Leaderboard

Popular Content

Showing content with the highest reputation on 07/14/24 in all areas

-

Thank you so much for the warm welcome! And even a fellow Norwegian I already love this forum! My first and only little project so far was a Seiko KZ211K1 / Landshark / Atlas 7s36 movement. I have a friend who is a real watchmaker and he told me this was a pretty bad decision for a starter movement, but now I have already dissembled it so its no way back Im afraid. One of the first screws I ran into was so small you have to use a custom screwdriver from Seiko or make one yourself of your smallest one. That felt like to big of a challenge on my first hour... but I somehow managed to get it done, and It felt so good! Next step now is cleaning. I have tried to learn what chemicals to use, but I understand this is a somewhat complicated subject. And we seem to have pretty strict rules in Norway so a lot of the brands and chemicals I see online are impossible to find. I think I will start with IPA which I already bought, and maybe buy Zippo Lighter Fluid? Honestly, this movement looks so clean, which was somewhat of a disappointment. The movement would probably be a lot better off If I had just let it be. But at least now I can learn some stuff. A few things i learned: -I loved working on these small things. -The parts were a lot smaller than they looked on youtube -I need to focus on taking my time. I was rushing and making mistakes because of it. Cant wait to find another evening to work and learn!2 points

-

It doesn't seem to be a floating balance to me. If I see correctly, then You should dissassemble and clean it. And pay attention to the down side balance bearing to see if it needs some restoring. If it is a real floating balance (on a string, and hanging on the hairspring), then dissassembling it without damaging is almost impossible.2 points

-

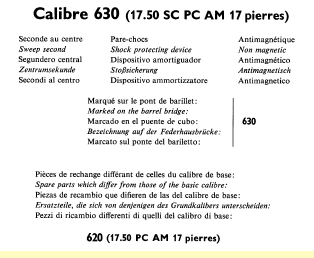

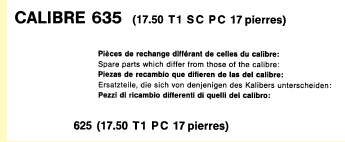

The reason I was missing was that the message board has been playing games again with my emails? In other words if I don't get an email I may not come to the message board. But this morning I was rather surprised with 19 emails going all the way back to July 11? Like they had been waiting someplace and suddenly they've all shown up? It looks like the only thing as far as the parts list is going to show is the roller table and the stem. The weird aspect is the parts list for 620 lists a staff and for the 625 it does not? I wonder if with all the exciting new changes that? One of the minor annoyances with watch companies are if you look at older technical documentation oftentimes you'll see all kinds interesting parts that have been dropped off later tech sheets because they do not expect you to for instance replace a balance staff hence the reason it's not listed here supposed to purchase a balance complete. Wonder if the doctor ever made a mistake? Then the definition a family could be interesting like their all physically the same size and that's what makes them a family. I'm attaching a whole bunch of PDFs of parts listings and one technical document the 625. If you look at all the parts lists you actually find two separate base calibers. The base caliber only list itself and the caliber that's based upon the base will reference the base caliber for all the parts not covered in the parts list. So in other words the movement based on a base caliber will only show us the secondary parts. So for instance the 630 is based on the 620 Then the 635 is based on the 625. Omega 635_1_2101.pdf Omega 630_complet_2100.pdf Omega 625_complet_2097.pdf Omega 620_complet_2093.pdf Omega 625_complet_4087.pdf2 points

