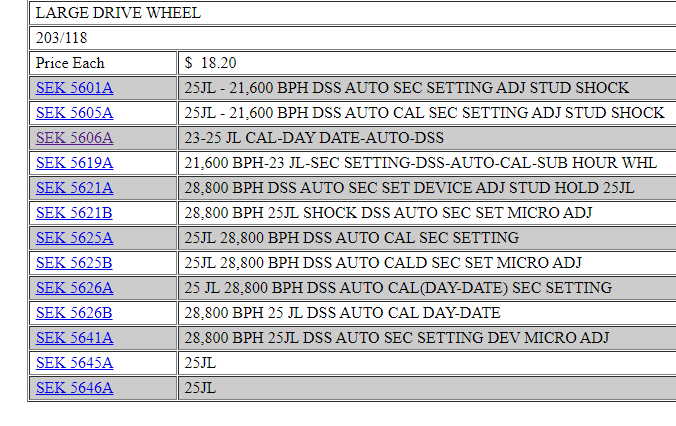

Leaderboard

Popular Content

Showing content with the highest reputation on 07/03/24 in Posts

-

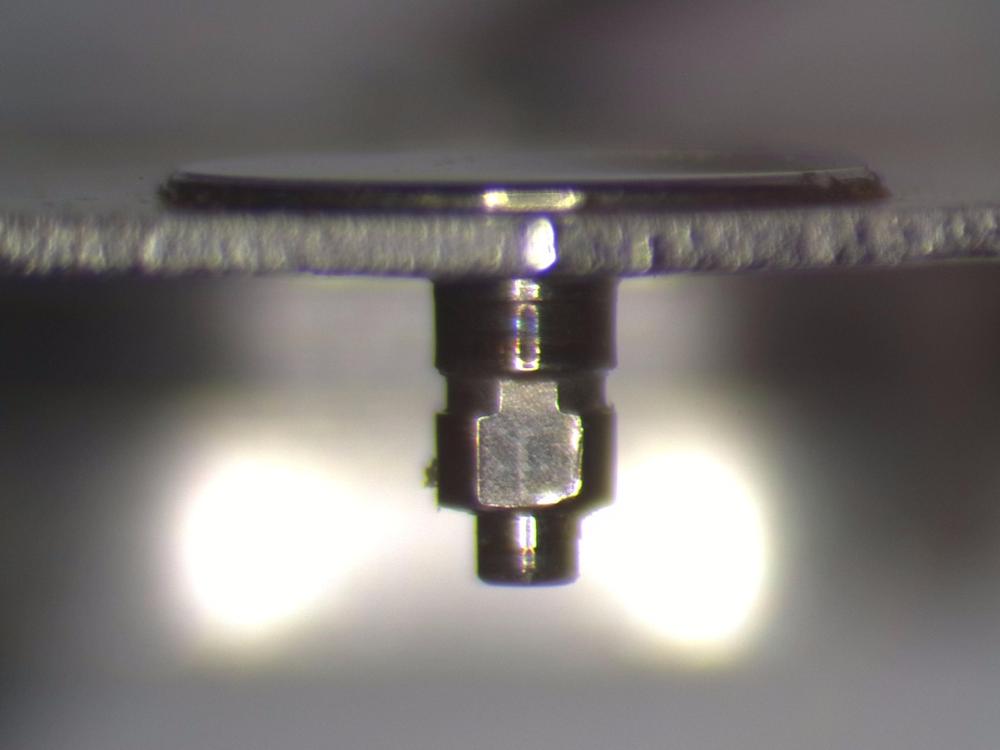

When I was in school (U.S.) we started with HSS Vallorbe gravers, learned to sharpen them, and eventually got to cutting blue steel with them. Then we got carbide, and I don't think I've used steel since. In the Swiss school I went to, the folks in the full training section were only allowed to use steel (HSS); knowing that, and that they didn't have carbide or diamond grinding ability, I brought my own grinding wheels and carbide, haha. They didn't care if I used it, they just wanted to make the guys learning from the ground-up to suffer.* If you want to try out carbide, Eternal Tools has a good selection of small diamond wheels, as well as carbide gravers. You can also use old carbide drills and regrind them, just fit it to a small wooden handle. If using round blanks you have to grind the sides quite a bit to end up with a traditional shape at the tip. Here's one I ground from a 3mm blank (this was a milling cutter before). You can see that it was ground with a coarse wheel, then a finer finish done where it actually cuts. *Actually just remembered- I also did a course for teachers at the Swiss school, to learn how to teach "their" way. At one point we (there were 5 of us) had to sharpen, free hand, steel gravers, then make pivot gages in the dead center lathes, using a hand crank for power. It was funny to see that some of the teachers hadn't done much turning in years, lots of complaints about the gravers being crap. There was an older Polish fellow who was piling up curly chips as fast as he could turn the crank, and I did OK as I wasn't that long out of school myself and did a lot of turning work for other watchmakers. So we would go to show the other teachers that yes their steel gravers could cut the blue steel just fine, hahaha. The main issue was getting the angle of attack right. So that was the last time I used steel gravers.4 points

