Leaderboard

Popular Content

Showing content with the highest reputation on 07/26/24 in all areas

-

If it were me, I'd (gently) slide a smoothing broach into the hole and measure the point where it where it stops. That should get you close.2 points

-

2 points

-

Tbh you might find something different inside, this watch looks to be a good 60 -70 years old. Hopefully its original but a repair guy might have altered it in some way, swapped to a one-piece spring or modded it in some way. The spring and its seperate bridle may well be ok to re-use, Its better to keep to the original set-up as mentioned earlier in another thread, manufacturers put a lot of time,effort and money into a watch's design . Btw that a lovely looking watch face, i adore textured dials Some re-luming to do as well, it'll keep you busy for a little while2 points

-

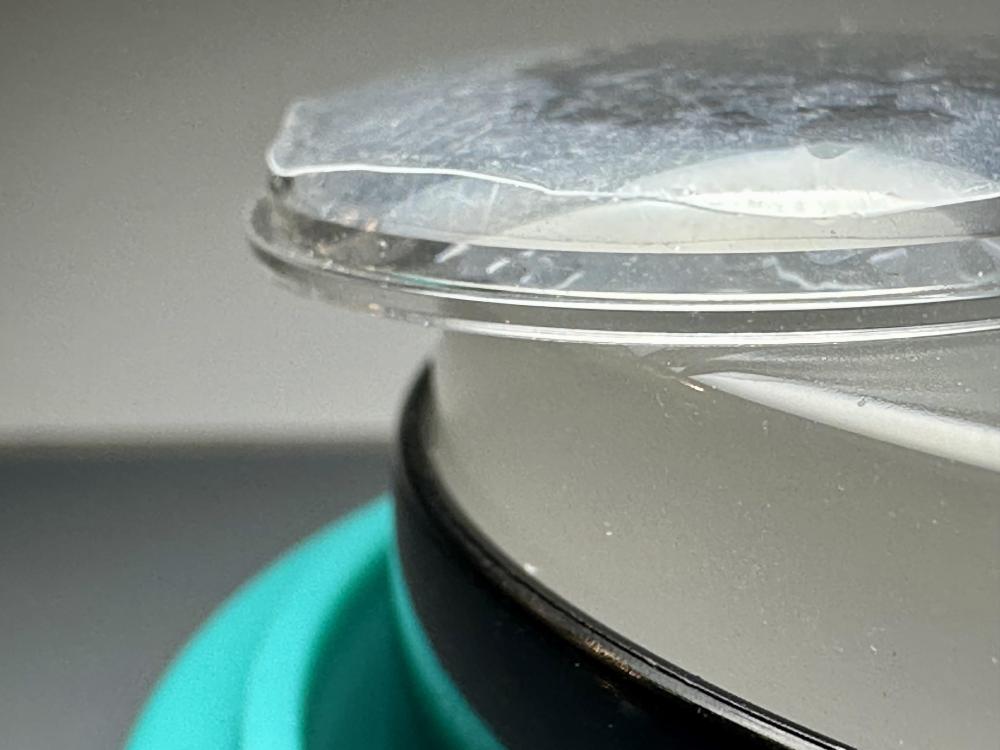

It locks the crystal in place as speculated: Place the case dial down and load the crystal thru the back. The original style crystals have a substantial lip edge to them and tightening the ring places forward pressure on this, pushing the glass into the underside of the front ‘bezel’…2 points

-

So the Buren DD also has one of these retainer rings. Mine was stuck and thought I’d find something in my case back tools but most of the nibs are round and taper to the end so are too fat to reach down inside the case. Welp, it had been over a week without buying another tool…In the states Amazon sells this Lyecun case back opener: The nibs are the perfect fit for the notches on the retaining ring… I unscrewed and reversed the direction of the nibs so the flat end was against the inside of the case. Worked a charm. Perhaps there’s something in your stash of case openers that looks similar?2 points

-

Don‘t be too disappointed if the rubber ball does not work. You will most likely need the proper wrench for your specific Rolex in order to apply enough torque.2 points

