Leaderboard

Popular Content

Showing content with the highest reputation on 07/27/24 in Posts

-

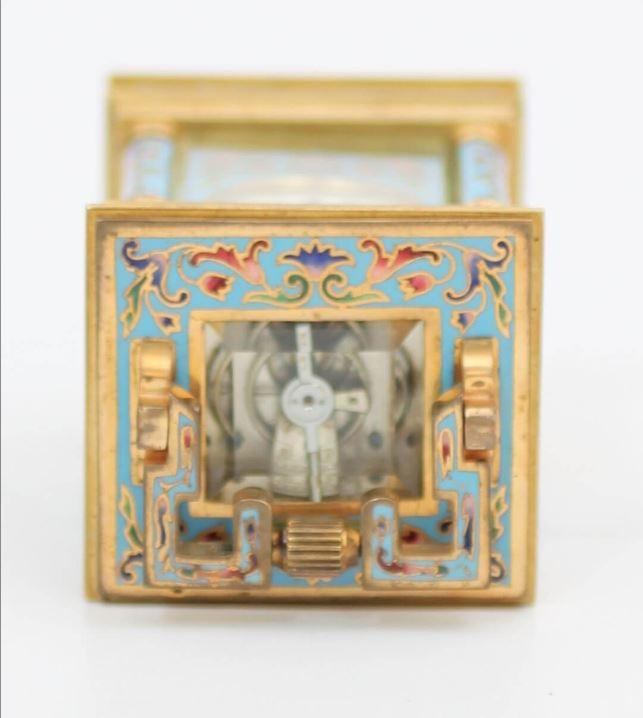

Kalang I will say you are the winner you are so close. The whole clock is a fake it was made in China. You mentioned the enameling it is called Cloisonne. It is rough and not mounted well. The complete platforme is cheap rubbish. Here is a genuine French Miniature carriage clock timepiece with Cloisonne and you can see the difference.3 points