-

As discussed previously on this forum, I was having problem sourcing parts for my tailstock for drilling. I got lots of help and advice, thanks for that. Having read the feedback and looking around, I finally found a tailstock with a slide that takes 8mm collets. It was a bit steep but, I received it today and, after a strip-down and service, it's working very nicely. I also got myself another "standard" tailstock for £40 which I was going to use for parts but I don't need them so I now have three! Incidentally, I know that I can use the collets but I found a 8mm collet with a JT0 taper and got myself a JT0 chuck so I am very much ready to go! Thanks again for the advice and help.3 points

-

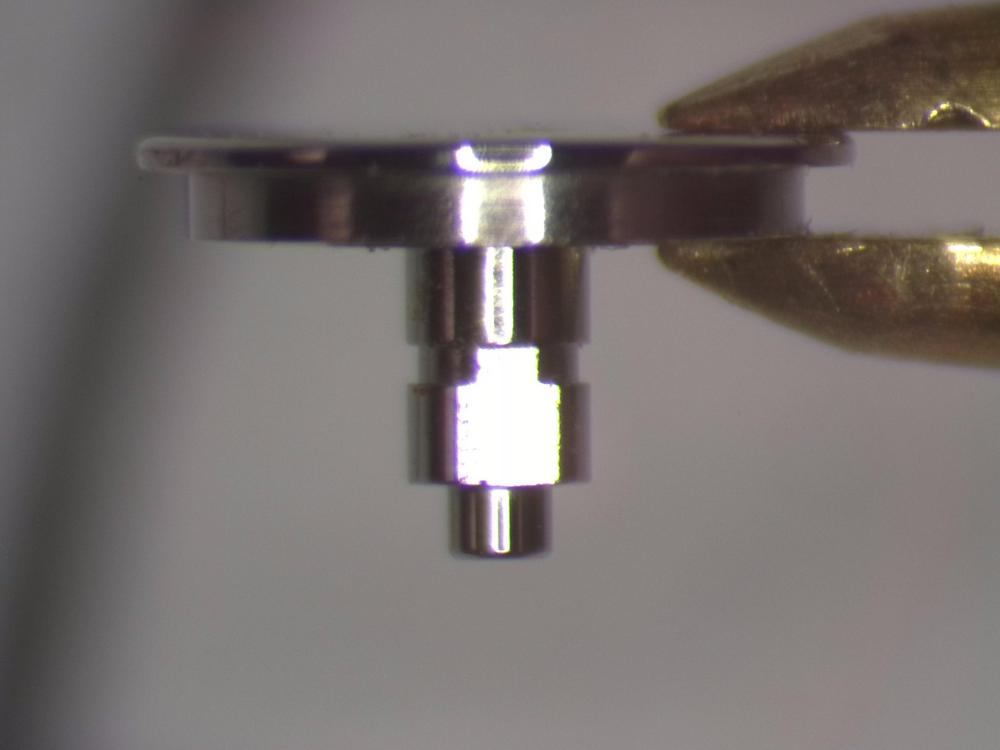

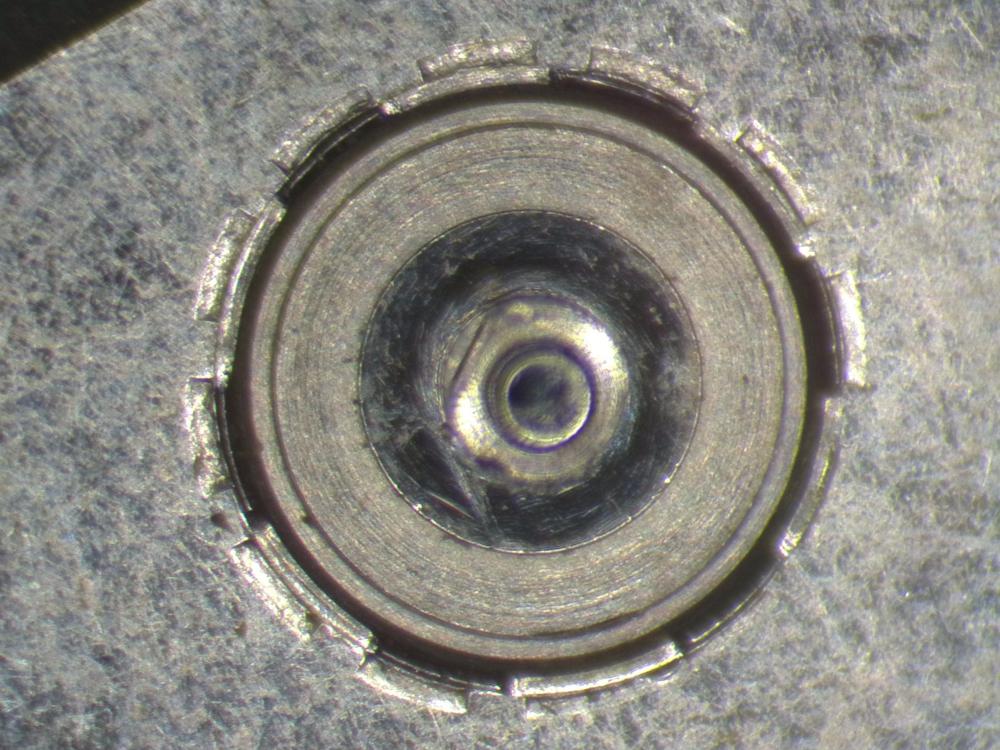

I made a very quick video of changing the axle from a Rolex 1570. When I've got more time I'll make a better one with commentary to put on my YouTube channel. Here's the link to my cloud where you'll find pics and vids https://drive.google.com/drive/folders/1uo47kyawtE-nTPkc9gVr9Z_I261oX-PR?usp=sharing The trick is, when you have the axle in place in the rotor and it isn't a tight fit holding it in place you have to make sure when you are holding the rotor on the stump that the rotor isn't angled down in any direction, because the axle will rivet in at an angle which could really damage the rotor and ruin the axle. Also, you'll notice the original rivet had twice as many rivet marks; the generic punches only have six. Don't worry about that, they work fine. You have to hit the riveting stake sufficiently hard enough to rivet the axle in place, but not so hard you'll crack the top of the axle, which is easily done. This pic is a worn axle. Compare the pic to the next one of a new axle Here's the new axle This is the new axle rivetted in place. Notice only six rivet marks3 points

-

Ok, I can now confirm for sure that the issue was the crystal. More precisely the width of the tension ring. The dial is 31.7mm wide and the internal diameter of the crystal/tension ring is 31.2mm. So dial, movement and movement ring didn't go in fully and the caseback couldn't close fully. I confirmed this by turning around the tension ring (which is triangular in profile). Normally, the flat side of the tension ring faces down and the pointy side upwards. By turning it around, I now have a slightly ugly flat side pointing up and the pointy side downwards so that there's a wider internal diameter for the dial to go in. While I don't intend leaving it like this, I can confirm that the case closes fully. I'll be hunting for other crystals with slightly larger internal diameter. Or, worst case, file away a bit of the tension ring...3 points

-

I will advice to do what I do - I make gravers out of this kind CNC router bits. I reshape and sharpen them with such kind of diamond disk, grit 800, dry. No polishing needed, just sharpening.3 points