-

A watchmaker friend of mine did some testing on braking greases back turn of the century. I don't think Kluber was around or commonly available, and from memory it was between Glissalube A (8213 brass barrels), B (8212 aluminum barrels) and Glissalube 20 (8217). He's an ex chemist and used new barrels, which he would buy as different auto calibers came in. He milled away a window in the lid to observe the slipping. He counted the number of turns to slip, then observe the amount of slippage, holding the position of arbor and barrel for some time. Unsurprisingly the results backed up manufacturer's and Moebius' recommandations. I don't remember the super specifics, but sometimes slipping occured before full wind, sometimes continuing for a full turn or more (up to 2+ I believe). Sometimes it occured too late- which would cause rebanking and wear or breakage in the auto mech. Glissalube A did work best for brass, and B for aluminum. 8217 did work well in general, but sometimes A or B were better. I have a feeling if he had had Kluber P125 it would have been the best general option. It's good to question things, but I also think the manufacturers put a lot of effort into finding lubrication solutions that worked best, both initially and over time. This fellow bought at least a couple of dozen different barrels for these tests, mechanically and machine cleaning between greases. Not to dispute what manufacturers said, just to satisfy his own curiosity and to see which lubrication was the absolute best for a given barrel.2 points

-

My only point is that as watch repairers we don’t have to worry about what parts are magnetised. Simply replace “balance springs” for “movements” in my sentence and I think we’re home. No one has suggested that only the balance spring should to be demagnetised, right!? As watch repairers we don’t need to understand the exact science, but we need to be able to recognise the symptoms of a magnetised movement, i.e., low amplitude and high rate. From the scientific viewpoint of it I’m sure Alex is just guessing (I wouldn’t know) but from a practical viewpoint he is spot on. That is, always demagnetise the movement before regulating it. The beauty of it in this particular case is that we don’t need to understand the problem (the only exception in watch repair that I can come to think of) We only need to be able to recognise the symptoms as the remedy is always the same. Demagnetise! I can understand the fascination for the science of it, but then it’s about something else than watch repair.2 points

-

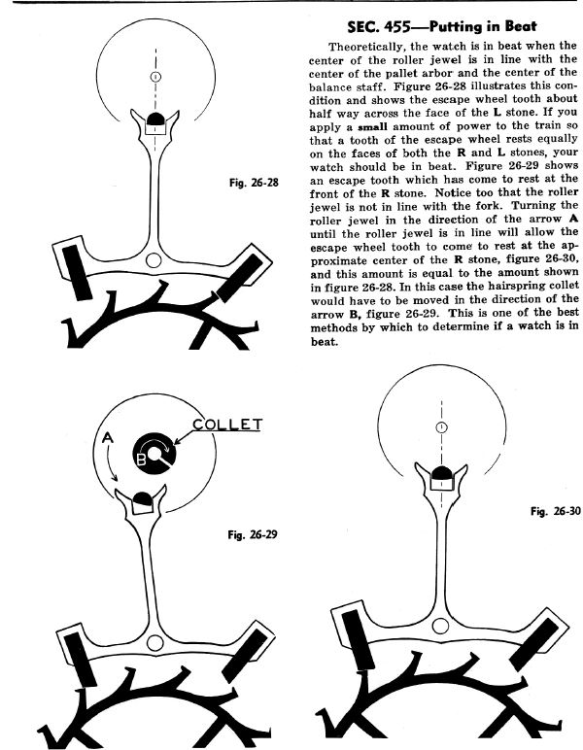

With no power in the barrel , ink mark ( as a reference point) a suitable point on a bridge where balance usually stops and another ink mark on rim of balance right in front of the mark on bridge. You now have marked two point , one on bridge the other on balance rim , both right in front each other where balance usually stops. Manually rotate the balance wheel whilst keeping an eye on the fork, when impulse jewel starts to engage the fork, fork moves, continue rotating the balance until the fork stops moving, indicating no engagement of impulse and fork, ink mark this second point, the two points on bridge where fork started and stopped to move indicate start and end of the arc at midpoint of which your impulse is in beat. Though not exactly accurate, this two points on bridge indicate the arc within which you must advance impulse jewel ,in order to have good range of adjustability . You would observe an interval in which forks interacts with impulse jewel, the midpoint of this interval is where impulse should come to stop, for good range of adjustability. Take your pick , either rotate the roller table or hairspring coil, to have a balance in beat (or near) in beat. An In beat impulse would maximize the amplitude, thus minimize the ratio of positional variation compared to out of beat balance, movement starts running with minimal wind, and maximized usage of reserved power in the barrel,,,, Rgds2 points

