Leaderboard

Popular Content

Showing content with the highest reputation on 07/13/24 in Posts

-

5 points

-

Alright, final update on this thread. And it's good news. I managed to find a vintage crystal by Robur wherr the tension ring is much smaller. Internal diameter 32mm (up from 31.2 with the Sternkreuz). Consequently, it doesn't touch the 31.7mm dial. AND the screw down back now goes in fully with no problems. Solved.4 points

-

Just to complete this thread - I got it all working. Runs well, good amplitude, accurate. Self winds. Date changes over at midnight. Chrono works as it should and all resets to zero. I learned a lot.3 points

-

3 points

-

A Gruen 510SS - I serviced the movement ages ago but was hoping to find a replacement case, as the original has been just about worn to death! No case yet, so reassembled; it's a nice wearable watch regardless! And a Waltham 1908 series with the worst impact damage I've seen inside a movement! I got three similar non-running Waltham movements on ebay; two plated and one brass. One of the plated ones tries to run & looks like it just needs a service, so no challenge. The other had a visibly very bent escape wheel! I though initially someone had used it for a donor and swapped parts in, but after examining it in detail it looks like it had been dropped - the lower pivots on the balance and pallet fork were broken as well, a pallet jewel shattered and several other cracked jewels! I never realised so many jewels could be damaged in one go. I can only guess that impact angle was straight in line from the balance through the fork and into the escape wheel. So far I've replaced all the damaged jewels, and with the escape wheel from the brass donor the escapement now seems to work as it should. I've not quite got the balance wheel as free as it should be yet - and with both this and the donor, the minuscule screws that hold the hairspring studs to the balance cock seems to have evaporated during the cleaning (And everything needs another clean after the jewels and alignment are finished). One of the replaced ones - this is why I got the Chinese jewel press!2 points

-

Placed a lowball Best Offer and to my surprise it is heading my may. Ok, not the 404 price. But I thought practicing on a Swiss wind up without complications might be a useful and rewarding exercise for a newb. I gather Belforte was a lower price point Benrus. Screw on back so it is not one of "those" I read about. More for practice, learning than for wearing.2 points

-

Screws may look to fit initially,head size, shank and thread diameters. But a lot to do with the thread can affect how compatible it is with it's joining thread. Different thread angles can make a tight or loose fit but the big one is making sure they have same pitch, get this one wrong and a turn or two in you think its ok, another turn and one or the other is going to begin stripping back and its nearly always going to be the one thats the hardest to fix. A well fitting machine screw should only need a light touch to be driven in, no force at all required.2 points

-

The dial and hands on the Gruen look absolutely stunning. Had it been in a stainless steel case I would have tried to find a copy. These days I stay away from all plated cases. I don't know how to restore them and I'm honestly not that interested in learning it.2 points

-

The screw in question is part 33.020.01. Have you carefully compared the screw you’ve used with the picture of this part in the tech sheet linked above? If you’ve accidentally used a similar but incorrect screw, it would explain the problem. For example if the screw you used is a bit long, it could be bottoming out before it holds the part down securely. It is hard to suggest what to do until you know whether you’ve used the right screw, and if it is the right screw, why it isn’t holding the part down correctly. EDIT : I missed that the original screw was missing. Given you found a random screw that fits, but doesn’t work correctly, I suggest you work out why it doesn’t work. If the screw is too long and bottoming out before it is holding the part down properly, then consider stoning down the screw until it works. Study the screw from the parts sheet and compare it to the one you used - are there any obvious differences? Hope that helps, Mark2 points

-

Both sides of the Gruen case are very badly worn, the lip around the case back has completely gone at both sides. I did get one "Gruen 510" case but it's a different style & needs a smaller dial. I'd rather keep the original, as it does look so good. It's got a rounded edge, and the hands are shaped to follow the edge curve.2 points

