Leaderboard

Popular Content

Showing content with the highest reputation on 07/25/24 in Posts

-

I thought I would list some of my clock books if that is OK. I have to go and have my eyes checked tomorrow for diabetes so I have to have drops so it will depend on how things go normally I can't see a bloody thing for about 2 hours4 points

-

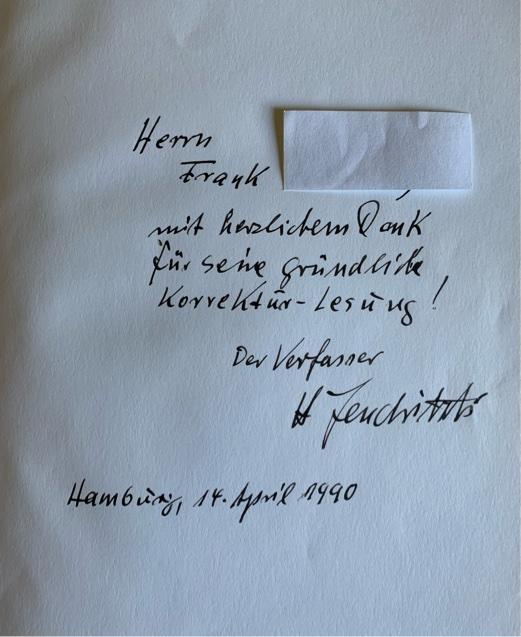

Ok, as a young man I sent him a review, questions and listed some print errors on the book. He thanks for „the thorough review“. I visited him in Hamburg then. Frank3 points

-

Correct, good practice is to demagnetise the movements before regulation. What I dissagree is different: There is a sentence "However, magnetised balance springs are not uncommon. Typical symptoms are an increased rate and decreased amplitude (not sticky coils)." there. The problem is that "magnetised movement" is often mistaken for "magnetised hairspring". That's what this thread is all about. It whent wrong from the point htat the OP's hairspring was claimed as "magnetised". Then everybody statred to explain about demagnetising and what demagnetisers they have and use. Well, the OP hairspring is not magnetised. And, the magnetised contemporary movements perform badly not because of hairspring magnetisation. They perform badly due magnetisation of the other parts of the movement, not the hairspring itself. And if one wants to prove that the magnetising of hairspring is the problem, He must take the hairspring off the balance, to magnetise it, to put it back and test the (not magnetised otherwise) movement with it. Not to magnetise the whole movement and claim the hairspring. There is also a stupid idea in the video about the "magnetic friction" in the hairspring. Well, the electromechanical watches with those big magnets on the balances that move so fast when balances rotate, how can they work at all?3 points

-

This fell into my lap today Schatz 53 with wall bracket it’s rare to find them as complete as this , manufactured Feb 68 and the only thing missing is the torsion spring ( usually broken) anyway. It’s been well over oiled but should polish up very nicely and Schatz are usually very strong runners, the only thing you have to watch on later Schatz torsion clocks is that the bush for the anchor rear pivot is in the back cock and one hole of said back cock is elongated so is in effect the eccentric bush to set the drops. Dell2 points

-

I picked this up recently for the 404 club, assuming it to be a Marlin from 1983, and probably a bit of a basket case, however it is actually a 1973 Mercury model number 160502473 and I have to admit I am very pleased with it. It is remarkably clean, tidy and scratch free which is all the more remarkable given the fact that it is 51 years old (I did fumigate it anyway just because I always give everything that arrives a good clean before I start working on it). It is probably one of the best preserved Timexes I have. Furthermore... it works, so I haven't even opened it up yet. For a few pennies under four quid, well worth the gamble.2 points

-

My only point is that as watch repairers we don’t have to worry about what parts are magnetised. Simply replace “balance springs” for “movements” in my sentence and I think we’re home. No one has suggested that only the balance spring should to be demagnetised, right!? As watch repairers we don’t need to understand the exact science, but we need to be able to recognise the symptoms of a magnetised movement, i.e., low amplitude and high rate. From the scientific viewpoint of it I’m sure Alex is just guessing (I wouldn’t know) but from a practical viewpoint he is spot on. That is, always demagnetise the movement before regulating it. The beauty of it in this particular case is that we don’t need to understand the problem (the only exception in watch repair that I can come to think of) We only need to be able to recognise the symptoms as the remedy is always the same. Demagnetise! I can understand the fascination for the science of it, but then it’s about something else than watch repair.2 points

