Leaderboard

Popular Content

Showing content with the highest reputation on 07/07/24 in Posts

-

Thanks, R! We safely arrived at the Almont Beach Resort in Surigao and here's a picture of my son enjoying the view from our balcony. He is wearing a Helson skin diver as the true and stylish gentleman he is—a gift from his very proud dad. It's not the original strap. Instead, he wanted a coarsely brushed bracelet which I polished for him.5 points

-

5 points

-

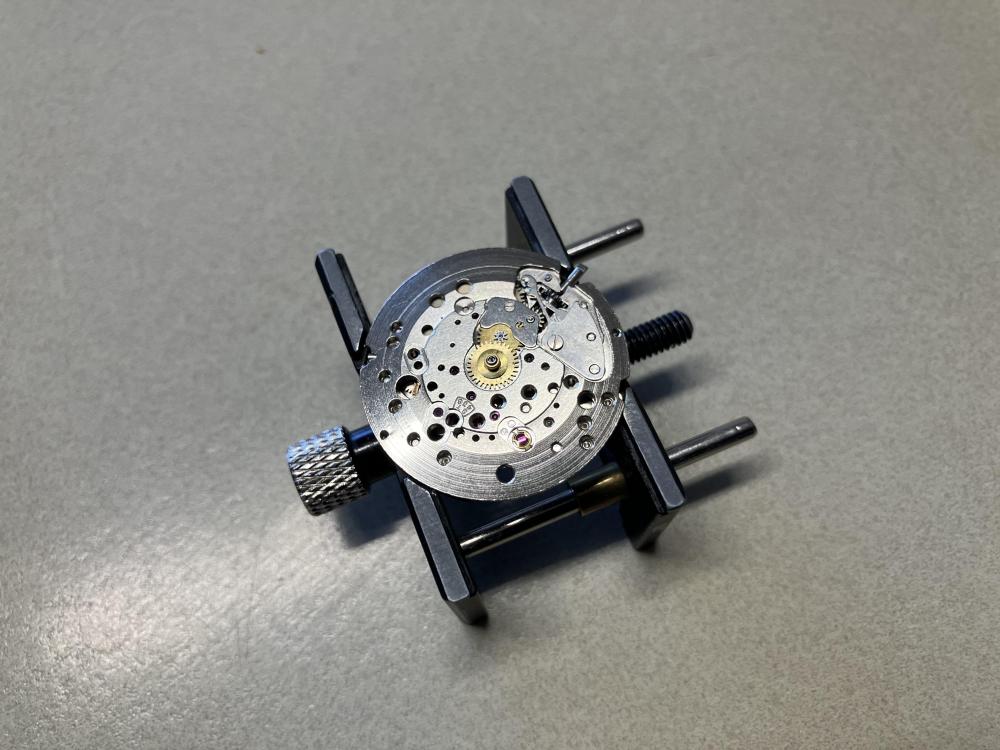

I didn't want to put this watch on the I'll-finish-it-once-I've-got-hold-of-the-right-tool pile while looking for a faceplate, so I've drilled it freehand (Thnx Nev!) using a set of cheap carbide drills and pressed in a steel 0.5mm stud. It lines up nicely with the cover plate and both wheels turn very smooth. I'm happy. Thanks everyone!3 points

-

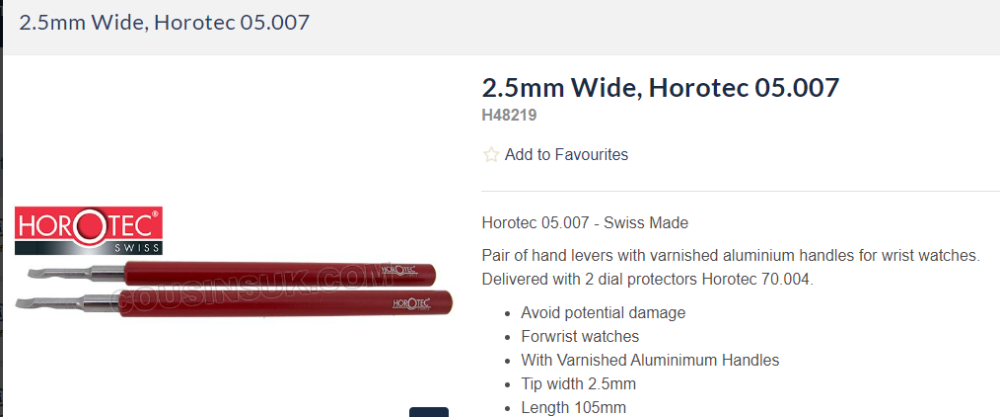

I struggled with the cheap ones. I changed the shape many times, but I never managed to get them as I wanted. So I bought some Horotec ones. They are so much better to work with - polished to the perfect shape. They aren't cheap, but as you use them on every watch, I think they are one of the list of tools (screwdrivers, tweezers, movement holders etc) where it's worth spending extra.3 points