-

3 points

-

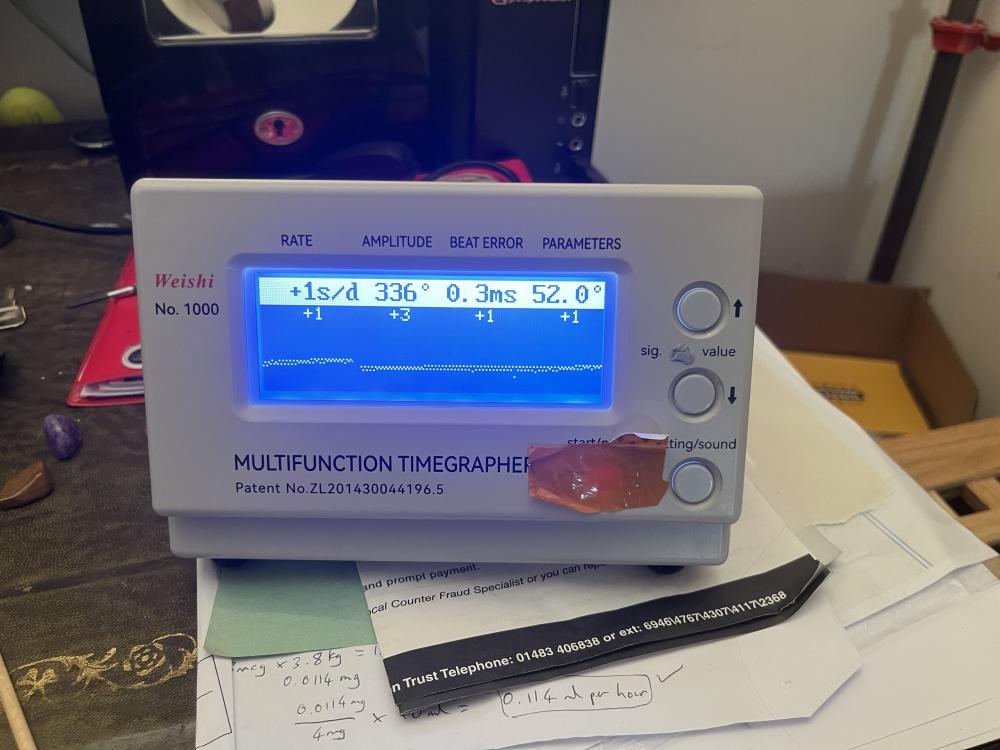

Yes, that is the relevant question. As the OP stated, if you agree with the methods, then the conclusion from those efforts is that breaking grease isn't an improvement over a non-lubricated barrel for a short trial winding period. But there is also an acknowledgment that prolonged metal-on-metal contact wouldn't be a real-world option. So, if the "myth" this thread is addressing is the need to use a special breaking grease, then investigating how other types of lubricants compare would be the next step, perhaps using an automatic watch winder or something that could put the treated springs/barrels through successive days of winding. I personally don't doubt that watchmaking companies use this because it does what it says and is an improvement, but I can see that it might be a situation where a hobbyist could opt to not stock the special grease for their own projects if there is a multi-use lubricant that is functional without tanking the reserve so low that the wind wouldn't at least last overnight when you set down an auto watch. Then again, this is probably one of those "If you want a new idea, read an old book" situations because there were auto movements before many of the modern lubricants were available, so there might be old-school suggestions out there.3 points

-

2 points

-

2 points

-

I am pleased to say that thanks to the help from this group and a new spring I have managed to fix my Rolex.2 points

-

I don't recall what I paid for it, but I got the teensiest cutie patootie little bottle of braking grease a few years back. Couldn't have been that expensive, but undoubtedly cost more than most of the 404 watches I've used it on! If it is any improvement at all, it's worth it to me to know it's done "right"; whatever that actually means. I'm screwing things up enough in ways I know the actual ramifications of!2 points

-

It is plate so be careful when polishing as you could rub the plate off. They were about in the 70's I can remember repairing this sort of Russian crap. I think the movement is a raketa which means Rocket. I t has a little shim under the balance cock.2 points

-

△u10 or AU10 means 10 Micron Gold Plated Edit The movement is a 1509B.1 which wasn't made until 1980 https://17jewels.info/movements/z/zaria/zaria-1509/ https://ranfft.org/caliber/10762-Zaria-1509B12 points

-

1 point

-

Sounds like it needs a service. You don't usually need to change the mainspring. I'm currently testing a cal 625 I just serviced. The hairspring looked a little 'tired' in the centre coils, but I thought I'd try it. It's giving a healthy 290° amplitude (240° after 24h) and power reserve of about 40h (spec is 30h).1 point

-

That link at Emmy Watch had me fooled too. The part on Ebay that it actually leads to is #609, the intermediate wheel. But no sweat, I am about to post an update. UPDATE: DONOR MOVEMENT HAS BEEN FOUND AND PURCHASED! Many thanks to anyone who was looking on my behalf.1 point

-

Found a few things wrong that’s probably why it was sold, the top had a bit of damage to one corner so it had probably fallen, only one jewel the other has been replaced with a bush that is to long so that would cause extra friction and a bush for the escape wheel that is to long as well and probably because the escape wheel arbor has a broken pivot they tried the long bush to reach the remaining part of the pivot. As for making small mark to be able to setup the drops what marks do I go by 1st picture, I only put a very inconspicuous small mark on the side of the plate when I service them, this one has quite a few on face of plate. Well I have to start somewhere so I decided to replace the broken pivot on escape wheel first, not done one that small before although I have done a few standard torsion clock arbors but it turned out fine. Dell1 point

-

The wife approves. One look at the face and said it would be beautiful with a gold case…1 point

-

1 point

-

AU, atomic symbol for gold. The 10 I think is 10 microns, so gold plated.1 point

-

Franken? To me. Not. My personal thought on a Franken watch, of which I have quite few, due to my lack of purchase price. Parts missing, wrong parts, broken parts, wrong screws, incorrect backs, wrong crown. All these I have. I'm working my way through them with replacement donors. If, when I get them running, they will have been Franken, but will then be part of my collection of 'watches'. Different views for different people.1 point

