Leaderboard

Popular Content

Showing content with the highest reputation on 07/24/24 in Posts

-

The local and only watchmaker with a storefront in Concord, NH is a Hamilton devote. When asked what the best American made movement was he responded promptly with the 770. Added that for everyday use it is the watch as it has shock protection. Given the plethora of Hamilton movement numbers made in Lancaster this gave me something to focus on. I found one on eBay that was pleasing and he serviced it. 770 are small movements and I was not going to cut my teeth on them. I wear it often. It is a tad slow but perhaps with my new timegrapher I can give it some extra attention that he may not be inclined to provide. Note the H and W on the gate. I just thought it was calming to sit in some of the many blue Adirondack chairs on the yard and soak it all in and imagine the hustle and bustle pre war and the dramatic change when we entered WWII and the mass production of fuses and naval clocks behind the brick walls. Not knowing this intense war effort would set in motion the death of the American Watch industry. Interestingly the HW clock tower that I spent time around had no hands. Some research on this sad tale is that the original mechanical mechanisms are long gone and they were replaced with electronic motor driven mechanisms by Hamilton back in the day. If we only knew what we knew today. And apparently even the electric versions are hopefully being restored. All things are relative. Horology is a fascinating topic of investigation. So glad the Hamilton Watch Company buildings still stand. I grew up next to Waltham and the lore still existed back in the '70s. I recall an old guy up the road who used to work at Waltham and he flashed his Accutron Spaceview when I was 12 years old. I have an odd visual memory. When I showed his children a picture of the watch I recalled they were speechless that some little bratty kid they use to babysit remembered their father's watch. Have a look at these photos re the loss of the Elgin factory. So sad. Thankfully Hamilton's towers are now on the National Historic Register. As is Waltham.3 points

-

3 points

-

Let me clear something... Beat Error is not something that can be bad. It doesn't show that there is any problem in the movement and doesn't affect the timekeeping. It only depends on initial (neutral, zero) position of the balance and if this position is wrong, the movement will not start working by itself and will need shaking. Further, if BE is wrong, the movement will come sooner to 'galooping' if the amplitude is very big, than if BE is correct. So the correct BE allows maximal amplitude without 'galoopiung'. Yes, it is possible that other things than initial position may cause BE. For example, artificial limiting of balance movement in one of directions. But, such problem will cause many other things and wrong BE will be the last thing to be concerned about then. Something more - the way BE is calculated in timing machine is such, that the result depends on amplitude. If You have BE different than 0, then it will depend on amplitude. So You don't need to worry if BE is bigger in vertical positions, this is normal. Generally, You don't need timegrapher at all to adjust the initial position correct. You just need to ensure that the initial position is such that the impulse jewel holds the pallet fork exact in the middle of it's movement (imp. jewel on the line balance bearings-pallet fork bearings) in static when DU/DD. If it is so, then You can ignore what timegrapher shows as what You see in the movement is more relevant than what timegrapher calculates. An easy way to adjust initial position (if the roller is placed in such manner that the impulse jewel is on the bisectrix line of the angle, formed by the spokes/arm of the balance wheel) is to observe the figures that spokes/arm draw when balance rotates. This figures must be symmetrical with line of symmetry balance bearings-pallet fork bearings.3 points

-

3 points

-

Thank you all for your kind and warm welcomes. ah Letchworth, just up the road from me. Home of the UKs first road roundabout….2 points

-

Dell I'm sure members on here will find this interesting on how you go about cleaning and polishing brass. It brought back a lot of memories for me even though I had different ways to yours. One thing which is the same and that is it's a mucky task.2 points