-

3 points

-

Waiting for my flight from Manila to Surigao this was very entertaining to read @Jon. Missing the workbench but this helped me imagine I was at it for a minute. Thanks!3 points

-

3 points

-

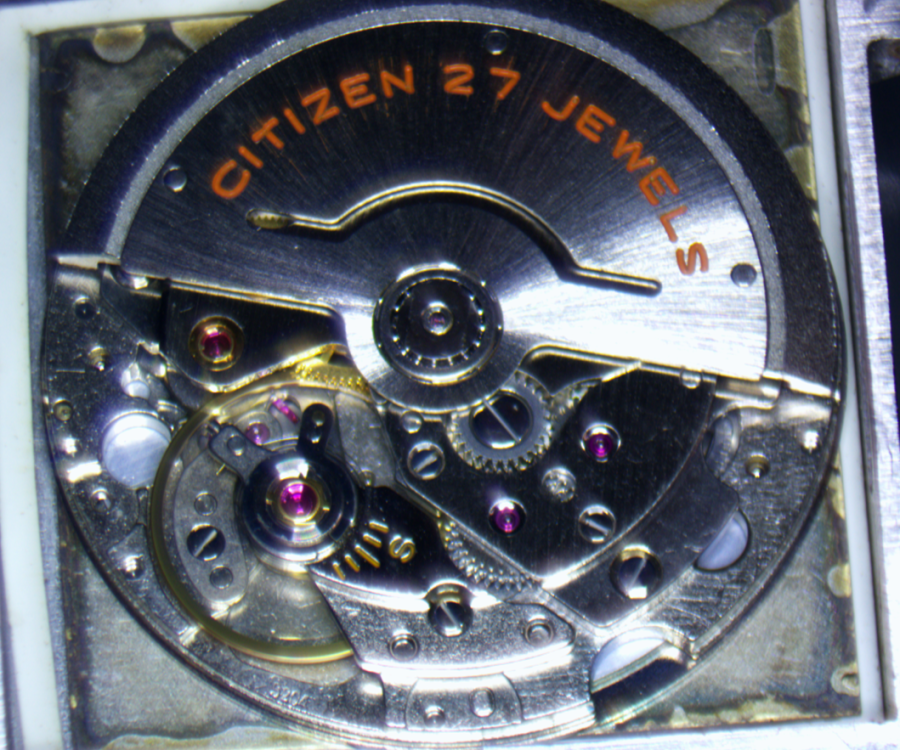

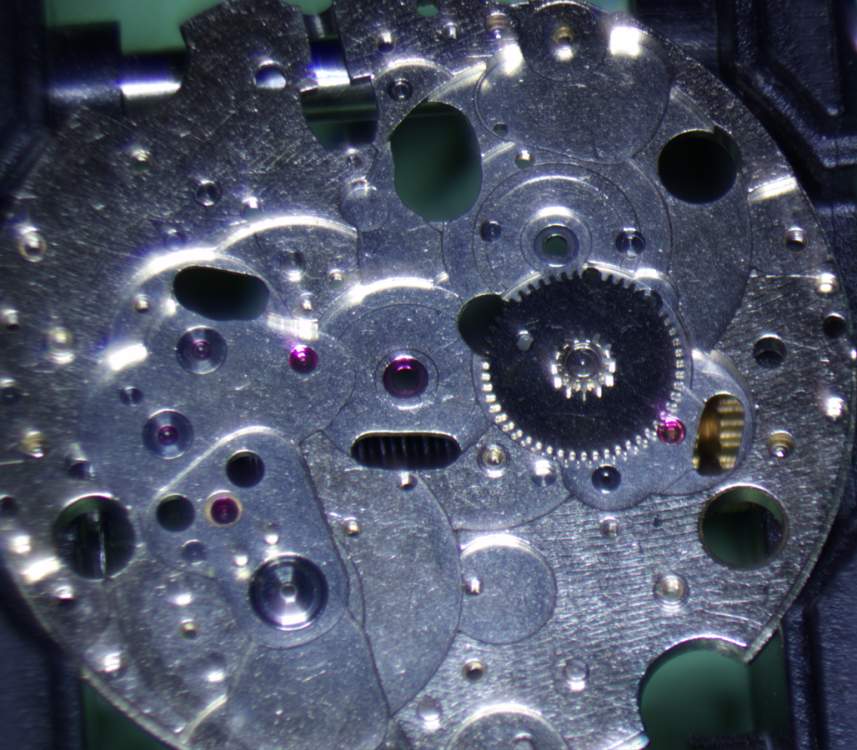

I posted about this guy in the "Which watch have you got coming" thread, but here's the teardown. 27 is a lot of jewels! Cap jewels as far as the eye can see. I also figured out that the black screws are left-hand threaded. Looks like this last wheel is riveted to the plate, so I'm going to clean it in place.2 points