-

Hi all. Engineer (the B.Sc.E.E. kind), 59 years old and living in Denmark. One day while searching AliExpress for an electronic gadget I came upon a strange round technically looking object of a clearly mechanical nature. A 'movement'. Besides being involved with embedded software (which is as close to 'real world' you can get in that context) I happen to be interested in mechanics. From Lego via car-repair to 3D-printer modding - it's fun to tinker and gain an understanding. That movement sure looked interesting... This was three months ago. Last week I assembled my first NH38-based watch from pre-made bits bought off of AliExpress. And I have more stuff coming. This time the aim is disassembly-reassembly of a cheap 2813 movement to learn the ropes. Because I'd like to be able to service my own little collection of mechanical watches, acquired over the last decade or so. Surely I'll get myself into trouble - that's where you learn the most, wiggling yourself out of a tight spot. I'm here to read and - when things go pearshaped - ask for knowledge and direction Let the festivities begin!1 point

-

Yeah please come back and update us on this one. I haven't seen a dial like this on a 21j before. I'm wearing my black one (not the two tone) today. It's picked up a lot of wear in the 5 years I've had it. I put it on a couple times a week and it is legitimately rugged and waterproof. Now that I have accumulated a few mineral crystal scratches, I'm thinking about fitting a sapphire from alix. I will eventually get the blue and red bezel model too.1 point

-

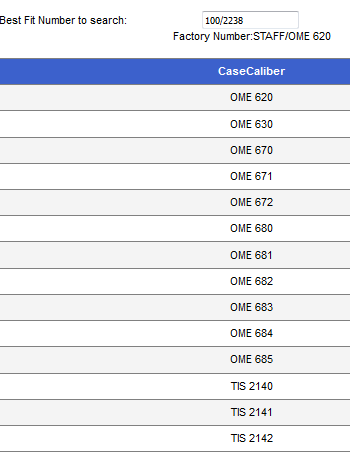

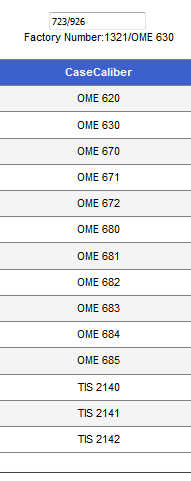

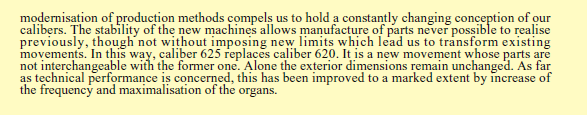

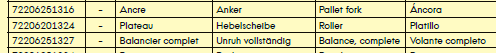

What's interesting with the Swiss watch industry is the perception that for instance Omega would make 100% of all other parts? For instance here's a link to the YouTube video the company's been around for how many years? Now as you can see everything it has a CNC and their making watch parts for who exactly what how everybody in Switzerland probably. So yes conceivably all kinds of parts found in the watch have been outsourced to other companies. https://youtu.be/6Skc3QGISCA?si=Qf7D01fVDdUFx0Ku So I did this a little bit different I looked up Omega 620 and wind up with two separate balance staffs? Then if I look at the reference for 625 balance staffs once again there's two of them but I suspect they're probably identical even though the listing below says there are different? But in real life there supposed to be one staff the reason for this is an off to go to the best fit online would be the 100 number would be the generic best fit and the 723 number would be for Omega original. But they both should be identical. The problem sometimes with aftermarket balance staffs are they may not actually be identical. This is why when replacing balance staffs you need to use a micrometer and measure the old versus new preferably before you start to assemble and then discover there's a discrepancy. OME 620 100/2238 STAFF/OME 620 BESTFIT BALANCE STAFF OME 620 723/926 1321/OME 630 GENUINE BALANCE STAFF Okay I'm having a confusion? Currently I'm on the best fit site and I wonder verifies of staffs you really do cross reference here and they don't? Okay let me look up the 625 parts Okay this is weird for the 625 parts there are no balance staffs listed at all not a generic or an original? Okay let's look up cross references the parts such as 100/2238 Now we have an interesting problem I'll just copy and paste Not expect anything different but let's look up the other reference number Tech sheets can be fun can't they? So the initial 620/625 tech sheets and looking as it does not reveal anything of use and I did not see a balance staff at all. But further searching in the computer revealed a new verse 625 tech sheets with an interesting paragraph Man I found I have a much much newer 625 parts list one that of course every single corner is watermarked so not that I give it to you but it does confirm that for the most part all the parts are unique to the 625 and of course there is no balance staff but there is a roller with the interesting part number So it does look like the roller table interchanges with the 620 but as we don't have a balance staff number and nothing else is now confirming? I thought I'd look in the bestfit physical book itself but it only shows the 620 because the 625 is after the books were printed. I am guessing that somebody made an assumption that the 625 is more or less identical to the sixth 20 and didn't read the one technical sheet that I quoted up above where the most part it is not. It's one of the problems of the technical reference material where this stuff was readily available into the 70s and then when the watch companies got well hate us all the amount of technical information available to us dramatically shrinks. Out of curiosity why did you need to change the balance staff? Then you do have to be careful in that the 620 versus 625 for instance a running at different frequencies which means the balance completes are obviously not going to be the same and even some of the subcomponents conceivably I didn't look the roller tables may be different but the reference I'm looking at says both balance staffs should be the same. 723/926 STAFF, INCABLOC 1321/OME 620 http://cgi.julesborel.com/cgi-bin/matcgi2?ref=[^]D`FY 100/2238 STAFF, INCABLOC http://cgi.julesborel.com/cgi-bin/matcgi2?ref=U\ZDYFVM1 point

