Leaderboard

Popular Content

Showing content with the highest reputation on 07/17/24 in Posts

-

3 points

-

@Neverenoughwatches unfortunately Rich I had to hand it back to stores when I left the unit. Watches for issue were always in short supply, there are fewer genuine issued watches out there than you would think. They are decent quality robust watches which do what they say on the tin, a real grab and do anything watch. I bought a MWC version for myself a few years ago, the one I posted above, a limited civvy edition with T25 tritium tubes. I also had a spec ops specified one which is a kinetic hybrid With T100 tritium tubes. I gave it to my son in law who promptly gave it to my daughter when they split up. I don’t think it was fancy enough for him as instead he kept the somewhat trashy skeletonised watch I gave him. I suspect that he didn’t realise that the real military spec watch cost more than 4 times what the bling did. These were both rated for 10 years battery life, my newest one is a 2018 batch so will see if that holds up. a piece of trivia on these, although issued with a grey NATO strap very few of us wore them on that, certainly in the units I served with. Generally we used a leather Bundt style strap with a pop button cover for the watch head. This was for protection mainly as you were fiscally responsible for any damage to anything you signed out of the G1098 on a form G1033. IIRC for a watch to be issued to you the G1033 had to be countersigned by the officer commanding your unit. Tom3 points

-

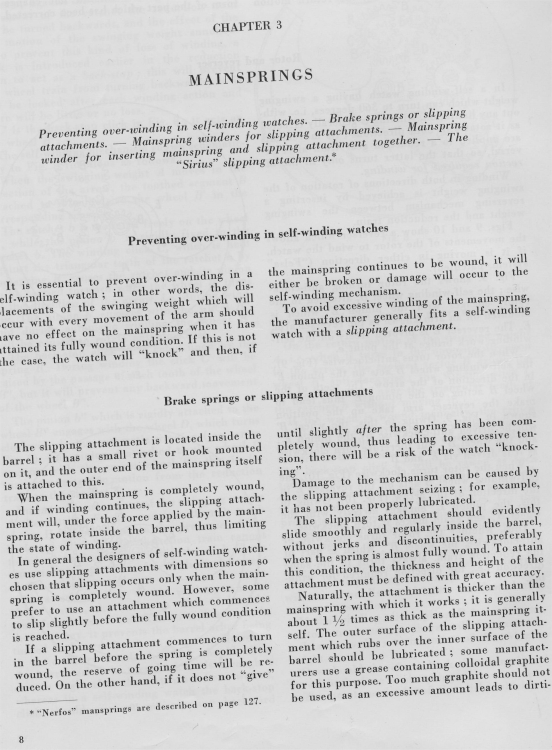

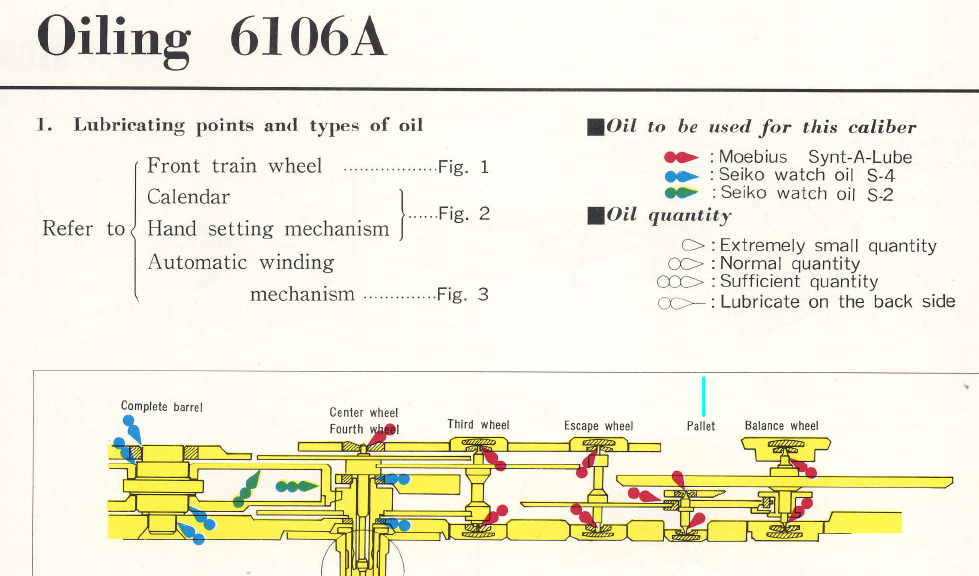

Stuff like this becomes very subject to the person doing of the test. In the case of Seiko is we get a interesting problem of the original spring usually have a much heavier bridal which in itself provides greater something. Versus the aftermarket which tend to be lighter and people have reported different slipping issues. Which is probably why Seiko gets away with using the grease that they use because designed it for the mainsprings they have versus the aftermarket. Okay maybe some light reading3 points

-

Thats why i ended up with four basic oil viscosities . Hmm and past party blowers and candy is probably why I've ended up with not enough energy to go to work. I see it as finding a compromise . All the different ideas seem to stem from discovering the pros and and cons of each lubrication and likely their interaction with each other from component to component. " It does this great but its not so good at that " . Then making a decision on what is the lesser of all the evils. I doubt there will ever be an all singing all dancing lube, I'm sure ones that companies claim to have developed with the use of science bluff, thats what makes money. Ive already developed one myself from pigeon poop , i just need a world renowned science geek to add his name to it.3 points