-

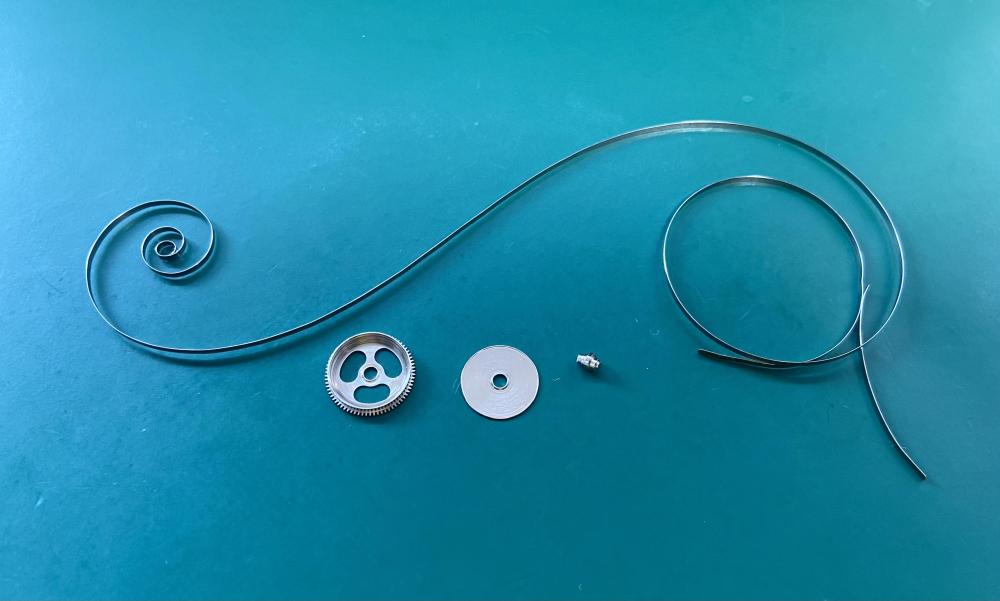

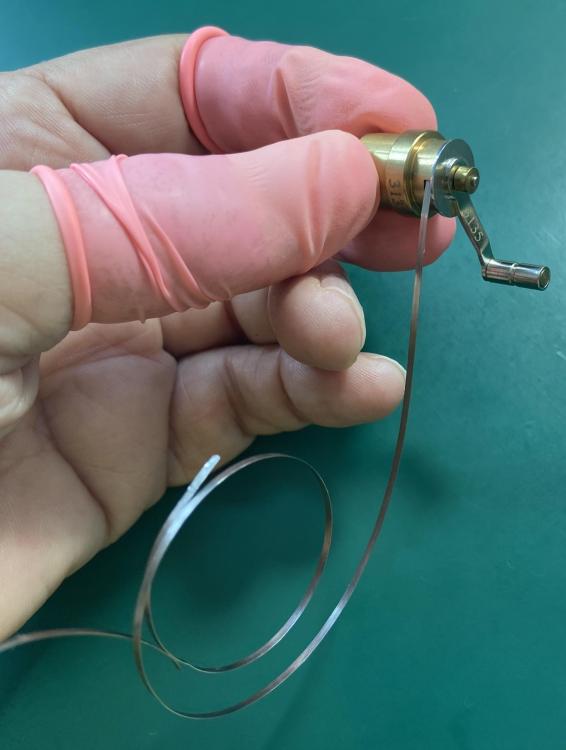

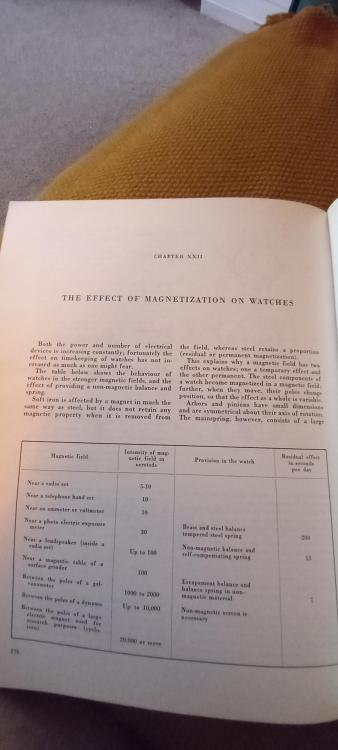

So Jendritzki doesn’t have a great deal more to say about it than has already been covered, magnetism can have permanent or temporary affects on how a watch runs depending on the materials used in the movement. Soft iron being non or virtually non magnetic as is nickel, nickel plated components can take on very small amounts of magnetism that have little affect. After conducting tests on watches with non magnetic hairsprings , balance wheels and mainsprings . Attempted applications of magnetism to these parts before installing them with fairly high levels of exposure resulted in relatively insignificant changes of rates. Big moving components such as a mainspring if composed of steel when magnetised will have varying affects on non magnetic hairsprings .2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

From a practical standpoint I don’t think there’s much to be gained from analysing what parts get magnetised, unless you’re a watchmaker (manufacturer). Just demagnetise and be done with it. It only takes a few seconds.2 points

-

Not at all. What I am saying is that the effect of magnetism in a scenario where the coils do not stick together is significantly less the impact that sticking coils has. I'm certainly not trying to suggest that magnetism has no discernible effect. It's interesting to note the differences between Alex's magnetised trace in his video, which I would (rightly or wrongly, I'm happy to learn) attribute to a shortened effective hair spring length and the wavy traces you presented above which might be explained by magnetised wheels with poles whose orientations change relative to each other periodically as the wheels turn relative to each other. @praezis there's nothing like a bit of experimentation, and while you were posting your link (worth a read) I was torturing an old Nivarox hair spring from an ETA 2879 with the neodymium magnet out of an old hard drive to see if I could get the coils to stick together, and I couldn't. The spring was deflected by the magnetic field but nothing stuck. I had no means of measuring the degree to which the H/S was actually magnetised though so not very scientific, and it may not have become magnetised at all.2 points

-