-

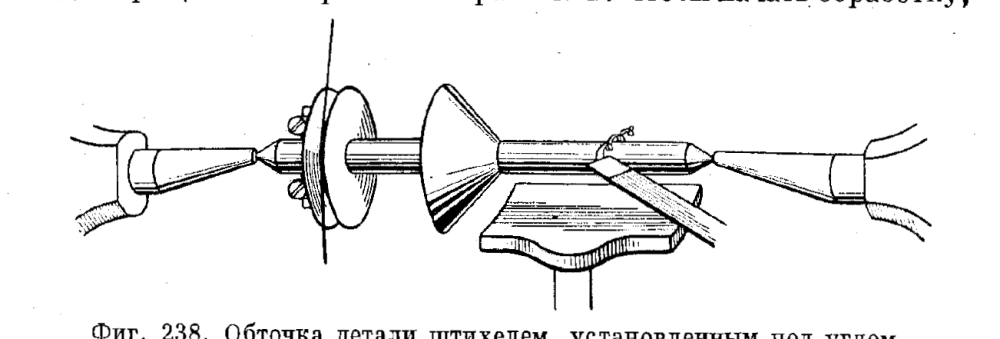

Something important about the cutting itself. No mater what kind of cutter - the steel ones can easy get dull, carbide ones can chip easy. One have to be carefull not to break the tip in both cases... On the picture is shown the correct position of the cutter when cutting most of the work. Pay attention where the shavings come out from. They get out from the middle of the cutting edge of the cutter, the tip is not engaged in the routine cutting at all. The tip is only used to form sharp internal angles. This way of holding the cutter gives longest time between sharpenings and eases cutting. Try to understand and use it and wili be pleased by the result.2 points

-

Received from eBay an hmt watch the movement should be almost as simple as the ST36 but smaller so “level up “ if you want so I plan to practice on this one too. The seller was supposed to send a couple more which I guess are on the way too bad they weren’t in the same packaged. I have to say for $14 I expected it to be in worst shape.2 points

-

I make 5 sided tapered carbide broaches from time to time. I do this on a tool and cutter grinder with diamond wheels, and they have to be quite short with a corresponding very small range of size. Carbide is too fragile to do them long like a regular steel broach. I haven't tried grinding up one with a D shape like a Seitz reamer but it would be doable- I do frequently make "D" single lip cutting tools for the mill and jig borer. For something like your tweezers I would do it like it sounds you did more or less- a brass pin of the desired size, and lapping paste. I've put concave radii on carbide lathe tools like this, using diamond paste and a brass lap, and it works great.2 points

-

Hello, if you have seen some of my posts since I started in this forum you know that I am new to watch making and I have had my share of mishaps but I think here is an accurate statement of where I am: 1) I think I can disassemble and reassemble an ST36 correctly without damaging the hairspring or loosing parts (most of the time) 2) I think I can clean a movement which is reasonably dirty (a new movement or one like the 6T15 I worked on which has 15 year old lubrication but no actual dirt or water ingress). 3) I have an idea of how to lubricate a simple movement but not practiced much and I am pretty sure I am messing it up 4) I made a watch out of an ST36 and parts. I messed up doing the same for an NH35 as I cut off the wrong dial feet (I swear I checked which I needed to keep and then somehow cut those off). Here are the different things I did to learn (mostly in order) Learned to disassemble and reassemble the ST36 and broke the setting lever screw and messed up royally the hairspring in doing so. I have had some success correcting some of the hairspring mess then made it worst when trying to completely correct it. I have put repairing hairspring aside for a bit Disassembled and reassembled a cheap Chinese skeleton 2650G movement with center second Disassembled and reassembled a cheap Chinese Date, automatic and center second movement DG2813 ( mostly a Miyota clone for the base movement and automatic works but different for the date) almost successful but lost the spring for the date jumper Disassembled cleaned reassembled and lubricated a 15 year old 6T16. Nothing lost nothing broken but the movement is working worst than before with a crazy timegrapher reading. This came from a watch I haven't put it back in yet Disassembled cleaned and gave up on reassembling 2 junk slava 2414 movements coming as part of a set of broken soviet movements So finally here is my question. What do you think I should work on/practice next? In term of available movement I mostly have a new ST36 and a new NH35. I was thinking about practicing more with the ST36 trying to correctly clean and lubricate it. I also thought, now that I have a working microscope camera and I should have a reader for the SD card soon I can not only take pictures but videos. If I filmed the process and posted it would it be too much to ask for comments on what I should do different/better and what I am doing correctly? I could try to do that with the NH35 too but with the date and automatic works it will be more complicated and I only have Moebius 800 and Molikote DX so no lubrication for the barrel.1 point

-

Hi everyone, I've been lurking on and off here for a week and thought I should join and say hello. I'm already on another forum (can I say that???) and spend too much time there perusing watches. I'm quite late to the watch party, but so far the watch world feels like a very friendly, civilised, and kind place. I had a couple of decent watches when I was in my teens, bought for me by my older brother. I then gradually stopped wearing them because of allergies, and have only recently started to wear a watch again, mainly because my Mrs bought me a running watch! So, my current collection of watches is growing, and also consists of what I have been gifted, or inherited. Seiko 5's, Festina's, Bulova, Citizen, Timex, Tandorio, TAG, Casio, and there's also a couple of Garmin's , and a couple of daily tickers. I've spent so long bike racing and riding, (pedalling) that if I ever had enough money to buy a good watch, it got spent on bikes and bits! Catch you around the forum sometime1 point

