Leaderboard

Popular Content

Showing content with the highest reputation on 07/01/24 in Posts

-

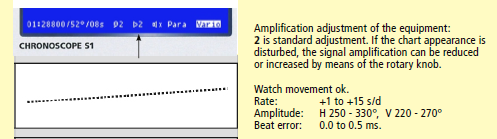

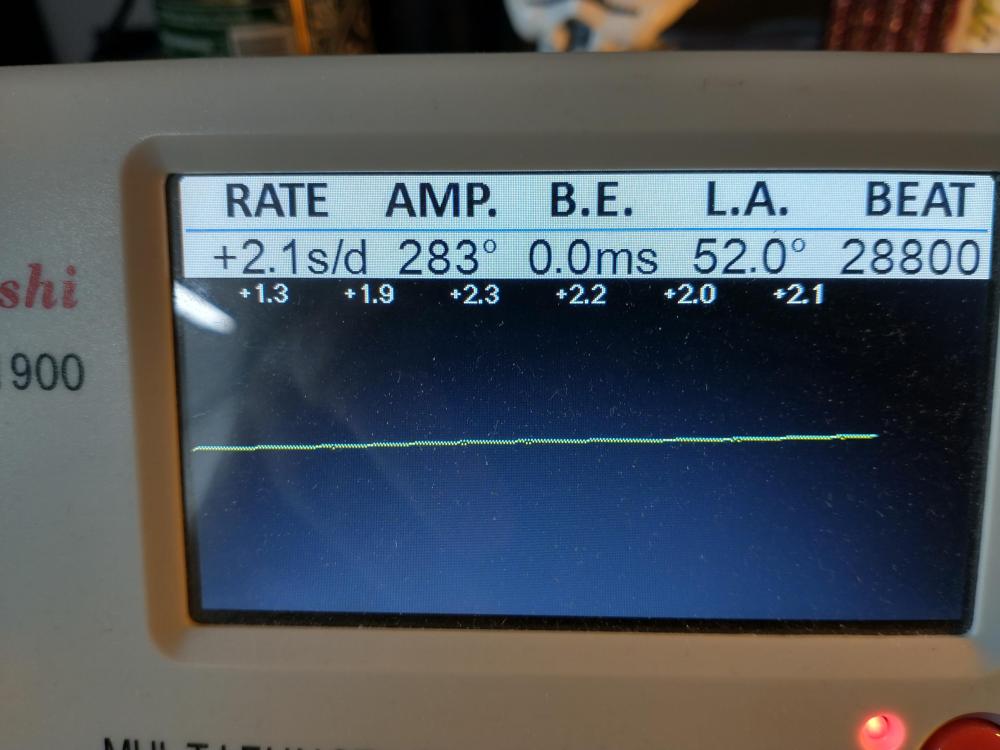

When I do vintage work for factories, which is often pieces from mid-20th century but back 100 years as well, they expect to see timing printouts in 6 positions at full wind (minus an hour or so) and at 24 hours. At full wind they really want to see 270+ amplitude, but if that's not possible, similar to John's info above, there are minimums for 24h. They get a bit testy if the amplitude is much below 260 at full wind, that's for sure. When I do work for a local shop, he wants to see 270, but for a mid-range 60 year old piece is happy with 250 as long as it's stable in rate over 24h. The best book I've seen on watch adjusting (precision timing), by Joseph Rugole*, states that if a watch isn't capable of hitting 270 in the horizontals, with not more than a 45 degree drop going to verticals, it's not worth trying to rate it to any high standard. In the Hamilton links from John above they don't state any amplitude requirements, but I'm sure the fellows rating those for railroad use knew the rules and it's easy enough to see the amplitude on two arm balances (especially pocket watches) without a machine that tells you. From the Hamilton stuff I've worked on hitting "ideal" amplitudes is really not an issue at all. So I think the Omega info from John above is probably a good guideline. There's a max amplitude at full wind, and more importantly a minimum at 24h. I've certainly had pieces that sung along at 270+ full wind, and were a disaster at 24h. Then you start getting fancy with balance pivot shape and such, and it becomes rather time consuming. *Watch Adjustments by Joseph Rugole It's a collection of articles he wrote for the Horological Times in the 80s, and it's fantastic. - Also- you don't have to wait 24h to see those rates, most watches have around a 7.5 ratio between barrel and center pinion, so you can let the mainspring down about 3 1/3 turns and that's where you'd be at 24h.5 points

