Leaderboard

Popular Content

Showing content with the highest reputation on 07/04/24 in all areas

-

I have an unknown movement blue dialled "Marquis" early quartz Swiss movement day/date "chunky gents" (according to the listing) watch on its way. This just failed to make it into the 404 club, but gets into the "ten ten" squad with ease. The combination of the blue dial and the unknown early quartz movement had me intrigued, and as is often the case, I was the only bidder. There is a slight chance it may be another Tissot 2030 based watch, or something similar from that era. It may of course be something much more mundane. I'll keep you all posted if/when it arrives.4 points

-

For sanding cases, or when making parts, I find sanding sticks really useful. I also have some Valorbe Escapement files with fine cuts #6 and #8. When making small parts you need them with cuts this fine. Where would you buy a tin block? I get good results with 3M lapping film (9 ,3 and 1 micron) stuck on to sheet glass (as shown in the Youtube vid). It only takes a minute or two to do screw heads.2 points

-

@VWatchieIf there is a bit of room between the axle and the inside of the hole in the rotor, I think you'll find trying to close up the hole very difficult because of the small amount of material that can move to close up the hole. Give it a go, but be careful not to deform it. I would be tempted to use something to keep the axle in the hole like some Loctite. This will give you the stability knowing that the axle isn't going to move whilst you position it on the stump and before that first blow of the hammer. Just enough to keep it in place just under the polished top part on the top of the rotor. I've got a rotor from a 2135 that has a hole that has been completely deform by hitting the axle when it wasn't centred, so I'm going to completely bore out the hole and turn and fit a custom made stepped bush to accommodate the new axle snuggly. well, that's the plan. Not sure if it will work, but it's worth a go and I haven't seen anyone else try it. A replacement rotor is about £1502 points

-

Just to say, most of the people who still have no experience, believe that the tail stock will solve their problems with the drilling. Well, it depends on the kind of the drilling and the drilling bits type, but in case of small holes for repivoting or similar, using tail stock with lever for pressing the bit to the work can only do harm. At least, this is what I came to in my practice.2 points

-

The VX43 Movement has a Day & Date which your watch doesn't and is a completely different size to the Y100. Edit Nearest equivalents I can find to the Y100 are a VX20 or Y320 but would need a spacer ring making. https://www.ebay.co.uk/itm/144642473798?itmmeta=01J1X57R31JFY8MQTGGAFJYVER&hash=item21ad5cff46:g:7QUAAOSwFHdizFbO&itmprp=enc%3AAQAJAAAA4CVloL5n5IJ7%2BdElMYd9%2FARJSOjUMZ0sTRjiHGA6s0%2FkQhb%2BTYSHvzsuk06bH4laWzPFmR0j6ecvShnB8%2BVVfTIq22ubCL2DoUxSYofTXW%2B3v5sD%2BnnVcoodzhJV%2BZ6bljRHx3hnAQKeXUWWpVo2y4s4ZKEsZwP2HDJKdey%2FGC90YGKWP%2BGSiSx--QUPcqB39DHPcJp%2FFoQIhoigE7y8RYAgA0Q0a2LEUtih1MsPDyMZXvK84a%2FvPm8D%2B0KjCN7ovGSdPaRQLmgdGaZ5EB14RFSbiSGUnYspi9BeK4fwjKm2|tkp%3ABk9SR8yBn6WPZA https://www.ebay.co.uk/itm/256558428698?itmmeta=01J1X5QH7MHVFVR991AKF47CBY&hash=item3bbc12f21a:g:Qn4AAOSwPbhmW7XY&itmprp=enc%3AAQAJAAAA4PkyXRpiRbdTSH4BM7xaQ%2FQG44w7PegXj4mdNMPgMYdCBX%2FRAs2OOFqJLq%2Ffx3GQjfCn6VMAuSKThAnFryx95b5O7OxvsJbCf0kafZ8j1o1yr%2B2jFnT6mq99ZPk9lwvlvRFU07dByGkiFW0yeO80mxv%2BxqxhGc2QhDPY8X%2Fc3Cs2oJr58hduHkSfJkw1GVD4tNmyMTENnRFKAJLrnwsgAY55scId8Q%2B1A96wJT7BU2LfyrdMqIAZJhDi%2Bxnfe0BOOg7Pt4MrEqg3SjBLJHeG9Qq9%2F75JKh4PUdxM76%2FTvW7W|tkp%3ABk9SR_qT3qWPZA2 points