-

For me, a braking grease is essential for the proper lubrication of the highly loaded contact area between the mainspring bridle (steel) and the barrel wall (brass or aluminum). Both in combination serve as a slipping clutch or „brake“ in an automatic watch. I always doubted the idea that braking grease can be used to prevent the bridle from premature slipping. After searching this forum and the net for some side-by-side testing of bridle/wall lubricants with no success, I decided to do the following test: 1.) take a brand new barrel with mainspring of an automatic watch and find the power reserve 2.) remove all lubricants inside the barrel and test the dry (unlubed) barrel again 3.) oil the inside with D5 and test again What would you expect? Here is the barrel of a brand new (Chinese) skeleton watch I used. The opening allows cleaning and lubricating the inside without removing the mainspring and risking a bent spring or bridle. I counted the turns of the barrel arbor before slipping. To be able to wind the spring I glued a nut on top of the ratchet wheel. The nut was turned with a socket. A mark on the socket helped counting. Here are the results of my simple testing after 10 repetitions with each setup. - barrel factory lubed => 7 turns +/- 10° - barrel dry w/o lubrication => 7 turns +/- 60° - barrel oiled with Moebius D5 => 7 turns +/- 10° My expectation before testing was a slightly lower power reserve of the oiled barrel and a significantly higher reserve of the dry barrel. So the result surprised me a lot! On the other hand the result supports my assumption that a braking grease should not increase the power reserve. Knowing that my testing does not comply with scientific standards, I am sure we will get at least some interesting discussions.1 point

-

With no power in the barrel , ink mark ( as a reference point) a suitable point on a bridge where balance usually stops and another ink mark on rim of balance right in front of the mark on bridge. You now have marked two point , one on bridge the other on balance rim , both right in front each other where balance usually stops. Manually rotate the balance wheel whilst keeping an eye on the fork, when impulse jewel starts to engage the fork, fork moves, continue rotating the balance until the fork stops moving, indicating no engagement of impulse and fork, ink mark this second point, the two points on bridge where fork started and stopped to move indicate start and end of the arc at midpoint of which your impulse is in beat. Though not exactly accurate, this two points on bridge indicate the arc within which you must advance impulse jewel ,in order to have good range of adjustability . You would observe an interval in which forks interacts with impulse jewel, the midpoint of this interval is where impulse should come to stop, for good range of adjustability. Take your pick , either rotate the roller table or hairspring coil, to have a balance in beat (or near) in beat. An In beat impulse would maximize the amplitude, thus minimize the ratio of positional variation compared to out of beat balance, movement starts running with minimal wind, and maximized usage of reserved power in the barrel,,,, Rgds1 point

-

1 point

-

IPA won't remove the grease, at best it will dilute it, making it less viscous. I really do commended you on your efforts but the experiment is flawed. The only way to do it correctly would involve removing the spring and ensuring everything is perfectly clean before trying the next grease. Once again, I have nothing but respect for your efforts.1 point

-

Oh great! Newbies are usually treated well here if they introduce themselves and include enough information as well as photos in their posts. All of which, you did. I'm curious about this watch. So you were able to remove the movement without the dial... were they not attached to each other? Dial feet now broken off?? Or are movement and movement somehow attached independently to the case? Any photos of the open watch before you removed the movement?1 point

-

Some petroleum based solvent shifts it better than alcohol . Difficult to know how well the old lube is being removed and new lube distributed without taking the spring out. Over time things also change, testing in a working environment might show different results. We all love a good experiment, great idea like this help us all learn1 point

-

I really don't know if IPA would remove heavy grease like that.. If it didn't, the following tests would basically be a repetition of the first. Maybe lighter fluid/benzine in the ultrasonic cleaner would get closer to removing the original breaking grease. But even with that, I'd be sceptical without removing the spring. I guess (like me) you don't have a mainspring winder? Then you could do the test properly. Or at least gently remove the barrel lid without removing the spring. Then you could have a slightly better look at the residual breaking grease that may/not have come off. Anyway, I really congratulate you for taking on this testing. I think the results would be very useful.1 point

-

If you see the hands stick as they pass then that's more then likely the problem. Otherwise it could be the movement that's seizing.1 point