-

Let's look at weird multiparty story of my experience with Kluber P125 The first time I ever used it. It used to be at work we had a so-called head watchmaker. I was working on a Seiko automatic and I asked how to apply the nifty grease and I was given an answer. Then we used to have a really wonderful YouTube channel called perplxr. The channels still there but the videos are not and one of the videos was on how to lubricate the mainspring barrel of a Rolex watch. So Rolex uses a different lubrication and it almost looks like toothpaste in a way and it goes all the way around the inside of the barrel to me it looks super access. But later on I ask somebody worked on Rolex watches and he said yes that's how that is applied. Now the so-called head watchmaker who only worked on Rolex watches told me how to use the nifty Kluber P125 Basically the exact same way all the way around the barrel wall so that's what I did because that's what I was told. So how can you tell if you get good or bad? The purpose of the breaking grease is hold the mainspring in place until enough? Basically of wound the spring up enough that it should slip and it should only slip a certain amount. In the case of the Seiko I was doing I was winding it up and when I reached the breaking part where held to be honest I was really concerned about breaking the screw head off the ratchet wheel and very concerned about whether the breaking grease even slept at all it did but it required a heck of a lot of force so yes you can apply too much of this nifty substance and you have way more breaking up an actual slipping I was very unhappy with my vice. Fortunately the so-called head watchmaker has left us that I don't have to put up with that nonsense anymore. What's the other extreme? When I was in school I needed breaking grease it was in the instructors door or somewhere I went and grabbed the bottle I applied my breaking grease and I had a problem. Basically the exact same problem one brownish colored bottle of Greece can resemble any other bottle of Greece and this obviously was not breaking grease because when it slipped it slipped a heck of a lot. If you look at some literature on some automatic watches they will basically tell you to wind the watch up to a certain point in time where it slips and then you can let the power back off to see how many turns of the mainspring you have. Now in the absence of that we could probably work out a new theory of if you are manually wind your watch up until you hear the spring slip and allow the watch to run for 24 hours I'm assuming the watch should run at least 24 hours. If it doesn't you have a problem. But I'm not even sure of that would be 100% right because normally automatic watches don't have to run 24 hours between manual windings. So yes there is a test somewhere to wind up the watch see how much slips and then figure out if that's within the specifications of whatever we were looking at. Conveniently I can't remember where I've seen that but I've seen it somewhere in the verse It's amazing how summer comes it's beautiful and nice and this room my man is currently too darn hot. That means that well today I don't care about amplitude at least for this discussion. One of the problems with 14 page discussions is did you mention which watch this is? Because in a discussion every single watch as far as I'm concerned is unique and it be nice to know exactly which watch are we talking about. Then of course I always like to know the history of brand-new watch vintage watch was running before you service did always nice know the background history of whatever was looking at.3 points

-

3 points

-

Hmmm.... looks like a good way to destroy a hairspring. I think it could be used to oil those blasted balance jewels with the screws on the underside without removing the balance wheel. I just tried doing that last night, using my left hand to hold the wheel and my right hand to slip the oiler between the coils of the hairspring. Managed to get the oil to the jewel perfectly but while getting the oiler out from the coils, the tip accidentally touched the hairspring and got oil all over the hairspring. If it can hold the balance cock firmly enough, it can probably be used to hold the balance cock to unscrew the hairspring stud screw or unclip an Etachron stud, without having to screw the balance cock back onto the mainplate and taking it off again. BTW watchmakers must have been a bunch of dirty minded creeps. Just look at the jargon in my above paragraph.3 points

-

2 points

-

Wish I had seen that when I first started to be interested in a staking set. You don't say how much it is on sale for. A good DIY project. I had one like it. Mine had a 4mm stake gap. I made a 3mm holder for a £12 box of cheap stakes. Works perfectly. Made an extending base base and adapted some of the 4mm stakes to fit the rotation base. Even made some stumps. I'd go for it. This is what I achieved. Have a read and see what can be achieved. Just seen a set like this on ebay today, starting bid at £200.2 points

-

I certainly am - every time I look at it I think it's stopped working again as I keep forgetting the seconds tick on the subdial only!2 points

-

You need to close the gap between the regulator pins (to reduce the play of the hairspring betwee the pins). This 40 years old USSR movements are actually the most precise soviet movements ever and no mater how old, they can perform not worse than any omega for example. The only problem that they develop after many years of work is wear of the hole for the barrel arbor in the barrel bridge. Why should You replace the main spring, it is OK for sure.2 points

-

I personally like the use the word amusing for a description of horological lubrication. Somewhere in the universe is another discussion group were if lubrication was even mentioned everyone would run away hide in their bunkers until the discussion blew over because the people were extremely opinionated and of course everyone has an opinion. Then of course we bring in the Internet with lots and lots of information. Plus all the various sources of information YouTube videos for instance they're all looking up their references and we end up with a gross overloading of information of insanity? So yes with your own personal watches where you can keep an eye on things then based on what you're seeing you can make course corrections. Yes it is an amusing situation isn't it? Even if you exclude a lot of stuff like my amusement. For instance I have a link below and he gives you search results number 40 is interesting. Here's an example of supplemental information. Originally our so-called technical documents appear to be primarily scanned the PDFs for the purpose of parts identification. This is because typically the people using this were either be watch material houses or watchmakers who don't need to know how to lubricate the watch. So many times the so-called technical literature is missing the technical if it was even there at all. Then a lot of the watch companies had supplemental information and as it has nothing to do with parts like the sampling of Omega working instructions found at the link typically you would never see these are never even though they even existed. It's only a relatively modern times to the technical documentation specify separate documents for these other subjects. For instance I'm attaching a PDF. This was a PDF that I scanned from the physical document which is why you typically don't find it online. So is a perfect example of a supplemental document for Omega on cleaning a lubrication. It does bring up an amusement though which lubrication are they using on the keyless? Plus are they using epilam anywhere? The yes no matter what with lubrication there is always going to be an issue. We have in the case of Omega where have the most documentation a slow change over time of like that keyless lubrication they're using the words but the number should be 9010 the lightest oil in the land and they're using it on the keyless. Then in individual sheets they did use 9010 later they switch to 9020 so it got heavier and now it's all the way up to HP 1300. So really for your own personal watches it's best to figure out whatever you like which is what I've done and not worry about what the rest of the world was doing as the subject of horological lubrication is quite fascinating and somewhere in that the word insanity should exist. It really would be nice to have a discussion with the various watch companies and ask why they do whatever they do but I wouldn't be are all surprised if they do whatever they do because that's what they've always done maybe no one has ever questioned the insanity of lubrication not in a factory level? https://www.cousinsuk.com/document/search?SearchString=Working Oiling Omega watches 1957.PDF2 points