-

Hi all the speculation in the world is not going to fix the problem it’s going to have to come apart carefully checking as we go. Hectors advice is best followed first as it’s the least invasive. Just power down the movement remove balance and pallet then check the train for freedom , if still stuck the bridge will need to come off to go further. Take pictures at every stage and ant notes that may be aplicable2 points

-

1 point

-

1 point

-

If that's the case then I'd have let the power down first and possibly removed the balance too. I think you already realised that the next time you need to remove the crown wheel and ratchet before looking at the gear train. Overall I think you've created a very good video and it's all a learning curve.1 point

-

Just watched the first few minutes and the thing that jumped out was you need to reinsert the stem and stop the hands before trying to remove them.1 point

-

1 point

-

1 point

-

Yes I did, bit more than I hoped but could have been worse. Thank you for the help1 point

-

Unfortunately this statement is true, either remove the automatic works or find a new case. You could remove the automatic works and use the watch whilst looking for a new case.1 point

-

yes an unfortunate problem in the universe is mixing and matching and building watches to sell. From unscrupulous sellers who don't really care and hope that you never going to notice the problem. then Omega case numbers are interesting? They usually don't exactly refer to an exact case sort of. In a case you can go to the cousins website editor in the case number and we end up with two separate cases. this is because depending upon what the case is made out of in other words you could end up with multiple cases with the exact same case number it just depends upon what they're made of and I wasn't paying attention when I downloaded so I'll just give you both of one's for solid stainless steel and other one is for yours. But no matter what it also confirms that it is the 1030 movement. then I was curious as to what the movement looks like and I have a suggestion you may not like? What if you remove the automatic part of the watch now you have a manual wind it will fit the case. Otherwise I think you have to find a new case https://ranfft.org/caliber/8285-Omega-1030 4790_Omega 136.0102 ST Case.pdf 4789_Omega 136.0102 MD Case.pdf1 point

-

Either wrong back or wrong movement in case. 136.0102 should be a 1030 Manual Wind1 point

-

I don't see any missing screws. The oscillating weight looks good when you touch it doesn't wobble so it is firm on the axcel. I good service is what is needed.1 point

-

That's the same set included in the 18R Deluxe Staking Set. Fortunately, you can use the reamer holder just as a normal stake.1 point

-

I’ve bought some diamond plates, 400-2000 grit in a set. Depending on how blunt I get the graver, I’ll start between 400-800 and keep going until the face has been completely removed, ensuring the corners are even. I then do about 50-100 passes (higher as the grit level increases, through the range of grits, checking the top sides adjacent to the face for burs and removing them as necessary. Once if finished the 2000 grit, I then finish the face on an Arkansas stone. I have a relatively cheap graver holder for sharpening but it seems to do the trick. The plates are pretty cheap too. I picked them up on Amazon1 point

-

If the crystals are glass as i thought they might be then no the autosol or any other polish unfortunately doesn't work unless you are prepared to put in lots and lots and lots of hours on it and then a few more hours. Dont try sandpaper as you wont get those scratches out by hand either, its not fun unless this is your idea of fun. Best bet Melissa is going to be diminishing grades of diamond paste used with a mechanical buffer.1 point