-

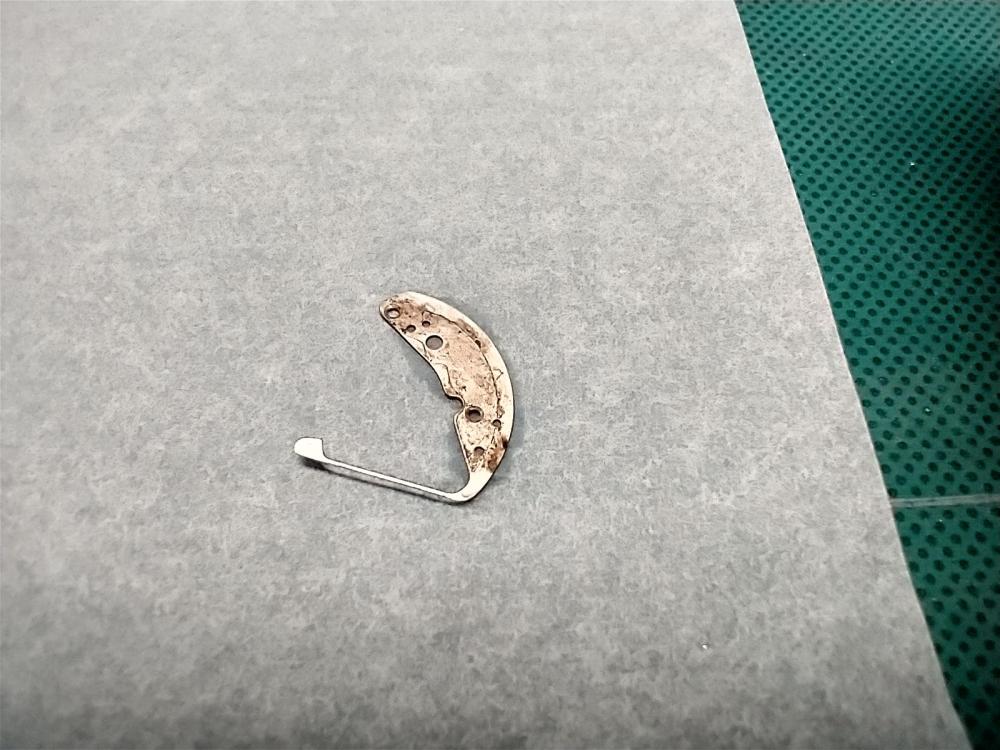

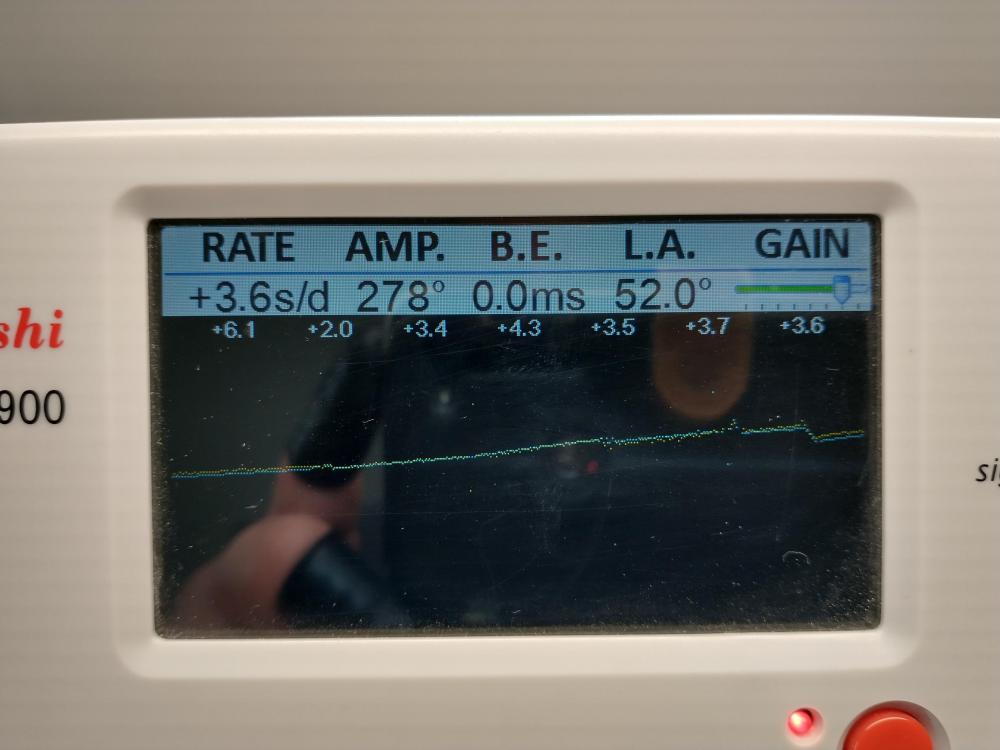

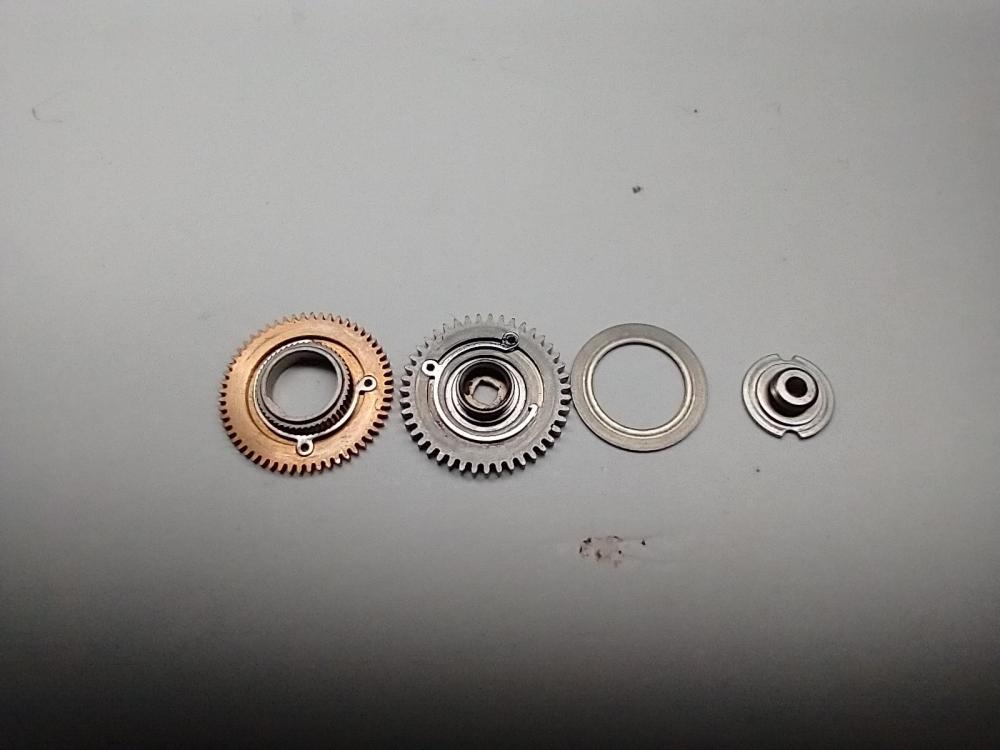

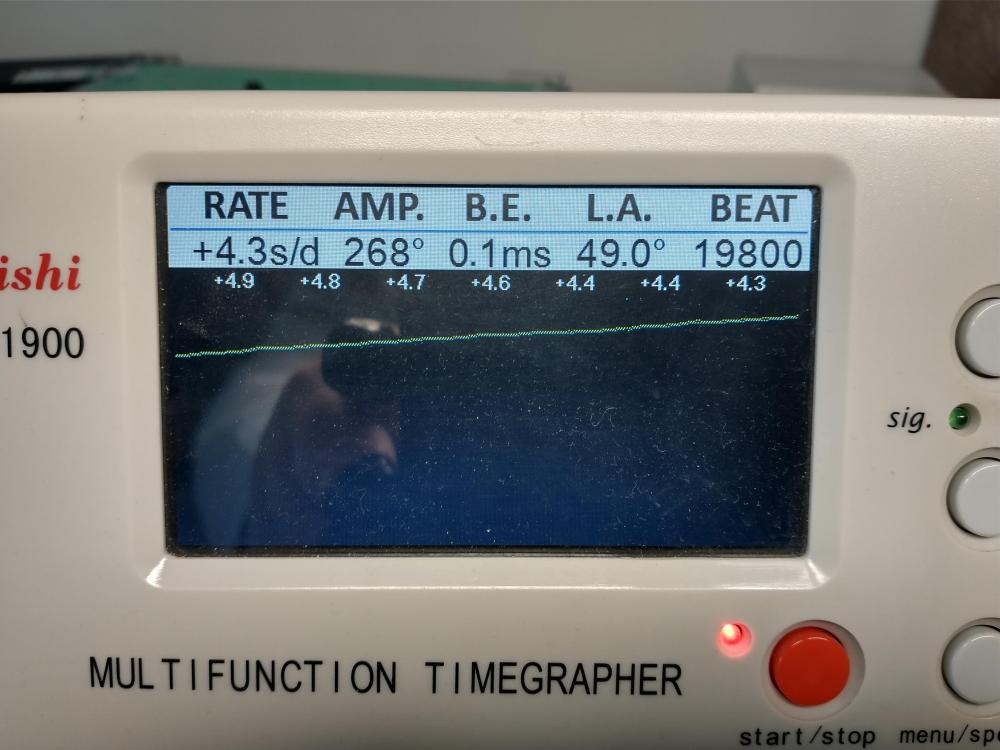

One of the things I love about my job as a watchmaker is the variation in what I'm servicing or/and repairing. One day will be a modern Omega Seamaster with a coaxial escapement, the next a Baumgartner pin pallet and the next a Goliath pocket watch. So the vast array of quality to the not so quality of movements. In fact that has been several of the watches across my bench this month, as well as the usual bread and butter work of vintage Rolex and Omegas, which personally I like working on, as you can get such great results from a 50 year old watch and even get them to chronometer standards again, which is very satisfying. This ladies Rolex watch with a 2135 under the hood came to me with a story, as all watches tend to. Now, the story that the client tells you is sometimes a lot different to what the watch movement is telling you. The watch never lies, but clients have a habit of missing bits out and massaging the truth, so to speak. Here's an example of what the watch is telling you and what the client is.... You decide. This watch had been sitting in a draw for almost ten years, said the customer and prior to that it had been working fine. Now, looking at some of the damage from water ingress and rust and the blob of metal that used to be called a rotor and I would say that unless that draw was in the swimming pool, I doubt very much what I'm being told is even marginally close to the truth The Gif shows dissolving a rusted in screw using Bergeon Vissin. The reason the movement is held upright in the Vissin, is because I didn't want to remove everything that was steel like the IncaBloc setting and minute wheel post, etc. Remember that this watch was in working order to prior to safely putting it in the