Leaderboard

Popular Content

Showing content with the highest reputation on 07/09/24 in all areas

-

2 points

-

There are three of them and it was covered in the link I previously gave up above and I'm giving again. Then the Russians and their electric watches you see some very innovative interesting things. Unlike the rest the world trying to get around patents typically they are trying to get around the problems of their technology and still make a product. Which means they make all kinds of very very interesting products like a variety of interesting electric watches. https://electric-watches.co.uk/movement-types/quartz-control-with-balance/2 points

-

2 points

-

Generally there is no reason why a TG cannot test pin pallet watches. But some use lower beat rates than 18000 that are not included with cheap TGs . Maybe that is your problem. Frank1 point

-

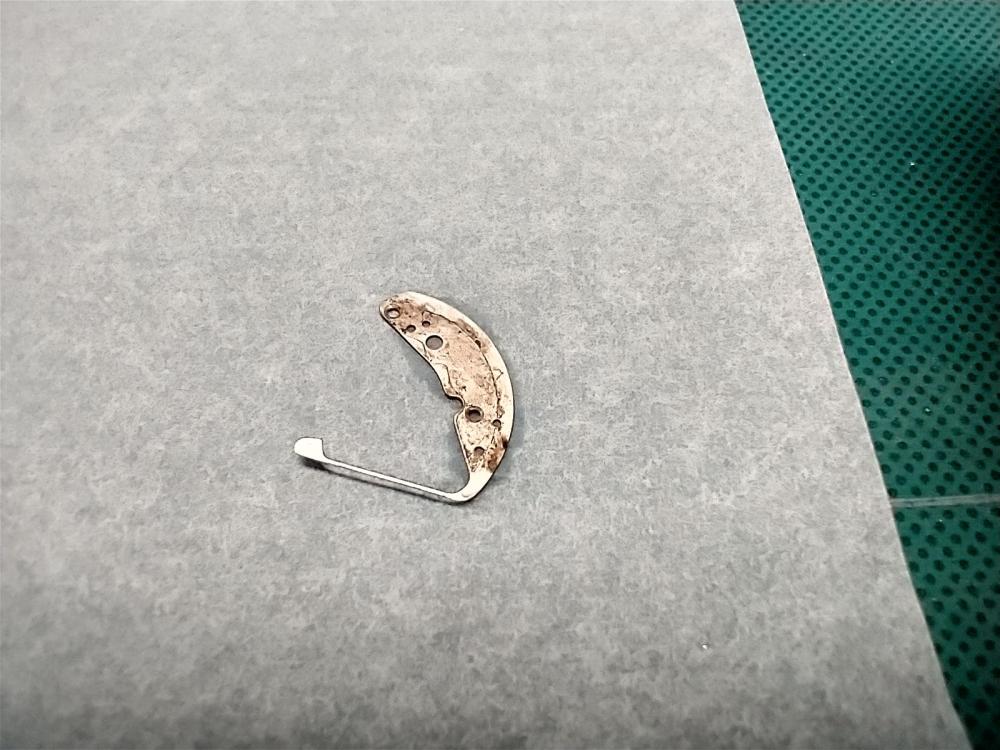

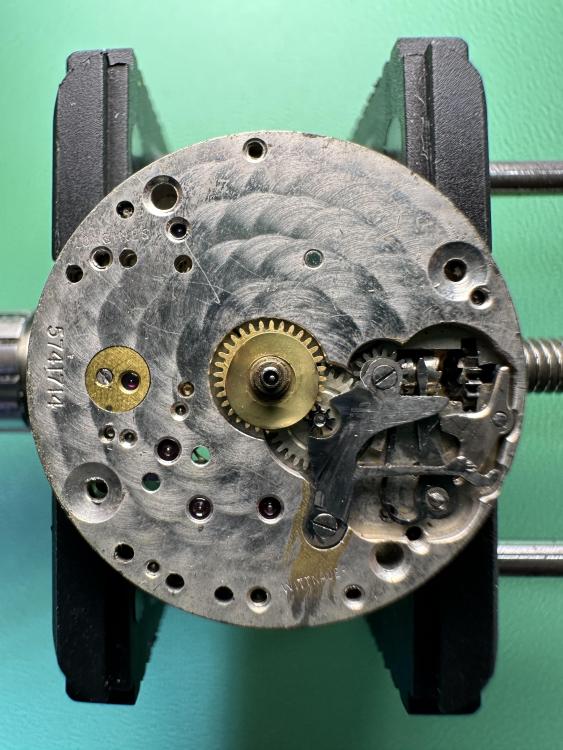

I promised a post on the weems I've been pecking on a bit at a time. Longines 10.68.Z what had a busted yoke screw and a pallet fork with a stubby pivot. This movement has seem lots of action and the plating is quite worn and fragile. While the plate was soaking in alum I