-

A quick Joseph Rugole Google search gave me three issues of the magazine. I haven't checked yet if those are the ones about Watch Adjustment but I wouldn't be surprised. https://mb.nawcc.org/threads/joseph-joe-rugole-the-greatest-slovenian-canadian-master-watch-and-clockmaker-longtime-correspondent-and-technical-editor-awi.187009/ Anyway, here's a collection of all the issues from 1977 to 2009. I wouldn't agree with "old and senile" but goat sounds just about right to me ("Greatest Of All Time")!4 points

-

As a beginner I remember some watches would immediately fire up with 270°+ amplitude, while others struggled at 220° no matter what I tried. It baffled me. I usually blamed it on the mainspring - it rarely is, (I only change mainsprings now if really necessary). As you gain experience you can notice where you are losing power - how free the balance and gear train are, what is the correct end shake etc. I now expect to see 270°+, and as I do this for fun, like to find the fault if I don't see it. I wouldn't be worried if you only see about 230°-240°, as long as it's still running well after 24h, you can make a watch keep good time. I have recently re-serviced a couple of watches from my own collection which didn't have great amplitude when I first serviced them, but now with more experience, I can find extra amplitude. Assuming the balance is swinging freely, what I would do to try to improve amplitude : Peg all the jewel holes (especially pallet arbor) Gear train - check all pivots are clean end shakes are correct. Barrel. Assemble without mainspring and check arbor can rotate freely with correct end shake. With barrel in the movement, check for wear in the top bridge. I have found that THIS is one of the main reasons for poor amplitude. Only a little to much play and the barrel can tilt and hit the bridge or centre wheel. I believe many beginners will not spot this, and it's an amplitude killer.4 points

-

3 points

-

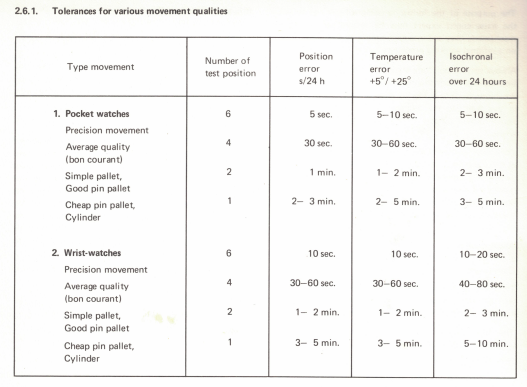

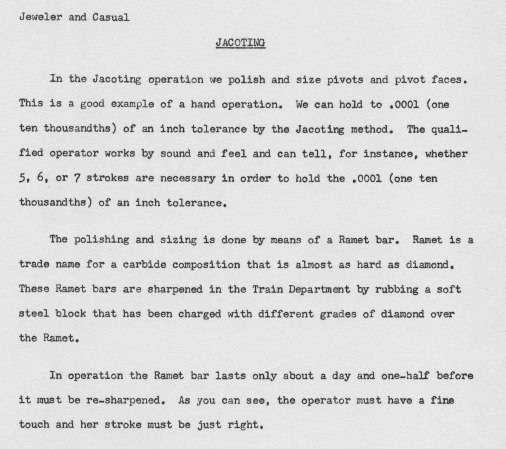

I can't tell you how reassuring it is to see 1min/day positional error & 2-3min isochronal error as an acceptable tolerance for a simple pallet or good pin pallet watch. This makes me much more confident in the performance I recently got out of a 7 jewel and not at all well built Junghans pocket watch caliber. Good time to buy stock in Casio. I almost never work on good quality movements. The handful of Unitas 6498's I have done all had no difficulty reaching >290 (and though 40-50 years old, all those were in like new condition). But otherwise, I mainly have serviced everyday workhorse movements out of old watches like the AS 1187, or Soviet movements. Nothing anyone would classify as high quality. I was seeing something on Watch U Seek or similar, where somebody complained about low amplitude on a Timex. A Timex! I'm still not all the way there with my tooling though. I don't have a microscope, I don't have a Jacot tool. I'm mostly stuck with whatever condition my pivots are in, beyond cleaning them. I imagine there's quite a bit of potential power being lost there. (and still, my question here isn't "how do I get more amplitude" - it's more like "is it just internet hobbyists who are hopelessly obsessed with high amplitude")3 points

-

I would remove the auto bridge, let down power, remove the balance and pallet fork and check the train wheels for problems.2 points