Or depending how good you are with a drill you could drill out the first few threads so it extends over the blank part of the stem.1 point

-

1 point

-

I suppose as long as? If you look at modern mainsprings there supposed to be prelubricated and require no lubrication at all at least on the mainspring itself. The breaking grease that may be another matter but the mainspring itself requires no lubrication. So yes one of these you could wash off the nonexistent lubrication although the breaking grease may be an issue again. Then apply a lubrication and may be at work maybe it wouldn't? Obviously you have to do a proper quality control testing like a watches supposed to run X quantity of hours after its wound up and if the watches on auto winder it should be a little run and not whatever is as long as it passes the quality control tests and everything seems to work fine then I guess it's okay unfortunately is always exceptions to the rule like anything that typically has a blued steel mainspring it should come out the make sure it's not set. The biggest factor in here is the testing to make sure that the watch does meet the criteria of proper power source. Because if you work on anything older the mainsprings can be set to longer functional or have extremely sticky lubrication which will never come out by just taking the lid off and cleaning in other words you do end up with a sticky mainspring. I once got the service a watch from somebody who said it to somebody with a online website promoting watch repair. The same individual promoting watch repair had another section on teaching watch repair because he thought IED that knowledge was nonexistent. I noticed on mainsprings he advocated not touching them at all because they're basically a pain in the ass. I don't harbor the exact wording but he did not promote touching the mainsprings at all. The individual who gave me the watch said that he set it to the person they came back and it didn't run I don't remember the exact description was too long ago. So he set it back with a complaint and they came back with Apsley no change at all. This is because as a guess the person wound the watch up put it on the timing machine everything past and didn't do proper quality control like how long does the watch run for for instance and yes what was the problem he should've looked into the mainspring which was.1 point

