Leaderboard

Popular Content

Showing content with the highest reputation on 07/21/24 in Posts

-

3 points

-

wristwatch revival got me into the hobby as well as taking Mark's great courses. I love vintage watches and have so far revived a few ones successfully. It's just such a great feeling wearing a piece that you fixed yourself.1 point

-

Just a quick introduction. I got pushed down this rabbit hole by another member of my family who purchased a couple of pre '91 USSR watches. I bought one that didn't work, and it seemed that it would just be an issue with the Keyless works. I bought a couple of tools, then a few more, and you know the rest. I've worked on a couple of Vostok 2409s and 2414s and a Raketa 2609.ha and I have (naturally enough) some others waiting. Other interests include portrait photography, woodwork, skiing, and other stuff. For my sins I work in IT.1 point

-

I acquired an old soviet era watch a while back & got around to trying to get it running a few days ago. It needed a good clean - and the mainspring was in two pieces. That was also of a design I'd not seen before, with a riveted end tag that had "ears" which engaged slots in the barrel base and lid. As I'd not been able to find any identification for this movement (until today), I was not hopeful of setting a replacement spring; the few possible matches I could find were silly prices. I have an "Anchor assorted mainsprings" pack, and one type in that looked a good match, other than it having a conventional end that needs a step in the barrel wall. I broke the remains of the old spring off its anchor near the rivet, so the flat end of the anchor was double thickness. That went in the barrel with the new spring hand wound in to press it against the barrel wall in about the right place to line up with the retaining slots. It worked! it fully winds and runs nicely. I cleaned up the raised (through-stamped) digits on the dial by carefully rubbing it on a fine sanding stick, as they were just a dull tarnish colour. It looks pretty good! Going to put it in the case, trying to remove the stem - I slipped and snagged the second hand. It won't re-attach as it has the end of the seconds wheel staff still in it - it broke, flush with the top of the cannon pinion. . Parts search begins! I believe the movement is a Sportivnie 2634 - but please let me know if I have that wrong.1 point

-

Hairspring is Russian movements are put together using whatever part they happen to have in their inventory. Don't believe me ??? ask neven he knows.1 point

-

Well, I do. I can't can myself an expert or a safe reference, though. But never had problems with power reserve (and amplitude). I put a little blob next to each notch in the barrel wall and then spread it out. For most barrels I've worked with, that would sum up to 5-6 blobs. The pictures below with show the quantity I use. By the way, do you have notches in your barrel wall? If not, maybe they've worn away and that could be the issue. But there are also notchless barrels (by design). Don't know about yours.1 point

-

1 point

-

Very similar; the attachment is shaped more like the one on the "Double brace pin end", less the overhang and second rivet. I had the movement at 45" on its edge on the bench, to keep the hands & face clear of everything while removing the stem. It slipped while trying to press the stem release and pull the stem; flipping around so I was gripping it front to back rather than side to side & the second hand hand snagged in the nitrile glove as it turned. I may have already got the replacement parts! I was in the middle of buying a different Soviet watch from an overseas seller & asked if he had the spare part for this one - he offered me a complete watch with the same movement, at a very reasonable price.1 point

-

I think we have to wait for @nevenbekriev to weigh in on this. I've seen Russian movements with flat hairsprings, cranked hairsprings and even Breguet hairsprings. Maybe someone replaced the hairspring in your watch with the wrong type.1 point