-

@quantieme, I feel I need to say few things more than the others already sid here. The auto winding module is a simple thing and finding faults in it is simple thing too. But You need to know how it works and what must it's behavior be first. First - how it must work and behave when it is in normal order: You have traditional bi-directional winding module with two reverse wheels, but here in Omega the two reverse wheels are united in one, they are two reverse wheels mounted on one common pinion. Then, I have seen in some Omega movements that You have one more reverse wheel, which is mounted on the ratchet wheel. The ratchet wheel is made on two levels, with reverse function between them. This allows separate winding by the crown without bringing to motion of the auto module. I am no sure if You case is this, I have not worked with such movements long time ago, have only distant memories. You have to know how normally such auto module performs as to check and understand if there is a problem with it. When the spring is not wound, turning the rotor in any direction will slowly turn the ratchet wheel, and You will fill almost no resistance. Turning the watch will make the rotor turn the module because of the rotor mass. BUT when the spring is already wound, You will fill significant resistance when turning the rotor , and slow turning of the watch may not make the module turn, as the mass of the rotor may not overcome the resistance of the spring winding. This is the reason why some movements will not auto wind fully on winding machines. But it is important to know that in this condition (fully wound mainspring), turning of the rotor in any direction must continue turning the ratchet wheel (actually the arbor of the barrel, as there might be reverse wheel in ratchet wheel that may be out of health). Further more, a healthy module will have relatively small angular free play of the rotor. This will be about (no more than) 90 degrees. And, if You turn the rotor only to +/-180 degr., this must be enough to make the ratchet wheel turn. So, here You have the way to check the function of the winding module. No use to check it's function when the spring is unwound, as then resistance is small. Wind the mainspring fully (6 revolutions of the ratchet wheel is enough) and start turning the rotor back and forth in the limits of 180 degr angle, not making full revolutions at all. Observe what is the angle wit small resistance (the free play) and is the resistance increasing (spring is wound) within the limits of this 180 degr. oscillation. Does the ratchet wheel turn ahead? Of course, as @oldhippy said, the main reason for faults here is the double reverse wheel part. If it is out of order, usually disassembling it shows that one of the posts of the pawls inside has broke or smash. Replacing of the post (tapered steel pin needed to be pressed in place and then cut and filed to correct height) normalizes the function of the part. But, if there is reverse wheel in the ratchet wheel, it may be the reason too.2 points

-

2 points

-

If the pivots have defects of any kind it can affect amplitude quite a bit. I've seen phenomenal differences before and after burnishing pivots. It's like the jewel holes. Any defects and the movement won't perform its best. The only tricky bit with using a Jacot tool is how to hold the burnisher and not press your face into the tool but keep a distance. Fortunately @nickelsilver has shown us how it should be done and I have tried to illustrate it in a video.2 points

-

Take the movement out of its case and see how it runs. If it works you know it is something to do with the case is the glass the correct one is it seated right. If it stops you then need to find the reason, start by just have the basic running and work from there up so that you end up with the complete movement working.2 points

-

Could the rather large regulation adjustment have distorted the hairspring & caused it to bind? Other than that I'd take the movement out & remove the hands and dial again, then see if it runs OK? If so, you know it's something binding or catching when assembled.2 points