-

I'm not sure where I heard it, but it is said that Berguet was asked by Napoleon to make the perfect watch and Breguet replied: "Give me the perfect oil and I will make the perfect watch".2 points

-

Interesting as always @JohnR725 , life would be so much easier with clear guidance on lubricants and lubrication. There is so much conflicting and potentially confusing information from all sort of sources these days of the internet. It must have been much easier in the days before, you done what you were taught in watchmaker school or followed the method of your master as an apprentice. Now we hunt around and find all these conflicting ideas and bring them here with the idea that someone has the magical title of watch lubrication oracle and is all knowing. I would expect in the past that people would start off with what they were taught and when a new magical Swiss unicorn tears formula came out would try it, if it suited their way of working and expected results would be kept otherwise go back to the old way until the next magical potion appears. so, what am I trying to say? Start with what makes kinda logical sense to the individual and experiment as you gain experience. I don’t think there can ever be a conclusive methodology which is “the one true way” , the reality is if it works for you fine and good, if not then change something and test how it works. Tom2 points

-

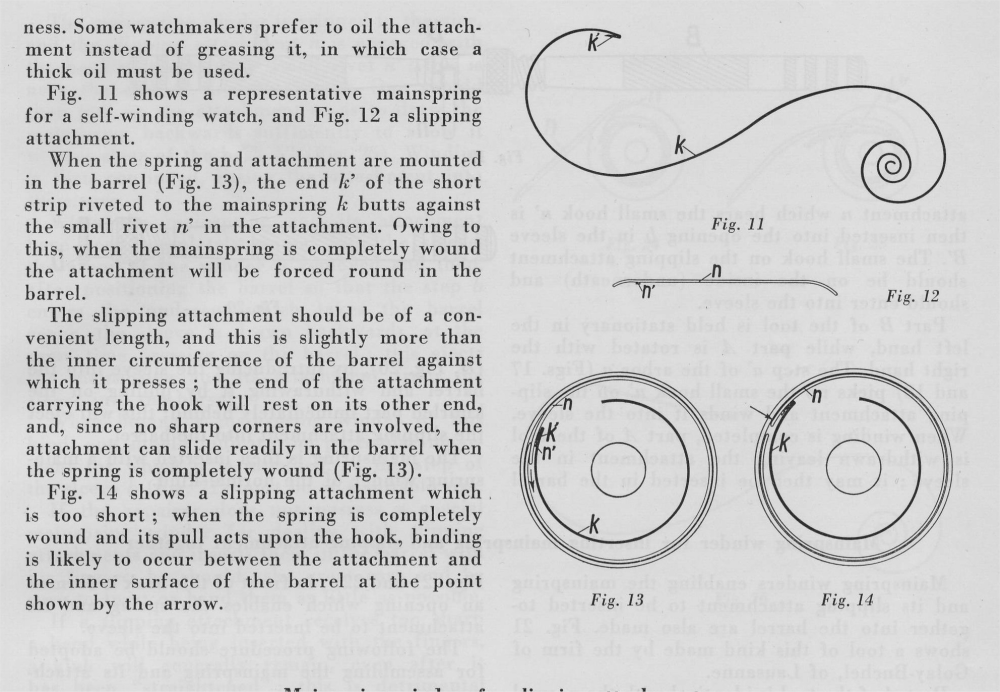

Actually for barrel arbor's I like 9504. When I was in school we use 9020 for the entire gear train. With 9010 on the balance and the escapement lubrication. But it's always interesting to look at what watch companies recommend or even more interesting to watch companies recommend over time especially when they get in the servicing their own watches and maybe they discover that they got it wrong in the first place? This becomes interesting for a number of reasons. The current trend is the use the HP oils because are modern synthetic and hence they should be preferred. But improper servicing a barrel they typically epilam everything to keep the lubrication from spreading all over the place. Then there is my favorite the company who makes the lubrication I wonder if they know what they're doing? At the link below you get tech sheets the product catalog and the always bizarrely strange lubrication chart with recommendations of insanity. So for instance if we download the lubrication chart. Then I'll sniff out something for you notice at the very bottom a reference to the HP oils and what kind of bearings are you supposed to use those HP oils in? Then if you're not using those particular bearings what do they recommend? The classic problem of anything related the lubrication is somebody must've had a reason to put this down here beyond amusement for John to the must've been a reason but no reason is given. So mainspring barrels don't have jewels so based on this should be using D5? Oh wait that goes against what Omega recommends and isn't Omega part of Swatch group the same as the company making the lubrication shouldn't there be a memo on this? Maybe they didn't get the memo? https://www.moebius-lubricants.ch/en/products/oils2 points

-

Three or four dabs, then smeared around the barrel wall so it's not just pushed away when the spring is installed. Basically, enough so it looks like it will give a continuous film once the spring is fitted and starts slipping.2 points