-

4 oscillations, 8 beats/second. So we are looking for 200 beats of the hairspring or 25 seconds to indicate good low friction of a balance. An 18,000 vibrations / hour movement would last 40 seconds for 200 beats. I often see around 1 minute to dead stop1 point

-

Final update on this: I sent the damaged movements back, and he sent replacements. Didn't wait for the first pair to arrive, and actually sent the replacements before I was able to even get the first set in the mail. Not really here or there, just a detail. The replacements arrived in much better shape and well within spec. In fact, the 7750 seems to have been hand picked as an especially tight example. It's reading +/-1.5s/d. WELL within chronometer spec. Looking back, I see I neglected to mention the seller's reason for non-response. Small shop, and he was flying solo. Couldn't keep up with everything. After he got back to me that most recent time (I assume the other shop helper had returned), responses were very timely. Ultimately, this worked out well. I will likely buy more from the seller, as he has stuff I haven't seen elsewhere and at pretty decent prices to boot.1 point

-

If I understand the tracking info, it just made it stateside. https://www.aliexpress.us/item/3256807066408888.html?spm=a2g0o.order_detail.order_detail_item.4.4c8bf19cNb9wmE&gatewayAdapt=glo2usa The listing states that it is 40mm mostly, but also says 38mm (the other size they come in) in a place or two. I'd definitely prefer 38mm to hopefully not have a plastic spacer in there, but I guess 40mm is more popular to the point that you have to go up a ways in price past whatever arbitrary limit my subconscious has labeled "throw away money". It says it has a sapphire crystal, but also says mineral glass and acrylic in a place or two. It says it has a gooseneck regulator, and doesn't say anywhere that it DOESN'T have one... What it doesn't say that has me slightly concerned is whether or not it has a transparent case back. There's a(n undoubtedly stock) photo of the profile where you can see the back crystal slightly elevated over the case back, and that's about all there is on the subject. Additionally, it's vanishingly rare to find the mechanical version WITHOUT a transparent case back. Hopefully, that's enough in the event I need to file a dispute. I printed a PDF of the listing as I hit "buy" in the event it changes between now and then. Finally, I have Ali-X's buyer protection, PayPal's buyer protection, and my CC's buyer protection all stacked up. It's a gamble, but I think the odds are more or less in my favor. It'll probably be lacking SOMETHING (i.e., I'm pretty sure it won't have a gooseneck regulator at a minimum), but it will hopefully be substantially what I ordered. Meanwhile, I've not seen where the "swan neck regulator" is cosmetic. How are they accomplishing that? It's hard to imagine something with the appearance of such a thing being somehow cheaper than the actual thing. It's not like that micro-amount of spring steel is very expensive, and I can't imagine there would be any labor savings installing one vs the other. Regulation would be EASIER, and thus likely cheaper with the swan neck, so that doesn't seem like the juice would be worth the squeeze... In other news, I threw down on a passel of 1010s the other night. Snagged one so far. Two still have a day or so to go. The one I got is OK. Fully jeweled, all stainless, Swiss (AS movement, IIRC), etc. I'll post photos in the thread when it gets here. One of the still-pending 1010s is almost certainly not coming my way, but it'd be awesome if it did. The other is still in 404 territory, and it'll probably come my way.1 point