-

Somewhere recently on the group someone was pointing out the obsolescence of mechanical watches because of course smart phones. I was going to ask a question the salespeople at work but since I found the whole subject in the waiting I didn'tsort of. I work in a mall store that sells watches and of course services them and say goes for instance are literally flying off the shelf and they're not necessarily known a super good timekeepers. It would be interesting to see if any of the watch companies do offer stock and whether you'd actually make any money at all? I have Seiko has stock probably not. On the other hand Seiko is so diverse in the so many other fields. Oh dear I will get in trouble again. The last time I commented on microscope I got annoyed with the discussion and did not participate anymore on the other hand this discussion just end it all by itself? So yes having a microscope is nice. We have one at work not in the best location for me but we do have one. People look at it all the time. I have mixed feelings about people who work under microscopes often times in that other discussion the microscopist set up the looked straight that we as opposed to watchmakers are typically look into their work. But I got chastised by somebody that microscopes are the way to go today and that I'm an old senile goat although the word old senile goat wasn't actually implied but it was definitely there. Then the pivot polishing tool had one sold it. I'm not authorized to discuss my experience somebody will swoop down and burn me at the stake like last time. There are other ways to polish pivots though although it would be nice if you to watchmakers lathe. Then if you really want to get obsessed about your pivots for better everything and if it's practical which it isn't always especially on vintage replacing the balance staff. I know somebody who worked in a Rolex shop authorized Rolex and he said they changed more staffs for timekeeping issues and anything else. Just the slightest bit of anything in other words not perfect they just change the staff. Vintage becomes a problem of getting the right staff and introducing issues because of prior work. Like often times on the pocket watches I do the jewels are slightly different size's of I change the staff I'd have to change the pivots size or and change the jewels and we don't taken enough money to cover restoration of watches back to the original factory condition. So I usually just leave things as they are but I will polish the pivots if I don't like the amplitude and or I can see a difference between dial up and Dial down. Oh and just to nail my coffin shut microscopes do not necessarily allow you to see better if you don't grasp what it is you're looking in the first place. Oftentimes seeing something really big and not grasping what it is isn't going to help Or if somebody I know who makes YouTube video is who I help with will send me a video and the pivot looks like it's flopping around in the whole because you're looking at it at such a microscopic level were the pivot is just fine so sometimes things can Actually look worse because of the magnification you're looking at them. Will be really nice to find is original watch company timing specifications of what they expected?So for instance the Elgin watch company in 1955 had the specifications of -10 to +50 seconds a day. It unfortunately what I'm looking at doesn't specify how many positions and it definitely doesn't specify amplitude although some or else the document there is a reference to amplitude. Rather than amplitudes by degrees it refers to a number of turns the balance wheel has and if it's too little it goes back to the escapement adjusting department and If it's too much it sent to the mainspring department where the swap with the weaker mainspring. If you look in the vintage Elgin parts book They did have weaker mainsprings that of course no longer exist. Than not just Elgin even Rolex has weaker mainsprings which seems weird it seems like we show stronger mainspring skip that amplitude up. Yes I have an obsession with poking fun at amplitude. then railroad grade timekeeping and look at the year because were dealing with a very very nice watch. Cheers example of railroad timekeeping which might actually beat out on Rolex over time. In the last thing when you're dealing with watch running issues watches can just wear out. Especially when you seven jewel watches the bearings will get worn or people of played with your watch before you. Typically on American pocket watches the banking pins always have been played with. Things done to the balance wheel lots of creative and interesting things have been done to the watch before you got it which makes things interesting if you're trying to restore it to something that's got keep time trying to figure out what somebody is done to this watch before you and try not to think about why they did it because it makes no sense at all. One of the last watches is working on had the balance wheel out of round they bent the bimetallic arms in by several millimeters so it's grossly out of round it looks horrible when it's spinning. Then they get text 16 timing washers off I'm guessing they were put on to make up for the watch running too fast because somebody bent the balance arms? Yes the joys of vintage both wristwatch and pocket watches Hamilton 992b 950 timing.PDF2 points