-

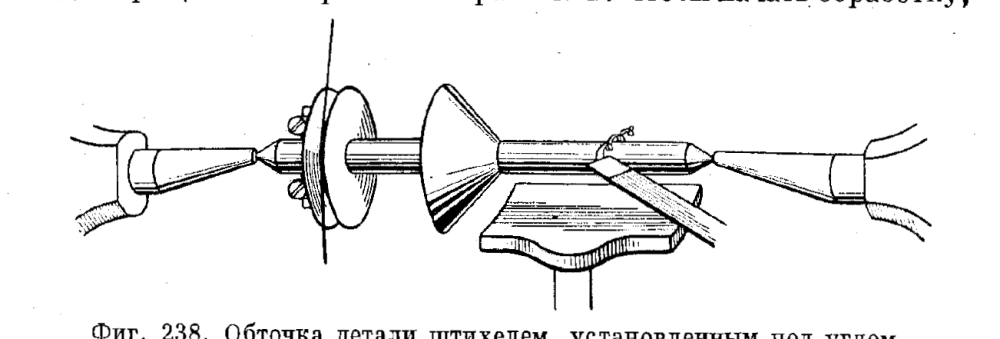

A similar principle is used in wood turning though the chisel tip has a different shape in order to plane the wood but the same skew angle is maintained. In timber around 45° with either a skew chisel or a skew approach angle, the cut comes from the center of the tool except when detailing .1 point

-

Something important about the cutting itself. No mater what kind of cutter - the steel ones can easy get dull, carbide ones can chip easy. One have to be carefull not to break the tip in both cases... On the picture is shown the correct position of the cutter when cutting most of the work. Pay attention where the shavings come out from. They get out from the middle of the cutting edge of the cutter, the tip is not engaged in the routine cutting at all. The tip is only used to form sharp internal angles. This way of holding the cutter gives longest time between sharpenings and eases cutting. Try to understand and use it and wili be pleased by the result.1 point

