Leaderboard

Popular Content

Showing content with the highest reputation on 07/11/24 in all areas

-

Borkulating a hair spring is a rite of passage. We've all done it. Several times.2 points

-

My humble addition for those few who don't have a Witschi: current Version of free PCTM will measure and show the beat rate, too Frank2 points

-

I am not sure if heat deforms pivots when doing this, so I try to carefully apply heat to the collet only. Nail polish is the safest I know of, have not seen any sign of chemical damage to the metal by nail polish applied 50 years ago.1 point

-

Hello everyone I just joined since I'm getting started on my watch repair journey. I've been gathering some old non-running watches off ebay that I liked the look of, nothing really expensive and I've even gotten a few of them back up and running. Mostly been doing old Seiko 5 watches, some old soviet stuff and just anything that catches my eye really. I'm located in Iceland which makes this all more expensive since shipping tools and parts here often doubles the cost but I think money spent on your hobbies is usually well spent.1 point

-

Not just the hairpsring , but the pivot must be cleanest with no adhesive on it. 1- I smear a bit of shellac on base of the pivot, 2-Let dry, 3-Shave off ( with safety razor blade) any shellac that's not where its suppose to be. in case any adhesive has got on pivot, clean entirely and try again. 4- Press the collet onto the pivot, make sure no shellac has got on the wrong part, 5- Apply heat ( soldering gun) to the collet, until shellac re-melts, the melted shellac fills all available cavities. You can also steal nail polish from the lady and follow the same procedure except no need for heat. Nail polish does not damage metals.1 point

-

There are a handful of confusing specs in the listing. I printed it as a PDF as insurance, because it does technically state all the things I'm after save one (transparent case back), and the alternative is vanishingly rare among the mechanical versions. If any of the options don't show up as expected, I have Ali-X's buyer protection, PayPal's buyer protection, and my CC buyer protection all stacked up. This will be the first truly new watch I've bought in nearly 20 years. I bought a new old stock watch when my daughter was born, and that may or may not count...1 point

-

I thought about fitting it to compound but decided to fit it to a non tip over tool rest , I have since made a dedicated tool rest for it because I also use the solid tool rest for the saw table so now I don’t have to keep removing them. Dell1 point

-

1 point

-

I check alignment of hands at 12, 3, 6 and 9 o’clock just because it seems to make sense to me, ymmv. Tom1 point

-

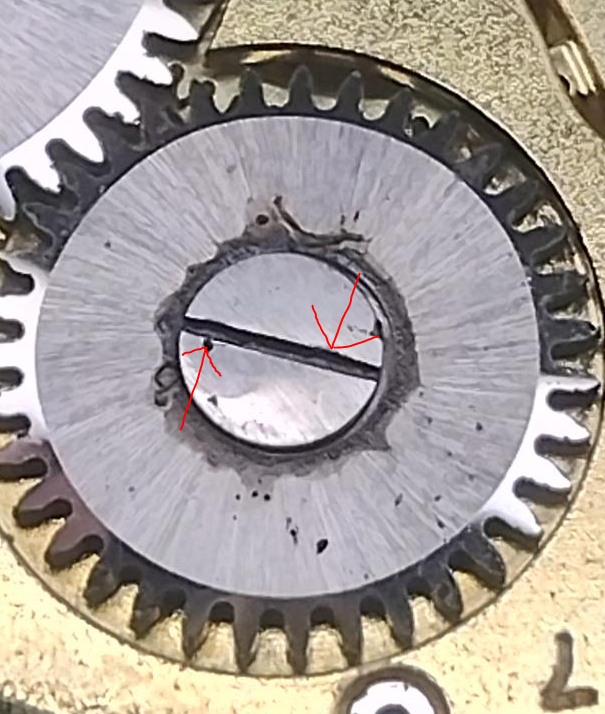

You could put some penetrating oil on the setting lever release and between the crown and case. yes the crown wheel should be anti-clockwise, but also looks like there may be some rust on it, as I suspect there is water ingress from the crown.1 point

-

My point is (and I've just done more tests to verify this) - IPA does not work well as an oil or oil residue remover. It's probably not removing the dried residue from the initial wash. I tried the adjacent drops test again, with 3-in-1 oil and IPA, and the two do not mingle - it gives the same very clear line where the two are in contact. Ethanol, by comparison (denatured alcohol) flows in to the oil and dissolves it. I'm not saying you should use the commercial cleaners; what I'm suggesting is stick to lighter fluid only for both initial clean and rinse, or rinse with ethanol rather than IPA. Or start with paraffin / lamp oil & rinse with lighter fluid? The IPA probably works OK if the movement is pretty clean to start with, but if there was a lot of old oil the initial lighter fluid wash probably left a small amount of gummy residue, that the IPA never removed. (I admit I was surprised with the effect of the change to different cleaning liquids, and now even more surprised when I tried that test with the drops and found the IPA just did not mix at all!) I'm going to try other fluids such as paraffin & see how it compares to the commercial stuff, as that is far cheaper - £12 for 4L locally, or £36 for 20 litres (as Kerosene) on Amazon, compared to the dedicated watch cleaner at around £10 per litre.1 point