-

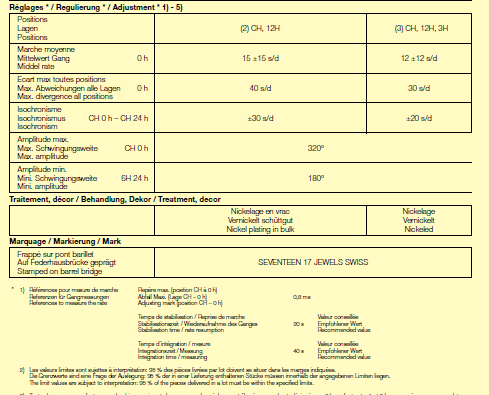

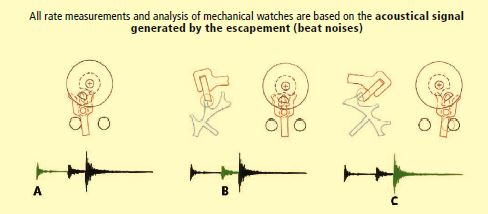

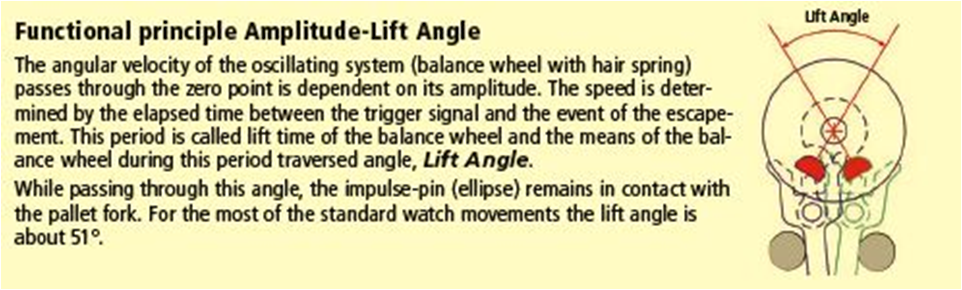

Why settle for 270? You should strive for more never ever accept less especially with this group I'm assuming for your vintage movement you have the lift angle set correctly? Then proper timing procedure like checking dial-up and dial down looking for pivot faults. Checking the escapement lubrication the condition of the pivots etc. you do end up with some interesting problems on vintage like why don't they publish amplitude specifications? Or for that matter why don't they would publish timekeeping specifications? As the watch companies usually don't publish lift angle before certain point in time because timing machines didn't exist that would measure amplitude which brings up the question of how Did the watchmaker survive without having a timing machine To please. As the most important function as a watchmaker is pleasing the timing machine by getting it acceptably high amplitude numbers who cares about timekeeping? So if you look on timing machine manuals typically they'll make suggestions like in the witschi training course we find this Obviously witschi doesn't know what they're talking about amplitude from 250 hasn't even hit that magical 270. But there is a reference to timekeeping and the beat error. Now is amplitude really that important? Let's look at this in a little different fashion?For instance image out of one of the witschi documents escapement where to the sounds come from? Now let's combine it with another image Let's look at this a little different than you normally do lift angle with the image above tells you the time span that the escapement is screwing up the oscillation of our balance wheel. From the impact of the roller jewel on the fork until locking the escapement is exerting and influence on our timekeeping. The loss of energy on impact with the fork the artificially pushing from the mainspring or basically screwing up timekeeping. So if we were to make comparisons like a watch running at 100° versus maybe 250° with a typical lift angle around 50°. Then on the lower amplitude 50% of our amplitude is under artificial influence versus a higher amplitude where 1/5 influence. So typically a higher amplitude the escapement isn't screwing up things as much. But it also depends on the quality of the escapement the adjustments. Then somewhere in all of this would be the physics of the spinning balance wheel bigger amplitudes possibly better immunity to vibrations shock twisting motion etc. but it also stands on the type of the balance wheel a larger pocket watch friends since the timing machine especially if you have a nifty microphone that rotates by itself it needs more time to settle just because it does and of course amplitude will come into play here so a lot of things amplitude is better but a magical number or death well that's only acceptable on this group.anywhere else timekeeping that's what I spent a lot of time at work doing trying to get vintage pocket watches to keep time. I'm less concerned about amplitude and I don't have a magical amplitude or else. I'm typically looking at things like the difference in dial-up and dial down indicating pivot problems or if it looks really too low than I might go through in figure out the lift angle to make sure that's correct. But the biggest thing is it has to keep time on the timing machine I must please the timing machine or my boss gets unhappy. Fortunately I get paid by the hour so that takes lots of time to please the timing machine So my boss is pleased the world will be good. But the big thing is timekeeping not amplitude unless it looks really bad. Yes the classic problem watch repair discussion groups with the obsession of worshiping their timing machine and a magical amplitude versus what does the watch Due on a wrist where we don't have a timing machine to verify its amplitude. Somebody really needs to get a phone app with clip on microphone with recording so we can keep track of that amplitude when it's on the wrist timekeeping specifications become a problem as I mentioned before as we typically don't get specifications for anything vintage. Timing machine manuals are good as they would give specifications like this comes out the Greiner manual notice no amplitude though how sad Then let's look at typical Swiss not vintage unfortunately. I'm attaching a eta document one of my favorite documents they do is the manufacturing information sheets hard defined as far as I can tell every mechanical and quartz watch probably had one. Filled with all the nifty specifications of everything. Typically when looking at basically anything relatively modern can find timing specifications this is what you're going to see. Number of testing positions better quality watches get more positions normal watches you'd only check at least for specifications I would still personally check in more positions just as a good way of looking for problems or issues but officially for timekeeping purposes they only look at a couple positions increasing as the quality the watch does of course. Then they give you a timing. Timing difference between the various positions this is why a lower grade watches zero I'm looking between two positions not six as this gets harder to do as a number positions go up. The isochronal number this is quite interesting. Basically the difference in amplitude this is where watch that would maintain a even amplitude over 24 hours even if it's not the magical whatever the group expects will keep better time typically the watch that starts at 300 and drops to some lower number. It's also where the shape of the mainspring comes in as the shape of the mainspring will change the power curve. Then we get the classic what is the maximum amplitude because anything over this can cause issues. Note we do not get a target amplitude target timekeeping but not amplitude. Then at the end of 24 hours this is the minimum and it varies between the watch companies. I think Omega might have some watches as low as 160° but they still have to keep time. So yes the most important thing in the universe except for this discussion group is does the watch keep time? How many customers are how many people wearing a watch are concerned about their amplitude?, A Rolex customers are concerned about the amplitude they get really cranky of their watches off by more than one second a day. Oh and no one not kidding about the Rolex customers we had somebody come and they were unhappy with the servicing done some more elsewhere in the past there were happy but this time somebody adjusted the Rolex to the actual specifications but the customer expected much closer to zero. Yes people with watches are obsessed with timekeeping. Witschi Training Course.pdf ETA 6497-1 Manufacturing Information.pdf2 points