-

A watchmaker friend of mine did some testing on braking greases back turn of the century. I don't think Kluber was around or commonly available, and from memory it was between Glissalube A (8213 brass barrels), B (8212 aluminum barrels) and Glissalube 20 (8217). He's an ex chemist and used new barrels, which he would buy as different auto calibers came in. He milled away a window in the lid to observe the slipping. He counted the number of turns to slip, then observe the amount of slippage, holding the position of arbor and barrel for some time. Unsurprisingly the results backed up manufacturer's and Moebius' recommandations. I don't remember the super specifics, but sometimes slipping occured before full wind, sometimes continuing for a full turn or more (up to 2+ I believe). Sometimes it occured too late- which would cause rebanking and wear or breakage in the auto mech. Glissalube A did work best for brass, and B for aluminum. 8217 did work well in general, but sometimes A or B were better. I have a feeling if he had had Kluber P125 it would have been the best general option. It's good to question things, but I also think the manufacturers put a lot of effort into finding lubrication solutions that worked best, both initially and over time. This fellow bought at least a couple of dozen different barrels for these tests, mechanically and machine cleaning between greases. Not to dispute what manufacturers said, just to satisfy his own curiosity and to see which lubrication was the absolute best for a given barrel.1 point

-

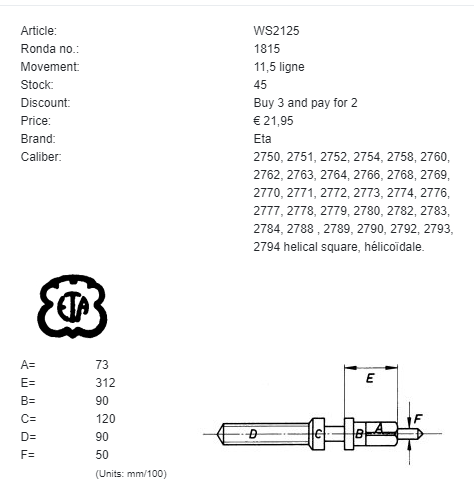

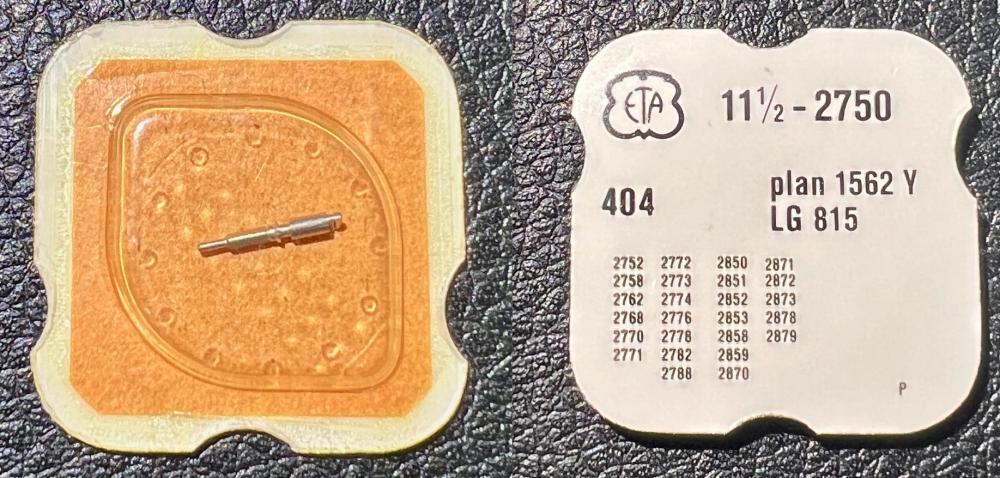

As far as the split stem, I think you probably require the same one that I put aside to use in a GG-W-113 with a Hamilton 2750-based military movement. Benrus generally used the male section in the crown on 2370/2750 watches, but Hamilton put it on the stem side. It's designed to be very short so the break is just outside the mainplate. I don't recall where I sourced it, but the photo shows the stem and part number information. Then you can grab a corresponding female coupling with a short unthreaded section and cut it where you need it.1 point