-

This fell into my lap today Schatz 53 with wall bracket it’s rare to find them as complete as this , manufactured Feb 68 and the only thing missing is the torsion spring ( usually broken) anyway. It’s been well over oiled but should polish up very nicely and Schatz are usually very strong runners, the only thing you have to watch on later Schatz torsion clocks is that the bush for the anchor rear pivot is in the back cock and one hole of said back cock is elongated so is in effect the eccentric bush to set the drops. Dell1 point

-

The rule is that the jewel must get in the bed without resistance and (almost) without free play. So using the pushers is correct idea. Just find the one that will get in as described and see it's size. Be aware that modern levels intended for press fit are not good for rubbing in. They can be used, but after reshaping the outer part like in the old stones1 point

-

Franken? To me. Not. My personal thought on a Franken watch, of which I have quite few, due to my lack of purchase price. Parts missing, wrong parts, broken parts, wrong screws, incorrect backs, wrong crown. All these I have. I'm working my way through them with replacement donors. If, when I get them running, they will have been Franken, but will then be part of my collection of 'watches'. Different views for different people.1 point

-

Thank you very much! One of the logos looks like the one I have under the balance wheel.1 point

-

1 point

-

I found this forum because I am desperately trying to resurrect my Tag Heuer Formula 1 2005 WAC1110.BA0850. It's my only "proper" watch outside of my fitness trackers. I'm in the UL and I think that there are a load of us looking for a solution to the perished rubber on the case of this fine watch.1 point

-

Hi Rich , I best go hide myself. Many thanks . Not sure but think this one is propriatory. A few was made for use on manufacturer's assembly line. Rgds1 point

-

Yup, a Q tip with some IPA or, worst case, acetone will clean up any permanent marker.1 point