-

…with my amateur experience I’m able to achieve that magic 270 or better so often that I do go looking for faults when I don’t. Sometimes the movement might not be capable of those amplitude numbers but quality Swiss movements from the early 20th century respond well to modern lubricants and cleaners, Seikos and a few Swiss are lower amplitude by design. The bigger question to answer is will it keep accurate time worn on the wrist? …but if you’re consistently getting those lower numbers with good quality movements I’d take the time to audit what you’re doing…esp if you replace mainsprings…2 points

-

I'm attaching the service guide and a parts list. Then if you referring to the colorful images that look like a service guide but are not. Omega went and consolidated common issues into some general working instructions but they have an issue so you don't get the have them. For instance I have a link below for a for a specific search on the cousins documentation site. All sorts of interesting things that you may want to download https://www.cousinsuk.com/document/search?SearchString=Working Then if you download the Omega documents for which to nice impressive list except that just a tiny fraction of what Omega has. In a case if you download the document look carefully at the corners of each of the pages do you see something like this? So we know exactly who downloaded the document their contact information and an exact date and time. Swatch group is very paranoid over who downloads or documents and of course cousins no longer has access the Swatch group. So if you did have access to somebody who had access the Swatch group it would not be in your best interest to post those documents publicly but some kind soul might snip images out. Then as far as servicing information only one attached is what's existence watch companies usually assume that people know how to service watches except for common things that require special instructions which is why even modern Swatch group or Omega doesn't actually have service guides the you have parts list or the general instructions that covers several calibers of special problems or things 418_Omega 1010New19-10-12.pdf 1001750927_Omega_Omega 1010 1011 1012 1020 1021 1022 1972.pdf2 points

-

Hopefully this doesn't raise too much ire. Very often when someone presents a timing machine result on a newly serviced watch and the amplitude is on the low side, someone will chime in right away to say something to the effect of "don't bother reading those results until you get the amplitude closer to 270, take it apart and clean again." Then I remembered watching Mark's service of a 1960's Cyma where he states "we would normally expect a vintage watch such as this one to be within the range of 180 to 220 degrees." Later after servicing and troubleshooting that movement to fix the barrel arbor bearing, it reaches somewhere around 195 degrees and he says he is much happier with that result. Ultimately it goes to about 215 (and somehow then 245 when shown on the Weishi 1000, unexplained). 200-210 is closer to what I am typically able to achieve on an older Swiss movement, even with a new mainspring and I have been working under the assumption that I need to keep doing better. But do I? Is the "270 or start again" mentality shared by most professional watchmakers or is this "180-220 is probably pretty good for a 70 year old movement" attitude okay?1 point

-

Hi everyone, I'm thinking of doing the Distance Learning Course (DLC) Technician Grade course with BHI - this is to round off my knowledge, as I am sure there are gaps - I don't know what I don't know. However, I am in two minds about if I need the support and tutor feedback which is £615 in addition to the course cost £725, which is quite a bump. My question is, is this something that is needed, how east/hard would it be to get through the course without it. What I don't want to have happen is that I pay for this and then find out that I didn't really need it, but if it will make a big difference than I will bit the bullet. I know a lot of this comes down to personal ability and experience, but if you could tell me how valuable you found it this will help me weigh the pros and cons.1 point

-

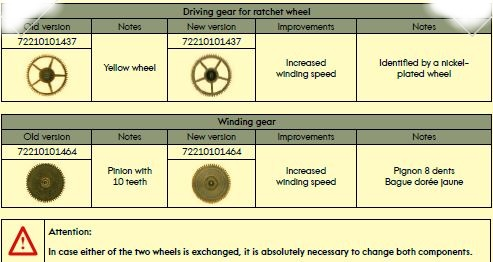

Thinking about how the watch works on page 1 of this discussion I posted an image. This came out of an Omega document specifying things related to This watch and there's an upgrade. I'm reattaching the image notice the upgrade's purpose is to increase winding speed they must've grasped they had a problem. Also notice that both components have to be right in other words you can't just upgrade one you must upgrade both. Fortunately they tell you how to identify each one. One of the reasons I bring this up is when people start mixing and matching components well if you have the wrong ones you're going to have an issue.1 point

-

The tutor feedback fee is on top Ross. Total 1335.00 In all honesty Ross and I'm not knocking it for what it is, but really just a back door qualification .1 point

-

Not much activity in the Relaxation Zone recently, so I thought I'd stir things back in to action with "Gran Vals" by Francisco Tarrega. .. of course, you might also like "Capricho Arabe", or indeed "Recuerdos de la Alhambra".1 point

-

1 point

-

Something under that auto has probably moved out of position1 point

-

So if the barrel is winding but you've got no movement then it's got to be something on the drive train.1 point