considered trying to replace but I don't have the skill or equipment to re-pivot. These 10L movements come in seemingly infinite variants. there are so many different length center seconds springs I assume they chose random locations on the bridge to fasten them. I had another 10L what took me three tries to locatre the appropriate length. A similar situation with the pallet fork. After a false start I pulled the appropriate new pallet complete from a donor. The alum worked a charm but it was difficult to remove the mess without damaging the fragile plating remaining on this movement. Anyways, up and running and I love the look. This one appears to have never had a a bezel lock. I tried to find definitive information on variants but there is surprisingly little detailed information on these. I did find a couple photos of similar variants like this one...1 point

-

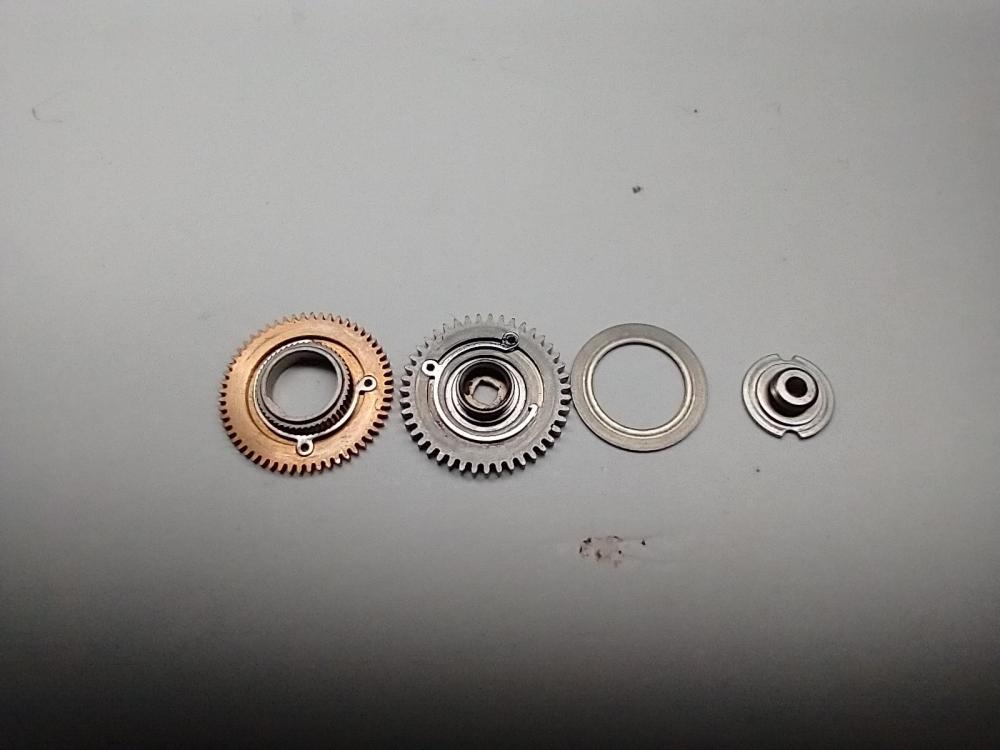

You are correct that is when parts were plentiful. These days you have no option but to open them. Look at the side and you will see a very thin mark around the barrel, you need a very thin blade a razor blade is best to open it. Be careful with the teeth and the cap as it is thin you do not want to distort it.1 point