-

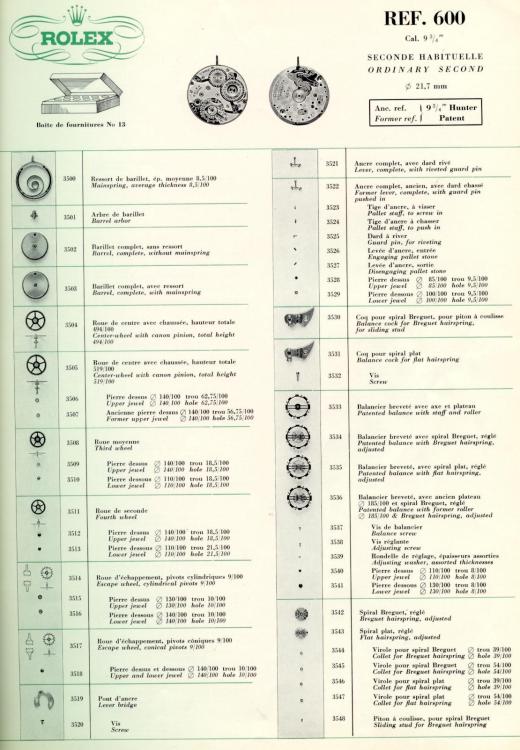

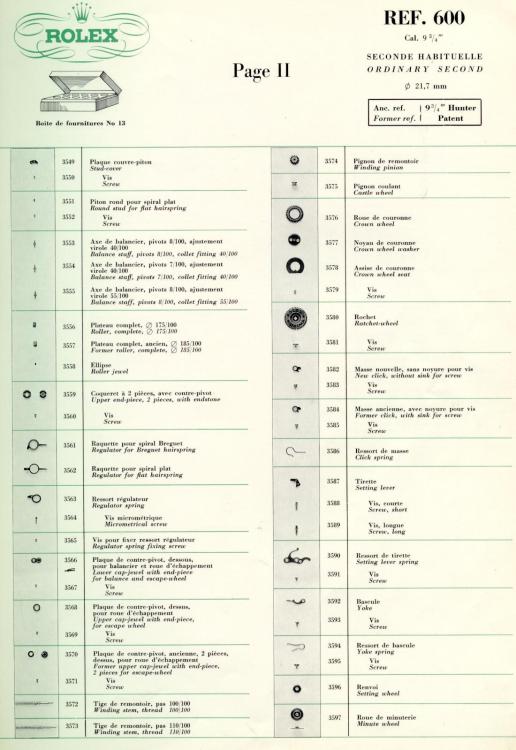

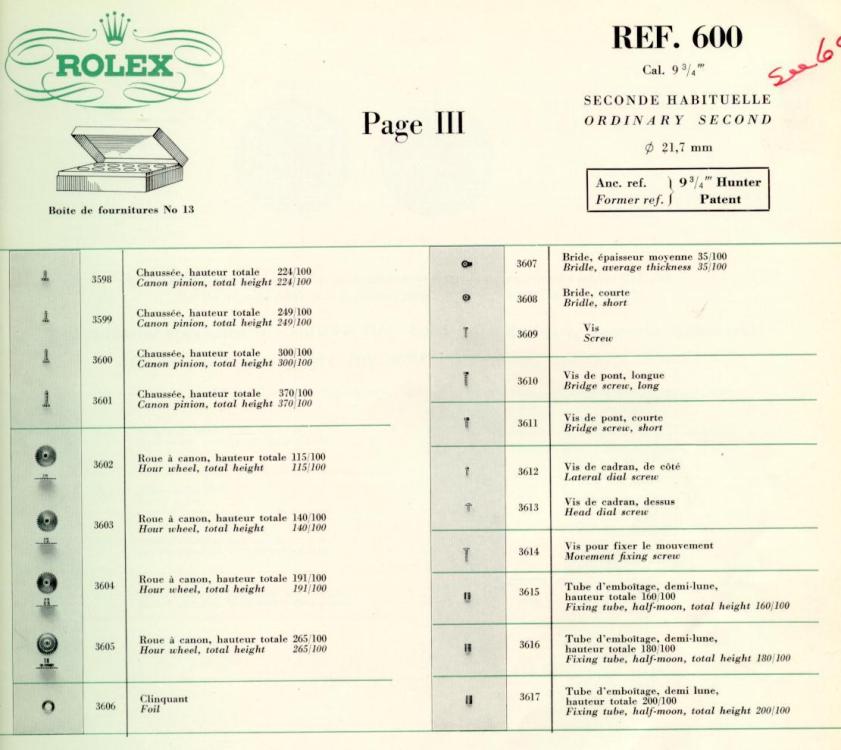

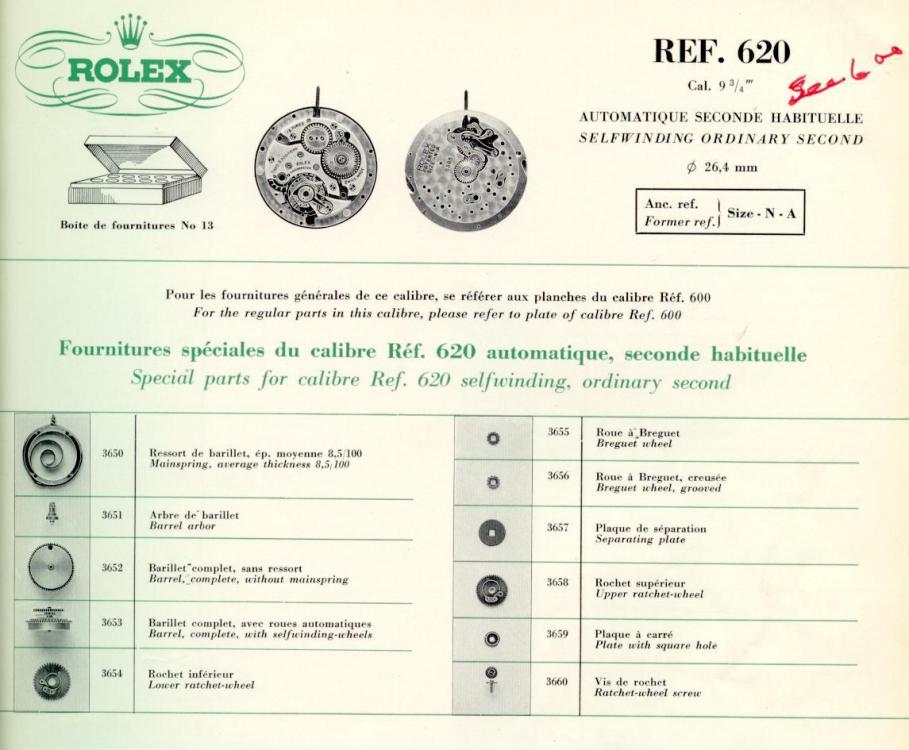

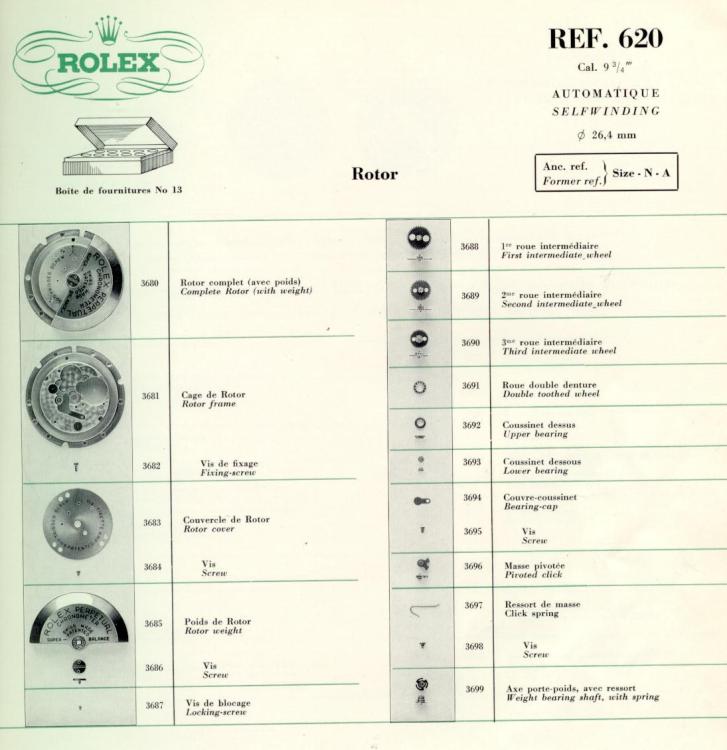

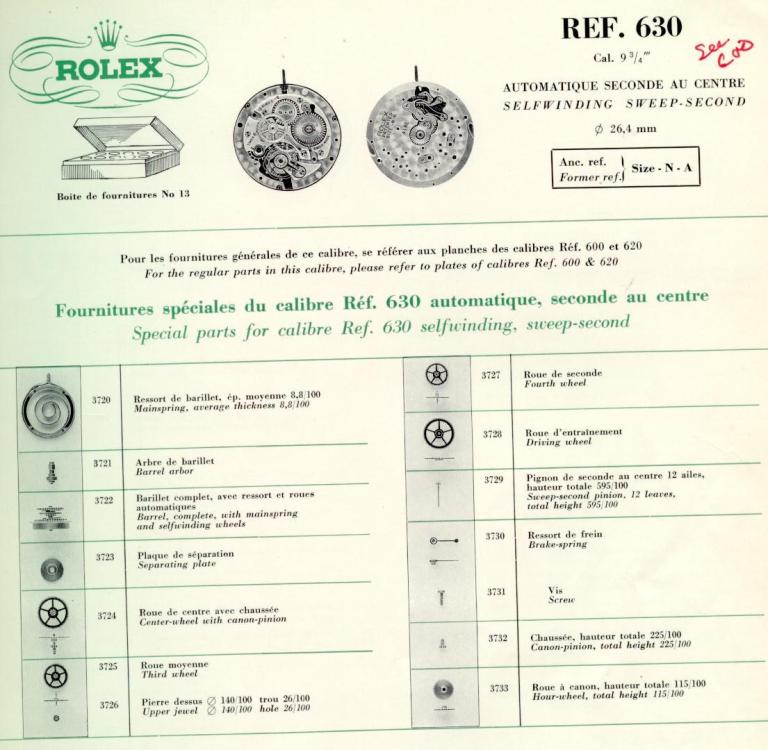

In addition to these requirements you would also hope that if someone did one or perhaps help someone else do one in February 2013 that they memorized everything they did? Well if hoping my memories that good well you're out of luck. All we get is a folder of things and I'm going to snip out the thumbnails so if there's anything else you what let me know Then I don't know if you have the parts lists I will attach those. So the unhelpful answer would've been I would've service the watch helping that person way back when based on whatever lubrication's I was using at the time. I've now become a big fan of 9504 for the grease so that's the grease said be using on everything now. Then as whatever choice you like for the oils for the rest the gear train balance escapement etc. Then if I had any other notes or anything on lubrication or anything at all it should be in this folder and it's not.2 points

-

2 points

-

Fortunately for a watch like this the entire jewel assembly pushes out and is replaced as one unit. Then traditionally anytime you have a broken staff always check the jewels which you would always do anyway as party or servicing. Because traditionally when a staff breaks usually it will take out a jewel at the same time.1 point

-

1 point

-

Fascinating how different we are. I'm not sentimental about most things. If I have only one tool that works, I'll keep it, if I have a better tool, then why not sell it. I'm not saying you are wrong, just a different perspective.1 point

-

Have a look at my post on this subject regarding the gap in the curb pin and boot (regulator pins) But by your pics the endcurve of the hairspring looks a bit suspect. Have a look at this post where I show the correct endcurves1 point

-

If you posted this and said "I've found this staking tool and it costs £1000 and I want to know if it is worth spending my money on." It would be very different from "I've found this staking tool and it only costs £10, do you think it's worth buying?" To give you any informed answer, you have to first provide some important information to base our answers on, like the price of it! To be honest, you are going to find a good Favourite or other known brand of staking tools and all or most of the anvils and stakes for about £150 to £250. If this is under £50 I would probably buy it and find the other bits and pieces needed, but that can be a pain in the ass, so it's back to buying a complete set. It depends what kind of person you are. I Ilke to buy something and find other pieces to go with it, especially when it comes to watchmaker's lathes and all the attachments and countershafts, chucks, etc. But some like to have it all now. I suppose it boils down to 'delayed gratification.' Having a psychotherapist as a wife has its upsides!1 point