-

When you say stuck movement, does the weight still rotate and wind the barrel (don't try too hard if it doesn't want to move)? It could be the fourth wheel that's moved so you may need to remove the bridge or at least loosen the screw again to re-engage. Edit Maybe best just to remove the bridge if you can and check the pivot or teeth aren't damaged.1 point

-

Good thinking, I'll drop them a line and let you know what they come back with.1 point

-

" and HER stroke must be just right" Wouldn't get away with that these days.1 point

-

1 point

-

1 point

-

If you don't have a Jacot tool, you can still give pivots a bit of a polish. Use some pegwood with a hole in the end, and some abrasive like jewellers rouge, then spin the pegwood between your fingers to give them a clean. Also the pinion gear teeth (leaves) can be dirty. I use some sharpened pegwood to clean between the teeth.1 point

-

Well at least not the senile bit I still appreciate those issues H enough reading to last for years1 point

-

Thanks for the info Geotex. I did press it back in with my press and it went in without any issue so I may have dodged a bullet there. The crystal is not in great shape. It has a lot of micro cracks around the edge. I ordered a PHD 25 (28.5 mm) crystal. It seemed to be a good match in terms of shape and the diameter was spot on. I do have a bit of experience reshaping them if it’s not quite right. We’ll see how that plays out. The dial and the case were both sort of a mess but they cleaned up nicely so I’m hoping that I can get a new crystal to fit (see pic). Thanks again.1 point

-

From what I have been reading about the course on their site I think it is a waste of money and time. It will cover beginners as well as advanced it also takes in clocks so if you don't repair clocks that will be a waste.1 point

-

Hi As we assume all was ok in the first place and the watch was running THEN you had a problem do as @rjenkinsgb suggested remove the crystal and start again, if it runs ok the crystal is binding the hands.returning to the status quo.would give you a starting point1 point

-

What's the movement and what exactly have you done?1 point

-

At what point did the movement stop running ?1 point

-

Even if you open the watch and determine whether or not excessive play of the rotor is responsible for the rattling noise, what then? There could, as has been pointed out, be damage elsewhere in the movement due to the metal lost from the rotor bearing being free in the watch. There could be other wear and tear that is not visible until the movement is disassembled, cleaned and inspected. There is a danger of being blamed (rightly or wrongly) for any problems that surface after you opened the watch. In this game, the last person who did anything to the watch is ‘it’ and often unfairly blamed for problems that arise later. Unless you are able to repair and service the watch, I see little to gain, and potentially much to lose by opening it. It is a beautiful vintage Omega, I hope the owner can find a good watchmaker to repair it. At the end of the day, you know your manager and your abilities and are best placed to make this decision, but do consider what potential gains there are if you opening the watch before proceeding. Also worth considering is that professional repairman may inflate his quote to repair this watch if he’s told a hobbyist has opened and diagnosed it, being wary of the hidden damage that may lurk within as a result. The most difficult watches to repair are those that have been subject to poor quality botch work in the past. Best Regards, Mark1 point

-

Sorry to hear that work is getting in the way at the moment. HP1300 is also known as Moebius 9104. The HP in HP1300 stands for high pressure. It is designed to stay between bearing surfaces even under high loads, where less viscous, thinner lubricants would be displaced. Esslinger.com describes it as follows : “Commonly used on almost all posts and setting components, and used to lubricate many of the jewels in the gear train. The Synt HP1300 can also be used for the gear train (wheels), barrel-arbor, and steel on steel in most mechanical watches.” If all you have is 9010 and 1300, then I would treat the balance wheel, escape wheel and the fourth wheel as the faster moving pivots. Use 1300 on the remainder and 9415 on the pallet stones. I’m suggesting a way to get good performance with a minimum of products, what I described above is easily good enough for watch lubrication whilst learning on movements like the ST36. Lubricants and lubrication of watches is a topic where a diverse range of opinions exist, there isn’t always just one right answer and discussion often ends up in unpleasant arguements. I hesitated to get into it above for this reason. As you progress and want to move towards what a professional would use, I suggest you read the document on watch and clock oiling I’ve attached, from the British Horological Institute. They set out what products to use and where to use them depending upon the size of the movement you’re working on. They also explain which products can be used as substitutes for other products. If you are guided by this document, you won’t go far wrong. Edit to add : As for your stainless tweezers getting magnetised, not all stainless steel is non-magnetic. If you look on YouTube for videos on demagnetising watches, you’ll see how to use your unit. Watch tool are demagnetised in the same fashion as movements. Best Regards, Mark BTI-The_Practical_Lubrication_of_Clocks_and_Watches.pdf1 point