swimming pool.... I mean the draw in their bedroom. What I usually ask is, 'Are there any children in the house?' because that throws a different light on everything. What one of their little treasures could have done with that watch is anyone's guess and the 'story' the client is giving you is now seeming a little more truthful with throwing in the 'X' child factor, but alas they didn't have children, not even a random niece or nephew we could possibly pin this on. It was looking more that the version of events or non-events that was being fed to me, didn't add up. The underside of the rotor actually still had moisture on it! When I showed the photos of the damage and the estimated repair bill, they didn't seem phased by it and a passing 'Oh, I wonder how water could have gotten inside?' In the end she cleaned up really nicely. I wish I had taken a shot inside the case. The last shot of the timegrapher shows the timing in all six positions For some reason, some Rolex movements you will only get 286 amplitude out of them in horizontal positions. For some reason 286 is the magic number. I've seen this many times. with a new spring and getting 286 amplitude, I'm happy. Another watchmaker friend of mine who works for an accredited Rolex watchmaker told me the same. This isn't all Rolex movements. On a side note, I serviced a beautiful Omega Seamaster a few years ago. The rubber gasket had turned into a sticky paste just like Marmite, which had gotten everywhere The movement had an intricate slipping pawl ratchet wheel to stop the keyless work from turning as the rotor turned this to put power in the mainspring and vice-versa if I can recall. Great to discover this over engineered piece of kit and see the similarity of this to a reversing wheel! It was serviced and returned to it's owner and unfortunately because it has 'Seamaster' written on the dial he thought it would be