-

I think the key point learnt here should be not to just use any random screw that seems to fit. Moving on, the question would be as per @Mercurial is have you got the correct screw now and how does it compare to the screw you used.1 point

-

1 point

-

I could be mistaken, but I believe they're numbers from the German supplier "Flume".1 point

-

There was a Smiths A453 Antarctic for sale in October 2020. It was discussed on one of the forum sites (possibly NAWCC) as being too far gone for repair due to water damage to the movement, dial and hands, and the degree of wear on the case. I found the post after I had bought the watch. If anyone happens to recall it and can find it, it would be a very useful comparison to this post because I forgot to take any 'before' photos, however, there were deep scratches in the main body and the lugs were completely worn through. I attach repair and 'after' photographs showing what the watch looked like after repairing the damage to the case and now following replating. The other photographs show a case back which is made of brass and was originally gold plated. It had worn through completely at one point and had serious pitting corrosion. No 'after' yet, but a photograph taken just now - this has been repaired and is ready to be polished and plated. The Gruen case is definitely repairable. Alec1 point

-

1 point

-

The dial and hands on the Gruen look immaculate, could the case be replated or is it too battered? I've never seen an escape wheel look like that.1 point

-

I use a rust remover made from 5g EDTA powder in 100ml deionised water, plus a drop of washing up liquid (dish soap). It's not fast, but it does not affect the base metal. These are some bits I've just done, from an old wooden case I got to store some watchmaking tools; before and after an overnight soak. The residual light brown marks are from me not drying them properly (plus the box was originally varnished after the latches were added). I use the same mix on watch parts and old tools, and it works equally well:1 point

-

If You remove it, probably will find that actually the original catch doesn't work. Leave as is and use it.1 point

-

May be this needs some deeper explanation. What I writed is exactly what I mean - 100 oscillations. Yes, the number 100 is dependant on the type and size of the balance. If it was good quality pocket watch balance, the number should be 200-250. But here we have small size wrist watch and the number is about 100. Why not time, but oscillations? The idea of this whole thing is to determine the Q-factor of a resonant system. The balance is a high quality resonator and it has Q-factor. We don't need here theoretical measurement like Q=3022 for example, but practical way to realize if the balance as resonator is good or has problems. Such simple way to evaluate Q factor is the number of free oscillations as a result of charging the system with measured portion of energy. That's why I say 180 degr - this is the measured portion of energy we give to the system. Not just puff with air. Specific measured portion of energy, which will be relevant for all sizes and types of balances. Then we count the oscillations. For sure, it wiil be the same effect if we measure the time, but it will be true only if the frequency is always the same. But no, there are alot of different frequencies (different BPH of different movements) For example, If You put some weaker hairspring on the same balance wheel, the Q-factor is not expected to change much, as the main loss of energy in the system is thru the bearings of the balance. If You do the free oscillation thest, You will see almost the same result as oscillations count, but time may be for example twice longer than what it was with the first hairspring, as the frequency is reduced due the weaker hairspring.1 point

-

The shoulders on the stem are square not bevelled, so you have to push the setting lever button to reinstall.1 point

-

After reading through this thread and some others, I purchased a setup to replace the small fixed-magnification dissecting scope that I had been using. I bought a black "3.5X 7X 45X 90X Simul-Focus Parfocal Trinocular Stereo Microscope Head" from AliExpress for $143 shipped to the U.S. - this is just the microscope, eyepieces and a 0.5X Barlow. I then scanned Ebay for awhile until I found a good deal on a used heavy-duty pin-mount stand that set me back another $145 but was cheaper than a new one from Amscope. This design allows perpendicular angled-view mounting and slide-out storage to the side which works with my fold-down work surface. I already had a circa-2016 3.2 megapixel microscope camera which is now mounted with a 0.35X focusable C-mount adapter. As discussed here, this gives a good working distance while the field of view for the camera and the eyepieces matches very well. So, thanks to everyone for sharing your experiences good and bad and helping the rest of us more easily navigate the process! Pictures (taken without the camera or lighting set up) shows it stowed and then extended. I needed a bit of ballast on the base of the stand, so my case opener has a new place to live!1 point