-

Ben here! New watch collector. Been buying up vintage watches for a decade+ at garage and estate sales. Have lots of Bulova, Hamilton, and Gruen watches. Nothing too exciting. Inherited my grandfather's Seiko automatic. Needs a new crystal. Ordered a Tudor Prince yesterday. Should be here in a week. Ultimate goal is a classic Datejust in yellow gold. Hopefully sooner rather than later. Thanks!1 point

-

We discussed this before, no? You could use the flat punch to flatten and slightly tighten the hole in the rotor such that the axle (=shaft?) will hold in place. That looks very pretty! Nice job.1 point

-

Only harden after you have the shape and cutting faces 95% of the way to sharp, So yes! what I do is as follows: -Shape my cutter to the desired rake and relief, then sharpen the cutting face and relief faces to something that would cut brass. -Heat to a cherry red and hold at the temp depending on thickness of material. A 1/8in graver I would hold there for 30-45 seconds. -Immediately plunge into oil and swirl to maximize heat loss -Stone all faces of the cutter back to a nice finish with 3K oil stone, including the cutting face and relief faces -Temper with a torch to a light straw color only to about an inch from the cutting edge, this happens quickly if you arent paying attention and is why we want to stone to a nice finish before hand, so we can easily see the change -Let air cool after it has reached a straw color for a few seconds, then plunge into water or oil, doesn't matter at this point -Stone on a fine oil stone, I use a ruby stone, and it gets me a mirror finish.1 point

-

As stated by Neven and Hector, the tool generates an alternating wave form which pulses the rotor. With the coil off and the circuit block off it will spin the rotor. For an understanding of how quartz watches work read the attached documents. a cheap line release tool can be made from a low voltage transformer or a mains transformer the active ingredient being the generated wave form. Introduce the watch and the wave form acts on the rotor ElectricWatchRepairManual.pdf Witschi Training Course.pdf1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

Well, you could try Kroil. I have some success with it. May need to leave it for days.1 point

-

Post photos, so we can tell you how to remove the stem.1 point

-

WS is tool steel that is water quenched. It should still work for you, and if you heat and temper correctly, it can actually get a bit harder than O1 steel. Don't give up on your gravers just yet. Work on cutting profile and I firmly believe you will get great results.1 point

-

Good work! I've had a couple of very tricky situations that took a lot of time and effort to sort out. The nice thing is that once you've figured it out it feels like you've already solved the problem, even though the job remains to be done! If of interest here are a couple of links to those tricky cases. https://www.watchrepairtalk.com/topic/25822-need-help-fault-finding-why-the-train-of-wheels-is-binding/#comment-215574 https://www.watchrepairtalk.com/topic/11959-what’s-wrong-with-this-eta-2824-2-movement/#comment-1141271 point

-

No, it doesn't work this way. You can rip all the wire off the coil and the hands will still turn on the magnetic field generator.1 point

-

1 point

-

1 point

-

Carbide is a good choice, but remember that you need something much harder than steel to sharpen and polish. So you WILL need a diamond wheel and diamond compound to grind and polish. Everyone has preference and I guess I'm a bit old school, in that I like M2 and O1 steel to make gravers out of, mostly O1. AOA is the most critical when turning blued steel. Just practice. you can turn it with M2 steel1 point

-

It doesn't work that way. You can remove the coil completely and the line release tool will still rotate the hands.1 point

-

Just place the watch over the MECANIC part and activate it. The magnetic field will induce a voltage in the coil and cause the hands to rotate. This does sometimes help to free a stuck mechanism where you can see the second hand twitching but not moving, but the main purpose is it shows the coil doesn't have a break.1 point

-

Hi. The crystals will polish out ok , Sovol autosol. Chrome polish from your auto store will do the job, takes a bit of effort but it works for surface scratches. I think the Hattori VX43 would be a close match you may have to alter or remove the dial feet and use dots.1 point

-

1 point

-

Could you post a few nice clear photos please. That will help us a lot.1 point

-

I think your best chance of finding a movement is having to buy another working watch but this sort of defeats the object. Edit This is all I use but not sure if they're still available. https://www.amazon.co.uk/gp/product/B0B9HQLP11/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=11 point