alright to get into the shower with it! This only had one outcome, which water logged the case and movement within seconds. The watch wasn't returned to me for two weeks, so I had to get to work quickly, but the damage was already done and set in and I wasn't sure if the old girl wasn't going to pull through this one. The client didn't try to dress this story up! There was no cosy warm dry bedroom draw to talk about. No niece, nephew or child to hang this one on! The thing with a movement with power in the mainspring and a jammed gear train is, it's like playing Jenga. You know at some point it's coming crashing down, just like the movement, you know as you remove parts at some point the power is going to hammer through a train you are taking the bridge off, so it's minimising the least expensive replacement part to break, so holding back the train to remove the escape wheel as a priority because this is the most delicate part to break and then if you can the fourth wheel. The third and second wheel might come off lightly. In fact, I was able to remove all the train by holding back the second wheel which wasn't that hard because of the rust was doing a great job at that. The only parts that was permanently damaged beyond repair was the whiplash regulator on the top of the balance and a few bits and pieces from the auto works, which had fused together. The timegrapher results were pleasing once it had been cleaned and serviced again. Even with all that water and the work needed, a perfectly working vintage Omega 503 brought to within Chronometer standards. It's so pleasing to bring that look of joy to a clients face when they tell you they've been to several watch service places and they've said it can't be repaired and you tell them that you will get her working again. Priceless! Two services and a complete de-rusting in less than three weeks was a costly mistake2 points