-

its the seam on the brass side. Seiko does want you to replace them, but for the 2200 series they are hard to find now. you can open it and service it.1 point

-

So, how did you get the superglued nut off the caseback? Or, are you wearing it with the nut?1 point

-

Are you also cleaning the balance and pallet fork with IPA? IPA will dissolve shellac (i.e. roller jewel on balance and pallets on the fork).1 point

-

Yes, copper wire is soft. But it is beter than nothing. At least, when I was school boy and made my first attempts, I used copper wire and it actually worked for me.1 point

-

5 quarts mechanical from the link provided including citizen detailed below. https://sweep-hand.org/2020/06/23/todays-watch-citizens-first-quartz-8811/1 point

-

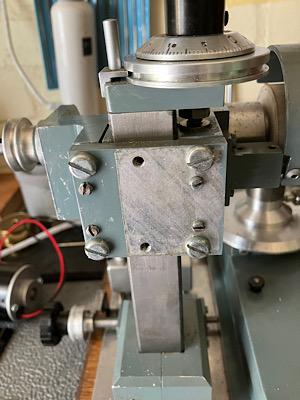

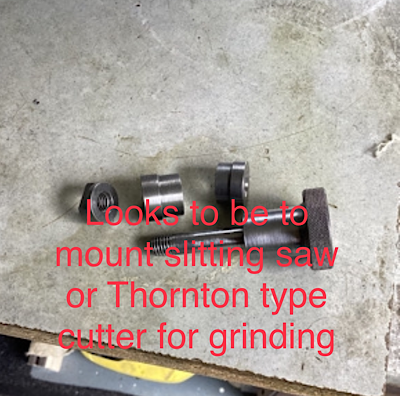

Wasn’t sure where to put this post but decided here if wrong please move, this tool cutter & grinder came from a watchmakers workshop, I have been looking for one for some time but most are way to big for me , I don’t need a large one because most of my grinding is on 3mm square HSS just occasionally 6mm 1/4” and I don’t have much room anyway , upon receiving it I fully stripped, cleaned and rebuilt finding the sewing machine motor knackered and the spindle bearings I replaced the bearings and am fairly sure the motor isn’t original as there is a telltale where it’s not painted on back of upright I needed to find a replacement motor but most were to big and the place where the sewing machine motor was had only 2 screws, as did the bit on back of upright where I think an original motor was mounted any way I found and ordered a motor from Amazon rated 7000RPM @24 volts not sure it was going to be man enough I mounted it with the bracket that came with it after modifying it as I didn't want to mess about making one just in case motor not good enough but it is well man enough, it ground a graver no bother at all, made a box for it to sit on with power supply & switch in, just got to make a proper bracket now, I am fairly sure the bit where the paint is missing was where a motor was originally, I can't think of any thing else that could have been there, the pulley's are only temporary as well. It was most definitely shop made because I found lots of scribe lines when I took it apart. Dell1 point

-

1 point

-

The second "three for a quid" got a new after-market band. I was going to go with a black one but plumped instead for a bright orange. Described as "High Quality Rubber Wrist Strap For Casio MW-59 MW59 MQ-24 MQ24 MQ-71 MQ71 MQ-76 MQ76 Replacement Black Bracelet WatchBand Strap" on AliExpress, it cost a mere £1.75 plus vat, free shipping (as I was ordering other stuff, so combined shipping was free). Add in a battery and I now have two MQ-24s that look like new.1 point