-

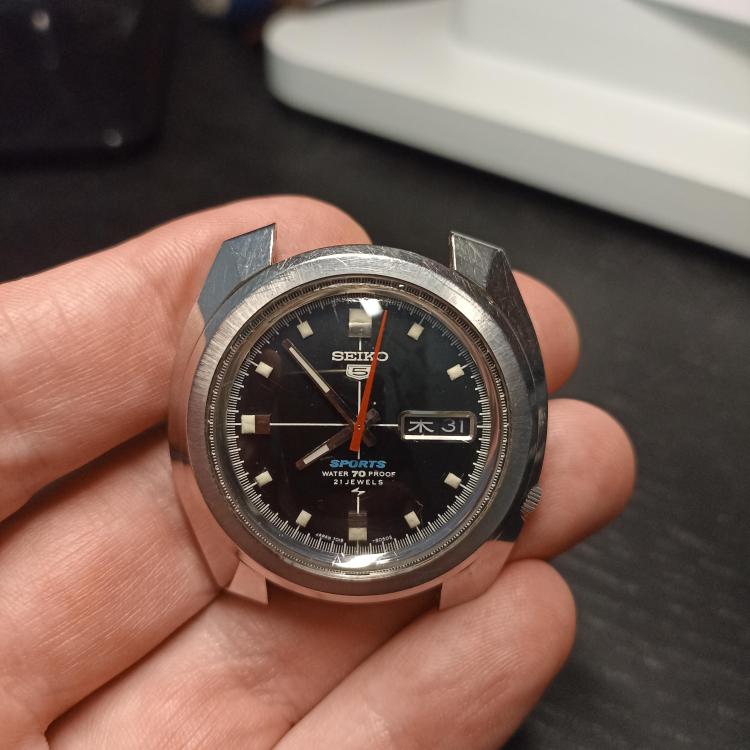

Seiko really made some interesting pieces in the 60s/70s. This one I recently acquired from Japan Very Japanese case design. 7019 movement, not running. Usually vintage Seikos are runners so it's gonna be interesting to see the reason. This one is still on the way: Very dirty and very cheap. Dial has some obvious damage but I like the rugged look. I hope the case and bezel will clean nicely.2 points

-

Bloody gorgeous looking watch MSB. Some of the Lord Matic styling has to be about the best around with funky case shapes and very unique dials. I need to get on board with these watches.2 points

-

2 points

-

Correct mark we know amplitude is the degree of travel of the balance in one direction from its rest point. I think you have the last bit wrong though. Nev suggests releasing the balance at a point of 180 ° from its rest, equivalent to a balance oscillating with an amplitude of 180°not 90° The drop of tippex on the balance wheel is not to line up with a mark on the plate as you might do with the timing of a car's combustion. The white dot is merely to make the oscillations more visible. Or maybe i misunderstand your description Mark. I can't figure out where you have 90 ° in this ??2 points

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

Hi all 40 year old guy from Norway here. I started getting interested in watches only about three or four years ago when I randomly stumbled upon a watch restoration video on YouTube. I had no idea what I was looking at, but I found it relaxing and therapeutic. I started using it as a sleeping aid late at night For the last few years I have been obsessing over watches in general. I am reading books, looking at youtube videos, reading forums and listening to podcasts. Buing and selling a lot of different seiko, citizen, and some others here and there. But now the last month or so I started to think I might want to try some restoration myself! That pushed me to buy an online course (that I got a big discount on, but wasn't too impressed by) and also watch every youtube video I could find about the subject. I also bought a few books, including "Watchmaker" by George Daniels. One of the first things I learned was that I didn't even really know how a mechanical watch really worked. I mean I thought I did, but I didn't. I still don't really understand how everything works, but Im learning every day. I have ordered SO much tools and equipment and built a small workspace in our basement. The tools range from premium swizz to temu When I find the time I want to start to practice on my own cheaper watches, before moving to some buy-to-restore projects. Hope to learn a lot from you all! -Kruttskjegg (which translates to gunpowder-beard or something1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

No, the russian (USSR) movements have the same standarts for free plays like the other watches. There is something wrong with You movement.1 point

-

Seller just dropped the price another 10% on that ST1901 chrono... $73 delivered seems insane... No telling what I find when I open that... Bag? Box? Envelope? Could be just about anything.1 point

-

Mild collector, mostly Omega dive watches. My son and I recently finished a week long watchmaking class with AWCI (fantastic experience with unbelievably skilled watchmakers. We learned a ton which only scratched the surface So NEXT WE PRACTICE PRACTICE no prctice. Have a few movements already, especially the one we learned on. Can’t wait to get my new glasses and start rolling. I’m doing this for fun, but my son (23) is exploring it as a career. And wants to go to one of the big schools like Seattle (Per recommendation) In any case, time to get to reading the wealth of wisdom here! we are in the north Atlanta/Roswell area Note that I also have a vehicle addiction (land rovers, bmw, bronco), but I’m starting that culling to fund more tweezers and epilame David1 point