-

The Hermle 340 020 is a 8 day mechanism. Winding it once a week is good. Can it run properly for the entire week? If the clock has not been serviced recently, a full disassembly, cleaning and oiling would be advised. If you intend to undertake the task yourself, many of us can guide you through. But @oldhippy would be your bet when it comes to anything clock related. He has helped me much over the years. You will need some essential clock repair tools like a power let down key and a mainspring winder. The mainspring winder can be rather expensive, costing about $300 to $500. So, unless you plan to repair a lot of clocks, it might make more sense to send it to a reputable clockmaker. ( Not the one who told you that the adjustment mechanism is missing. )1 point

-

A few more disassembly pictures were uploaded to my OneDrive (link in my previous post). Getting the jewel off the cam yoke was a bit tricky but not to the extent I broke a sweat. However, as soon as I gently released the spring towards the cam yoke, the cam yoke tried to join the Rolex space program. I tried to replace it three times but each time it was pinged by the spring, so I gave up. This could prove tricky during assembly...1 point

-

during the week I did put back the movement together. I had similar "sticky" hairspring issues as last time and this time even after fixing them the watch runs with very low amplitude (170) so something else may be wrong. I'll see if the next round of disassembly cleaning and reassembly will help. What I did today was practicing lubricating the balance jewels. But for that I didn't start with my working ST36 but rather with the first one I ordered which if you remember has had the setting lever screw broken and the hairspring tangled and warped. I managed to oil both cap jewels, there were a few close call when the shock system spring was lost even though he didn't fly away (it had in fact fallen into the movement). As well as when after oiling the lower cap jewel when I was moving the whole thing to the mainplate before putting it back, by the time I was under the microscope again the jewel and chaton where nowhere to be seen. turned out they had fallen through a hole in the mainplate and were now stuck between mainplate and escape wheel. So a bit of disassembly later I had it back and I reset the spring. As long as I had that movement out though I did two more things, I replaced the setting lever and setting lever screws with 6497 parts I got from ebay. I also detached the hairspring from the etachron regulator and manage to untangle it. It is still very much warped in both directions and I don't know when I'll have the confidence to try again to repair it. In any case I hope I am slowly improving. PS: I have videos of my struggles with the cap jewels and shock spring I may end up editing them and posting them if anybody is interested in giving feeback1 point

-

Thanks all, really appreciate the input. My son has just offered to take it into work, they restore pre-war cars and are used to dealing with this sort of thing, if they can't fix it I'll try OH's method.1 point

-

1 point

-

So no problem as long as you understand what needs to be done. Very good! I started the disassembly yesterday. With a few exceptions the screws looked untouched so maybe the watch has never been serviced. I have the principle of treating all watches regardless of value and brand in the same way but hand on heart, I took extra time and was extra careful to dress my screwdrivers and tweezers. This level of quality is beyond anything I have experienced except possibly a couple of Omega movements. In general, it is easier to handle high-quality movements because all the parts fit together so perfectly, especially during assembly. Just screwing the case back on and off feels almost a little sensual. It almost makes you blush and look over your shoulder The fit is exceptionally precise! In the long run, maybe sometime in the fall, I plan to create a service walkthrough. Therefore, I take lots of pictures of which I may then use a third. If there is interest in taking a look at the status of the movement, you can click on the link below where I will gradually post the raw material. On Thursday, the family goes on vacation so the continuation first in the second half of August if all goes as planned. https://1drv.ms/f/s!AnVrKJ9agkNWkoFMtyD2O4kPIs66Jg?e=oMRKbn1 point

-

3035 Yes, keep it in situ. For some reason I thought you were working on a 3035. Here's a pic of a 3135 spring in situ. Push the spring out of the way which allows the date driving wheel to be removed and the tension taken off the side of the arm with the jewel on the end. You can see the hole in the stop lever which the setting lever goes into. Dead easy to line up! There is still the crown wheel to support the winding pinion and clutch in the 3135 so it isn't in mid air1 point

-

They both ran but not consistently so basically I serviced them, but that did not fix any problems they already had. Thanks, everyone for your continued assistance. I know I am new at this, but I have fixed quite a few watches already so I know I can do it. I just need to keep learning and keep inspecting these parts for anything I might've missed.1 point

-

Hammer time can cause some burrs, so don't forget to check for those after using the smoothing broach. A large size Seitz reamer is perfect for removing burrs.0 points

-

You can now see why you part a lot of money for these and where that money goes, especially the exceptional engineering. They practically service themselves and results are truly amazing. Here's a 3035 from this week. As you can see from the second to last pic, the hairspring was in a right tangled mess. Either someone had tried taking it out and back in again, or the watch had taken quite a hard tumble. I'm guessing the latter. The last pic is the carnage that someone inflicted on the case trying to get the bezel off! Jeez! That is one deep groove! Even one of the bridges had the part number scratched into it. Classy!0 points