-

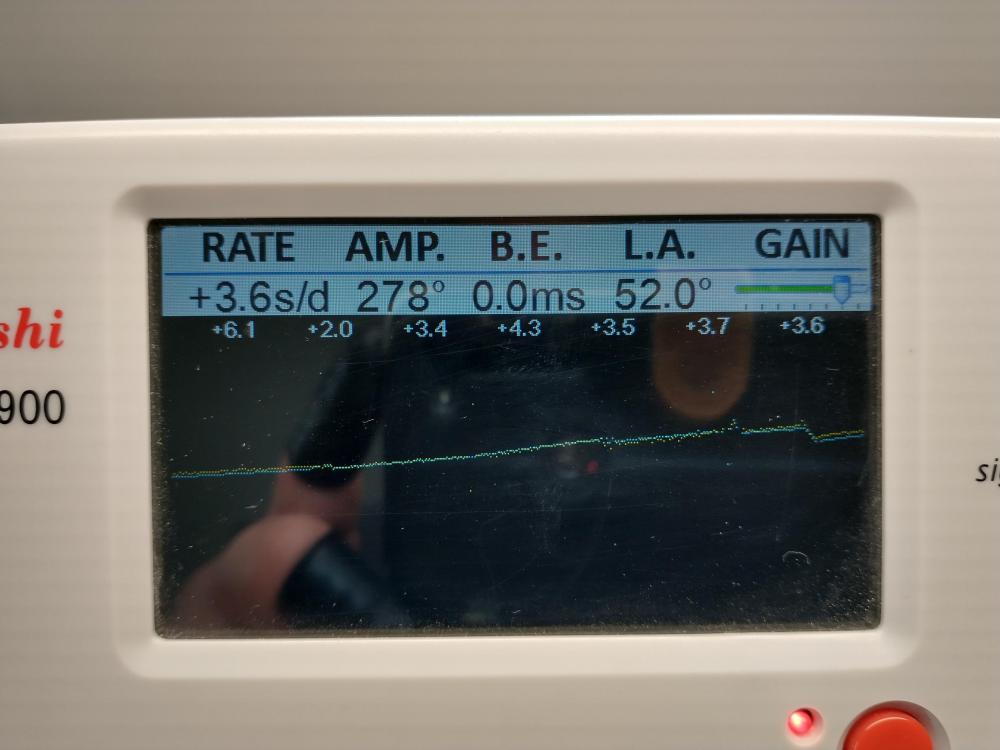

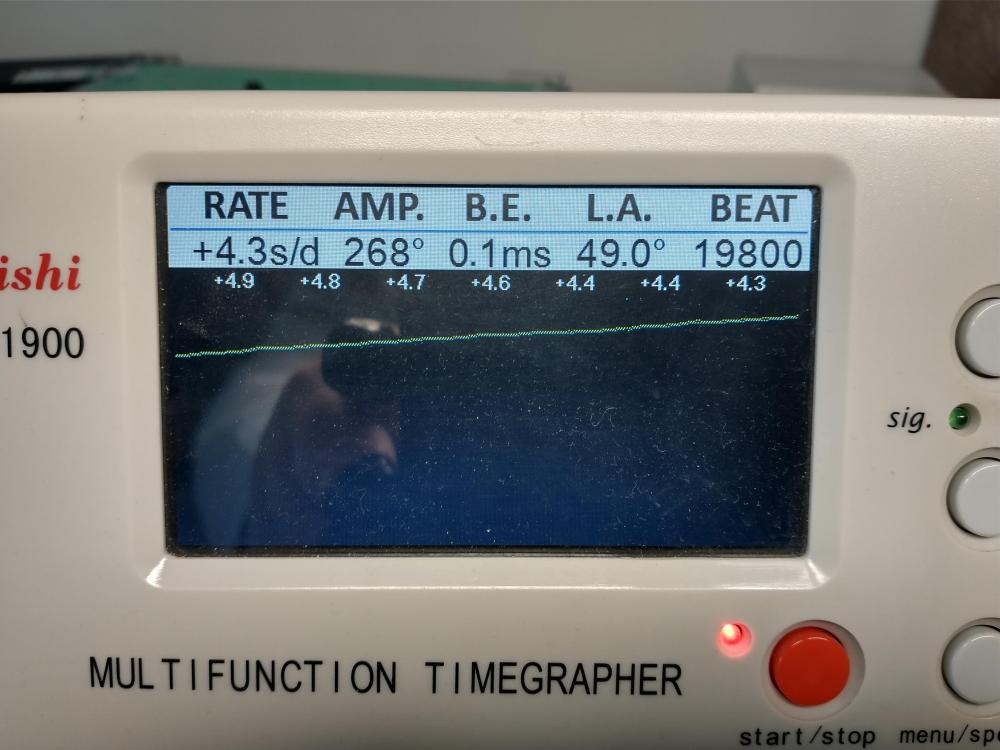

One of the things I love about my job as a watchmaker is the variation in what I'm servicing or/and repairing. One day will be a modern Omega Seamaster with a coaxial escapement, the next a Baumgartner pin pallet and the next a Goliath pocket watch. So the vast array of quality to the not so quality of movements. In fact that has been several of the watches across my bench this month, as well as the usual bread and butter work of vintage Rolex and Omegas, which personally I like working on, as you can get such great results from a 50 year old watch and even get them to chronometer standards again, which is very satisfying. This ladies Rolex watch with a 2135 under the hood came to me with a story, as all watches tend to. Now, the story that the client tells you is sometimes a lot different to what the watch movement is telling you. The watch never lies, but clients have a habit of missing bits out and massaging the truth, so to speak. Here's an example of what the watch is telling you and what the client is.... You decide. This watch had been sitting in a draw for almost ten years, said the customer and prior to that it had been working fine. Now, looking at some of the damage from water ingress and rust and the blob of metal that used to be called a rotor and I would say that unless that draw was in the swimming pool, I doubt very much what I'm being told is even marginally close to the truth The Gif shows dissolving a rusted in screw using Bergeon Vissin. The reason the movement is held upright in the Vissin, is because I didn't want to remove everything that was steel like the IncaBloc setting and minute wheel post, etc. Remember that this watch was in working order to prior to safely putting it in the swimming pool.... I mean the draw in their bedroom. What I usually ask is, 'Are there any children in the house?' because that throws a different light on everything. What one of their little treasures could have done with that watch is anyone's guess and the 'story' the client is giving you is now seeming a little more truthful with throwing in the 'X' child factor, but alas they didn't have children, not even a random niece or nephew we could possibly pin this on. It was looking more that the version of events or non-events that was being fed to me, didn't add up. The underside of the rotor actually still had moisture on it! When I showed the photos of the damage and the estimated repair bill, they didn't seem phased by it and a passing 'Oh, I wonder how water could have gotten inside?' In the end she cleaned up really nicely. I wish I had taken a shot inside the case. The last shot of the timegrapher shows the timing in all six positions For some reason, some Rolex movements