-

1 point

-

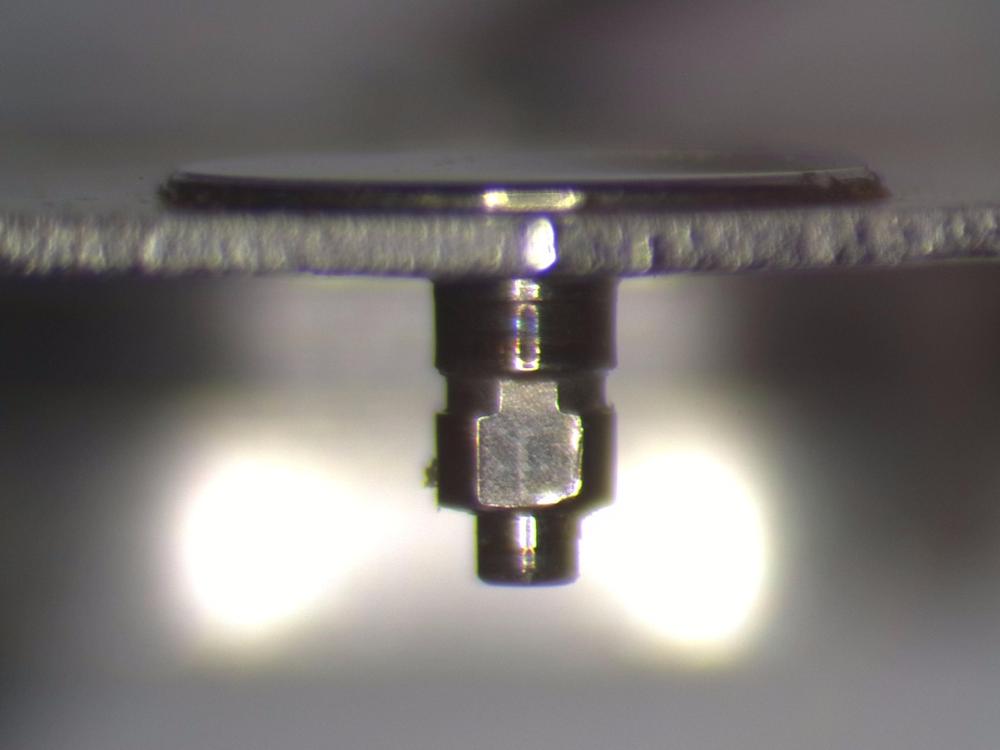

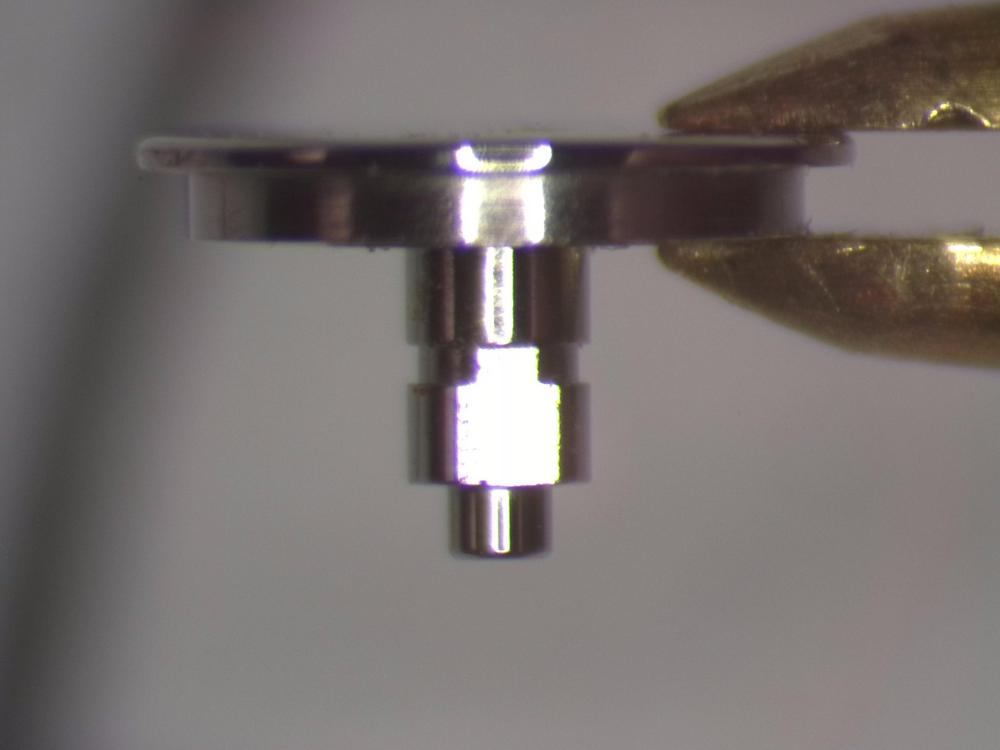

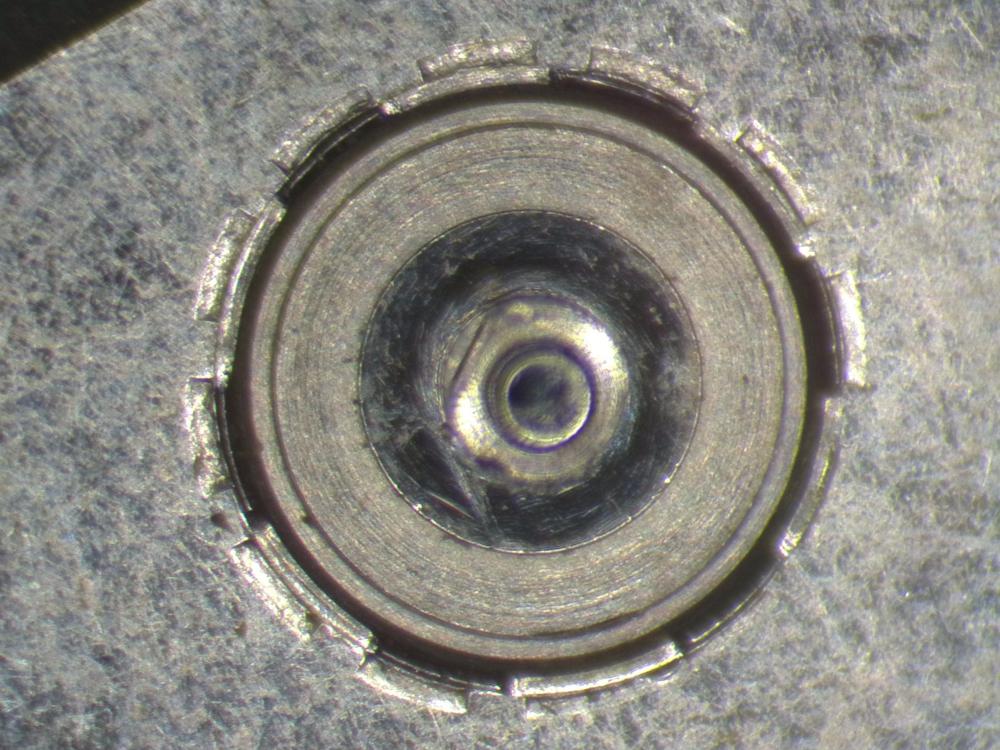

I made a very quick video of changing the axle from a Rolex 1570. When I've got more time I'll make a better one with commentary to put on my YouTube channel. Here's the link to my cloud where you'll find pics and vids https://drive.google.com/drive/folders/1uo47kyawtE-nTPkc9gVr9Z_I261oX-PR?usp=sharing The trick is, when you have the axle in place in the rotor and it isn't a tight fit holding it in place you have to make sure when you are holding the rotor on the stump that the rotor isn't angled down in any direction, because the axle will rivet in at an angle which could really damage the rotor and ruin the axle. Also, you'll notice the original rivet had twice as many rivet marks; the generic punches only have six. Don't worry about that, they work fine. You have to hit the riveting stake sufficiently hard enough to rivet the axle in place, but not so hard you'll crack the top of the axle, which is easily done. This pic is a worn axle. Compare the pic to the next one of a new axle Here's the new axle This is the new axle rivetted in place. Notice only six rivet marks1 point

-

1 point

-

Search for watch case vice, something like these mine is like the 55mm diameter one. https://www.cousinsuk.com/product/hand-or-vice-held for the case back search here for crystal press, here is a good thread about one with a review video too. Tom1 point

-

1 point

-

@quantieme, I feel I need to say few things more than the others already sid here. The auto winding module is a simple thing and finding faults in it is simple thing too. But You need to know how it works and what must it's behavior be first. First - how it must work and behave when it is in normal order: You have traditional bi-directional winding module with two reverse wheels, but here in Omega the two reverse wheels are united in one, they are two reverse wheels mounted on one common pinion. Then, I have seen in some Omega movements that You have one more reverse wheel, which is mounted on the ratchet wheel. The ratchet wheel is made on two levels, with reverse function between them. This allows separate winding by the crown without bringing to motion