-

Looks like the stem was removed in the wind position where I think these need to be removed in the set position.1 point

-

The pin that holds the stem in position is resting on the stem's winding square. I had to put my sunglasses on, but once i did that i saw it straight away .1 point

-

1 point

-

1 point

-

This is OK, but have in mind that every time when the balance is replaced and the free oscillations test is not OK, one should not simpy conclude that the balance is not good for this movement. The good watchmaker will start investigating what is the reason, the same way if this is watch with some problem and the problem has to be diagnosed. Usually some slight adjustment is needed to bring the things to normal, but one will never know what to do if He doesn't know what is the specific reason for the specific problem. In case of balance, the usual reasons are incorrect free plays in bearings - radial and axial, balance rim rubbing on something (pallet cock, cetner wheel...), balanse arm/spokes touch the regulator or hairspring stud, the bottom of roller touches the main plate, all the hairspring caused problems... So one must put the loupe ont His eye and observe and investigate the balance behavior and all the critical points that may cause problem. There is a way to test and confirm/exclude all the possible reasons. Gaining experience and knowlages about the pivots/stones, hairspring, escapement function and behavior eases the process alot. Untill then You can ask here what to check next and You will receive good advice. OK, leave the watch alone for some time. When You decide to start again, You can count on support here.1 point

-

We will be interested, please post in the relaxed zone or watch industry. Tried a quick Google and didn't find any information. If anyone can provide you with the machine, cost's can be discussed by PM.1 point

-

I guess you could "just" calculate what the frequency is. Using the number of teeth/leaves on the individual wheels going back from the cannon pinion to the escape wheel.. Or take your phone and make a "super slow mo" recording so you can count the number1 point

-

If they both measure exactly the same what happens if you try to put the old staff back in? Then at one time Hamilton did have replacement blued steel hubs.1 point

-

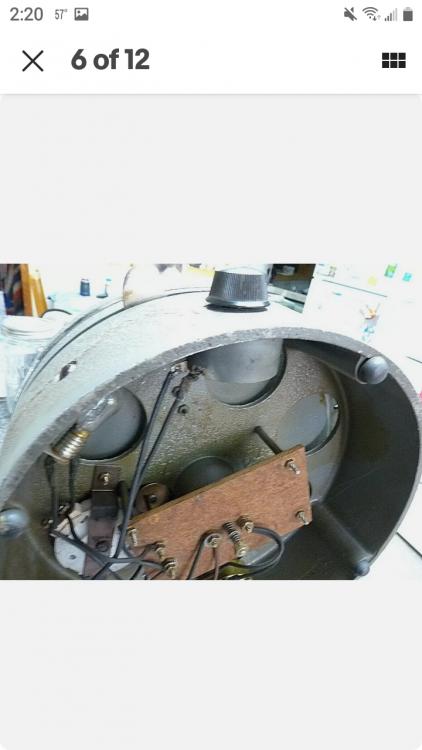

Thanks for that clarification. I'm a newspaper journalist in nearby North Platte, NE, and my late father was an electrical engineer specializing in capacitor design for Goodall's successor firms TRW and ASC. I can tell more about Robert Goodall's impact on the world of inventions as well as during World War II if anyone's interested. Good luck to you.1 point

-

Happy to oblige. This lists calibres. Hope it is what you want. https://watchguy.co.uk/cgi-bin/lift_angles1 point

-

Hello. I just joined this forum because I spotted the posts by both MechanicMike and Dalich. The Good-All watch repair machine was made in my hometown of Ogallala, NE. I don't know whether Dalich has the machine, but if so and Dalich still doesn't want to keep it, I would be interested in acquiring it to donate to my hometown museum if the cost isn't too much. It certainly doesn't need to be in operating condition. Please let me know! Thanks.1 point

-

1 point

-

When talking lighter fluid we usually mean some type of processed naptha, distilled. A petroleum based chemical that acts as a solvent. IPA also known as Indian Pale Ale is alcohol based.1 point

-

1 point

-

I pull up the tailstock and use the sleeve as a guide for the pinvice to rest inside. Its loose but keeps it in the ballpark and feel does the rest.1 point

-

Well, it’s been bugging me all week. So today I thought I’d give it one more try to shift the collet counterclockwise to shorten the hairspring while still maintaining enough room on the stud carrier to make beat error adjustments. Happy to report that I was able to get things sorted out to an acceptable configuration. While the stud carrier that adjusts the beat is pretty far over, there is enough room left for andditional adjustments if ever needed. The most important thing is the hairspring was shortened enough to allow proper setting (the picture below shows the setting at 0 beat error and about ~+/-20 secs/day). again, thanks for all of the great advice. .1 point