-

Restoring plated cases is certainly not a commercial proposition. In a way, that's why I have had to do it. Many of the watches I am interested in come from an era of plated cases so I would be very restricted if I stayed away from them. If it isn't worth anyone else's while to fix them I end up doing it myself. This was yesterday evening's lug repair - one lug on each side was worn right through and the other was paper thin; now taken back to the correct size for a spring bar pin. Alec1 point

-

*DISREGARD this post, it’s nonsense, but I leave it in place for continuity* Don’t forget that when we talk about amplitude, we are talking about half of the full rotation the balance wheel makes in one complete oscillation from its maximum excursion clockwise to its maximum excursion counterclockwise. ie If the tippex drop on the balance wheel is moving through 360 degrees and the balance wheel is changing direction of rotation at both extremes of its travel (clockwise and counterclockwise) with the tippex drop in the same place, the total rotation of the balance wheel is 360 degrees, but the amplitude is 180 degrees. When nevenbekriev describes releasing the balance wheel after rotating it through 180 degrees, that’s equivalent to the amplitude for the initial swings of the free oscillations test being only 90**(wrong - see below) degrees. Best Regards, Mark EDIT : **this is wrong, as pointed out in the post directly below it should say almost 180 degrees.1 point

-

Just type into google tension ring crystal with round magnifier. Don't forget when buying to say if it is chrome ring or yellow.1 point

-

Thanks! You learn something new every day. I wasn't sure about the difference between a beat and an oscillation. So good to know. 2 beats = 1 oscillation. I sure will. It's going to be interesting. So far I've turned the balance near 300° before letting it go and on a really healthy balance it has been swinging for about 70-90 seconds in the horizontal positions. Anyway, when doing the test, I'll only swing it 180°. I will be surprised to see it swing for only 25 seconds or less, but we shall see. That could be because I've never tried to count oscillations and only assumed it would be impossible or difficult. Anyway, let's see when I get a chance, hopefully in a month or so as I'm still on vacation and far, very far, from a workbench. Here's Kalle Slaap doing the kind of test that I do (start at 12:30). An interesting observation is that when Kalle starts the balance towards the end of the video at 14:40, it oscillates for about 50 seconds before the video ends. It is difficult to judge whether the balance swings more than 180° at the start, but it looks like it could be close to 180°.1 point

-

1 point

-

Hi all. Engineer (the B.Sc.E.E. kind), 59 years old and living in Denmark. One day while searching AliExpress for an electronic gadget I came upon a strange round technically looking object of a clearly mechanical nature. A 'movement'. Besides being involved with embedded software (which is as close to 'real world' you can get in that context) I happen to be interested in mechanics. From Lego via car-repair to 3D-printer modding - it's fun to tinker and gain an understanding. That movement sure looked interesting... This was three months ago. Last week I assembled my first NH38-based watch from pre-made bits bought off of AliExpress. And I have more stuff coming. This time the aim is disassembly-reassembly of a cheap 2813 movement to learn the ropes. Because I'd like to be able to service my own little collection of mechanical watches, acquired over the last decade or so. Surely I'll get myself into trouble - that's where you learn the most, wiggling yourself out of a tight spot. I'm here to read and - when things go pearshaped - ask for knowledge and direction Let the festivities begin!1 point

-

And here is the disassembly video. Once more any remark on something I can improve is more than welcom1 point