-

There is always a need for profanity . If you dont want to let the steam out then dont light the fire. In other words keep your cool, its not a major crisis, no one is going to die lol. Handle them light they're slippery buggers ( round shape and made of brass ). Check your tweezers are dressed correctly. You could file a round in the tips of some old tweezers. There are trains of thought that the pin should have a flat on it so you can correct the hairspring before you push the pin home, I've rarely seen that but have put my own on. I have also filed 2 flats at the fat end so i can turn the pin a bit easier.2 points

-

Yes, it happened to me too. And it was @Nucejoe who taught me a very nifty trick. He told me to put a smear of grease on the tip of a screwdriver and use that to pick up the stud pin by the back end. Never lost another stud pin since.2 points

-

It is in fact a Schatz 8Day Anniversary Clock Visible Wheel Movement 2Jewel. Silly woman. Carriage clocks are called so because it has a handle, you get them most are 8 day duration. Timepiece 8 day, Timepiece and alarm,Strike 8 day on a bell or gong, also with or without alarm, Grande Sonnerie and et petite sonnerie strike these are complicated strike and chimes. She is also wrong carriage clocks are not made with just a chime.2 points

-

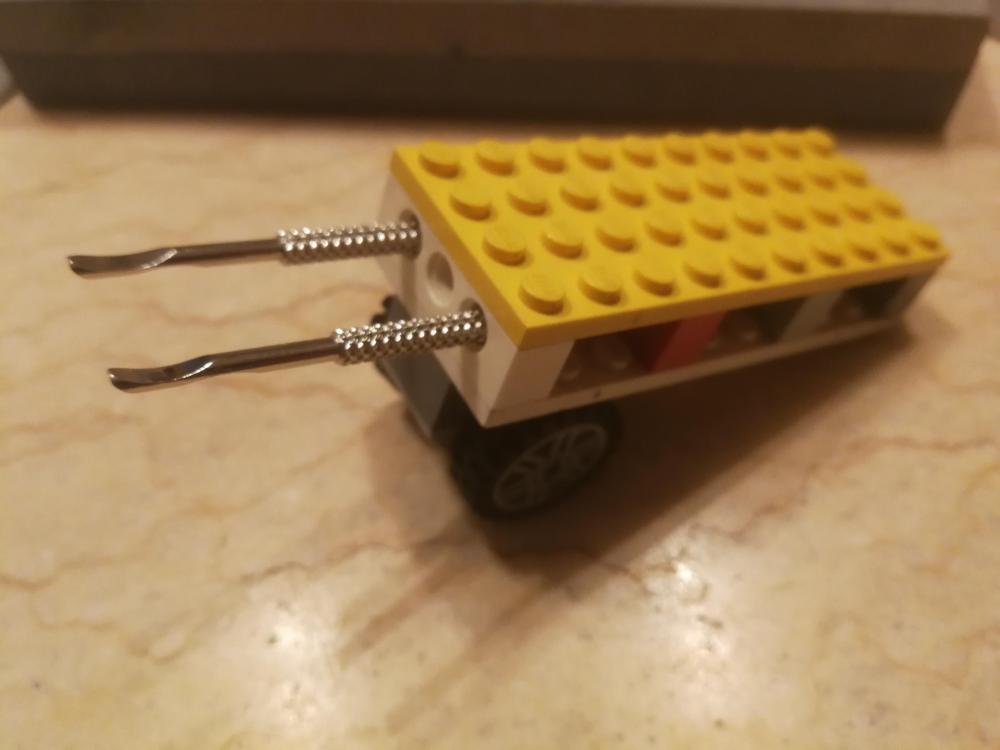

Hi gents, so I managed to grind the tips of the hands removal levers. I borrowed some LEGO pieces from my kid and built a small cart to keep the angle when I'm honing the tips. I honed enough, in my opinion, to be able to lift the hands. I didn't want to grind too much and get them too thin, I'm afraid the tips could bend or snap. Below the "toy" I built and final result. What do you think? What is the thickness of your tips, by the way?2 points

