Leaderboard

Popular Content

Showing content with the highest reputation on 07/22/24 in all areas

-

Here in the Uk, actually i think its more of a yorkshire saying. A big girl, and i mean a really big unit of a girl we say " jeez wouldn’t want to mess with her she's built like a Russian shot putter " hairsprings are maybe built the same way.3 points

-

2 points

-

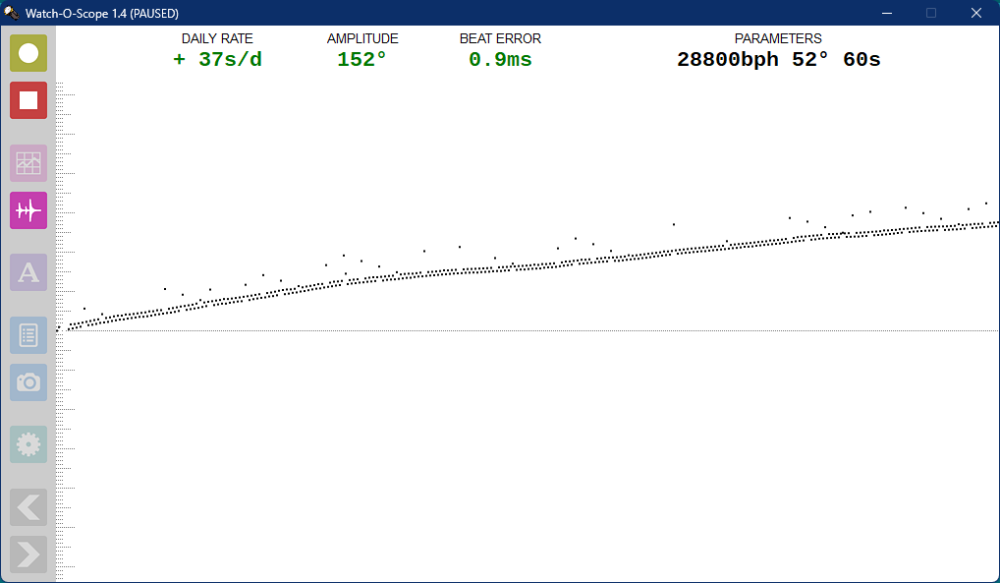

Got this wonderful 1971 $8 eBay find running. Other than a broken mainspring and a crack in the crystal, it just needed a good clean up. It did have a beat error problem, but I got it adjusted to a 0.6ms BE, a 260° and positional error of +/-30s. Not bad for essentially a novelty watch probably not expected to make it much past the '70s. I think the hardest part was fitting the pallet fork without jewels. Those holes are TINY! That brass plating was 10 kinds of awful so I just polished it off for now. I might nickel plate it. Or 24k rose gold, for such an elegant timepiece.2 points