-

1 point

-

This is an extremely interesting test! Thanks for doing this. I was also wondering about this. My initial understanding was the you'd apply D5 as a [wrong] breaking grease (i.e. to the barrel wall) for the 3rd test. But now I'm wondering if you did or not. Also, how did you clean the barrel's initial (presumptive..) lubrication? I understand that you left the barrel assembled. I see that the barrel lid is skeletonized, but I still wonder if lubrication can effectively be cleaned this way. How did you do that?1 point

-

If you aren’t opening the barrel and removing the spring to clean and lubricate (or not lubricate), how do you access and experimentally control the space of interest which is between the outer coils and the walls? Even with skeleton fenestrations you can’t really clean without disassembly, can you? Or maybe I misunderstood your methods.1 point

-

1 point

-

I think classic laypeople think that magnetized hairsprings are stuck together. But they would be running it so insanely fast if they were the timing machine wouldn't even show anything at all at least not the conventional timing machine and even then you'd be going insanely fast. I think you're more likely to see worst-case scenario what I showed down to just minor variations. Then yes is not fun putting a super magnet on top of the balance wheel. Not something normally recommend but interesting thing to do anyway.1 point

-

1 point

-

OK, in that drawing it looks like either part of the keyless works, or a switch that disconnects or clears the electronics in setting mode. I'm not sure from the drawing if it is purely mechanical, or possibly it's the metal contact next to the crystal the goes to the rightmost pad on the circuit board??1 point

-

I see, it now. I read it now refers to the V252A manual, which I linked now. Looking at it. I am not sure how to press it to reset the movement? Edit: I found that the black pin is the reset, and now the movement works. HATTORY-PULSAR-V252A.pdf Thanks everyone.1 point

-

Only a small book but as others have said its non fluff. Worth seeking out the book as it has a really good fold out diagram. I paid a fiver for it , i think Tom paid the same.1 point