-

"What do you think of this." I think I'd need a stiff drink before working on it. What in the ever-lovin' purgatory is going on with this thing??? It looks like it was assembled by a time traveler. I can see the fusee chain peaking out from one side of the back plate, so I know the movement is likely not very modern. But the case style looks a lot more recent, although it seems to have had a hard life. With a solid, slab shaped brass back plate, there isn't much else to see with the movement. I don't recognize the make at all. And, above the "83" stamp, I can't if it is stamped "V&E" or "L&F", but it sure doesn't look like "W&H" in the picture. It looks strange to see finials only on the front corners, but who knows. And seeing a slot cut in the bottom to accommodate the length of the pendulum would lead one to believe that this case was not the movement's original home, but I concede that I have not seen very many clocks like this. No clue what's going on with the shiny ball either. Likely it was once painted to display moon phases...but I don't know, maybe it's the Loc-nar or one of those spheres from Phantasm. Overall, the dial, hands, case, pendulum, finials, movement in general, all seem like a bunch of awkward strangers who were wondering if they joined the wrong flash mob. The movement quality and accuracy *might* be pretty good. That isn't something I can see very well in the pictures. But the whole clock is rather like a train wreck, isn't it? Something tragic that one shouldn't stare at, but one can't seem to look away. How do you find these, @oldhippy; do they just kind of leap out at you now and again? EDIT: well, I guess if there was a sphere to display moon phases, it wasn't from this movement and I don't think it was the sphere in the picture. I see that this one has a threaded shaft coming in from the back and is held there by a hex nut. I see that some of the other deficiencies are listed in the description, so the seller seems like he is at least attempting to be honest about it. At this point, I think I will let others have a go. The longer I look at it, the stranger it becomes to my eyes.1 point

-

What date is it as Type 4 is the thinnest at about 3.5mm1 point

-

Sounds like you had one of the original high dome lenses which didn't last long due to chipping and changed through a couple of variations over the years. You'll find it easier now to try and polish the old one while it's out and see how much you can improve it.1 point

-

I suspect that once the spring starts slip, it will distribute the grease around barrel wall - and squeeze out any excess to the sides. After a few slips, the main factor affecting the slip force will surely be the grade of grease rather than the amount (unless there is too little & you get direct metal-to-metal contact, causing wear)?1 point

-

I would be shocked if you can swap bridles, they're riveted in. This movement/mainspring combo is used by many members here. I would think it's just trial and error with the breaking grease. I just got the thing reset and am struggling to get the arbor in but i'll know soon if that is my problem at all. Troubleshooting the underwinding issue seems easy enough. Not entirely sure how to troubleshoot OVERWinding if i used too little BG. Basically i put 5 little smears before, this time i tried lowering it to three.1 point

-

1 point

-

Hi, there is absolutelly no mater how You assemble the indicator. If You continue winding the movement, the indicator will sync with the mainspring condition by it'sself. If the indicator reaches 'full wind' before the spring is wound to the end, it will stop moving and continuing winding the spring wil wind the spring to the end, thus syncinc the indicator. If the spring is fully wound but the indicator is not at 'full wind', then continuing winding will move the indicator until it reaches the end and thus get synced. Well if the indicator never gets to '0', this will only mean that the real power reserve is smaller, and it is probably due incorrect mainspring fitted. PS Now I see there is 'stopwork' and it is probably connected with the power indicator. If this is the case, then this stopwork must be activated when the power indicator reaches '0' and this is the one and only needed indicator adjustment. But if it is done and still the indicator never gets to 0, this again means that the real reserve is smaller than needed.1 point

-

Glad to hear! I'm actually relieved that it worked. Had you said that there was glue (which you'd intend to keep in place), I'd have assumed that the L&R cleaner would remove that, too. I'm surprised it doesn't. Interesting! Thanks for keeping us updated.1 point

-

I doubt that there is shellac on the impulse jewel. They are press fit in contemporary watches, not glued. As the hairspring is glued to the collet, then this for sure is contemporary movement. The glue on the hairspring end should be resistant to acetone , petrol and alcohol.1 point

