Leaderboard

Popular Content

Showing content with the highest reputation on 07/08/24 in Posts

-

Now, that's just way to British for me to even begin to understand EDIT: I think I got it now that my old brain had time to process it. "Like father, like son"? No, I'm afraid not, he's stronger, smarter, and a lot more handsome3 points

-

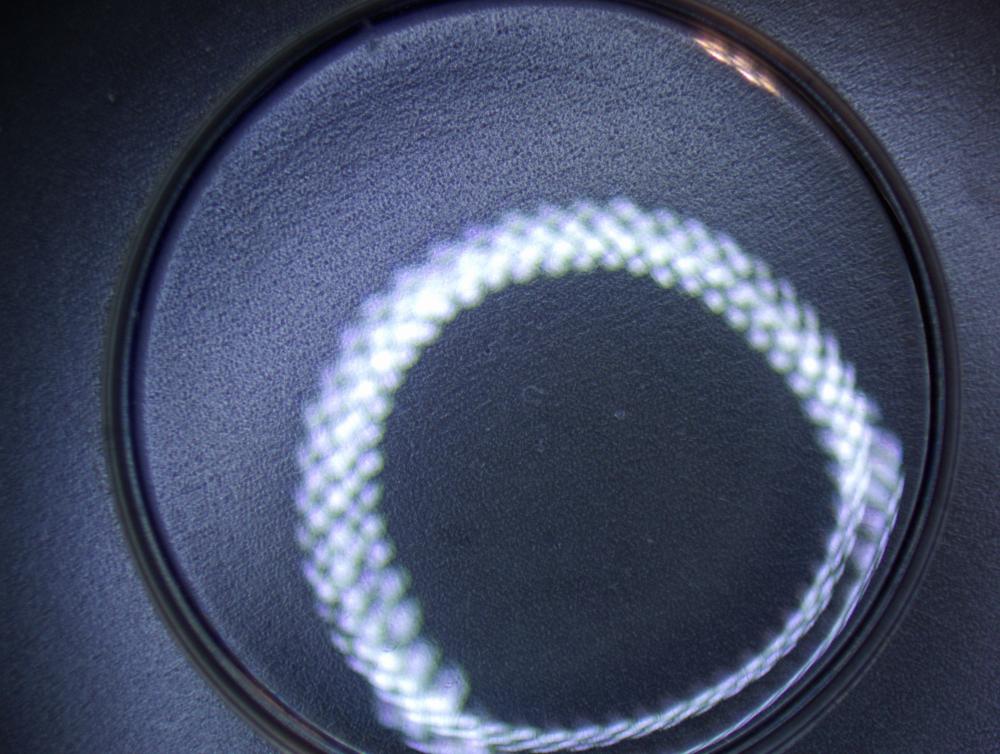

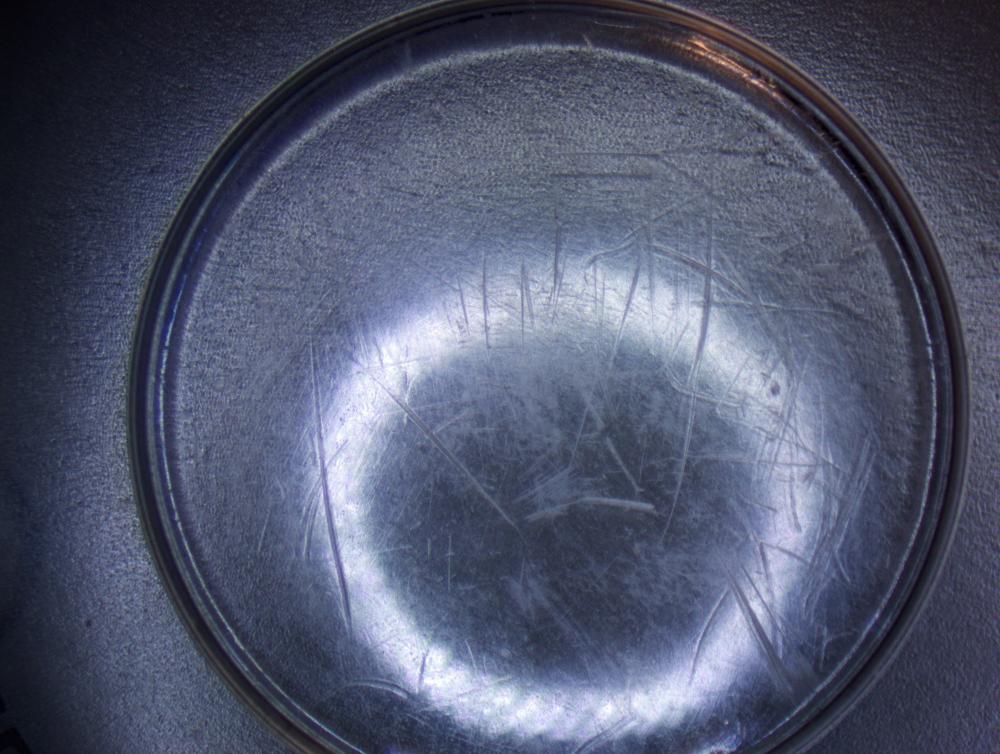

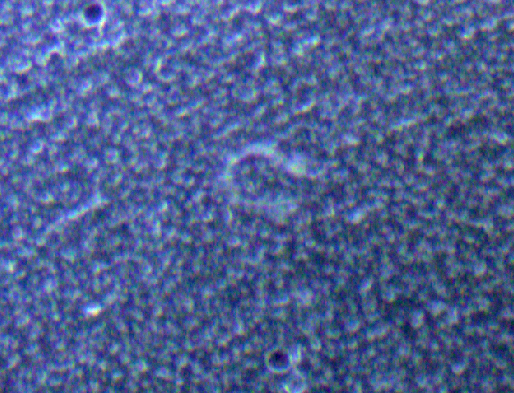

Just a little update. The movement is back together and running nicely after lots of fighting with me. Tonight was case prep. Wet sanded the crystal with 400 through 1500 grit, ran in on a polishing wheel with red rouge, then finished with automotive headlight polish. It's my first time working out scratches this deep, and I have to say it was a lot easier than I expected it to be. Edit to note that what I thought was a tiny blemish I missed in the center is actually an Omega symbol! ENHANCE3 points