-

This is the definition of a grease from Wikipedia:- Grease is solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. Grease generally consists of a soap emulsidued with mineral or vegetable oil. So, it seems that grease is not a homogeneous substance but a suspension of oils and soap. So a carrier solvent might not leave behind the lubricants in the desired proportions. But having said that, there are spray on greases that come in an aerosol can. The grease when it first comes out is more liquid and immediately starts to bubble as the propellant and solvent starts to evaporate.1 point

-

1 point

-

I might have missed something... The difference is that +/-50°, right? The grease makes the full wind turn count more predictable, which I guess matters if you're trying to meet advertising specs for run time off a full wind (and why bother when the marketing wanks don't bother trying to meet their specs to reality?). Seems the actual reason for the grease is to protect the barrel so that it KEEPS being 7 turns and prolongs service intervals and component life. (In the event I missed something up there over the last two days or so that the thread has been going, please see my previous post and excuse me. That whole baby mollifying situation repeated last night/today.) The test I thought would have been interesting in this would be a NON-braking grease vs braking grease. Every time I see the words "braking grease" it makes me wonder what about it makes it good for braking... Kinda like the friction modifiers used in clutch-based LSD differentials? Or something else?1 point

-

You should be able to tell if part of the tube is left in the case and maybe even push/pull it out.. If you can't then I'd probably drill to 2mm and reamer the rest to get a tight fit with a 2.2 tube.1 point

-

So even a 1.3mm tube has an I/D of 1.0mm which would be tight even for a 0.9mm stem let alone a split stem.1 point

-

I would have expected it to be a standard size tube. I've got a set of these drills to use when measuring things like tubes along with a 2.1 & 2.2 I got loose. https://www.cousinsuk.com/product/0105-to-0200mm-set1 point

-

there's an interesting discussion currently going on looks like you can throw your breaking grease away as you don't need it at all apparently?1 point

-

sometimes I hate the advertising on the message board as I read the original message and then saw the advertisement and didn't realize the conversation had continued with multiple people asking the exact same question that I had which is you can't properly clean the barrel without removing the mainspring. you should try some P1 25 see if that makes any difference. The other problem with the test is what is the purpose of the breaking grease? the other purpose of the breaking grease is when you reach the point of time that the mainspring slips how much does it slip? I remember using the wrong grease when I was in school I just grabbed the bottle out of the drawer it looked right and found that when the spring slipped it basically lost all of its energy. so the other purpose of all of this would be when it loses its energy I guess you're getting seven turns every single time which means we can throw away one more lubricant or basically not by another lubricant that we don't actually need.1 point

-

1 point

-

Thanks for the welcome. Of course I'd like to reply by saying I'm only joking, as if I'd be silly enough to buy a lathe before removing a back off a watch... Regrettably please find attached photos requested (OK maybe I'm slightly exaggerating about not taking a back off a watch, but I'm several light years off legitimately needing a lathe).1 point

-

Ultimately, what magnetism is affecting is a moot point, it is detrimental to the correct running of the movement, so demagnetification should be part of the service routine. Many on here though, including myself, like to understand the problem and not just accept it.1 point

-

Split stem adapters are available with a range of lengths of that unthreaded portion, so you can get one that is very short when needed.1 point

-

1 point

-

IPA won't remove the grease, at best it will dilute it, making it less viscous. I really do commended you on your efforts but the experiment is flawed. The only way to do it correctly would involve removing the spring and ensuring everything is perfectly clean before trying the next grease. Once again, I have nothing but respect for your efforts.1 point

-

Some petroleum based solvent shifts it better than alcohol . Difficult to know how well the old lube is being removed and new lube distributed without taking the spring out. Over time things also change, testing in a working environment might show different results. We all love a good experiment, great idea like this help us all learn1 point

-

I certainly would oil both sides, doing just one side can push the wear and tear on the dry side.1 point

