Leaderboard

Popular Content

Showing content with the highest reputation on 07/19/24 in Posts

-

Hi Joe, Well it really depends on the type of the escape wheel. In case of english lever and also all clocks, etc. making escape wheel is easy as as piece of cake. Also, brass wheels is much much easier to make than steel ones. I only have one video that shows how the movement (english lever one) works with the new wheel made, and some pictures of the making itself. But, I didnt manage last night to find this video in my Youtube channel, which is strange. Didn't manage to fint the message in the russian forum, where I have shown the pictures and the video, a lot of time has passed... I still have all in my old laptop, so will show here, but give me some time.3 points

-

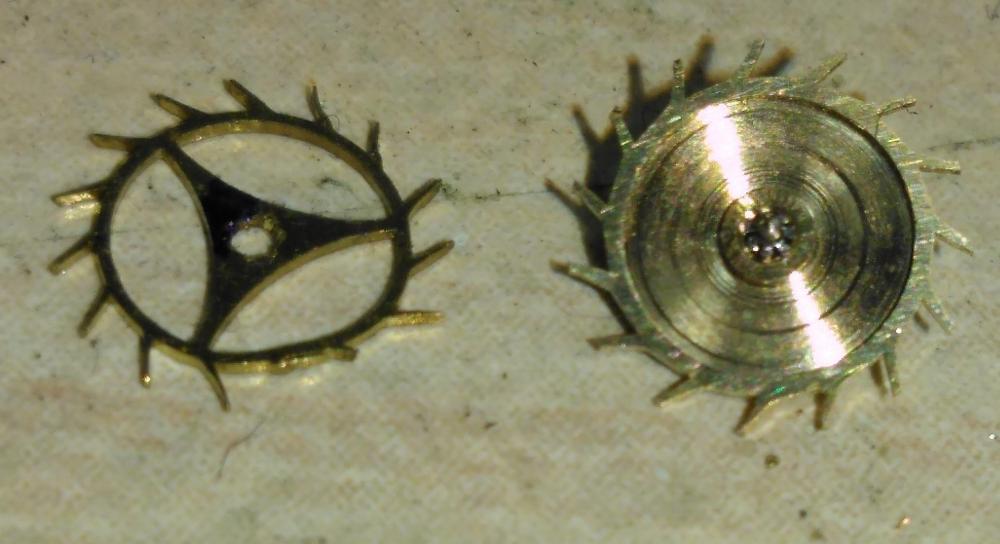

Here are two pictures and the video On the pictures You will see the original damaged table of the wheel and the one that I have cut with the help of milling attachment on the lathe. The video just shows how the movement works with the new wheel: By the images and video names You will see that this has been made back in 2018. I must explain some steps of the making as they are important and are not seen as the images are not enough to explain everything. First, the new table is made with a little bigger diam than needed, and the teeth tips are not sharp as they must be in the end. The cutting here is simple process and is made with one passing only with shaped by hand cutter to give the form of the teeth as shown. The rough table then is riveted to the pinion and engagement with the lever (the drop lock) is examined on depthing tool. Then reducing of the diameter by grinding with fine diamond file while rotating the wheel between centers (in turns) is done untill the desired drop lock is acheaved. This is because in english lever one can not regulate the depth by shifting pallet stones. Finally, sharpenning of the teeth by hand filing the rear surface of the teeth is done until the tips get almost sharp (just verry small plates left on the tips)2 points

-

2 points

-

2 points

-

2 points

-

Looking at this video it appears to be a special tube but think you'll probably just have to go with a parallel. Edit Just realised with a standard tube you may have a problem with the split stem. What's the OD of the stem?1 point

-

1 point

-

It comes out from the front, so the bezel needs to come of, have a good look around the bezel you should see a place for the blade of your case knife to fit in als pull the button out as if you are setting the hands.1 point

-

2.2 is a Standard tube size but it depends if you want stepped or parallel along with other variables.1 point