of the auto module. I am no sure if You case is this, I have not worked with such movements long time ago, have only distant memories. You have to know how normally such auto module performs as to check and understand if there is a problem with it. When the spring is not wound, turning the rotor in any direction will slowly turn the ratchet wheel, and You will fill almost no resistance. Turning the watch will make the rotor turn the module because of the rotor mass. BUT when the spring is already wound, You will fill significant resistance when turning the rotor , and slow turning of the watch may not make the module turn, as the mass of the rotor may not overcome the resistance of the spring winding. This is the reason why some movements will not auto wind fully on winding machines. But it is important to know that in this condition (fully wound mainspring), turning of the rotor in any direction must continue turning the ratchet wheel (actually the arbor of the barrel, as there might be reverse wheel in ratchet wheel that may be out of health). Further more, a healthy module will have relatively small angular free play of the rotor. This will be about (no more than) 90 degrees. And, if You turn the rotor only to +/-180 degr., this must be enough to make the ratchet wheel turn. So, here You have the way to check the function of the winding module. No use to check it's function when the spring is unwound, as then resistance is small. Wind the mainspring fully (6 revolutions of the ratchet wheel is enough) and start turning the rotor back and forth in the limits of 180 degr angle, not making full revolutions at all. Observe what is the angle wit small resistance (the free play) and is the resistance increasing (spring is wound) within the limits of this 180 degr. oscillation. Does the ratchet wheel turn ahead? Of course, as @oldhippy said, the main reason for faults here is the double reverse wheel part. If it is out of order, usually disassembling it shows that one of the posts of the pawls inside has broke or smash. Replacing of the post (tapered steel pin needed to be pressed in place and then cut and filed to correct height) normalizes the function of the part. But, if there is reverse wheel in the ratchet wheel, it may be the reason too.1 point