-

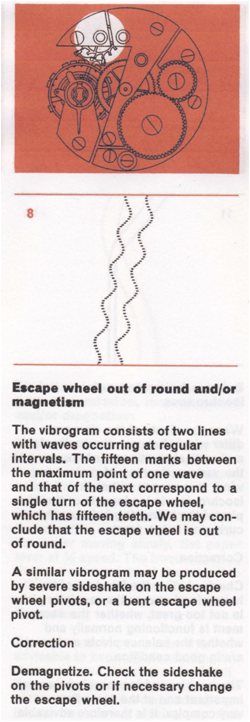

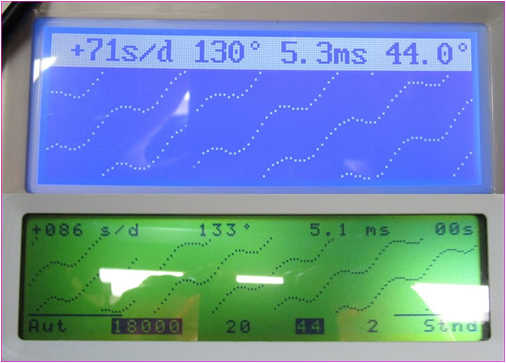

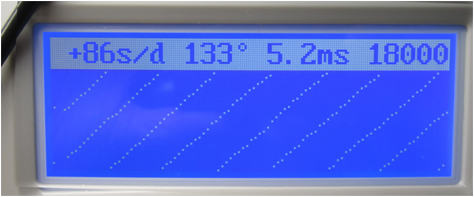

so basically what you're saying is magnetized hairsprings are overrated as to the consequences of them being magnetized? Here's a image from a timing machine manual they show an interesting sine wave effect that could occur then does it really look like this well sort of it depends upon the timing machine. Normally most people will demagnetize their watch before even putting it on the timing machine. so normally this is something you should never see at all. except a long time ago somebody purchased a Chinese 1000 timing machine apply recommendation and he was bewildered by his collection of watches. his meant I did not follow the normal procedure but instead placed all of his watches one of time on his timing machine and for reference compared the mine and you'll notice in this image magnetized watch then identical watch demagnetized and now comes some other interesting things. There is a minor problem of it's really hard to synchronize both timing machines's they're always be a little bit of variation of exactly what part of the waveform they're averaging but to still really close. you will notice there is not a spectacular amount of it's running fast because it's magnetized. Yes this watch along with several other was watches were extremely desperately in need of proper servicing. So the amplitude totally sucks and yes the watch is out of beat. then this is not a modern hairspring this is a blued steel I believe it was a Howard pocket watch. So obviously it's going to be much greater affected by magnetism that a modern watch but it does show there is in fact. Often times at work they forget to demagnetize wintertime a modern watches so if they see anything that looks a little off then they'll do what they're supposed to do to make things look a little better so true it's not a spectacular amount but it can be seen on the timing machine.1 point

-

Yes I used that site often and also the spreadsheet calculator what circulates on these boards...As nevenbekriev mentions I should need an original spring as baseline for turns so on to the next challenge on this one...1 point

-

A never ending and so rewarding (to some) story of magnetism in watches … A certain German forum loves it, and such threads get 2-digit page numbers easily. I undertook extensive experiments there with magnetized hairsprings. Even Nivarox hairsprings will get magnetized (not quite as easily as steel). And in magnetized state coils didn‘t stick together. I never understood, why they should. Do magnet poles of equal polarity stick together cause they are ‚magnets’ ? Surely not. The rate with magnetized Nivarox hairspring differed by several dozen s/day and returned to zero unmagnetized. I am with the suspicion that external forces between hairspring and surrounding steel parts influence the rate. Frank1 point

-

I don't buy Alex's line of reasoning here. He states that the magnetised hair spring is showing no sign of sticky coils yet the rate and amplitude have been severely impacted. He shows us a video of the breathing hair spring in which sticking coils cannot be observed, and a view of the hair spring from underneath with all the coils separate. This, he claims is proof that the increased rate and decreased amplitude are not due to sticking coils and therefore must be down to something else, so he attributes it to "magnetic friction". I believe that he is completely missing an important mechanism here which dramatically diminishes his argument for magnetic friction, ie. that of momentary sticking. This is where the magnetism isn't quite strong enough to cause the coils to stick with the inter-coil spacing of the spring at rest, but is strong enough to cause them to momentarily stick as the inter-coil spacing is reduced when the spring breaths in, but release again as the spring breaths out and the inter-coil spacing widens enough to overcome the magnetism. When this happens the effective hair spring length is reduced (and therefore rate increased and amplitude decreased) for that period during which the coils are close enough together for the magnetic attraction to cause them to stick, which is also when the hairspring diameter is smallest and so the whole spring is hidden by the balance cock. However as the balance spins the other way and the hairspring expands the breathing action of the spring overcomes the magnetic attraction and the coils separate again. In Alex's video the hairspring diameter only shows us between 2 and 3 coils (excluding terminal curve) at max diameter, and no coils at all over half of the circumference at a smaller than at rest diameter. Whats more the part of the spring where the inter-coil spacing changes the most (opposite the regulator) and is therefore the part of the spring where the coils are closest at minimum diameter and most likely to stick, is completely hidden under the cock the whole time. As this is the part of the spring where coils are most likely to become momentarily stuck it is not surprising that we can't see sticking coils, even when the balance is stopped or removed and viewed from below with the balance at rest. However that does not mean that we can't see evidence of a sticking hairspring. One of the things that I look out for is trembling coils. By this I mean coils that vibrate as the coil expands. A spring that has no sticking coils at all breaths in and out smoothly as the balance oscillates. On the other hand if two coils momentarily stick and then suddenly release, the spring will vibrate like a plucked guitar string, and this can be seen even when no actual stuck together coils are in evidence. This is easier to observe in lower beat movements, but can be seen in 28000bph movements as well. I don't think that Alex's video is clear enough to be sure but I think I can see it there. I don't know enough about electromagnetic induction to be able to comment on the magnetic friction theory other than to say that my gut feeling is skeptical.1 point

