin for much else. Some dial feet are too long for the holders I have so you can't close the lid, but I would say that about 80-90% fit just fine. There are larger ones and I am thinking about getting a set of those for those dials that do not fit in the ones I have, it's on my list of things to do. Not £8.90, 8.90 AED - that's UAE Dihrums so about £1.92 for 101 point

-

£8.90 for ten? That's expensive!! I use these: https://www.amazon.co.uk/gp/product/B08CDFDP6B/1 point

-

1 point

-

1 point

-

Why not thin down a couple of hand removal tools? That would seem the most logical to me. Tom1 point

-

3035 Yes, keep it in situ. For some reason I thought you were working on a 3035. Here's a pic of a 3135 spring in situ. Push the spring out of the way which allows the date driving wheel to be removed and the tension taken off the side of the arm with the jewel on the end. You can see the hole in the stop lever which the setting lever goes into. Dead easy to line up! There is still the crown wheel to support the winding pinion and clutch in the 3135 so it isn't in mid air1 point

-

Maybe someone could give you better advice but I would make a support, same size or larger than the dial, drill a hole just bigger than the hour wheel and then push on the hour wheel pivot.1 point

-

1 point

-

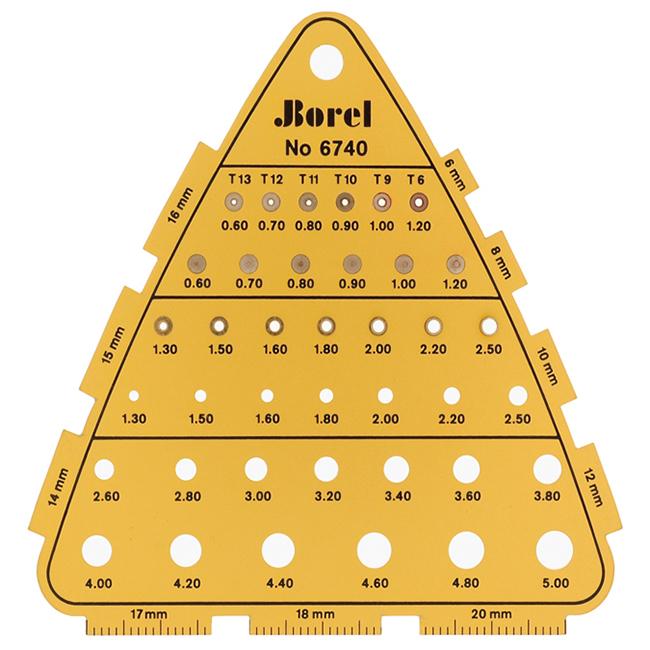

I agree with Mike, those don't look great (I've seen way worse that still worked fine), but that shouldn't keep the crown from going on. I'm guessing the crown has a smaller thread in it. A really handy tool is one of these plates, we always called them "Borel plate/gage", but I see Bergeon has one too. They aren't cheap, but very useful. You have male and female threads to check stems and crowns, tubes for checking crowns (the fit of the gasket) and holes for checking tubes and crown ODs, plus gages for straps.1 point

-

@rehajm I think the topic creator contacted the Liverpool contact listed on the BHI list. And they never heard of a Cricket.. I agree with you that a good watchmaker can service any watch. But a professional watchmaker that never heard of a Vulcain Cricket... to me, I wouldn't trust them1 point

-

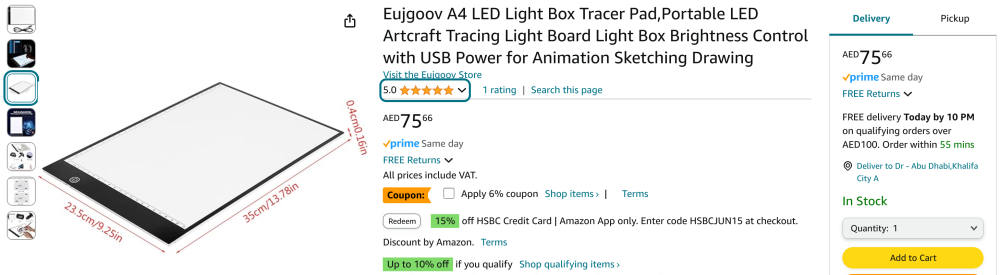

Another idea stolen from Mrs W. The pointed cotton buds allow better cleaning in the nooks and crannies of the main-plate and mainspring barrels etc than the normal rounded ones do. The holder makes it neat and tidy on the desk, and the squishy top dispensers work for IPA and acetone, however naphtha seems to light and it drains from the tube/plunger mechanism before it gets to the outlet. If this watch thing doesn't work out I can switch to a nail salon Note 1 AED = 22p = $0.27 And I use these for small jobs like removing rust from screws or small parts with evaporust, or dissolving out a broken stem with alum etc. Best part is that they are free (Mrs W's eyes roll each time I scavenge the used ones from the hotel dining table) and seal much better than anything else I have bought on Amazon, and the metal lids do not react (swell) with chemicals like naphtha etc. On a roll here..... I got this a while ago too for finding cracked jewels, beats trying to balance the main-plate on top of a torch/phone and focus your scope at the same time. Just put this on the desk top, turn your room/scope lights off, place your main-plate on it and turn it on (powered by USB cable). You then have hands free experience to focus/zoom your scope and poke the plate around to search fro those cracks. There are smaller cheaper version out there (this one is +/- A4), but this was on half price when i got it so couldn't resist a bargain! I also confirmed that these generic Mr Clean magic erasers (Melamine Sponges) are the same as the Bergeon 'pith wood' alternatives OK this is my last one for today.... This is what I mix my lume powder with when doing watch hands, find it much easier and convenient than the resin and thinner that you find in lume kits. just mix it directly with the powder and apply.1 point

-

Have a look here. https://www.facebook.com/TimelineWH/videos/the-fusee-chain-maker-the-worst-jobs-in-history-at-sea/1778730682206168/1 point

-

1 point

-

There are numerous formulas in old horological texts, but the simplest I've found (and use) is by weight: 1 part silver nitrate, 2 parts table salt, and 2-3 parts cream of tartar (potassium bitartrate). These get mixed up and stored in a glass container, brown preferably, and kept from light. I mix them with a mortar and pestle to get the particle sizes fairly uniform. Some formulas call for silver chloride, but that is what you make when you wet the silver nitrate and salt. I don't know what the commercial finishing powders are but with the above formula you wash off the remaining silvering paste with water, then rub down with straight cream of tartar, rinse again dry and lacquer. I also don't know what the exact reaction is that gets the silver to "stick". I do know that if you keep going the silver layer can get quite thick and will eventually flake off.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)