-

Wow, that patent is impressive. Where did you look to find that? My races look a little different from the patent. That looks like there is no space between the bearing balls and the bottom of race where as mine has space and could accommodate a spacer. There is a shoulder that has a thickness of .20mm. As long as every bearing ball is touching the races they should not slip in the races. My guess that if there is only 12 it is unlikely that the balls would touch each other and only once you increase up to 72 does the spacer be required to keep it efficient. I have made contact with the watchmaker from the Omega forum and he said he still has the spare so I should be able to purchase the spacer and I can do some testing and see how the mass preforms with and with out the spacer with various amounts of ball bearings. I have only ordered 50 bearing balls so it may fall slightly short of the 72 number. I think in variations of this movement, they used ruby bearings balls. That would quite the cost but would be very beautiful to watch.1 point

-

I. LOVE. THIS. I'm trying to keep a baby from melting down though, so I have nothing to contribute at the moment.1 point

-

I only take the practical approach to magnetism. If a watch has been properly serviced and repaired but still displays an unexpectedly low amplitude and high rate, demagnetizing can dramatically improve the performance. Exactly why that is I leave to my MagnOmatic. As a matter of fact I don’t even bother to check for magnetism.1 point

-

These are just bought parts so all you need to be able to do is cut the stems.1 point

-

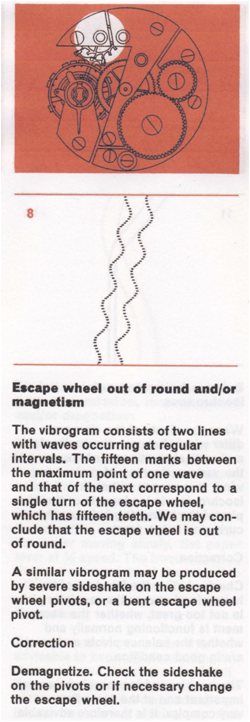

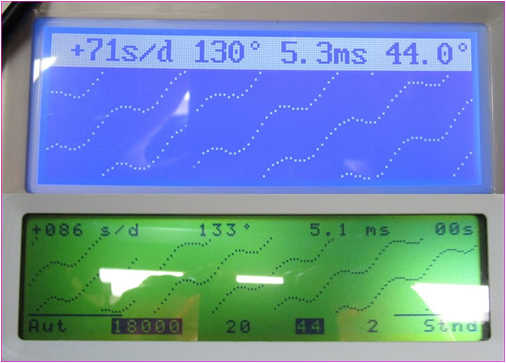

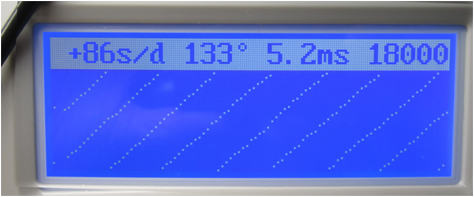

so basically what you're saying is magnetized hairsprings are overrated as to the consequences of them being magnetized? Here's a image from a timing machine manual they show an interesting sine wave effect that could occur then does it really look like this well sort of it depends upon the timing machine. Normally most people will demagnetize their watch before even putting it on the timing machine. so normally this is something you should never see at all. except a long time ago somebody purchased a Chinese 1000 timing machine apply recommendation and he was bewildered by his collection of watches. his meant I did not follow the normal procedure but instead placed all of his watches one of time on his timing machine and for reference compared the mine and you'll notice in this image magnetized watch then identical watch demagnetized and now comes some other interesting things. There is a minor problem of it's really hard to synchronize both timing machines's they're always be a little bit of variation of exactly what part of the waveform they're averaging but to still really close. you will notice there is not a spectacular amount of it's running fast because it's magnetized. Yes this watch along with several other was watches were extremely desperately in need of proper servicing. So the amplitude totally sucks and yes the watch is out of beat. then this is not a modern hairspring this is a blued steel I believe it was a Howard pocket watch. So obviously it's going to be much greater affected by magnetism that a modern watch but it does show there is in fact. Often times at work they forget to demagnetize wintertime a modern watches so if they see anything that looks a little off then they'll do what they're supposed to do to make things look a little better so true it's not a spectacular amount but it can be seen on the timing machine.1 point