-

The hairspring itself will not be magnetised, but there are many other steel parts in the movement which magnetising will influence it's work. The closer to the balance and the bigger they are, the more influence. The balance staff itself and the roller (if made of steel), the regulator and stud carrier, the pallet fork(when it is made of steel), the escape wheel, the ratchet wheel, barrel arbour, the mainspring... and all the screws at the end.1 point

-

We did discuss this sometime ago. While non-magnetic nickle alloy hairsprings do not become magnetic themselves they can be drawn to something that is magnetic. If i remember correctly they have paramagnetic behaviour .1 point

-

Sounds like the way to go but I'll need to find a stump or bench block that would work, I don't think I have anything suitable. I'll give it a try if I decide to remove that cracked collet... In the meantime I'm waiting on a bunch of other parts to arrive in the mail so it might be a few weeks before I can give an update. Cheers.1 point

-

1 point

-

If that were the case i should have been banned a long long time ago. A bit close to the knuckle i guess, harmless fun, but point taken lol. Besides i can blame you, for losing your pivot in a hole where you shouldn't be losing it. Just realised my double entendre " point taken "1 point

-

1 point

-

Got this wonderful 1971 $8 eBay find running. Other than a broken mainspring and a crack in the crystal, it just needed a good clean up. It did have a beat error problem, but I got it adjusted to a 0.6ms BE, a 260° and positional error of +/-30s. Not bad for essentially a novelty watch probably not expected to make it much past the '70s. I think the hardest part was fitting the pallet fork without jewels. Those holes are TINY! That brass plating was 10 kinds of awful so I just polished it off for now. I might nickel plate it. Or 24k rose gold, for such an elegant timepiece.1 point

-

Yes, Jaxa tool or the rubber ball. Calibre 630 seems plausible. I recently fixed a 625 (similar to 630, but without centre seconds) and the size/design are similar. 12-13 hours isn't enough, without question. The cal 630 should do 30h and I believe that's pretty much the lowest you'll find.1 point

-

Looks like my gamble paid off again. I haven't opened the caseback yet (still at work) but it arrived ticking at a ridiculous rate, the second hand sweeps, the day, date, and time all set. There's a little ding in the dial, but I was expecting that. The back is slightly dented in, but we can fix that too. For the price I paid, I am extremely happy. I took a video to try capturing how the dial shimmers. It's like a butterfly's wing.1 point

-

Hi Daisy welcome, with the information you've provided from the previous repair guy this sounds very much like the short flat spring that keeps the sweep seconds pinion engaged with the indirect sweep wheel. Without the correct spring tension the second hand can stutter, the arbor that the hand connects to has too much free play so the pinion leaves and wheel teeth do no remain constantly meshed. Haha you beat me to it matey and with a picture Ps just be careful with your outlining in future if that spring had 2 fixing locations then............i need say no more1 point