-

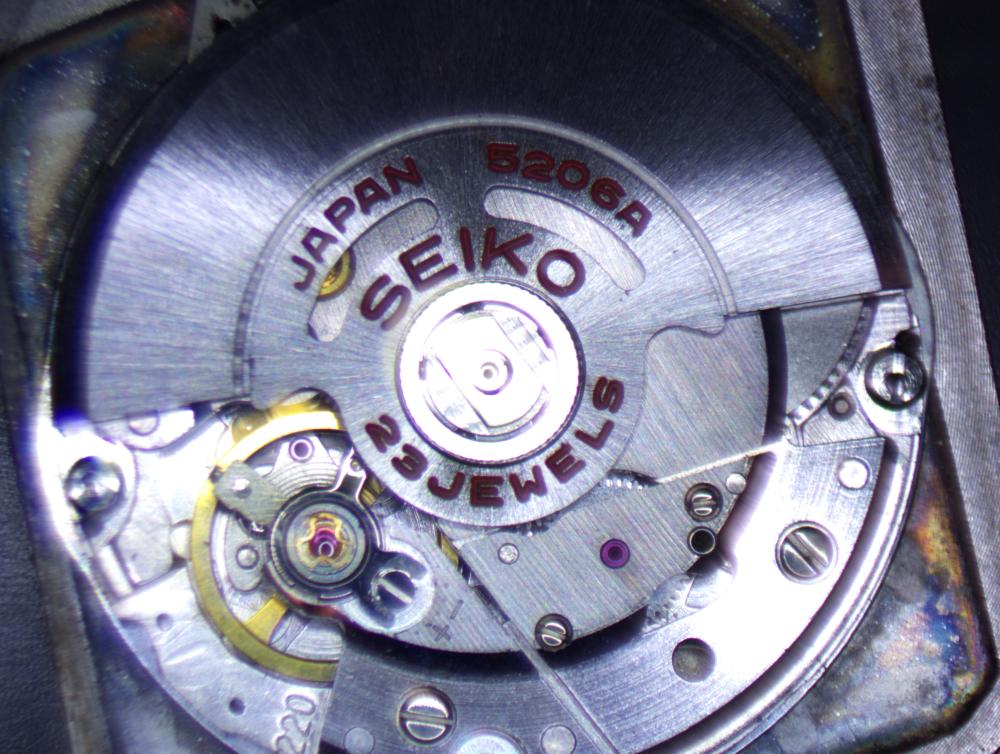

Looks like my gamble paid off again. I haven't opened the caseback yet (still at work) but it arrived ticking at a ridiculous rate, the second hand sweeps, the day, date, and time all set. There's a little ding in the dial, but I was expecting that. The back is slightly dented in, but we can fix that too. For the price I paid, I am extremely happy. I took a video to try capturing how the dial shimmers. It's like a butterfly's wing.2 points

-

2 points

-

Well, I do. I can't can myself an expert or a safe reference, though. But never had problems with power reserve (and amplitude). I put a little blob next to each notch in the barrel wall and then spread it out. For most barrels I've worked with, that would sum up to 5-6 blobs. The pictures below with show the quantity I use. By the way, do you have notches in your barrel wall? If not, maybe they've worn away and that could be the issue. But there are also notchless barrels (by design). Don't know about yours.2 points

-

The cheap blue ones do work pretty well but you have to draw the part away from the coil while pressing the little red button. And they seem to work well only when your power supply is 230VAC. If your power supply is 100/110/120 VAC, the magnetic field might be too weak the demagnetize properly. There are also automatic demagnetizers from China, which are a copy of the Elma but costing only a fraction. https://a.aliexpress.com/_msLCEnw2 points

-

1 point

-

The idea of @Nucejoe was probably not clear enough but the idea is to find another cheaper movement as a donor that you can take the parts from to repair yours. Where in the world are you and is it an actual watch maker/repairer you've taken this too as the screw highlighted by @RichardHarris123 is from the barrel?1 point

-

if you look at older books on watch repair you will find making the replacement hook from a screw ideally a special screw is the preferred procedure. Ideally when you're making the screw it supposed to be slightly tapered so when I goes into the whole it becomes tight. Then you didn't show us the end of the old mainspring? Oftentimes that's handmade also when it works much better with the replacement hook. You may be able to get by with the modern spring and the old but probably not it may look good but it probably isn't1 point

-

From the "which watch have you got coming" thread, this is a watch I bought off eBay from Japan. There were no pictures of the movement, so it was a bit of a gamble. Initial timegrapher reading looks decent, other than the low amplitude. The case was difficult to separate, but I got it apart. The dial shows a bit of wear, but I think it'll clean up pretty well. Super interesting that instead of a split stem, you get access to the setting lever release through the dial. I like that. It seems like it hacks when it's out of the case. I didn't take it apart yet, but I'm super interested to see how that works. Then I noticed something that looks suspiciously like super glue. And sure enough, I discovered one of the springs that holds the case halves together is missing and was glued together. That explains why I didn't get any movement photos!1 point

-

Well, try with the dial and the hand on and evaluate how much the free play of the tip of the hand will be and if it will matter at all1 point

-

First of all, the whole assumption is wrong. The truth is that the holes are interconnected by defoult. Clean and lubricate the movement and enjoy it, no point to wоrry.1 point

-

definitely would be an option if I would have had proper tooling. now that Im thinking, the proper question would be, is there anyone from Switzerland who would be willing to help?1 point

-

1 point

-

Despite your explanation on the number of turns until slippage, I think it would be extremely helpful if you could just test the power reserve once. Having always used 8217 with no apparent problems, I don't think it is causing you issues per se. But I'd be very interested in a 1-to-1 comparison.1 point

-

I went looking for pictures of the balance wheel like yours. Yours seems be suffering from a hairspring issue probably beyond magnetism. Then the stud I find it odd that the Omega replacement balance complete would have the wrong type of stud. so couple of pictures so you can see we hairspring is supposed to look like and the stud is definitely not round in this example. here's a slightly different image where you can see the stud does not look like yours1 point