-

Clocks can be lacquered to preserve the polish on the brass but the lacquer is not hard enough wearing to work on a watch, and you don't want brass against skin as it will end up green and nasty. Titanium nitride (TiN) is used to give a hard wearing gold colour. It was used on cheap watch cases in the 1980s (and probably still is) with just a flash of gold over the top to claim that they were 'gold plated'. It does last well but all plating is thin so wears through over time. Alec2 points

-

I picked up this beauty on eBay for almost eligibility in the 404 club. I think it was around $8 US. It has a simple pin pallet movement marked BF 866 which was in pretty good shape except for a broken mainspring. After cleaning and reassembly I got a decent amplitude of 250° to 280° but a beat error of 3.0° so I thought what a perfect opportunity to practice some adjusting skills. So I got the stud pin out, turned the collet a degree or two and proceeded to ping the stud pin into the ether. No way I was finding that small brass splinter. No problem, I popped one out of a junk balance from my parts box and put the balance back together. Naturally I turned the collet the wrong direction and was now seeing a beat error of 5°+. Once more to the bench and once more I adjusted the collet --the right way this time -- and launched the stud pin. Okay, so again i thought to turn stupidity to opportunity and make a stud pin on the lathe. Except, the only brass round stock I have is 4mm rod. That would be like making a toothpick from the trunk of a Redwood. I've got a box of 100 coming from Cousins. So, what are your tips, trick and techniques for handling and inserting hair spring stud pins without the need for profanity?1 point

-

Hi Doc, Rotating the roller table is less risky and wouldn't hardly disturbe the rate.....etc . You guys have rodico, preferred to grease or oil to hold the stud when your re-fitting it. Yes remove & refit. With spinning you risk loosening the grip of balance wheel on staff, or who knows what else, unless one has tools that facilitate spinning safely. Rgds1 point

-

You can rotate the roller table instead, and if obsessed you might inaccurately re-pin , ink mark the loose end of hairspring. Rgds1 point

-

What the hell is the point of buying unfinished tools.1 point

-

Mine from the photo are 0.3mm at the tip going to 0.5mm over about the first 2mm. The other set I've got at work are like a razor on the tip but I don't use them that much.1 point

-

Has anyone experience of pen plating gold? I wondered if it would be any good in improving the appearance of small defects/wear in gold plated cases and straps?1 point

-

1 point

-

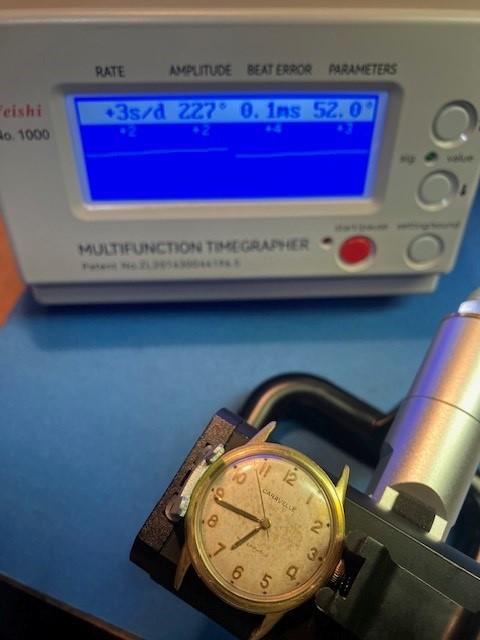

Another eBay parts Caravelle arrived Friday. I am still hoping to get a parts watch I feel good about parting out to get my "setting lever spring". I pulled it apart to find I have a $14 Swiss AS 1686 movement. Argh and yay at the same time. I removed the junky metal band so it can do no more damage. Wound it up and let it sit for a day. With little expectation on this parts watch, I was surprised to find it still running in the morning. Unpacked the TG and put it on correctly. DU -57 s/d | 201 amp | 0.2 BE |52 deg and 18,000 which is correct for a 1686 per Google. So, took it out of the case with the small screw I learned about on the ST36. Started playing with the regulator to speed it up. Not silky smooth. But three attempts got me to what I call good enough. DU +3 s/d | 227 amp | 0.1 BE. I was so excited I put the watch back together FORGETTING to tighten the crown locking screw. The back was not easy the first time nor the second. More lessons. In truth, I did nothing to the watch but speed it up a bit. M2 or 1962. First service in '64, '66, '67 and '68. Maybe it went in a drawer soon after. I would think old lube should be an issue. Noted on tweezer dressing. I will look at them with the 10x and address. Cleaned up my work area but have many improvements needed. I now have a AS movement in the collection for practice. Seems the 1686 was used by many brands. Good reading on the interweb. Impressive movement to a newb. I think the 11DP 7J is my next practice victim.1 point