-

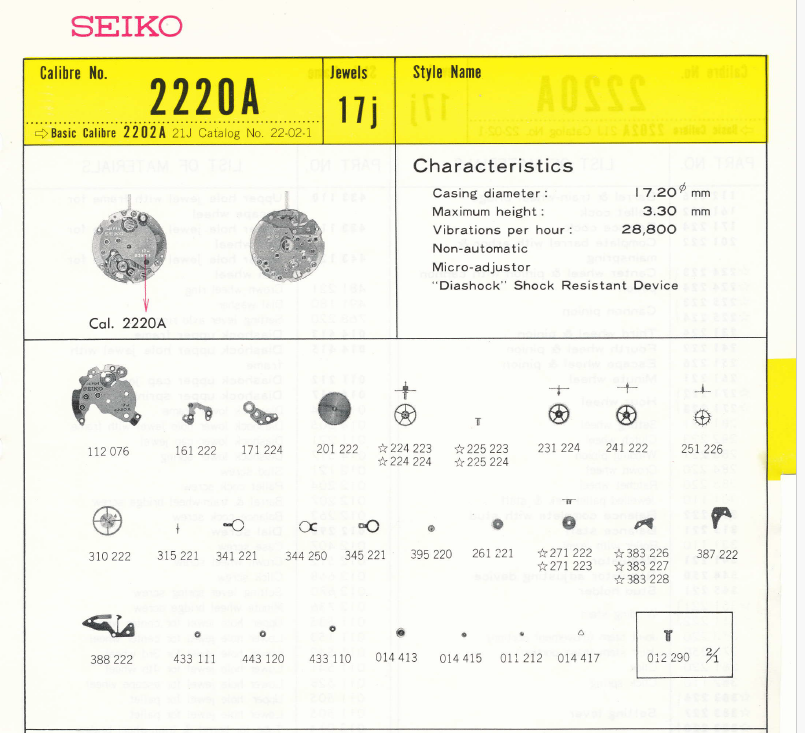

620 is not the base calibre for the 625 as shown by @JohnR725 as this is a completely independent movement. A base calibre is one that is then modified to create a new calibre as an example shown below. The base calibre here is the 2202A which is then modified with the parts shown to create the 2220A1 point

-

One point about my commentary in the video which is done at the time of disassembly (not added afterward). I didn't prepare anything (hence all the hesitations) and the audience is a supposed to be both knowledgeable people from this forum but also some of my friends and family. So I hesitate between explaining things which will be obvious to all of you and things which will make no sense to my family and friends.1 point

-

1 point

-

Final update on this: I sent the damaged movements back, and he sent replacements. Didn't wait for the first pair to arrive, and actually sent the replacements before I was able to even get the first set in the mail. Not really here or there, just a detail. The replacements arrived in much better shape and well within spec. In fact, the 7750 seems to have been hand picked as an especially tight example. It's reading +/-1.5s/d. WELL within chronometer spec. Looking back, I see I neglected to mention the seller's reason for non-response. Small shop, and he was flying solo. Couldn't keep up with everything. After he got back to me that most recent time (I assume the other shop helper had returned), responses were very timely. Ultimately, this worked out well. I will likely buy more from the seller, as he has stuff I haven't seen elsewhere and at pretty decent prices to boot.1 point

-

I use a rust remover made from 5g EDTA powder in 100ml deionised water, plus a drop of washing up liquid (dish soap). It's not fast, but it does not affect the base metal. These are some bits I've just done, from an old wooden case I got to store some watchmaking tools; before and after an overnight soak. The residual light brown marks are from me not drying them properly (plus the box was originally varnished after the latches were added). I use the same mix on watch parts and old tools, and it works equally well:1 point

-

May be this needs some deeper explanation. What I writed is exactly what I mean - 100 oscillations. Yes, the number 100 is dependant on the type and size of the balance. If it was good quality pocket watch balance, the number should be 200-250. But here we have small size wrist watch and the number is about 100. Why not time, but oscillations? The idea of this whole thing is to determine the Q-factor of a resonant system. The balance is a high quality resonator and it has Q-factor. We don't need here theoretical measurement like Q=3022 for example, but practical way to realize if the balance as resonator is good or has problems. Such simple way to evaluate Q factor is the number of free oscillations as a result of charging the system with measured portion of energy. That's why I say 180 degr - this is the measured portion of energy we give to the system. Not just puff with air. Specific measured portion of energy, which will be relevant for all sizes and types of balances. Then we count the oscillations. For sure, it wiil be the same effect if we measure the time, but it will be true only if the frequency is always the same. But no, there are alot of different frequencies (different BPH of different movements) For example, If You put some weaker hairspring on the same balance wheel, the Q-factor is not expected to change much, as the main loss of energy in the system is thru the bearings of the balance. If You do the free oscillation thest, You will see almost the same result as oscillations count, but time may be for example twice longer than what it was with the first hairspring, as the frequency is reduced due the weaker hairspring.1 point