-

I wrote something up on this subject, see below, and I'm happy to answer any questions1 point

-

Hm, how many devils can gather on the tip of a needle? Sharp means absolutelly sharp, then one-two slight rounding movements with burnisher to round the tip. If leaved without this final rounding, the tip can cut in the cup. Watch this video. the staff there is not well grasped in the collet, but othervice the process is shown as it should. I don't use polishing compounds, You know why, only burnisher. Normal free oscillations test before and after will show what the condition of the pivots/bearings is.1 point

-

Timex conic balances are quite easily removed to do maintenance. Just unpin the hairspring, back out the hairspring from the regulator, unscrew one of the conic cups and balance will drop out. The balance staff is incredibly hard and really difficult to reshape with a cutter. I usually sharpen them on a lathe with stones or more recently, with diamond files. I start with #1000, #2000 and end with #3000. I would stop when tip is almost needle sharp. I then put some autosol on a piece of leather and strop the point to round it off a bit. I've also seen conic cups that have become damaged, usually more on clocks than watches because clocks remain in one position all the time. I don't see any replacements for these cups available. I haven't tried reshaping the cups with carbide drills yet, but I think that would work. Since the balance is out, you can easily put a drop of oil into them. I normally just fill them 1/3 full because when the balance is put back in, the oil level will rise.1 point

-

Like a sharpened pencil, I have heard it said. I don't have the ability to sharpen them myself so i just oil them and it's a gamble whether I get a strong amplitude. But I don't worry much about it because they're never going to have good isochronism anyway. I never take out the balance anymore though as they describe in the service manual. Instead I focus on getting them into beat because they're usually miles out. The collet is reachable with a .6mm screwdriver if you remove the brass end shake screw. At which point I also stuff 9010 into the cups. Speaking of, how is yours set? I like to tighten the balance screw until it seizes, then back it out 1/8 turn until the balance frees again and that seems to work. Timex suggests non-spreading oil on 2 escape teeth, but 9451 on the pallet pins usually makes a huge difference if the balance doesn't want to keep running.1 point

-

1 point

-

1 point

-

sorry haven't been reading all the fine print, what exactly was disintegrating in this Rolex? It does seem to be a problem I think I recently saw a YouTube video where someone was commenting about a Rolex basically a disintegrated. Probably the consequences of people not servicing them on a timely basis. Forgetting that the gaskets go out in the lubrication is gone and then well the watch follows but does seem to take a while. Now you know why the cost of getting a Rolex service to so expensive as the service people who have infinite supply of parts from the company that hates us and won't give us any parts will replace lots of things. Then it's sad I don't think we even have any technical literature on what is standard replacement parts for Rolex which would be helpful for servicing.1 point

-

No, I just have one that came with my Marshall jeweling set. A little spherical thing with ridges, about 2.5mm. It's only just big enough for most barrel holes; not as big as the largest 2.99mm Seitz reamer.1 point

-

1 point

-

Hello and welcome Feli. Not sure from the photo but it looks cross threaded, the right of the photo looks lower than the left. Try putting something like peg wood under the right side and gently push up, whilst rotating.1 point

-

Can you confirm which way you were rotating it when this happened? I'd say you've applied too much pressure while trying to unscrew it and crossed the threads. To be honest I don't know of any safe way to open this where you'll keep the threads intact but other may be able to help.1 point

-

yes the problem of mangled hairsprings fortunately with American pocket watches you have replacement hairsprings. But they don't put a little star after the replacement hairspring and explain something in the fine print? Classically with modern balance wheels the hairspring is individually vibrated to every single balance wheel. Which is why for the most part she would never can find a replacement flat hairspring. There are some minor examples out there where you can but for the most part you cannot. But if you have an over coil hairspring because it was made to very exacting specifications then it comes first in the balance wheel is matched. this is why if you look carefully in the Waltham parts catalog or any other watch catalog for that matter their replacement timing screws. Even Rolex had replaceable hairsprings at one time with timing screws to match the balance wheel to your shiny new hairspring. Then changing the strength introduces interesting new issues? Like the strengths of the hairspring was to match the various mass or simplistically weight of the balance wheel. So in addition to now having a match your balance wheel to its new hairspring the also have to change the mass of the balance wheel to correspond to the hairspring itself. Strangely enough I did this with an Elgin watch a week or two ago it's good that I have lots of Elgin timing screws. just re-reading what you wrote above no you do not change or modify the hairspring its pre-made to exacting characteristics yes you have to change the balance wheel to match the hairspring. one time we had a incoming pocket watch that looked basically like that there were almost no timing screws at all. The owner of the store told the customer we would fix this problem but I did not. Because whoever had a bad hair spring day did an outstanding job of matching the balance wheel to the hairspring and the timekeeping was absolutely perfect and the watch ran perfect. If everything seems to be perfect it's just fine even if it was practically naked.1 point