-

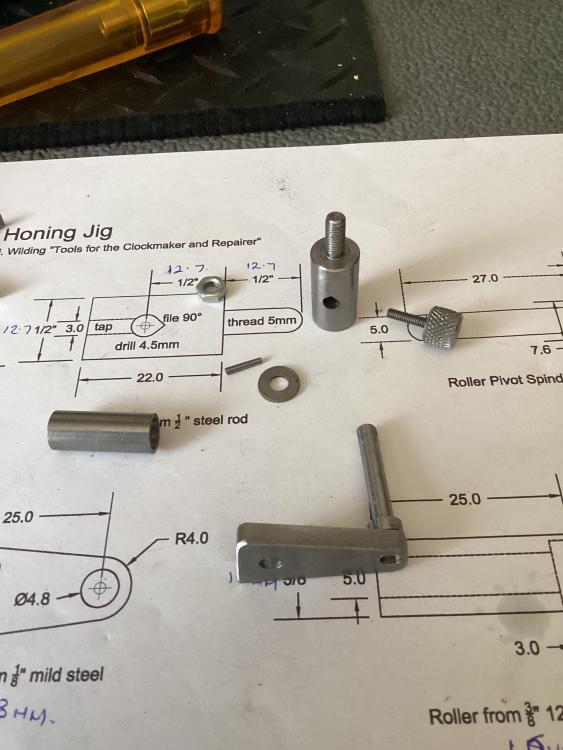

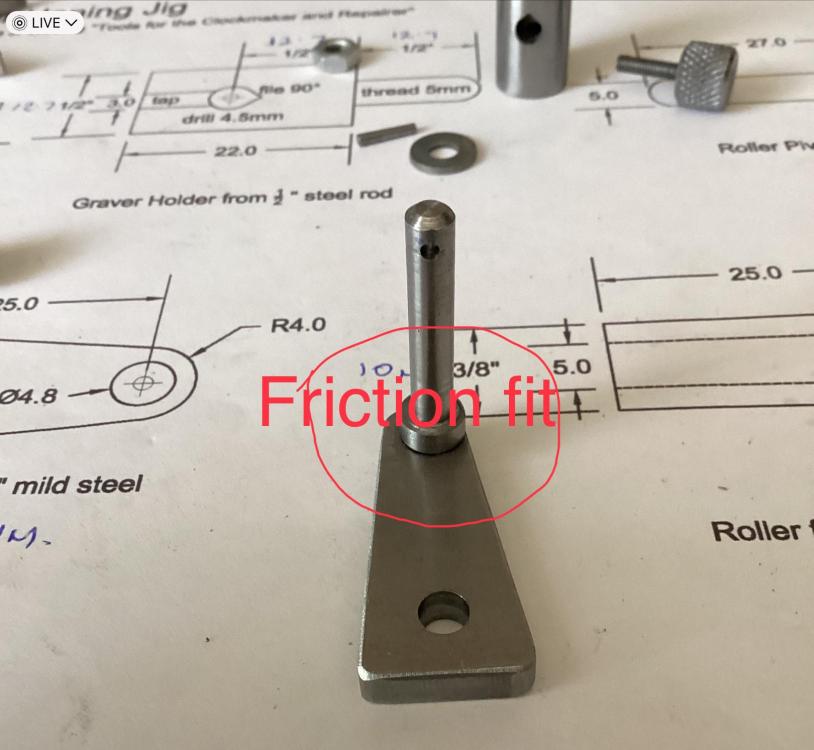

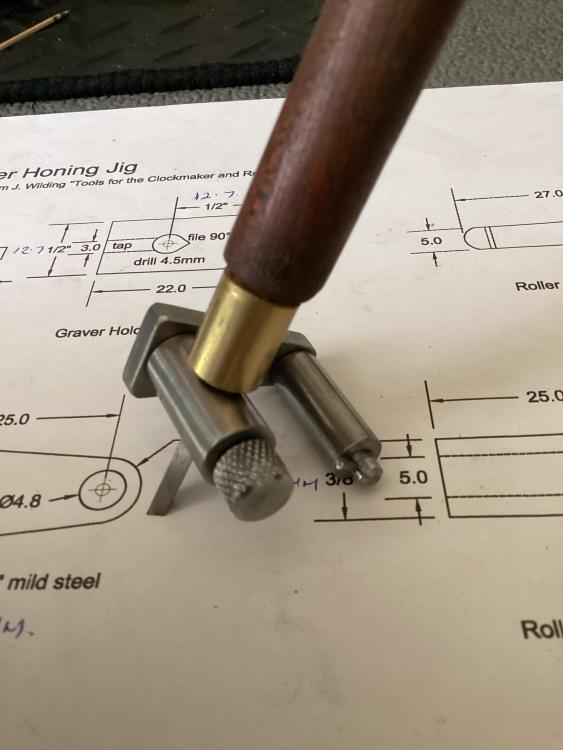

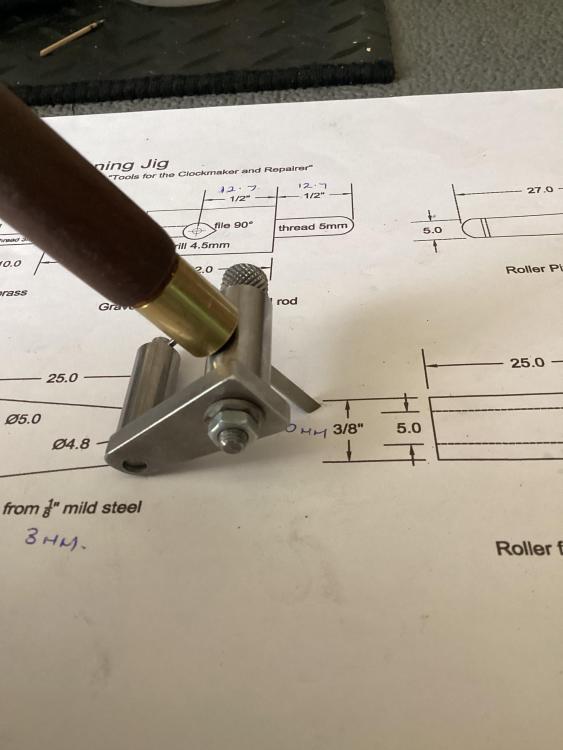

It may be my age but I can’t get on with the Crocker style jig for honing my gravers , I would have liked the Bergeon one but there is no way I am paying £120 just to sharpen gravers , I used to do it free hand but having gout in both hand has made it difficult, I chanced upon a set of drawings from John Wildings book tools for the clockmaker & repairer so today I made it and I must say it does a good job, not sure if legal to post drawing so if anyone interested then PM me . Dell1 point

-

Regulating a floating balance is not easy if the regulator is not easy to move just touch it with something instead of using your fingers. From what I see there is no signs of dirt around the pivots but they do look dry so you could oil the movement. I have never replaced movements such as electric or battery in clocks that never had them in the first place. That is not the way I worked.1 point

-

My experience with reporting things the eBay is a waste of time. Then I suppose we give the seller the benefit of the doubt of just being extremely stupid. Notice the price is based on the appraisal price and the appraisal is for insurance purposes. Where I work on a fairly regular basis people will find watches in the estate of and will bring them in hoping that that Rolex is and it's never real. So somebody is looking solely at the appraisal and maybe we should find another watch like that on eBay there's a lot of them typically and show it's not rare expensive I guess you could try reporting them to eBay for stupidity but usually it's a waste of time Oh and for some amusement let's look at the other item for sale. They are definitely clueless stupid people as they are embracing the appraisal which is total rubbish. Fortunately the prices are so insanely high there be unlikely anyone would be as equally as stupid as to try to buy one of these. https://www.ebay.com/itm/235622992795 So basically you're just dealing with extremely stupid person that there really isn't much you can do with. Blood be really interesting though as to who did the appraisals and report them to is there supposed to be I think a licensed I think and obviously there is incompetent with their appraisals.1 point

-

Three or four dabs, then smeared around the barrel wall so it's not just pushed away when the spring is installed. Basically, enough so it looks like it will give a continuous film once the spring is fitted and starts slipping.1 point

-

Col is back in the house ,good evening young man. And if you keep mentioning not enough amplitude @JohnR725 will explode, probably with an array of good reasons that you should stop mentioning it, starting with he's about to explode1 point