-

From the pic, I can't tell if the entire setting ought to be replaced or just the pierced jewel? You best go by your measurements of pivot diameter and OD of the brass jewel housing. My experience is, seller claim to have a part to Ball, but sent one that didn't fit. You might end up looking into fitting a brass housing with larger OD. Rgds1 point

-

Thanks Richard. That's what I figured, but I wanted to check with the more experienced folks before I went on the hunt for a new jewel. I later discovered the corresponding plate jewel is likewise chipped. Thanks again for for prompt advice. Arron1 point

-

Here's mine. Officer's watch from the wrong side of WWII. Back is scratched all to hell to get rid of the D#. There are little tangs around the crystal from the tip of a bayonet resulting from a battlefield repair attempting to keep the crystal from falling out (this according to the watchmaker I took it to to have it serviced shortly after I got it). I got it off eBay out of the Ukraine when I was in college nearly 20 years ago for $35. That sourcing location suggests it was possibly traded for cigarettes or something in a POW camp, or picked off a corpse on the eastern front. I had no idea what it was beyond a cool looking hand wound watch. It's negatively water resistant due to the crystal, so I don't wear it anymore. Insane little bit of history to have on ones' wrist.1 point

-

DU and DD are basically the same (+12 DU). It runs slow in the vertical positions (-14 PD, -17 PR). It seems pretty good, despite the beat error. I think I will call it a day.1 point

-

You haven't discussed positional error but @ +10 on a not Swiss I'm stopping there1 point

-

Yes that's what you need and it's got the correct day/date dials too which was something else I was going to mention. Obviously easier and cheaper to get hold of in Europe than here in the UK.1 point

-

So yes, some good eyes here - there's one completely genuine '89 in that trio, most easily identified by the lugs - the two with pins rather than fixed bars and ever so slightly larger lugs are the giveaway front side. They also lack a tension ring. Dials are all original - the Swiss one is from an earlier Fatboy. Cases on the other two are the Rdunae ones which are decent if you ever find yourself with a dial and a mate who wants a watch like yours like I did!1 point

-

Yeah, i get how it works but i'm still unsure whether i'm doing anything wrong. From the sound of it even if i'm not getting full wind that this would effect power reserve more than amplitude?1 point

-

We need to see the casebacks, they should have a nsn as a part number with the first 6 digits would be 6645-99. 6645 is the grouping for timekeeping equipment, 99 is the designator for UK. Most CWC/MWC G10’s kicking around were never issued but bought by squaddies outside of the G1098 stores system so wouldn’t have the nsn. In addition they were also procured by the UK establishment for police services etc. these also wouldn’t have the nsn. Watches were not on general issue, only issued to corporal and above who were in charge of a section, unit etc. Tom1 point

-

Lol, i know i don't need the extra 30 degrees of amplitude but i CAN get it. I feel like if i'm not, i did something not up to par. It's not a matter of necessity but learning best practices and getting things done right. And hey, good to see ya again! Got the watch bug again and excited to do a couple projects so ill be hanging here a bit more often for awhile. Got my bellmatic sitting here in pieces, got my grandpas beautiful eta 2451. You got any insight into this? There's gotta be a way to know whether you overgreased a barrel or something? You been doin this longer than me. Hmm, i might try 3 dabs instead of five. Let's just pray i can get this mainspring back in without my winder eating it lol.1 point

-

Col is back in the house ,good evening young man. And if you keep mentioning not enough amplitude @JohnR725 will explode, probably with an array of good reasons that you should stop mentioning it, starting with he's about to explode1 point

-

The one far left is the odd one out for me. Swiss rather than Swiss made, this would indicate a Swiss movement but built outside Switzerland. Same watch has less prominent logo and numeral printing. What do the casebacks look like? you would think I would be better at this as I wore one daily for about 5 years Tom1 point

-

This reasoning makes a lot of sense and since you have practical experience, I join the recommendation not to oil. I have no experience myself so initially I was considering that there are two instead of one friction point. One around the pivot and one against the underside of the cap jewel. The probably erroneous thought was that a thin oil could help overcome the friction towards the cap jewel. However, the contact area between the top of the pivot and the underside of the cap jewel is of course extremely small. John's recommendation (Moebius 9000) will be best if you decide to oil anyway, but as I said, there is probably nothing to gain from it. I just had a look at my service walkthrough for the ETA 955.112 and ETA recommends Moebius 9014 for the rotor pivots.1 point

-

I think it's more a case of viscosity dampening acceleration, not rate. Think of the fluid filled shock absorbers on a car. They allow the suspension to move steadily up and down at a steady rate, but dampen sudden accelerations. The train wheels are turning at a steady rate, so the oil should reduce friction and not have much dampening effect. The pallet is accelerating back and forth, so any oil would have more of a dampening effect.1 point

-

1 point

-

May be another picture out of the book I suppose it depends upon whose technical literature were looking at. So for instance if we were following Seiko's recommendation then yes we always oil the pivots because that's what Seiko recommends. Unless of course we don't follow what the manufacturer recommends then maybe we would do something different. But typically if you're anywhere in the universe and asked too many lubrication questions whoever is giving the lecture will always say follow the manufacturer's recommendation because after all the manufacturer should know what they're doing and typically you would not. Unless of course you decided that the manufacturers are all totally insane and you do whatever you feel like. Which works out fine for me because I'm working on vintage watches and there are no lubrication guides on that so I can do whatever I feel like. Strange I believe that's what my instructor in Switzerland said? Oh and you also forgot that all lubrication has a dampening effect. So in other words you want your pallet fork to swing really really really fast and classically putting lubrication on it prevents that from happening. Then a course if we go back early enough to organic lubricants as the lubrication disintegrates and gets typically sticky then this would be extremely bad. Fortunately today synthetic oils typically don't get sticky but still could have a dampening effect? What about using if you really must lubricate or about using an oil kinda designed for this? Quartz watches are interesting because when the stepping motor steps it steps typically really fast. Anything that slows it down or interferes bumps up the current consumption. Which is why originally when quartz watches came out they said no lubrication except then we had issues with that. Then the recommended lubrication but on some quartz watches I found that had issues. Then the Swiss came to the rescue with 9000 lubricants specifically designed for quartz watches which I find works exceedingly well. So if you're going to lubricate something that needs to move really really fast may be issued user oil designed for that well designed for quartz watches but still you can pretend it's a similar situation.1 point