-

Hi As we assume all was ok in the first place and the watch was running THEN you had a problem do as @rjenkinsgb suggested remove the crystal and start again, if it runs ok the crystal is binding the hands.returning to the status quo.would give you a starting point1 point

-

At what point did the movement stop running ?1 point

-

You can now see why you part a lot of money for these and where that money goes, especially the exceptional engineering. They practically service themselves and results are truly amazing. Here's a 3035 from this week. As you can see from the second to last pic, the hairspring was in a right tangled mess. Either someone had tried taking it out and back in again, or the watch had taken quite a hard tumble. I'm guessing the latter. The last pic is the carnage that someone inflicted on the case trying to get the bezel off! Jeez! That is one deep groove! Even one of the bridges had the part number scratched into it. Classy!1 point

-

That one is easy Ross, OP means , the watch has not wound any, during the two days that was on his wrist. The question remains, where did the two days of wind come from, 1- Did it come from manual wind through the crown? 2- Or, got wound on Bergeon winder? 3-Manually turning the rotor? Other questions are, does ratchet wheel turn in either direction he turns the rotor? If it runs 2days with manual wind , power isn't prematurely discharged, so IT IS holding power. Was winder module checked, for shakes, worn holes/ jewel holes, and final power transmission to ratchet wheel, the jewel hole of the ( ratchet wheels reduction wheel) might be faulty, or transmit power in one direction only. All holes/jewels holes, arbours, gears, in auto device should be checked. that with broken ratchet teeth, holes barrel arbours fit in !!! We know nothing about the mainplate hole for lower barrel arbour, lower arbour, lower barrel hole, barrel arbour shakes..... etc. The less we know, the bigger the guessing game becomes. Its a simple mechanical machine, not state of the art particle physics or cosmoscience.1 point

-

Absolutely correct. Yes. If (too much) oil is dissolved in the cleaning fluid and the solvent/IPA then evaporates, it can leave a thin and surprisingly sticky oil residue everywhere. And hairspring coils are very sensitive to that. I learnt this the hard way, too.1 point

-

front loaded case - lift crystal. lift dial ring. at the 3 hour there is gap to insert tool. Timex recommended a flat screw driver. but I use needle nose pliers that are filed down to fit into the space. Grab the stem and twist the crown off. actually this is the same as the 1960 Marlin1 point

-

I just got a Timex Macguyver field watch for under $20US. From photos, condition looks pretty worn, but I'm happy enough because all my past attempts at buying one of these ended when I wouldn't go over $75. And it will be my first watch with a 2 piece stem, though not my first plastic monobloc Timex. (the weird UFO Fun Timer series has a little threaded nylon plug in the back to reach the stem screw instead of a split stem)1 point

-

I made a good job of sharpening the staff points by hand with a degussit stone and straightened out the hairspring. Then.......... made a real effing balls up of re-installing the balance, you gotta watch the far side of where its going, i found it tight feeding it in. Think I've trashed the lever pins or escape wheel, real dissappointed with ma self0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)