-

@Birbdad, I was just reading all your posts about this topic again. Question: have you tested the power reserve yet (after winding manually to full wind)? How does it compare to spec? If you get to full/above power reserve, I'd be less concerned about premature slippage of the spring. If power reserve is fine, then you could review the strength of the spring. The one you got from GR is 0.11mm thick. Watchguy.co.uk uses one that is 0.12mm thick (GR2378X): https://watchguy.co.uk/service-seiko-7s26-0200-scuba-divers-watch/#:~:text=I will fit a new,12 x 400 x 10.5. And Gleave lists one with 0.115mm thickness: https://gleave.london/mainspring-0-95-x-0-115-x-380-x-10-0-automatic-seiko-7009-swiss-made-generic/ Important disclaimer: I am NOT advocating to blindly use a thicker spring to get more amplitude. Only if everything else is fine and if the power reserve is at/above spec. And if anyone can confirm the thickness of the original spring, then that's the one to go by.1 point

-

When I said it was not difficult all I wanted was the word MARRAGE. It means that the case and the movement never started as one, they are from two or more clocks in this case it is two. The case is from around 1750 which include the dial and hands. The movement is from anything from late Victorian up to about 1920’s. The movement looks to be from what are known as school clocks which were in classrooms. Going back to the case and type of movement, it would have been a verge timepiece with some sort of attachment to revolve that ball which I expect it to have shown day and night. The finials and the feet are correct but the hole in the floor is later which someone said. You can see in one of the photos how bad the movement has been fitted. Also the handle is missing from the top. The whole thing is worthless. It is the experience I have gained over years I can spot them right away. Part of my horology time was going to antique auctions and advising a very good antique shop on what to bid for and how much to go up too. Thank you to those that had a go. Any questions just ask.1 point

-

1 point

-

Ok I was just checking no offence. Strange that the others dont fit if they are from the same watch. Check that the stem pivot of this original one isn't stuck broken inside the hole in movement1 point

-

I have spare stems for the exact same movement from another watches, I can be clueless sometimes but not to this degree.1 point

-

That's exactly what the seller suggested; actually a complete watch ten euros.1 point

-

What I guess is that the front cylindrical part of the stem is broken, so You will need both the male and female parts.1 point

-

I don't know if it's just me but I find the background very distracting.1 point

-

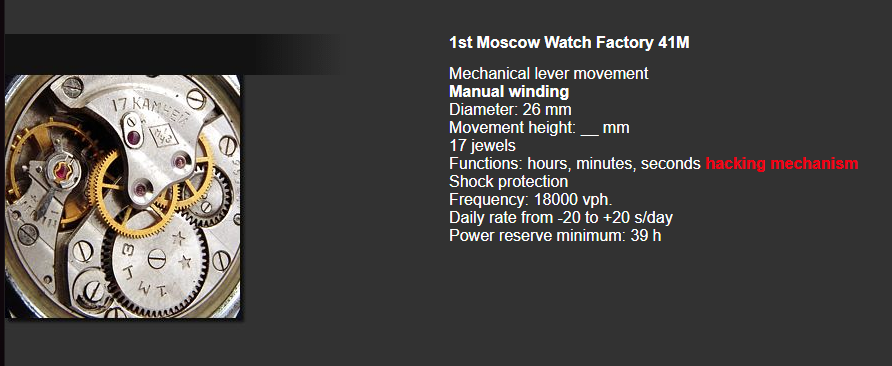

I still can't figure out where this 2634 originates from as I can't find any records showing this as a movement reference. I know there were a lot of undocumented movements from the eastern block around this time but think someone has created this number. I think this is actually what it is but figured as you only wanted the second wheel and pinion you'd just get a 2608 for £10-£15.1 point

-

1 point

-

I will just copy and paste my answer from another thread for the same problem: Guys, demagnetising this spring is like empting empty bottle. First of all, it is very hard, almost impossible to be magnetised. If it is sticky, then it must be cleaned. Usually hexane or generally pure petrol helps. If one can't obtain such materials, then He can distill some A95 petrol from the petrol station. But, sometimes petrol is not able to clean some sticky stuff and then pure acetone must be used. And, the heavy artilery - boiling in stuffs like NaOH. The last thing for sure will destroy the shellac if it is used to fix the imp. jewel, but in 2609HA there is no shellac there.1 point

-

If the oring is new and supple, this tool can pull it out very easily without any damage to the oring or crown. But if the oring is hard and brittle, the only way is to soak it in acetone until you get a black goop and scoop it out with an oiler.1 point

-

Are your confident that you've got the correct and genuine Omega parts?1 point

-

Hi knebo. This stuff is news to me. With high frequencies though, amplitude can be reduced to 220 degrees, ideal for isochronismic state for the oscillator, should add simple single impulse Swiss lever escapement. Possibly this 135 degrees amplitude is no longer invalid by standards of new improved horotech. Make me feel old. Rgds1 point