-

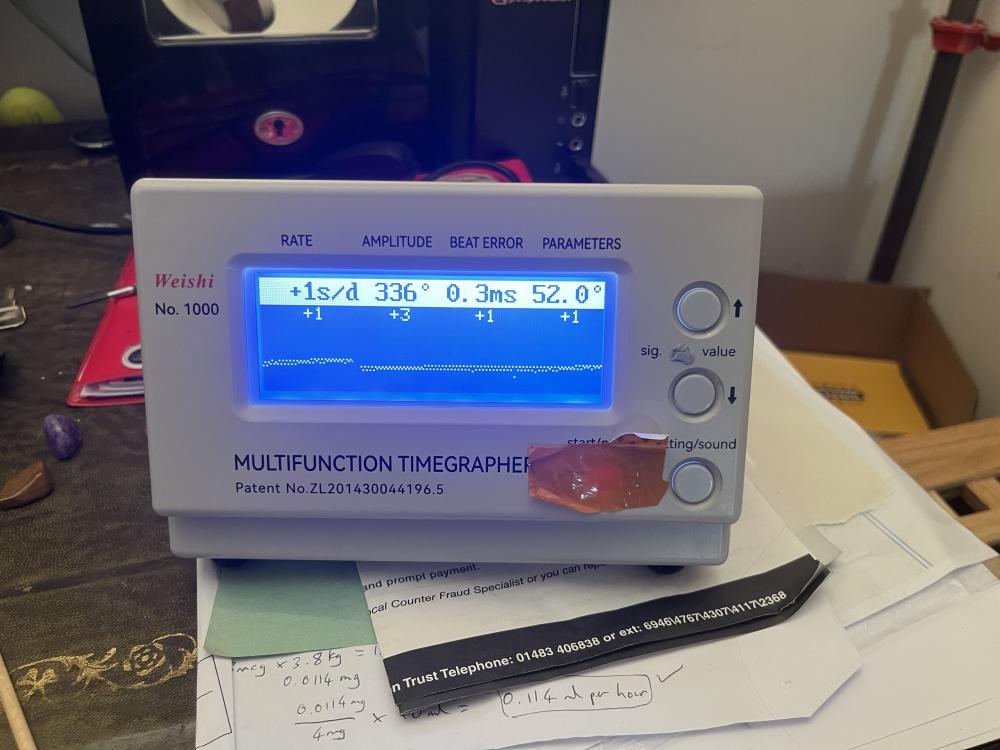

I think that amplitude needs to be addressed before anything else. 173 is pretty low, even with an old main spring. If this were me, first thing I would do is remove the balance to re-inspect the balance staff to make sure the pivots are in existence and clean and not scored up. Next let down the mainspring, remove the pallet fork, verify the train is free spinning when you give the crown a tiny wind. Even better if the escape wheel spins backwards a few turns after it runs down. Then I'd install the balance without the fork and make sure it spins freely with a gentle puff of air from your squeezy bulb or blower, and keeps oscillating for 30 seconds or thereabout. If it doesn't, first I'd check end-shake on the balance by VERY GENTLY lifting the wheel up to make sure it's not binding (use an oiler instead of tweezers to minimize the possibility of damage). If that's good, next I'd take the jewels out again, re-clean and lubricate, and double-check that they're installed correctly. Basically a step-by-step process of elimination. It's also good practice1 point

-

I find it interesting to use a website that will tell you what items have the most bids or watchers using standard criteria eBay search. In an effort to "learn" what the market is doing. And no, this is not a get rich plan. More a don't flush money plan....I seem to have found the toilet lever. The below watch is from US shipper. I limit myself currently to just US sellers to reduce complexity, risk. As a lark I tossed in a bid a dollar higher this morning with the belief I'd be quickly outbid. Well, I'm still the high bidder for this 17J 352 automatic movement. I thought Longines are high end watches. Maybe I will be ready to service in 2-3 years but not now. Please outbid me Item 256569152990 I really do not need this. All I had to drink was coffee.1 point

-

Yes shine a bright light - maybe a flashlight/torch underneath the bridge it will make the jewel looked x-rayed…. Extrapolating from your two pictures I’d say the jewel is fine and were looking at reflections of the overhead lamp…1 point

-

Not sure if it's just the photo but it's looks like there's a gear embedded in it?1 point