you will only get 286 amplitude out of them in horizontal positions. For some reason 286 is the magic number. I've seen this many times. with a new spring and getting 286 amplitude, I'm happy. Another watchmaker friend of mine who works for an accredited Rolex watchmaker told me the same. This isn't all Rolex movements. On a side note, I serviced a beautiful Omega Seamaster a few years ago. The rubber gasket had turned into a sticky paste just like Marmite, which had gotten everywhere The movement had an intricate slipping pawl ratchet wheel to stop the keyless work from turning as the rotor turned this to put power in the mainspring and vice-versa if I can recall. Great to discover this over engineered piece of kit and see the similarity of this to a reversing wheel! It was serviced and returned to it's owner and unfortunately because it has 'Seamaster' written on the dial he thought it would be alright to get into the shower with it! This only had one outcome, which water logged the case and movement within seconds. The watch wasn't returned to me for two weeks, so I had to get to work quickly, but the damage was already done and set in and I wasn't sure if the old girl wasn't going to pull through this one. The client didn't try to dress this story up! There was no cosy warm dry bedroom draw to talk about. No niece, nephew or child to hang this one on! The thing with a movement with power in the mainspring and a jammed gear train is, it's like playing Jenga. You know at some point it's coming crashing down, just like the movement, you know as you remove parts at some point the power is going to hammer through a train you are taking the bridge off, so it's minimising the least expensive replacement part to break, so holding back the train to remove the escape wheel as a priority because this is the most delicate part to break and then if you can the fourth wheel. The third and second wheel might come off lightly. In fact, I was able to remove all the train by holding back the second wheel which wasn't that hard because of the rust was doing a great job at that. The only parts that was permanently damaged beyond repair was the whiplash regulator on the top of the balance and a few bits and pieces from the auto works, which had fused together. The timegrapher results were pleasing once it had been cleaned and serviced again. Even with all that water and the work needed, a perfectly working vintage Omega 503 brought to within Chronometer standards. It's so pleasing to bring that look of joy to a clients face when they tell you they've been to several watch service places and they've said it can't be repaired and you tell them that you will get her working again. Priceless! Two services and a complete de-rusting in less than three weeks was a costly mistake1 point