-

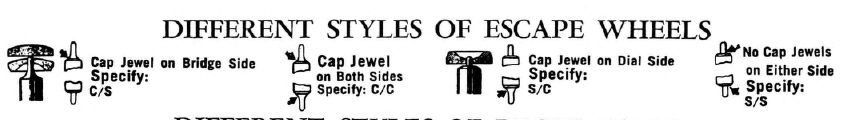

"S" is for straight (pivot), "c" is for conical. Conical would be used with a cap jewel.1 point

-

Wow I love your recourse page V! Last night I won a bid on a nice Enicar Star Jewels MRO 1969 (together with a Zodiac from around the same year) I will use your guide as a helping hand, although it might be a slightly different calibre number. In August when Im back from a little vacation I will make a new thread and start working on that. I can’t wait! I will read up on more of your guides today as well (not picture of the actual watch) I didn’t know anything about this brand, but I stayed up for hours reading about it and looking at their old catalog. They had some killer designs going for a period! https://enicar.org/ and https://vintagewatchinc.com/enicar/ I must admit that the design on the Star Jewels MRO isn't really for me, so this might be my first "buy to sell" watch. I think (hope) I got a good deal since I only paid around 169 Euro for both watches. —— Thank you for your recommendations! Macro Time looks amazing and is a channel a never found before! Im home from work today (covid) so this is perfect I used to watch these videos more for entertainment and therapy, than actual learning. But in the last months, this has slowly changed. It was Marshall from Wrist Watch Revival that first got me into this, and I still love his videos. He has a very calm and relaxing style that I enjoy. The perfect sleeping aid (and I mean that as a big compliment). If Im not mistaken he learned his skills from Mark Lovick / Watch Repair Channel who also runs this forum? I´m glad you mentioned Chronoglide which I already have learned a lot from In the last few days I have watched some videos from https://www.youtube.com/@thewatchmakersworkshop which also have very relaxing smooth videos. You got me curious about Nekkid Watchmaker! Trigger warning on a watchmaker channel? haha thats something. I have a few frends that has tried to push me into filming my upcoming watch rapairs. I used to hate the idea, but lately, I have been thinking it could be interesting to do videos from a beginner’s perspective. Im surprised to discover that a lot of my friends like to look at watch repair videos for entertainment as well. But none have expressed any desire to try for themself. I watched some of Marshall’s old videos the other day, and it struck me that he explained and talked about some things that were very beginner-friendly and something that made me understand something to «basic» for most repair videos to talk about. Can’t remember what it was of course But Im afraid I don’t have the time and energy to do it properly. I want this hobby to be a stress relief. But it is in the back of my head for the next few months and we will see. —- I have very high respect for Christian Lass, but his courses wasn't right for me. I got a good discount and his courses are already a lot cheaper than some of the others, so I guess its not to bad deal. I learned some stuff for sure! But in the end, I felt like the videos/course were too short and shallow. And also all the videos were shot in one take with no editing. I have ADHD so when I have to wait for more than a minute while something is happening outside the camera focus with no sound or anything… Then Im off to something else mentally. And I mean… Why not just edit out this minute? Almost every video had parts that clearly should be edited out. The level of information available for free is also just astonishing. We are very lucky to live in these times. But it also raises the bar on what I expect from a paid course I guess. I think my next step will be to buy the «Getting Started Bundle» on watchfix.com but since I already spent a small fortune on all this watch repair stuff I might have to wait a month or two1 point

-

I have come across pallets with cap jewels, and wondered about whether to oil or not. In the end I decided not to oil, as the pivot is moving through a small angle, with very little load on it. If I did oil, I would use the tiniest drop of 9010.1 point

-

Hi gents, thank you for all your inputs. I can understand why these are more expensive if we multiply their price by 10 and get a value much higher than a 20ml bottle. It's a decant. It's suppose to be profitable by splitting a 20ml bottle in 10 tiny bottle and selling it for double what each tiny bottle costs him. Makes sense to me. On top of that, the starting hobbyist doesn't want 3~4 bottles with enough oil to service hundreds of watches. Me, a starting hobbyist, I'm starting slowly, so the expiry dates concern me. What's the point in buying these bottles, if I'll only service, say, 10 watches in the next 2 years? I'll continue looking for good deals inside the EU. I guess my gut tells me not to go with the Chinese vendor. Thanks!1 point

-

I pored through the manual to get some troubleshooting things to try. Opened the back, checked the voltage: 1.4v. Turn it back over to try one of the procedures...and the watch is running. It's just fine now and I have no idea why. But I'll take that win!1 point

-

This thread just saved me $. I was just about to buy one of those oilers. Thank you guys. I’ve been using a very fine beading needle honed to a fine point and it works pretty well. I guess I’ll just stick with that.1 point