-

Envy is a terrible thing. Oh heck! Yup. That's me. Wonderful lady.1 point

-

I always use a large size reamer to clean the edges after reducing the hole size.1 point

-

If the time is out I would say it might need working on. The floating balance normally keep good time.1 point

-

When I do vintage work for factories, which is often pieces from mid-20th century but back 100 years as well, they expect to see timing printouts in 6 positions at full wind (minus an hour or so) and at 24 hours. At full wind they really want to see 270+ amplitude, but if that's not possible, similar to John's info above, there are minimums for 24h. They get a bit testy if the amplitude is much below 260 at full wind, that's for sure. When I do work for a local shop, he wants to see 270, but for a mid-range 60 year old piece is happy with 250 as long as it's stable in rate over 24h. The best book I've seen on watch adjusting (precision timing), by Joseph Rugole*, states that if a watch isn't capable of hitting 270 in the horizontals, with not more than a 45 degree drop going to verticals, it's not worth trying to rate it to any high standard. In the Hamilton links from John above they don't state any amplitude requirements, but I'm sure the fellows rating those for railroad use knew the rules and it's easy enough to see the amplitude on two arm balances (especially pocket watches) without a machine that tells you. From the Hamilton stuff I've worked on hitting "ideal" amplitudes is really not an issue at all. So I think the Omega info from John above is probably a good guideline. There's a max amplitude at full wind, and more importantly a minimum at 24h. I've certainly had pieces that sung along at 270+ full wind, and were a disaster at 24h. Then you start getting fancy with balance pivot shape and such, and it becomes rather time consuming. *Watch Adjustments by Joseph Rugole It's a collection of articles he wrote for the Horological Times in the 80s, and it's fantastic. - Also- you don't have to wait 24h to see those rates, most watches have around a 7.5 ratio between barrel and center pinion, so you can let the mainspring down about 3 1/3 turns and that's where you'd be at 24h.1 point

-

Shellac is what I used. Baloon chuck... Could work, but here the pivot is verry lo above the pinion shoulder and I am not sure if i will protrude enough from the hole of the chuck. It depends on the chuck. But I don't have one... Here it is crusual to make the pivot centrical and this is what I came to in my practice that really works.1 point

-

hard to find, could probably get refinished, maybe someone here on the forum has one, eBay shows movements but very pricey ....good luck1 point

-

it should have a screw-down crown, a picture of the movement would help, should be ETA, the newer replacement movement has a really small pin on the setting lever that holds it in its perspective place, it breaks sometimes but any of these movements could use lubrication in the setting, the o-ring in the crown can be replaced if needed too.....1 point

-

I realize that the tension must have been almost excruciating and have given you many sleepless nights waiting to find out the cause of the pallets stopping when the mainspring has been sufficiently powered. I apologize for the long wait, but now I have the pleasure to announce that the wait is over, and the cause has been determined! As usual, you can never take anything for granted when working with watch movements, but the work must be adapted to the design of the movement (in this instance a Raketa calibre 2609.HA), which I completely missed. During ongoing service, when I inspected the pallets, it looked like there was way too little shellac on the entry stone, so I "of course" put on some extra shellac to ensure the stone wouldn't risk being jolted out of position. It turned out to be a crucial mistake and the reason why no power seemed to reach the escape wheel. It is the case that the entry stone lives its life directly above the centre wheel rim and its teeth, and the distance between these is at most about 0.2-0.3 mm. Because I put extra shellac on the entry stone, the shellac on the entry stone and the centre wheel rim simply collided when the mainspring barrel came to press hard enough on the centre wheel pinion. For me, it was hard to find this error because I still (after a good six years) have not developed a natural understanding of fine mechanics, but I take comfort in the fact that I am probably not completely alone in this. I’ve realized that watch repairing takes many years of practice and experience. The fact that we work in a microscopic world also increases the challenge exponentially. It's simply very difficult to see what's actually going on. My method of finding the error was to use the method of exclusion. That is, carefully examine and test the wheel train one wheel at a time starting with the mainspring barrel and ending with the escape wheel. Since the fault only showed up with some power on the mainspring after about two revolutions of the ratchet wheel, I simply held each wheel to see if it would stop or behave sluggishly when I let go. Unexpectedly, everything worked perfectly, so only the pallets remained. After much back and forth I managed to find an angle in a small gap under the pallet fork bridge where I could see that the shellac on the entry stone and the centre wheel rim collided. Persistence wins! Without my beloved stereo microscope, this would have been nearly impossible to find. To fix the error I simply scraped off the applied shellac and reduced the end-shake on the centre wheel by a few hundredths of a millimetre to get some extra margin. Now the movement is ticking again, but I will have to redo the service because I was quite careless with the cleanliness during the fault finding. Anyway, another experience under my belt in my quest for becoming a decent repairer.1 point