-

1 point

-

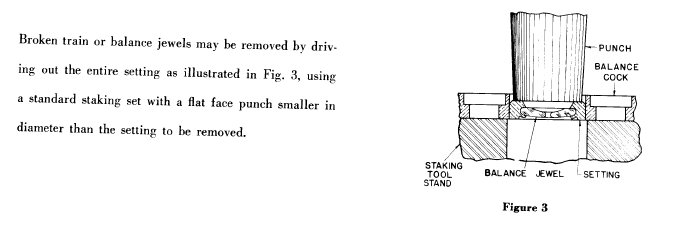

Actually I think it was you the whole thing would've been done ages ago. What you think 15 minutes to make a new jewel setting less than 45 minutes probably more like 30 to make the staff the whole job would've been done in less than an hour. That would probably be on a slow day or in case your sleep otherwise the whole thing would've been faster. But not everyone has your skill set or the shop all set up and Hamilton did design this watch to be easy to do with replaceable parts will at least if it's is basically based on the 992B and we would find that out if we ever get a replacement staff number? So for instance technical specifications the 992B and all their innovative improvements like the jewels in the settings Then this is bizarre there was a seller on eBay that was manufacturing jewels which is where I was going to send somebody but apparently they've run out? That seems strange if you were manufacturing but https://www.ebay.com/str/americanpocketwatchjewels One thing that was still bothering me was the over sized staff possibly? Normally when replacing a staff in American pocket watch where there will be variations is you would measure the old staff. You would look in the reference books to see what the staff is an see if you get a listing of what staff was supposed to go in the watch. Then when you get the new staff you would compare its measurements. But the problem with the B series staffs they don't list the dimension the friction part because they don't have to they're all supposed to be the same. But my experiences been the aftermarket can be slightly larger. This is why it's really nice to have access to at least the watchmaker's lathe to modify parts to fit the situation rather than changing situations that the parts. Now this entire last section will probably fall on its face but seeing as how I have a nice micrometer and a small assortment of 992B staffs let's see what the balance seat diameter is. Okay looks like is probably wrong? First staff measures 0.79. This is a nice bench micrometer I would build to see if it went over that I wouldn't get a nice decimal point number but it was exactly 0.79. Three more staffs exactly the same but the fourth staff 0.78 and I have to guess because the needles between two marks may be like six it's a little past the halfway mark but not quite three quarters. As I said I knew from the past there were some different size staffs even though there is not supposed to exist. then the last staff is even more interesting 0.78 exactly. I was trying to remember if I have any original packages of 992B staffs and I think I do but I'll have to find out later. Hamilton 992B technical data 127.pdf1 point

-

Seiko isn't etching these crystals. They're just glass circles with some marketing attached. The difference between NOS and new production is zilcho. You're overthinking it. If it were me, and I wanted to keep the original original, I'd just get another glass circle. If it were me and I wanted it to be something I wear without worrying about, I'd get a sapphire aftermarket crystal. Which is what is in my own Seiko.1 point

-

It's not an antique so replacing it will not do any harm to the value. Just keep the old one.1 point

-

1 point

-

I was thinking about this for a automatic watch you should be able to manually wind it up and it should run for 24 hours minimum? So if you're losing 50% of your power when it slips I doubt that you're going to run for 24 hours. So yes I think that's definitely an indication of you have a problem .This is actually come up for Seiko watches where the original mainspring the bridal is much much heavier or stronger than the aftermarket. Which is why I suspect Seiko can get away with the type a grease the use for breaking grease because of the heavier bridal. Now not that are not paying attention but which watch are we talking about exactly which mainspring exactly are we talking about? Sometimes it's hard to keep track of all the conversations I can't remember if we actually discussed which watch this is or not.1 point