-

Not all balance completes come in same grade, but different material and workmanship. You might pay different prices for two balance completes of same caliber to same supplier. An ETA 2879 can be had for 20 bucks, but you probably pay 200 to 250 bucks for an ETA 2879 which comes in a Tudor, as Tudor's is likely to be COSC approved. Workmanship, however , can get real expensive, a master watchmaker may have a watch on bench as long as two weeks to adjust its escapement in six positions. The price usually introduces the grade, some chinese balance completes probably won't qualify for lowest grade. Rgds1 point

-

I think this is what you're looking for. https://www.ebay.co.uk/itm/285205175491 Edit Presuming it's a 212.30.44.50.01.001 and Case Number is 178.0528 Actual Part No. 086CC0217 so orignal eBay listing may not be correct. https://www.ebay.co.uk/itm/1960684322441 point

-

Im not sure if they are legit yet...The only reason I think this was because I was going to buy a Sellita SW200-1 Mechanical Movement. But it seems the movement usually goes for around 180$ but im seeing it on sofly for 135$. I dont know if this is a major dip in price, still around that price. I guess im just worried im not going to get an authentic swiss made movement.1 point

-

This is OK, but have in mind that every time when the balance is replaced and the free oscillations test is not OK, one should not simpy conclude that the balance is not good for this movement. The good watchmaker will start investigating what is the reason, the same way if this is watch with some problem and the problem has to be diagnosed. Usually some slight adjustment is needed to bring the things to normal, but one will never know what to do if He doesn't know what is the specific reason for the specific problem. In case of balance, the usual reasons are incorrect free plays in bearings - radial and axial, balance rim rubbing on something (pallet cock, cetner wheel...), balanse arm/spokes touch the regulator or hairspring stud, the bottom of roller touches the main plate, all the hairspring caused problems... So one must put the loupe ont His eye and observe and investigate the balance behavior and all the critical points that may cause problem. There is a way to test and confirm/exclude all the possible reasons. Gaining experience and knowlages about the pivots/stones, hairspring, escapement function and behavior eases the process alot. Untill then You can ask here what to check next and You will receive good advice. OK, leave the watch alone for some time. When You decide to start again, You can count on support here.1 point

-

Hi Birbdad, I have ordered some ronda 585 parts and a few tools from sofly some two weeks ago, they just arrived neatly packaged, everything looks fine. At first I was somewhat hesitant to order but then decided to go for it. Result: for me sofly is a decent company. Order processing will take some time (expect at least two weeks), but wordwide shipping and even direct bank transfer works out perfect. Franky1 point

-

Time for an update. I've got a small issue with the Bengbu mov't which I'll tell later. So I moved on with the Lady one. It's powered by a ZQC marked mov't, meaning Chongqing factory. The main plate is chrome plated, that and the rough maching marks make so that isn't very nice. I will jump into some notable reassembly points. Replacing the train bridge isn't the easiest task. I have sort of developed a technique, which is to align first the seconds, then the third, and last the escape wheel, all that while applying light pressure in between jewels. The bridge doesn't really fall in place like e.g. a Seiko one, because the posts are tight, but that is the best way I could find. Not pictured the removal and reassembly of the barrel. The mainspring was easily fitted by hand. I cheated a bit and used 8301 in the barrel and on the arbour, it's metal to metal and may benefit from that. In this execution the click has a thin spring, which engage the pointy cut on the click. But in my case the lower side was actually better polished. Small detail, the 7 same screws have a nice chamfer and reduced diameter on the tip, which makes easy to refit them. They are however very fragile, it was enough to drop the screwdriver while wedged into the slot to snap one. Fortunately i was able to pull it out cutting the stump a bit with a thin saw, and the size is the same as a 7S26 screw. The rest of the reassembly proceded quickly, as the design is very optimized and rational. I was rewarded with an excellent result on the timegrapher, stable and solid across positions. The jump is because I moved the stand. To be concluded.1 point

.thumb.jpeg.41675e4c379a83213ccf286a123c75bc.jpeg)