-

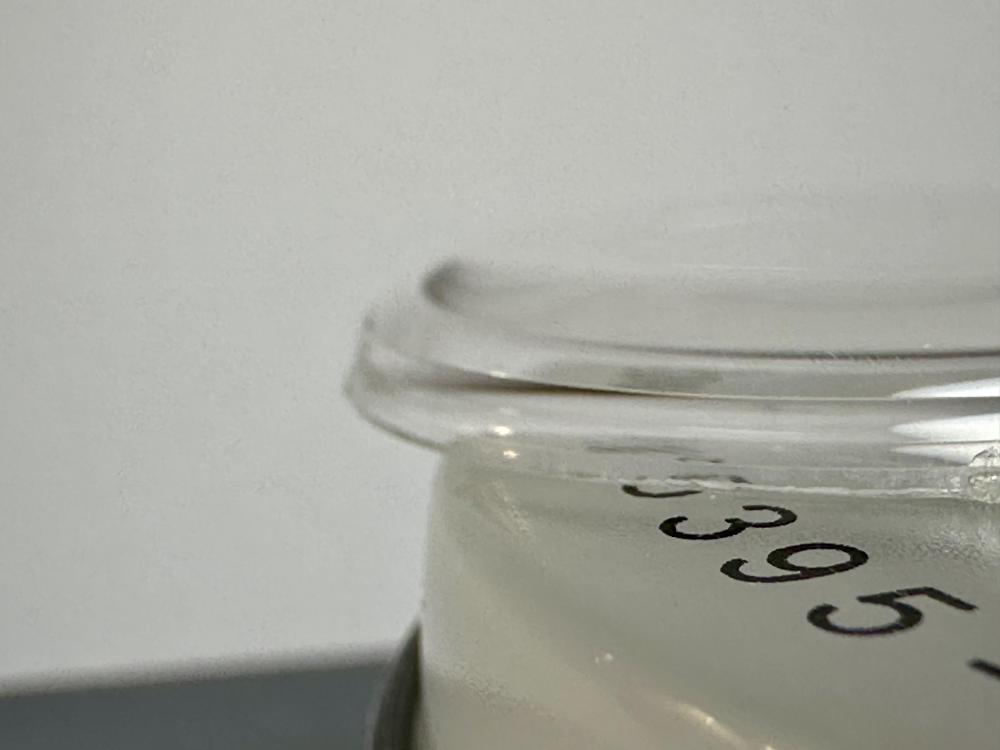

Alright...some photos. Forgive the macro photography. It's early in the US and I haven't had my coffee... First, the Record DD case... ...with the ring. I can confirm the ring for Vertex, Buren and now Record. Omega does not use the ring- regular press fit works fine. Here's the Buren case with my nifty wrench... Crystals...Long ago I purchased a couple from a Hong Kong (?) supplier called Lobtime. They claim one of their specialties is hard to find replacement crystals. Lovely website...and there are always US EBay sellers offering 'perfect fit' DD crystals. I've just assumed all these vendors are making proper measure to discover the correct size to order from the major suppliers, G-S, Sternkreuz, etc. then selling for a markup, but I'm not certain. Could be NOS... Here's some looks at the lip- perhaps it can be determined which Sternkreuz to order, if possible... ...the last two are from the Buren DD. I replaced the last one because of some deep scratches in the sidewall what showed. Replaced it with the 'Lobtime' replacement... END1 point

-

I assume you did make sure that they hairspring centered and everything looks fine with the hairspring? as nice as the movable stud holder is and timing machine you really should do this the old-fashioned way. The problem with trying to move it around looking at the timing machine there is no plus or minus and typically will sail right past zero and not even grasp you've done that. so basically could spend a lot of time moving a back-and-forth seemingly going nowhere because you really need to be much much closer when you start. Ideally it be nice if you could see the pallet fork like if it's in between the banking pins for instance. This should get you close enough otherwise you can try the alternative methods?1 point

-

Have you checked that the collet/stud/roller and staff are all firmly fixed? I've had unusual beat errors which turned out to be one of the above being loose.1 point

-

I’m a collet man myself but the tool is interesting. Turns the roller while mounted on the staff does it?1 point

-

I just cleaned up some crystals so I’ll take close ups…and I have a Record in the baddie radium storage waiting attention and all my hazard duty kit is out this week. I’ll try to take some photos of what to expect in the Record. I’m not certain all the DD cases have the retaining ring…1 point

-

1 point

-

Nickelsilver showed this proprietary tool used for fine adjustment of beat. Inspiring and I plan to make a simple inexpensive tool for same task.1 point

-

Ah brilliant thanks for that fella, i have a Record DD , gives me an idea what to expect when i take it apart. I'm assuming finding a replacement crystal might be a problem. There were also likely spanners dsigned to fit these retaining rings.1 point

-

The bridal should be OK to reuse but I would buy an automatic spring with the bridal attached.1 point

-

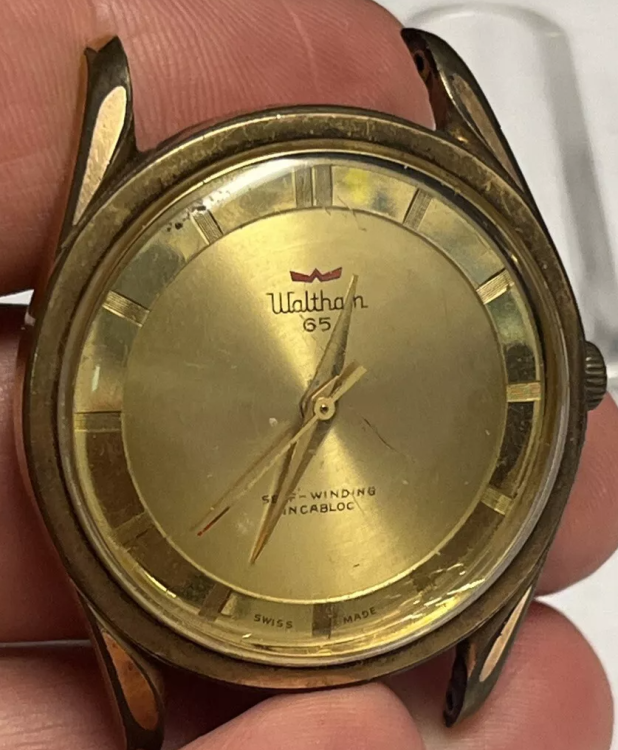

I particularly like watches that have unusual or technically interesting movements; I found AdamT's Watham Fontomatic absolutely fascinating, and while researching that discovered some other unusual Waltham watches & movements. These two are now on the way to me: The first one is an unknown; I cannot find any definitive information on what the movement actually is, but it is running and the typical selling price is seems to be two or three times what I paid for it: This second one is definitely interesting - a 65 Jewel one! I have found some further info on these & it seems the movement is based on an AS1580, using cap jewels just about everywhere possible plus numerous jewels inset in the rotor edge, to act as (sliding) guide bearings! It's a "parts or repair" with the dial separate, missing the crystal and minute hand at least; but a good price even so. And a bit of comedy value relating to the first of these - similar one at a discounted price (according to a clueless seller) as it's a non runner: Just $1500.00 please! https://www.ebay.co.uk/itm/1949408956371 point