-

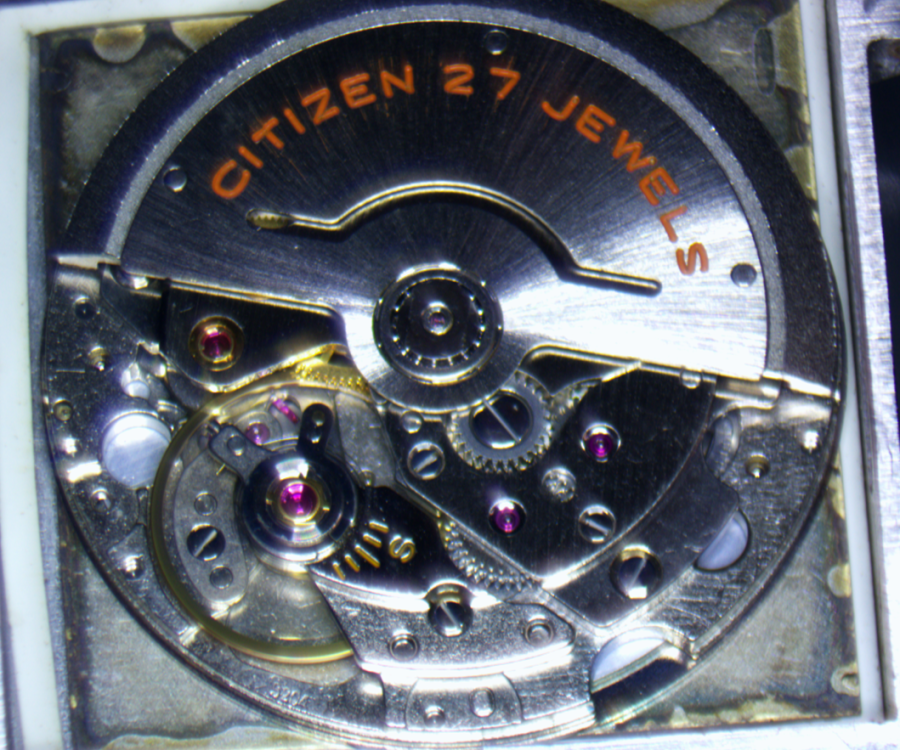

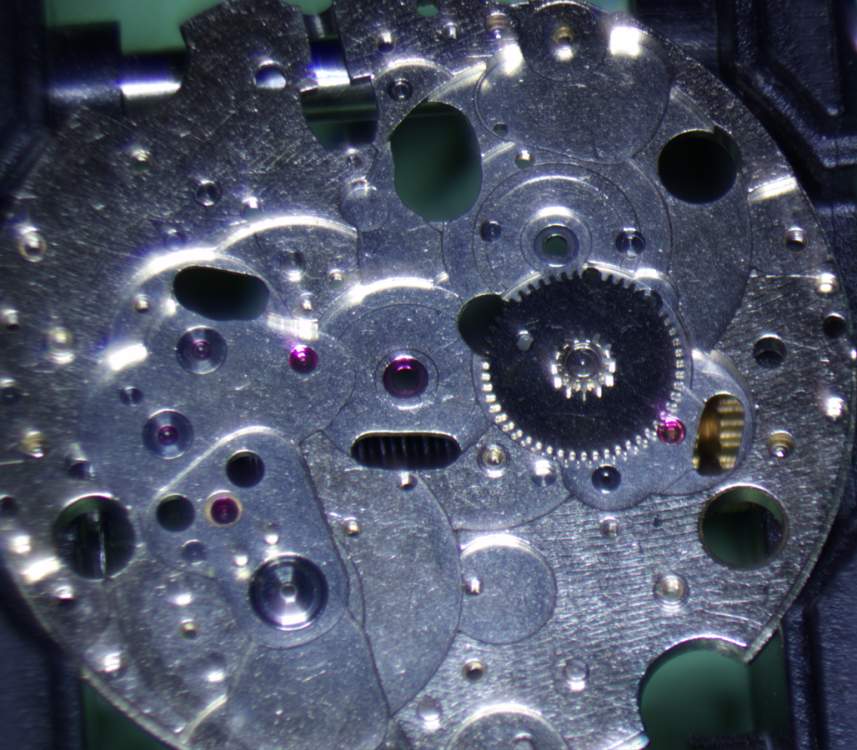

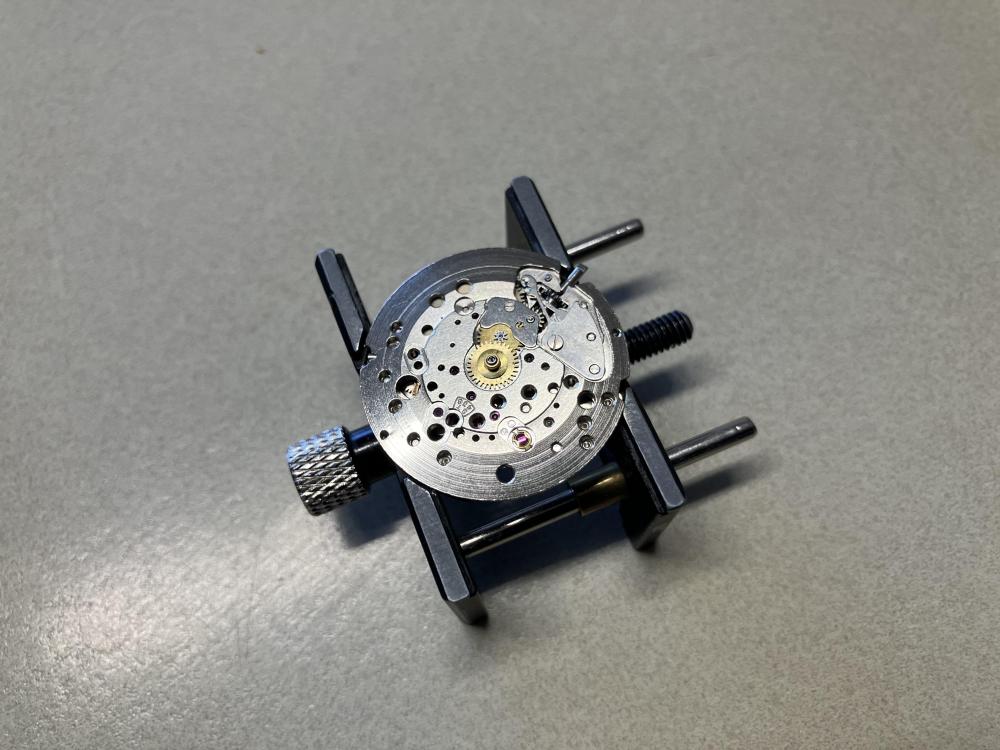

I posted about this guy in the "Which watch have you got coming" thread, but here's the teardown. 27 is a lot of jewels! Cap jewels as far as the eye can see. I also figured out that the black screws are left-hand threaded. Looks like this last wheel is riveted to the plate, so I'm going to clean it in place.2 points

-

When you have really tough setbacks, it is easy to get the feeling of wanting to give up and many times I have given up and thought that enough is enough, and I think that can be a good thing even if it sounds contradictory. Sometimes you simply have to let time pass before you are ready to try again or try something new. When the brain have calmly and subconsciously processed the problem, you automatically get the urge to make a new attempt and not infrequently it leads to success, or at least getting a little further. You will succeed! Sooner or later!2 points

-

Start by inserting a single cutting edge safety razor, open a gap, work your way around the bezel , gradually widen the gap to the point that your bezel tool can get inserted in, easier. Rgds2 points

-

5 quarts mechanical from the link provided including citizen detailed below. https://sweep-hand.org/2020/06/23/todays-watch-citizens-first-quartz-8811/1 point

-

I like that tool rest pivot holder. I might need to make one.1 point

-

The thing is you can't enter zero in the value box. So I ticked the "Gift" box and I indicated 20 € in the "Value" box. The parcel is on its way to the UK and I will inform you how things are going. As for the insurance, this is not an important matter because the parcel contains a very ordinary old Timex, the kind that was made to be thrown away instead of being serviced ... but I managed to repair it and my friend will recover the timepiece he had when he started working ... a long time ago !1 point