-

Skip indicates the minute drive wheel and sweep pinion's failure to engage. Providing other involved parts are undamaged, tension spring ( if intact) is a easy and inexpensive fix, so I wonder, repair might have been labour extensive which can explain why the repairman decided to return your watch unrepaired. We need to see a pic ( focused on centre) of the movement , like the one knebo showed above, then a few simple tests that you can do, helps decide if you should personally attempt the repair. Rgds1 point

-

Thank you. Yes, the Patek is a thing of beauty, and a genuinely nice company to deal with. The staff in the London salon were incredibly helpful, and very kind to my (then quite young) daughters. Alec1 point

-

If You remove it, probably will find that actually the original catch doesn't work. Leave as is and use it.1 point

-

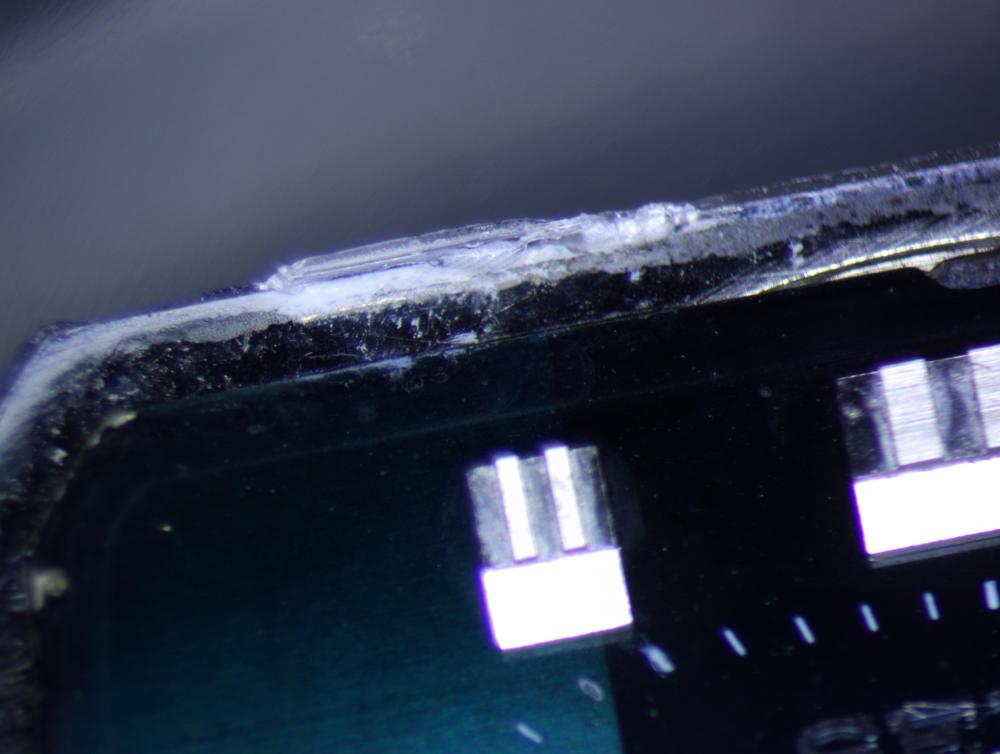

I won what looked like a fair condition Zodiac Sea Wolf on the bay. It arrived quickly and at first glance looked half decent. The lume had gone from the hands but it was ticking, which was a plus point compared to some other recent eBay purchases. Then I opened it up. The watch could have applied for membership of OPEC there was that much oil in the movement. It was everywhere, apart from some areas it should have been. Second observation was that the previous person who worked on this used a variety of small chisels and other assorted sharp implements to "service" the movement. Turning to the dial side, there were a couple of screws missing and some obviously put back in the wrong place, plus the hands must have been removed by Edward Scissorhands, going by the marks on the dial. It was also running like a dog; +280 seconds a day, 150 amplitude and a beat error above 9. So, two weeks of stripping, cleaning, ordering missing bits, installing the correct crystal, re-luming the hands, sympathetically restoring the bezel and it's back in operation. I also had to recreate a new seconds hand as the old one resembled a hockey stick that had been left out in a hailstorm. Whilst the amplitude is now up to 280 and the rate is +- 5 seconds, I'm still not happy with the beat error which is sitting around 2.5 - 3 so more work to do. A word of warning for anyone looking to buy a beater of this movement, Zodiac 70-72, to fix up. The parts are rarer than rocking horse droppings and quite pricey when available. The mainspring barrel is sealed, and I mean sealed. A replacement is around $140. Same for the balance. However, this movement was a collaboration with Zodiac, Favre-Leuba, Girard Perregaux, Doxa and Eberhard. I managed to find a Favre Leuba movement that was a lot cheaper than the Zodiac and the parts were fully interchangeable. On the plus side, this is my wife's favourite watch so I'm sure she won't mind me finding another few to fix up.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)