-

It is! There is a problem with the bridle tension imho.1 point

-

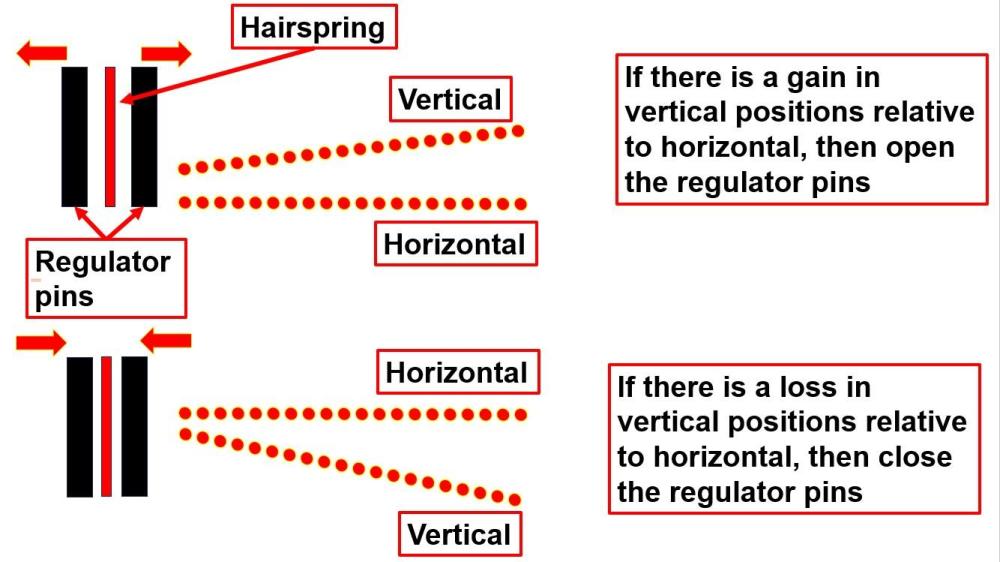

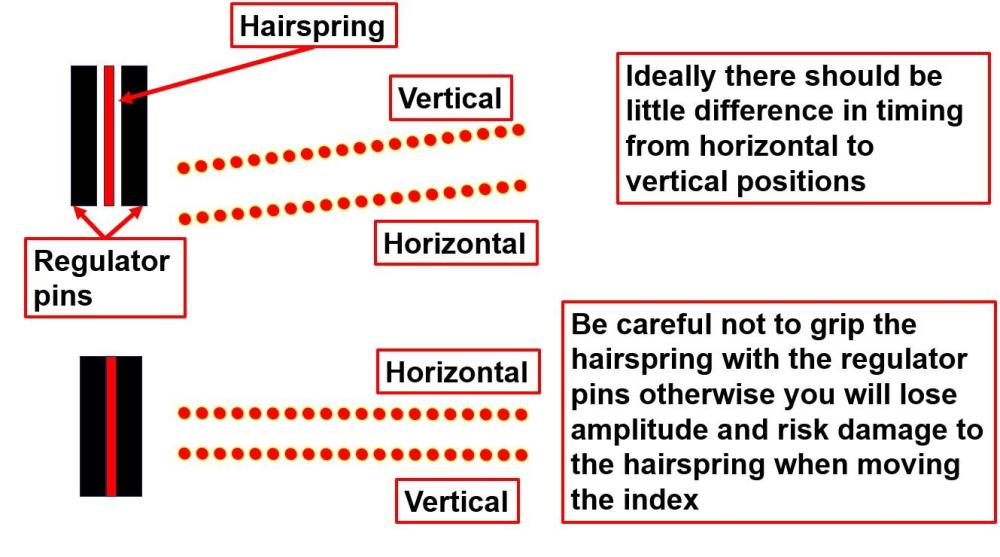

If the coils of the hairspring are equidistance from each other and the end-curve is perfectly formed, so the regulator pins (curbpin and boot) don't push or pull the hairspring regardless of where the index is at the extreme of '+' or '-' and the balance is poised (consistent + or - timing in vertical positions) then it may be the gap between the regulator pins. These slides may help explain which way to open or close them. This is why an EtaChron system works so well, as you can set where you want the hairspring to exactly be and set perfectly distanced regulator pins every time!1 point

-

1 point

-

You will find both a staking and a jewelling tool invaluable. As long as you continue with watch repair you will never stop spending money. Its like being married but without the nagging1 point

-

As watch porn goes the pictures are wanting- all the punches are upside down! Well done, anyways! I hope you enjoy...1 point

-

Nice looking tool my friend . Welcome to the jacot club, or the club of jacoters. Its not a massive club but its a club, and you are now one of that club. I will send you a badge that reads ' i have a jacot and i know how to use it '. Wear it with pride, if you get into a fight with someone , flash your badge and use the loud verbal warning " I have a Jacot ", then watch them slowly back away turn and run.1 point