-

I've been handwinding quite a few recently, due to them being sizes that do not work with any of the winders I have. (I wear nitrile rubber gloves with working on watches as I've not found finger cots that fit without cutting off my circulation..) Put a small smear of grease on your gloved fingertips and wipe along the spring with it, then wind it in to the washer while the last trace of grease is still on the gloves. Winding it just distributes the grease more. I've used that technique on some larger ones, or wound them dry then added two or three small dabs of 9104 on the side of the coil afterwards, as Hector advised.1 point

-

I use Moebius 8300. Put 4 dabs on the coil inside the barrel and almost immediately, the blobs will get pulled between the coils by capillary action. I think you could put 8300 on the coils in the washer and it would get sucked in also. Sometimes when I repack the grease in the bearings of my equipment, I put globs of grease between the raceways and flame it with a microtorch. The grease melts and flows into the bearings very nicely. You could try using your oven when the wife's not looking.1 point

-

There's debate about what a frankenwatch is- I've seen professionals call certain factory original Rolex watches Frankens because they have unique Rolex movements (I'd have to go look up which ref they are). Mods are mods, but if you swap out for a different movement and like it, congrats Dr. Frankenstein... ...I have no issue with Seiko frankens. Original parts are such crap or crap expensive its the only way to keep some of these classics alive. My first and possibly last foray in to Seiko taught me the expensive way... The nieces and nephews and their SOs in my family will all be receiving a rehajm restored vintage watch for their birth day this year. the first goes out in a couple weeks, which is a Seiko Full Franken... The nephew is a large fellow what enjoys a a few pints so this is perfect- indestructible and not a huge loss if it isn't. He will be recieving an education on what a Frankenwatch is and instructions to speak with uncle rehajm if he needs liquidity and wants to sell...1 point

-

I picked this up recently for the 404 club, assuming it to be a Marlin from 1983, and probably a bit of a basket case, however it is actually a 1973 Mercury model number 160502473 and I have to admit I am very pleased with it. It is remarkably clean, tidy and scratch free which is all the more remarkable given the fact that it is 51 years old (I did fumigate it anyway just because I always give everything that arrives a good clean before I start working on it). It is probably one of the best preserved Timexes I have. Furthermore... it works, so I haven't even opened it up yet. For a few pennies under four quid, well worth the gamble.1 point

-

I wonder if grease can be mixed in some type of fluid as a carrier ( alcohol or pertroliunm stuff) for lubricating mainsprings, to just dunk in the mainspring , then let alcohol evaporate and leave grease on the spring. I don't have a winder tool, just hand wind the old springs inside a washer like new mainspeings come, rinse and install, so you can see why I am after this invention. Laziness isn't the sole mother of inventions.1 point

-

Thanks for the welcome. Of course I'd like to reply by saying I'm only joking, as if I'd be silly enough to buy a lathe before removing a back off a watch... Regrettably please find attached photos requested (OK maybe I'm slightly exaggerating about not taking a back off a watch, but I'm several light years off legitimately needing a lathe).1 point

-

1 point

-

Ultimately, what magnetism is affecting is a moot point, it is detrimental to the correct running of the movement, so demagnetification should be part of the service routine. Many on here though, including myself, like to understand the problem and not just accept it.1 point

-

Oldhippy suggested I make a video how I strip, clean & polish the brass parts of a torsion ( Anniversary) clock ready for lacquering, it’s not the only way but it’s the way I do it. Dell1 point

-

Mohawk lacquer for brass is an American product but I get it in UK from master finish.co.uk. The polish I got from https://www.homecareessentials.co.uk/product/peek-metal-polish-paste-1-litre?gad_source=1&gclid=CjwKCAjwzIK1BhAuEiwAHQmU3lTPwGH4q3LXwAuXodjI_sDAGewUyDYSDtbBg5N-_fcWSD3YpgcWoBoCYukQAvD_BwE As Oldhippy said it is a dirty job but someone has to do it,1 point