-

One should be careful not to confuse the "unvarnished truth" with simple opinion based on an individuals personal experience (which can be base on as little as just 1 watch), preferences, and prejudices. I like Russian watches (and I have serviced and repaired many) but they do have their faults. Movement wise the designs range from direct copies, licensed or otherwise, of Swiss movements, to some highly innovative in house designs. Build quality can be somewhat variable, if you get a good one then fine, but if you're up for a bit of fettling then even the less that fantastic can be brought to acceptable levels of performance. The quality of finish ranges from quite acceptable to what can only be described as "agricultural", so the Massey Ferguson references have some grounding. A lot of the 1970's and 1980's watches came in cases that had absolutely no water resistance, or even dust protection what so ever, so the movements often suffered from corrosion issues. The cases were generally chrome or gold plated base metal, and would wear through to the brass quite quickly. However the full stainless steel cases with a screw down back and a water proof crown were not too bad, and the Amphibia divers are pretty good. This is of course a completely pointless comparison, you're not going to get high end Swiss watch levels of performance or finish from any budget watch where ever it comes from, but so long as you keep in mind that that is what most Russian watches are (budget), you shouldn't be disappointed. I don't know about current prices but it was only a handful of years ago that Vostok Amphibias could be had brand new for as little as £75 including shipping, find me an AP at that price point... As @HectorLooi says and it's a nice clean example, looks like a late '70's or early '80's vintage with a fairly well finished movement. The case is chrome plated brass rather than stainless steel but the chrome is in good order.The case back gasket appears to be missing but get that sorted and it should have reasonable water resistance. At the right price (I wouldn't pay more than £40) it should be a fun introduction to Russian watches, and of course provides you with the the opportunity to start to formulate your own "unvarnished truth" about them. It also opens up a whole world of customisation should you wish to personalise it. Well worth reading if you're interested in these... https://www.linkedin.com/pulse/vostok-watches-history-explained-muhammed-amjad https://www.hodinkee.com/articles/vostok-amphibia1 point

-

Well said Tom, young sir. When you reach the level of changing staffs and jewels you are doing ok, many youtubers are not even there and are making money from that system. Stating the obvious no matter where you are with it, you are only one step away from the next step. Before you know it a few months of practise can have you making leaps and bounds. Then you realise how much you underestimate what you are truly capable of. This applies to many things in life when you put your mind to it, this you know J x1 point

-

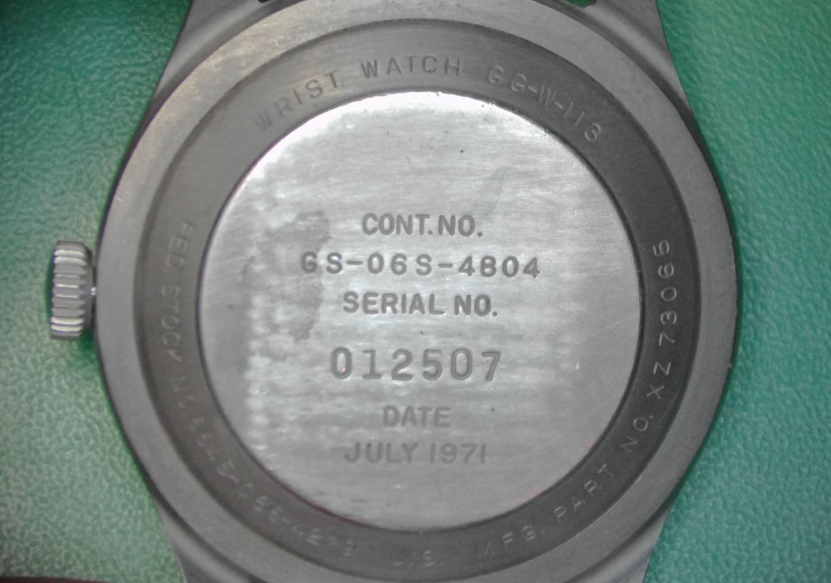

I don't own these, but I did service both of them recently for a couple of veterans I met through a local (non-watch related) group that we all belong to. First is a Benrus GG-W-113 US contract pilots watch from July 1971. It was issued to it's owner when he deployed to Vietnam, and then he later had it with him when he went to Libya. The second is a 1961 Bulova Type A17A military issue navigation watch. It's original owner was in the US Air Force, and it was re-issued to him in 1966. The original strap had long since deteriorated, and I was lucky enough to find an original NOS strap from the correct US military contract and I surprised him with his rebuilt watch on a NOS strap that was identical to what was on it when he first got the watch. I wish I owned these, but there was no way I would ever even ask to buy these from their owners. They were the ones who put the scratches and dings in those watches, and clearly cherished the watches enough to hold on to them for several decades after they stopped running. It was a pleasure to rebuild these watches. I'd love to find some of my own, but I have larger wrists and these watches are quite small. They just don't look very proportional on my wrist.1 point

-

Posted this up a good while back, but seeing as it fits in well and with some good History . Here is my Nato redialled Record DD, inside a 022K. Also has a broken staff pivot but i have around 20 of these. The serial number on the dial is designated specifically to Record, other brand redials will have different serial numbers . Redialled i would guess as a matter of routine service when called into army stores and to decommission the radium lumed dials. Serial number beginning with the letter L as assigned to the Record company. As most will know the Dirty Dozen watch was nick named after the film. So called as the British military approached 12 Swiss watch companies ( there is currently a british company called Vertex making the Vertex DD with some kind of dubious family connection imo but marketing stories sell, just look at the Daniel Wellington name crock of shite )with the task of making their mill spec watches. Look for the WWW stamp on the back. Wrist Watch Waterproof. These 12 companies in alphabetical order as i remember them easier this way. Buren. Cyma. Eterna. Grana. IWC. JLC. Lemania. Longines. Omega. Record. Timor. Vertex. In actual fact as part of the story as i read it Enicar was also approached but dropped out for whatever reason. All are worth a few bob but the Grana is the one to really look out for. Out of the approximate 250,000 DDs that were made the Grana (KF or KFG ) had an estimated manufacture of 1000 to 5000 ( not sure if anyone actually knows ) Coincidentally i do have 100 balance staffs for the Grana DD half fixed jewel half shock jewel. Great i have 100 staffs that will likely never be wanted .1 point

-

I wrote an article about these old glass sizes once, in German however. In short: they all depend on "ligne" = 2.256 mm. x/16 Just multiply the figure with 2.256 mm. Eg: "19 8/16" = 19.5 x 2.256 = 43.99 mm x/8 Much more complicated: Zero is 22.56 mm. Integers x 1.128 mm. 1/8 = 0.14 mm Eg: "19 1/8" = 22.56 + 19 x 1.128 + 1 x 0.14 = 44.13 mm Sizes below 22.6 mm are calculated differently (backward from 22.6!) Frank1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)