-

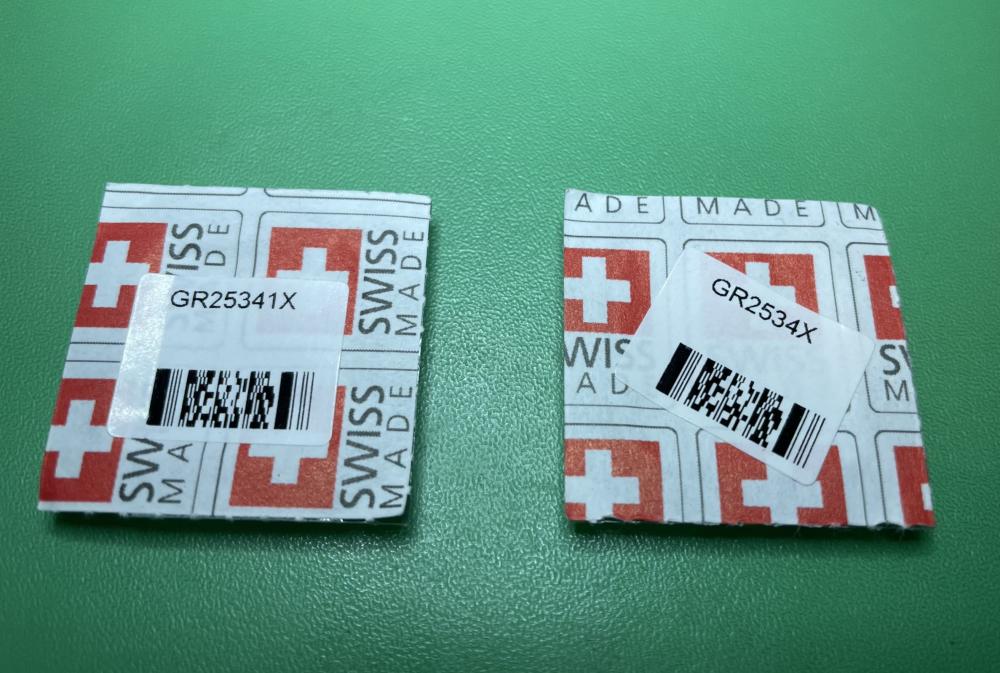

I know this thread is a bit dated, but I recently ran into some issues with 6138 and 6139 mainsprings from eBay being slightly undersized and underpowering the watch. I was finally able to find the exact correct replacement mainspring and thought I'd share it here for future reference. The correct dimensions for the spring are: 1.05 x 0.115 x 420 x 10.5 A search online references GR2534X, which can be found from Cousins. While the spring has the correct dimensions, the inner curve for the arbor is a bit wide and fits somewhat loose. This can be adjusted, but there is another (and cheaper) option. Cousins also has part # GR25341X, which has the exact same dimensions, but costs about 30% less. This part number is not referenced (anywhere that I could find) for the 6138, but the inner curve is smaller and fits the barrel arbor perfectly. If anyone is trying to source a mainspring for their Seiko 6138 chronograph, the GR25341X is what you'll want to get! I ordered a couple of them and just installed them in two of my watches. It brought the amplitude up from 190/200 (with the eBay spring) to 230/240. Here's a photo showing the difference in the inner curve between the two Cousins springs. The correct spring is on the left. FYI, the washers are the correct size and the spring drops right in. I hope this is helpful for someone in the future trying to find the correct aftermarket mainspring for their old Seiko.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)