-

Thank you all for your kind and warm welcomes. ah Letchworth, just up the road from me. Home of the UKs first road roundabout….1 point

-

Let me clear something... Beat Error is not something that can be bad. It doesn't show that there is any problem in the movement and doesn't affect the timekeeping. It only depends on initial (neutral, zero) position of the balance and if this position is wrong, the movement will not start working by itself and will need shaking. Further, if BE is wrong, the movement will come sooner to 'galooping' if the amplitude is very big, than if BE is correct. So the correct BE allows maximal amplitude without 'galoopiung'. Yes, it is possible that other things than initial position may cause BE. For example, artificial limiting of balance movement in one of directions. But, such problem will cause many other things and wrong BE will be the last thing to be concerned about then. Something more - the way BE is calculated in timing machine is such, that the result depends on amplitude. If You have BE different than 0, then it will depend on amplitude. So You don't need to worry if BE is bigger in vertical positions, this is normal. Generally, You don't need timegrapher at all to adjust the initial position correct. You just need to ensure that the initial position is such that the impulse jewel holds the pallet fork exact in the middle of it's movement (imp. jewel on the line balance bearings-pallet fork bearings) in static when DU/DD. If it is so, then You can ignore what timegrapher shows as what You see in the movement is more relevant than what timegrapher calculates. An easy way to adjust initial position (if the roller is placed in such manner that the impulse jewel is on the bisectrix line of the angle, formed by the spokes/arm of the balance wheel) is to observe the figures that spokes/arm draw when balance rotates. This figures must be symmetrical with line of symmetry balance bearings-pallet fork bearings.1 point

-

Hi Daisy welcome, with the information you've provided from the previous repair guy this sounds very much like the short flat spring that keeps the sweep seconds pinion engaged with the indirect sweep wheel. Without the correct spring tension the second hand can stutter, the arbor that the hand connects to has too much free play so the pinion leaves and wheel teeth do no remain constantly meshed. Haha you beat me to it matey and with a picture Ps just be careful with your outlining in future if that spring had 2 fixing locations then............i need say no more1 point

-

Hi Daisy, The diagnosis is most likely correct: there's a spring that puts a tiny bit of tension on the seconds pinion (which holds the seconds hand). If that spring is too loose, badly placed, or even missing, the second hand will skip. A skilled watchmaker should be able to fix this easily. Cheers PS: See picture. This is a Rolex calibre 1225, you may have this or a similar movement in your Oysterdate. The spring is surrounded in green, the red arrow points at seconds pinion.1 point

-

My thoughts are -with very small diameter fixed drilling the machine and tooling accuracy has to be really good and or very adjustable to make it accurate. Drilling with carbide its such a brittle material with no flexibility, I'm sure this is were the hand drilling comes in , your hand becomes the flexible give rather than the drill. You have to bring the drill bit in at the correct angle or close to it which can be difficult when using a microscope but by using the tailstock sleeve as a guide for whatever you are holding it does get you somewhere near.1 point

-

Just speaking for myself, I started buying relatively inexpensive watches that I liked the look of on eBay and fixing those up. I learned something new with every one. Then it turned out I really started enjoying Bulova movements and 70s styling, so it moved my focus in that direction. I got into Bulova Accutrons because my mom gave me her late father's, which she bought him new in 1973. Before I worked on that, I found some eBay movements to practice on until I could get my confidence up. So I guess my advice is start looking around for things to fix that you would enjoy, without the pressure of working on a family heirloom. Having watches around that you've fixed and can pop on your wrist is super rewarding and will help keep you interested.1 point

-

I shouldn't worry you are not going to end up glowing green in the dark. Looks like mid 50's to 60's watch.1 point

-

Oh no, I always though it was India Pale Ale. I guess this explains the sticky hairsprings. Oh well, you learn something new every day!1 point

-

The tip I read somewhere is to determine which way the hairspring has to move is to run the watch power down then ad a touch of power and the side where the pallet folk finally stops indicates the side that needs to be moved away from. I have tried this method and it works but I advise to do the test several times to make sure you are not getting a false reading.1 point

-

This what I used to adjust the collets on clocks and pocket watches. It's probably too big for a ladies watch. I don't remember where I learnt this from I slip the tool between the hairspring and balance cock and insert the sharp tooth of the tool into the split of the collet. Then I can turn the collet in whatever direction I choose.1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)