-

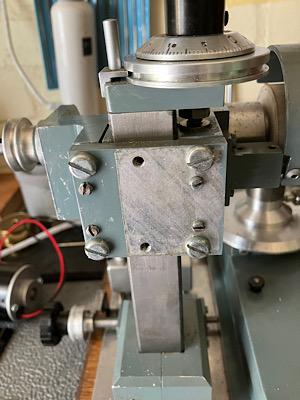

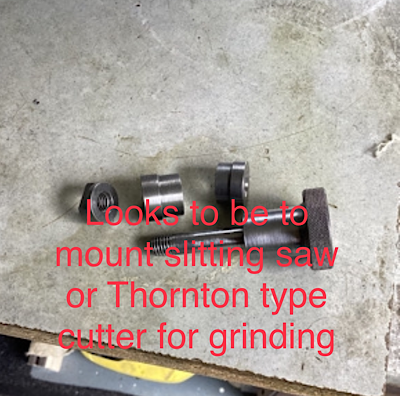

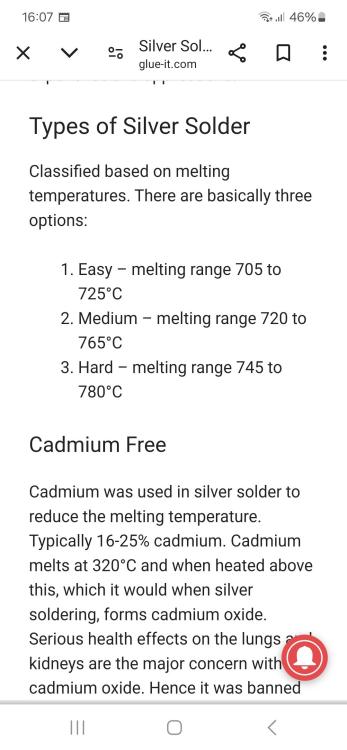

Wasn’t sure where to put this post but decided here if wrong please move, this tool cutter & grinder came from a watchmakers workshop, I have been looking for one for some time but most are way to big for me , I don’t need a large one because most of my grinding is on 3mm square HSS just occasionally 6mm 1/4” and I don’t have much room anyway , upon receiving it I fully stripped, cleaned and rebuilt finding the sewing machine motor knackered and the spindle bearings I replaced the bearings and am fairly sure the motor isn’t original as there is a telltale where it’s not painted on back of upright I needed to find a replacement motor but most were to big and the place where the sewing machine motor was had only 2 screws, as did the bit on back of upright where I think an original motor was mounted any way I found and ordered a motor from Amazon rated 7000RPM @24 volts not sure it was going to be man enough I mounted it with the bracket that came with it after modifying it as I didn't want to mess about making one just in case motor not good enough but it is well man enough, it ground a graver no bother at all, made a box for it to sit on with power supply & switch in, just got to make a proper bracket now, I am fairly sure the bit where the paint is missing was where a motor was originally, I can't think of any thing else that could have been there, the pulley's are only temporary as well. It was most definitely shop made because I found lots of scribe lines when I took it apart. Dell1 point

-

1 point

-

1 point

-

The second "three for a quid" got a new after-market band. I was going to go with a black one but plumped instead for a bright orange. Described as "High Quality Rubber Wrist Strap For Casio MW-59 MW59 MQ-24 MQ24 MQ-71 MQ71 MQ-76 MQ76 Replacement Black Bracelet WatchBand Strap" on AliExpress, it cost a mere £1.75 plus vat, free shipping (as I was ordering other stuff, so combined shipping was free). Add in a battery and I now have two MQ-24s that look like new.1 point

-

You might find this interesting. It seems it might not be cockroaches that will be wearing your radioactive pocket watch in a post apocalyptic world.1 point

-

I got them too and I'm very happy with them. That was very resourceful of you. Skilled watchmakers are good at improvising and finding solutions outside the box. I'm not very good at it, but I'm practising it and getting better and better. It's an important part of watchmaking. Perhaps I had tried to polish the hand levers using a polishing machine, starting with a 1st stage Gialla mopping wheel and orange Dialux. Not sure how good of an idea that would be though but perhaps worth a try.1 point