-

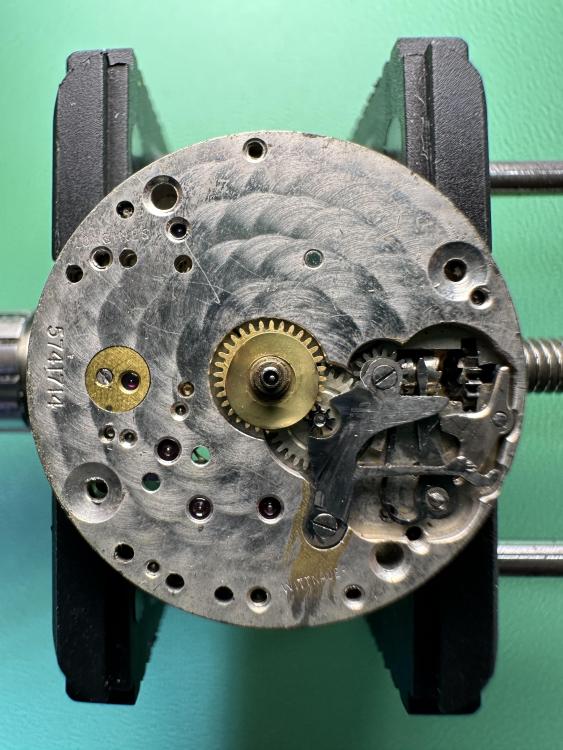

I promised a post on the weems I've been pecking on a bit at a time. Longines 10.68.Z what had a busted yoke screw and a pallet fork with a stubby pivot. This movement has seem lots of action and the plating is quite worn and fragile. While the plate was soaking in alum I considered trying to replace but I don't have the skill or equipment to re-pivot. These 10L movements come in seemingly infinite variants. there are so many different length center seconds springs I assume they chose random locations on the bridge to fasten them. I had another 10L what took me three tries to locatre the appropriate length. A similar situation with the pallet fork. After a false start I pulled the appropriate new pallet complete from a donor. The alum worked a charm but it was difficult to remove the mess without damaging the fragile plating remaining on this movement. Anyways, up and running and I love the look. This one appears to have never had a a bezel lock. I tried to find definitive information on variants but there is surprisingly little detailed information on these. I did find a couple photos of similar variants like this one...1 point

-

It is in fact a Schatz 8Day Anniversary Clock Visible Wheel Movement 2Jewel. Silly woman. Carriage clocks are called so because it has a handle, you get them most are 8 day duration. Timepiece 8 day, Timepiece and alarm,Strike 8 day on a bell or gong, also with or without alarm, Grande Sonnerie and et petite sonnerie strike these are complicated strike and chimes. She is also wrong carriage clocks are not made with just a chime.1 point

-

This how my master taught me when it comes to progress in watch repairing. Gents, simple large movement, sweep seconds, calendar, day date calendar, auto, auto sweep, auto calendar, auto day date calendar. The same order with ladies watches. This would also include learning about replacing mainsprings, buttons and stema and crystals. Then complicated gents which would start with gents chronograph watches, the same with ladies. When this was achieved it was high grade movements. Balance staff replacing and making, making stems. Escapement work such as dealing with hairsprings setting pallet stones jewels and all the other things I have missed out were included in the process of learning.1 point

-

Some of the skills that always could use improvement for an amateur watchmaker/hobbyist would be: Crawling on the floor with a flashlight and a magnet. Staring in bewilderment at a cleaning basket wondering why 18 pieces went in but only 17 came out. Removing a barrel bridge multiple times because you forgot to install the hack or the setting lever the first time. Memorize the expedited shipping rates from Cousins. Arriving home 5 minutes before the wife so you can stash the eBay packages before she asks "so NOW what did you order?" Seriously, while the ST36 and NH35's are low risk movements and can provide a decent amount of basic skills, I would see if you can get your hands on a higher quality movement. There is a world of difference in working with an ETA2824 or Sellita SW-200 vs. a Sea-gull ST2130. I would look at your last project and ask yourself what your weakest skill or failure was in doing it. Then do it again ... and again until you feel comfortable with the process. You will eventually get to the point where you won't accept "good enough".1 point

-

The hairspring is overlapping at the spot where the arrow is pointing. As @LittleWatchShop said, put this away until you have gained more practice. Fixing this involves removing the balance from the cock and then removing the hairspring from the balance. Then you'll need to reshape the coils until you have a smooth spiral, refix the hairspring to the cock and reform the terminal curve and centre the collet. All that is advanced work but doable when you have more practice and improved your dexterity. And you'll need a microscope for that kind of work. In the meantime, bag it up and put a note in the bag stating the fault, in case you forget in a few months time. (Don't ask me how I know.) And stick the bag to somewhere prominent, to remind you to work towards being able to fix that. You'll ruin a few more watches in the near future. Trust me, we have all done that. When I broke my first watch, my mentor told me, "Learn from your mistakes and move on." Good luck and don't give up. Practice practice practice.1 point