-

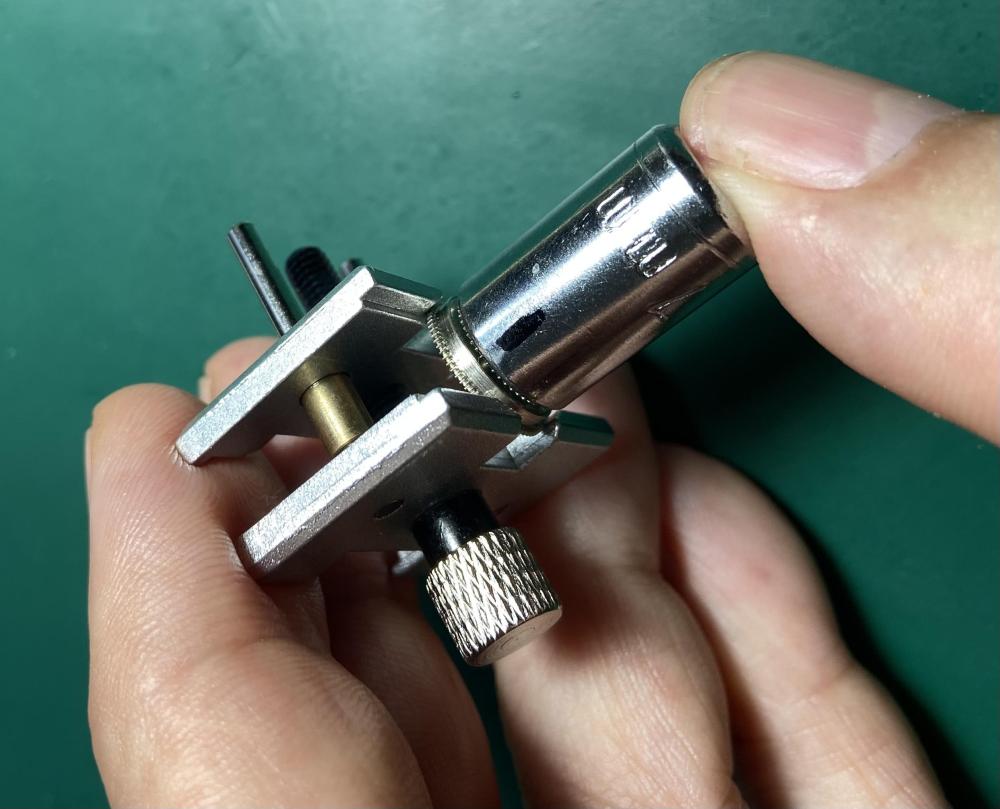

Hi Daisy, The diagnosis is most likely correct: there's a spring that puts a tiny bit of tension on the seconds pinion (which holds the seconds hand). If that spring is too loose, badly placed, or even missing, the second hand will skip. A skilled watchmaker should be able to fix this easily. Cheers PS: See picture. This is a Rolex calibre 1225, you may have this or a similar movement in your Oysterdate. The spring is surrounded in green, the red arrow points at seconds pinion.1 point

-

This is an old thread, but there is a much easier way to consistently, repeatably and controllably blue watch hands, screws and other steelwork compared to the traditional pan of brass shavings over a flame. A small metal container of brass shavings, heated over an electric laboratory hotplate is very effective. You have fine control of the hotplate temperature, and can achieve repeatable and consistent results by keeping records of what temperature was required to reach the desired colour for a certain type of steel. Beginners will achieve quality results, consistently, a lot quicker using a hotplate. The hotplate has other uses too, such as heating an escapement meter for adjusting pallet stones, and more, but that is beyond the scope of the dial restoration forum. Best Regards, Mark1 point

-

My DIY device uses a 12 v car battery charger as the power source. The dials are usually brass and the feet. Copper wire. I have used solder paste and solder chips cut off flattened solder wire with fluxite paste, never had one not work. A solid joint and no dislike damage. A damp sponge as Hector mentioned will cause problems with water transfer chapter rings. W hai I use is a bit of asbestos dampened just enough , not wet Do a search on the box door dial foot soldering machine and scroll down the results. Jan 4 th is my post and the machine I built1 point

-

This issue is a regular on the forum. I believe what is happening many watch the pro’s on vids and see that they seem to have no issues. BUT unlike us amateurs they have years of experience and have the uncanny feeling/touch gained through working on hundreds of watches. My advice is when releasing a spring always support using either some Rodico or some pegwood as they are springs and under some tension. Fitting a replacement spring is really tricky and covering the watch with some cling film while manipulating to save many hours in a search of the work area.1 point

-

Oh man, I was under the impression that compressed air method works only if the case is airtight. If its got holes/ gaps it would fart from every hole. and quite embaressing.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.d7e25789e398f0fbcfc1975a4182df55.jpg)

.thumb.jpg.f10e4a6d92fb0d228b8aa21a2b0ad450.jpg)