-

I have several things to say here, but have no time now. For sure, there is no need to unpin the hairspring from the stud. I need picture, but am almost sure that the stud can be removed from the cock. Then, no need to remove the studd and the balance at all, the rotating of the collet is done without it. Then, some words needed here for preparing of tapered pins. Yes, one can buy them, but the skill of making them is something that never will be unnecessary. And, no lathe needed, just piece of wood plank, good fine file and pin vise. And brass wire with close diam. Wire can be drown in drawplate. One will have previously prepared different sizes of brass wire for all the cases it will fit.1 point

-

What the hell is the point of buying unfinished tools.1 point

-

These are the second pair I got - very cheap and excellent quality for the cost! https://www.ebay.co.uk/itm/2257543170031 point

-

I have a Citizen Crystal 7, cal 5204 with 33 jewels. It looks similar to your movement. I remember it has a hell of a lot of springs (with 4 just on the dial side). I notice you seem to have a number of springs in the tray. Ping ! It all seemed a bit over complicated for just day+date. It put me off Citizen a bit, as Seiko do it so much more simply.1 point

-

@oldhippy and @Dell A quick update: after some re-bushing, a lot of cleaning and a sanity check with the synchronisation, I've managed to get the clock working really nicely. It's keeping excellent time and chiming/striking exactly when and where it ought to be. Emboldened by this early success, I'm now working on another one; this time with Westminster and Whittington chimes. Thank you both very much indeed for all your hints. tips, advice and encouragement. Martin1 point

-

I struggled with the cheap ones. I changed the shape many times, but I never managed to get them as I wanted. So I bought some Horotec ones. They are so much better to work with - polished to the perfect shape. They aren't cheap, but as you use them on every watch, I think they are one of the list of tools (screwdrivers, tweezers, movement holders etc) where it's worth spending extra.1 point

-

1 point

-

I have two sets, one very cheap, one cheapish. I dressed the very cheap ones and they work great.1 point

-

So my new HSS graver arrived, I’ve had a quick use of it. Definitely put the fun back into lathe work.1 point

-

I will advice to do what I do - I make gravers out of this kind CNC router bits. I reshape and sharpen them with such kind of diamond disk, grit 800, dry. No polishing needed, just sharpening.1 point

-

Thats why i dont wear a tie when I'm working with machine tools, come to think of it i dont wear a tie at all which makes my comment completely irrelevant.1 point