-

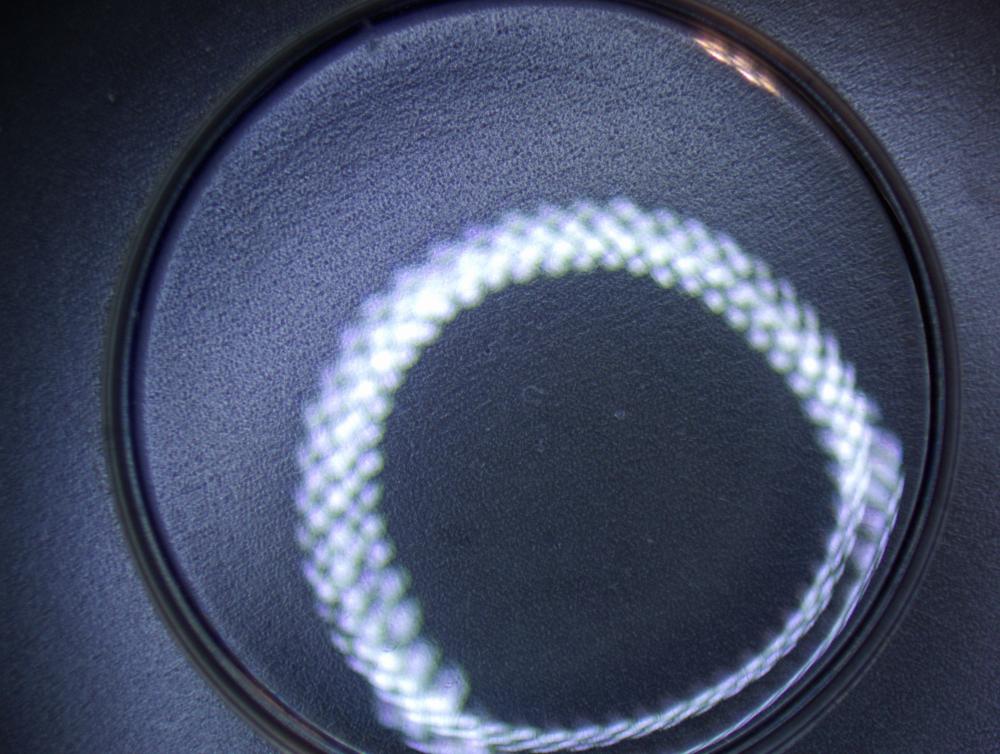

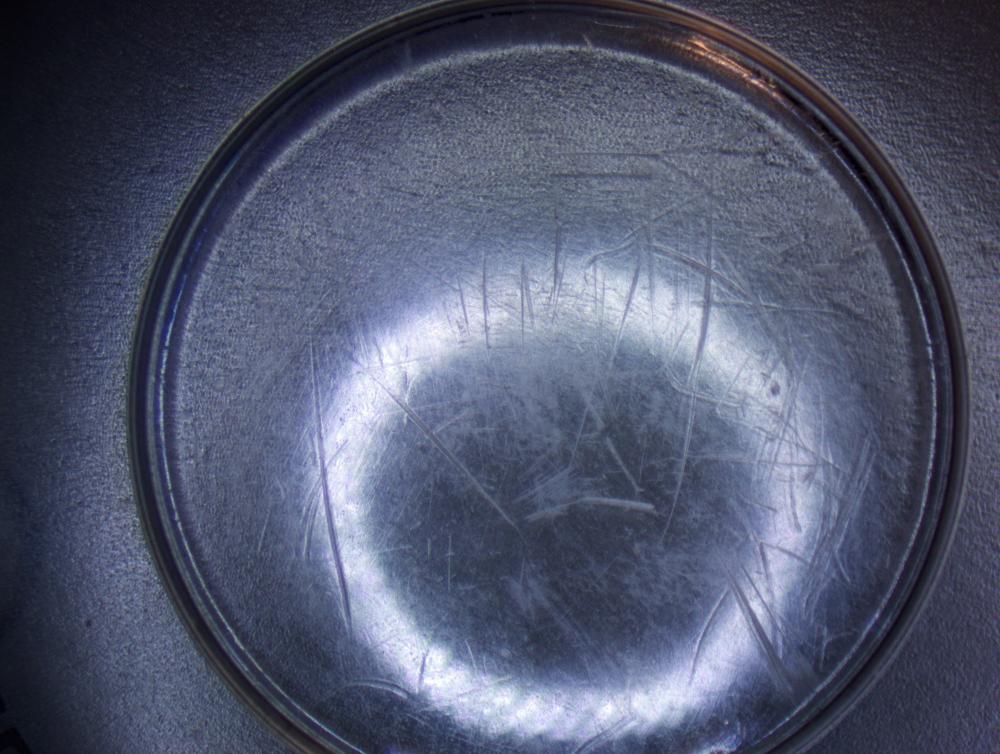

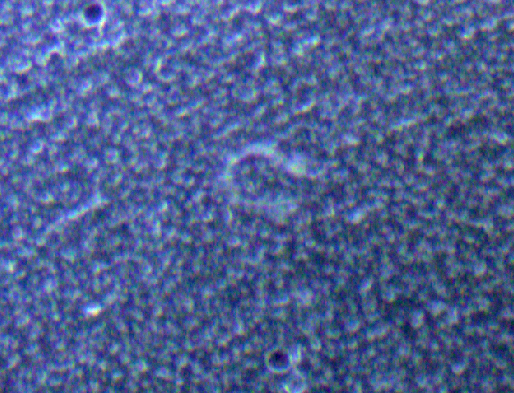

Just a little update. The movement is back together and running nicely after lots of fighting with me. Tonight was case prep. Wet sanded the crystal with 400 through 1500 grit, ran in on a polishing wheel with red rouge, then finished with automotive headlight polish. It's my first time working out scratches this deep, and I have to say it was a lot easier than I expected it to be. Edit to note that what I thought was a tiny blemish I missed in the center is actually an Omega symbol! ENHANCE1 point

-

I have never had a problem with it leaving marks but I never use lacquer on plates, if the lacquer is good I just clean if not then I remove it but early movements are not lacquered I use Renaissance wax on most movement parts , but I polish and lacquer base, pillars and pendulum if customer wants it done. Dell1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)