-

yes exactly. Normally if as a mechanical watch would be looking at the amplitude dial-up and dial down to see if we did see a problem. On electric watch the only way he could do that would be if we were measuring the current consumption words is her additional friction or something. But typically people working on electric watches don't have proper test equipment. Is also a test for dampening of the balance wheel in other words you rotate it release it and it's supposed oscillate a certain amount of time and that should've been done I both dial down and dial up looking for a problem. It may be that the sound were hearing at the very end when it stops may actually be occurring at all the time but when it's moving really freely fast maybe it's not really being heard it's only when it finally slows down. So a classic would be look at the pivots and the jewels see how they look.1 point

-

@mikepilk You may want to check out this website that shows plating of 3.0 to 3.6 microns as being achievable. https://www.hunterproducts.com/store-pen/1 point

-

So my new HSS graver arrived, I’ve had a quick use of it. Definitely put the fun back into lathe work.1 point

-

I had a spare 5 mins yesterday so I took a look at the first of the "three for a quid" I picked up recently. A new battery, a new strap and a fumigation of the case and it looks like new. Perhaps its most impressive feature is the lume. In the dark, it lights up like Hollywood nuclear spill, and even in daylight it has a slight glow. Well worth thirty three and a third pence I would say.1 point

-

A 50-50 mix of acetone and automatic transmission fluid makes a penetrating fluid that is as good or better than anything you can buy (as long as no plastic is involved).1 point

-

Sorry your shields aren't going to work old technology we have newer technology that will penetrate your shields. Now what we really need is newer technology than reading a crystal ball. Looking at our crystal ball and trying to predict the future or what's going on sometimes is a bit of well problematic we need modern technology which doesn't exist. Interpreting tea leaves or reading timing machine results is a bit of basically not the exact science it seems like it should be. I'm attaching a timing machine help but it's not an exact science of help oh and then there is the other problem. As you're well aware within a digital device you always end up with a plus or minus the lowest amount and conceivably on the pixels we could always see a straight line as being an up down up down because it's not exactly well if you have a different in 10 in your in between you're going to end up with a non-smooth line conceivably so as to how un-smooth that line is could be debatable as to the digital 10 air of the whole thing. Okay on the attached charts we have numbers 5, 7 and 10. Then further into the document now with five you'll sometimes even see that with lubrication where it's a little bit dry on one side of the escape wheel or one side of the fork doesn't have enough lubrication only one side is lubricated so you will see some of that they're just indicating here it's the pattern repeating and we don't seem to have a repeating pattern on Yours but still I see a rough waveform from not getting enough lubrication everywhere on the escape wheel and the fork both sides now for number seven is basically it certain degree the same as number five basically up to check everything in the escapement the pallet stones are both shellacked in place they're not lose. My obsession with getting the lubrication has to be right everything asked be nice and clean no chips flaws scratches old lubrication like shellac on the acting services. A oh and notice the reference to the roller jewel? I've seen this come up and this is really important on American pocket watches are probably all vintage watches check your roller jewel. Try not to break it when you're checking it but grab it gently and see if it's loose. Often times the roller jewel is loose and that wobbling around will give the exact same effect that were seeing. Then don't even read number 10 because basically it's a everything everything could be at fault and that's why you're seeing this. So all of the previous examples could be the reason in addition to just about everything in the universe. Magnetism a lot of times will produce a really nice pretty sine wave and then it goes away when you demagnetiz which you should be doing anyway. Oh and he did notice where there's a reference to letting the paper tape run for a while this is where if you have expensive machines or software-based machines you can run a time plot and then you can look for wheels that are out of round. So basically if it looks this bad you're really screwed and. But yours doesn't look this bad euros looks like a mild case of this. So if you haven't invested in a crystal ball this year you might think of getting one or learning how to read tea leaves because same skill set is required to read a timing machine graphical display and come up with definitive answers other than it points you in the direction of you have a problem. Timing-Machine-Charts.PDF1 point

-

You would use balance screw holders, which are small sliding pin vices with precise diameter openings. Grip the head and unscrew. They are honestly an essential tool for slotted screws as well; get the screw loose with a screwdriver, then unscrew with the holder, now it's held and easy to add a washer to and get it back on the rim, final tighten with screwdriver. The standard set is 3 pieces, 0.30, 0.40, 0.50mm. That covers things pretty well, unless you're working on a tiny 5 ligne LeCoultre or a big pocket watch. Do try to eliminate any other cause of the increased rate before going to adding washers though.1 point