-

It is a caliper and should have a scale attached somehow: https://www.datamp.org/patents/displayPatent.php?pn=1295327&id=149871 point

-

I've come to know a fellow watchmaker in Oregon. He's been a great source for tips and vintage tools. He sent me a mystery tool. One that I haven't seen before and am rather puzzled by. It is spring loaded and has a small pin on each jaw. The pins are solid, so it doesn't look like they are intended to hold the pivots of a wheel. I thought maybe that it was to measure the thickness of things, but there is no scale on the side with the pointer. It looks like a dog used the handle as a chew toy.1 point

-

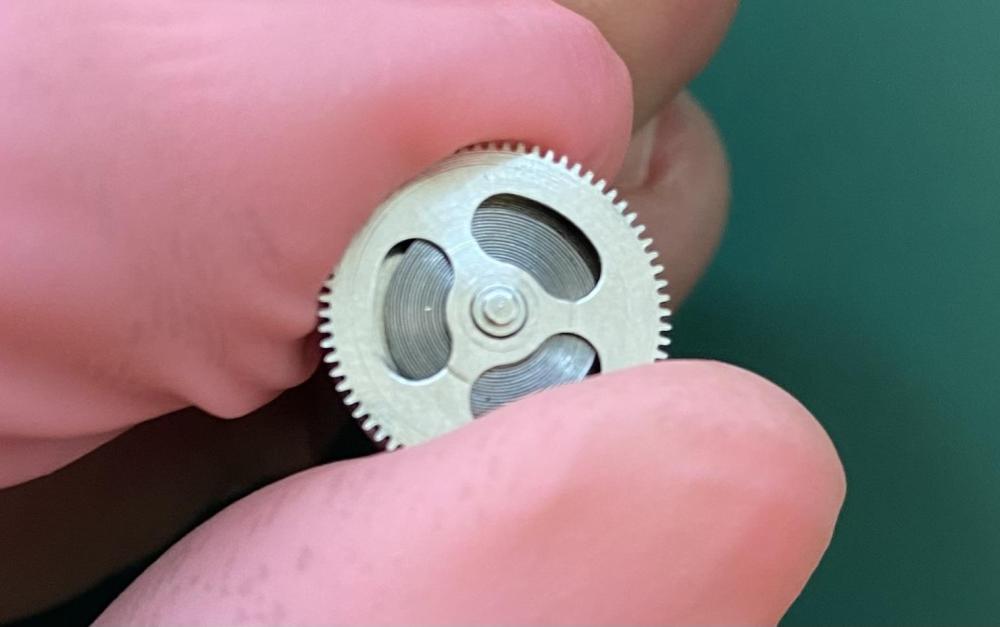

I went looking for pictures of the balance wheel like yours. Yours seems be suffering from a hairspring issue probably beyond magnetism. Then the stud I find it odd that the Omega replacement balance complete would have the wrong type of stud. so couple of pictures so you can see we hairspring is supposed to look like and the stud is definitely not round in this example. here's a slightly different image where you can see the stud does not look like yours1 point

-

I decided to do a little improvisation last night. I had a case where the sides were extremely worn, dented, etc. The case lines were nearly worn completely down. I've wanted a lapping machine for some time but those are far too expensive for my humble budget. I improvised by hooking up one of my sanders to a voltage regulator to bring the speed down as much as I could. I put some 1000 grit paper on the disc and started to gently work the side of the case. I'm quite surprised at what I was able to accomplish with these rag-tag tools and bit of creativity. I'm limited by the table because it can only adjust to 45 degrees, so there are some angles on that case I won't be able to reach properly. While looking up pictures on the internet of other examples of this case it looks like there was not a sharp line between the side wall and the lugs, so I just tried to bring back a gentle curve between those to sides. Not too bad for my first attempt! I'm going to keep moving forward and go up to 2500 grit and see what I can get out of this before moving on to the polishing wheel.1 point

-

0 points