-

Thanks to this video I undid the tangle. The spring is still out of round and the watch is still not starting when I put the balance in place. Since now I have a second movement, I’ll try swapping the balances to confirm that is the issue The result is not very conclusive. Swapping the balance didn’t make the first movement work. BUT, when putting the good balance back in the good movement I had a hard enough time doing it (it did work in the end but I think my problem is managing to sit the balance pivot in its bottom jewel or to fit the impulse jewel into the fork) that I keep wondering if the failure in the case of the old movement is because I broke it or because I am not good enough at reinstalling balances. I confirm that the main issue is between the seat and the tweezers. after more effort the first movement with its own bal and ou of shape spring started. No doubt the time keeping will not be good but IT’S ALIVE!1 point

-

Ricoh has a similar pallet fork Tressa 1970s ETA 2788 Unusual Grey Sunburst Dial all original except for the crystal Running really well for its age, + 0.5 SPD, 300 degrees amplitude horizontal after 12 hours. I have another crystal arriving next week with a wider tension ring that I hope can hide the gap between the dial and case (XAC 321.577). Wide tension ring crystals appear to be few and far between so if anyone has any tips for a good source then that's most appreciated. I did look at ATCB range from Sternkreuz but they seem a bit higher than I would like based on the dimensions.1 point

-

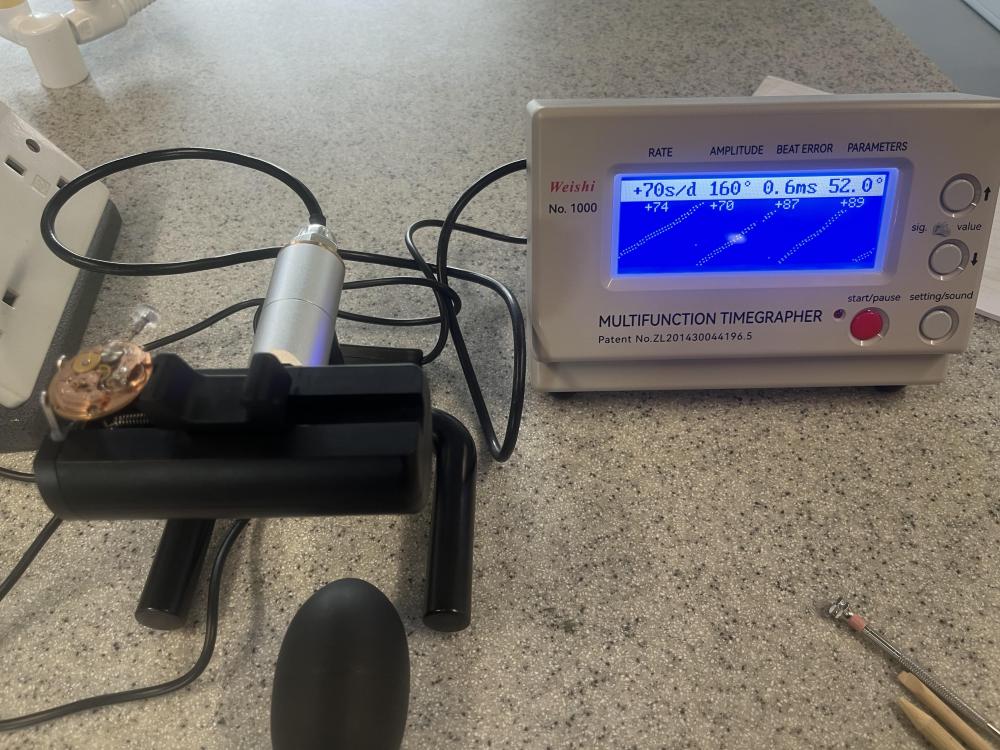

You couldn’t make it up, the complete pigs ear I made of this movement. So after the regulator (balance) cock up I finally got it all back together again only to realise I lost the screw for the balance stud in the process. Trusty bag of spare screws to the rescue (getting that screw in was tough though). I remounted the improved balance spring. Popped it on the Timegrapher and things were better hard not to be better than a snow storm really. Well when I moved the regulator around it didn’t behave predictably I think the afore mentioned lack of terminal curve to blame. Just as I decided to set about trying to form one. The movement pinged out of the Timegrapher then refused to run… stripped movement. Only to discover the fall bent centre pin0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)