-

Well this is very interesting, I've always thought that IPA is a strong solvent not only for watchmaking. We do have loads of Ethanol at work I'll get some and start cleaning with it instead of IPA and see the results. Ok I'll take this note in consideration, we have an RO water treatment unit at work so I can get as much I want.1 point

-

If you are using the naptha and IPA method of cleaning, which can produce good results, there needs to be a rinse between the naptha and the IPA in distilled water. That will get rid of some of the problems of the naptha sitting on top of the IPA, which will coat the parts as you pull them out.1 point

-

1 point

-

Hi Ammar, If You need real help, You should do what @RichardHarris123 asked to do - the free oscillations test when balance is in place but the pallet fork is not, and write here the result. You must turn the balance to 180 degr. and release it to oscillate till full stop, and count the number of free oscillations. About 100 is expected when balance is OK. It is no good idea to mix the bridges and cocks, as they are actually parts of their own main plare and are mashinned together with it. So generally it is recommended to choose the movement in which the good balance came with. You can use the original movement, but then the original balance cock is to be used. Mixing hte parts sometimes leads to problems that even for experienced watcmakers is hard to find and to solve.1 point

-

1 point

-

one of things helpful to do with screws is to arrange them in groups of identical screws. Usually once you have them all together ill become apparent what at least most of them are for. A lot of the components like the pallet fork bridge will either have one or two screws and those screws will be different etc. so you usually have the bigger category the plates screws and it makes it a lot easier if things are in categories.1 point

-

1 point

-

Well, "Speak of the Devil and he shall appear". As I mentioned (somewhere) I've been on the lookout for a Steiner Jacot tool in good condition having a runner for centre wheels. Well, the wait is over. This "Zapfenrollierstuhl STEINER hochglanz vernickelt Bestzustand" (Jacot Tool STEINER high-gloss nickel-plated excellent condition) popped up on German eBay (not found if you just search for "Jacot tool"), and I was, to my great surprise, the only bidder and got it for £165/€190/$204 Usually, in this condition, they go for around $500, and there are "buy now listings" for $600-$700 and sometimes more.1 point

-

I use lever type tools (Favorite, Chatons SA, Horia) for everything, and I have several of the screw-type (micrometric) Horia tools. I just find it easier and faster for the way I work. I do push in lots of pins and tubes and such doing prototype work; I like being able to come down in contact with the lever then raise the micrometer stop to touch, then descend and push- I think there's more feel. But both tools are great. True that with a lever type tool you can ream and drill and such with the appropriate spindles too. I know many pros who couldn't live without the screw-type Horia tool; it's all a matter of preference. But if you just want to get one, then a secondhand Seitz or Favorite is a good choice. I prefer the Favorite as it uses straight sided reamers held in a collet in their spindle, and a complete set will have several collets with sizes appropriate for holding drills. Seitz uses a taper fit to hold the reamers. Horia is like Favorite, with the collet holding spindle. If you have a Seitz the Horia spindle will fit if you want to have that too- the price is reasonable, but the Schaublin P4.5 collets are pretty pricy. I also collect pushers and stumps, and often make them for special jobs as well. Pic is of the drawer for those (main workbench drawer). It's messy but I know where everything is!1 point

-

The Citizen has via a D-tour (Germany-Denmark-Sweden-Denmark) arrived. First impressions are that the watch is nearly as new. No scratches on the crystal, hardly any on the bezel and no signs of ever been opened. The movement looks untouched. However, the movement runs but has a tendency to stop. Perhaps no wonder if you see the "heavy snow in Switzerland" picture on the timegrapher ...... but this is the reason why we are here1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)