-

There's debate about what a frankenwatch is- I've seen professionals call certain factory original Rolex watches Frankens because they have unique Rolex movements (I'd have to go look up which ref they are). Mods are mods, but if you swap out for a different movement and like it, congrats Dr. Frankenstein... ...I have no issue with Seiko frankens. Original parts are such crap or crap expensive its the only way to keep some of these classics alive. My first and possibly last foray in to Seiko taught me the expensive way... The nieces and nephews and their SOs in my family will all be receiving a rehajm restored vintage watch for their birth day this year. the first goes out in a couple weeks, which is a Seiko Full Franken... The nephew is a large fellow what enjoys a a few pints so this is perfect- indestructible and not a huge loss if it isn't. He will be recieving an education on what a Frankenwatch is and instructions to speak with uncle rehajm if he needs liquidity and wants to sell...1 point

-

1 point

-

Jax tool would work just spread a plastic sheet on the case back. Perhaps cal 630. Twelve to thirteen hours power reserve is low.1 point

-

1 point

-

Hi Daisy welcome, with the information you've provided from the previous repair guy this sounds very much like the short flat spring that keeps the sweep seconds pinion engaged with the indirect sweep wheel. Without the correct spring tension the second hand can stutter, the arbor that the hand connects to has too much free play so the pinion leaves and wheel teeth do no remain constantly meshed. Haha you beat me to it matey and with a picture Ps just be careful with your outlining in future if that spring had 2 fixing locations then............i need say no more1 point

-

I believe the base calibre is an AS 1203 and if you look on Emmy or Borels there are a number of calibres that use the same screw. https://www.emmywatch.com/db/part/screw_crown_wheel--5420_375/a_schild--1203/ http://cgi.julesborel.com/cgi-bin/matcgi2?ref=Y`\EVGZJ Don't know where in the world you are but Cousins has them for the AS 1123 https://www.cousinsuk.com/sku/details/as-movement-parts/as112354201 point

-

Really no one? Tool is used for milling the bearing for rubbed-in jewels. For those without a lathe… Frank1 point

-

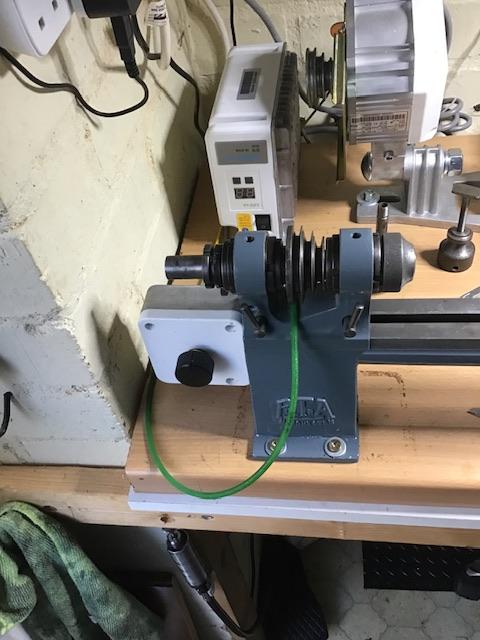

A lot of people seem to ask what motor to use to run a watchmaker or small instrument lathe so I thought I would post my observations on the motor that I use , because I only service, repair and restore torsion clocks I use a Pultra 10mm instrument lathe but the motor I use will work just as well for a watchmaker lathe, it is made by Jack and it is an industrial sewing machine motor although I have removed the foot pedal and replaced it with a potentiometer because I have trouble with my leg twitching, the motor is very quiet and smooth and the torque is very good even at slow speed and I have added a video of me making a replacement disc pendulum adjustment rod just to show how good it is, I tend to run the lathe a lot slower that most when using a graver the video is when I had my original Pultra 17/70 although I no longer have it because I needed a larger lathe for some work and as I am very short of space I sold it when I got the Myford something I regretted almost immediately ( benefit of hindsight) , anyway I have now found a Pultra P type in very good original condition apart from a broken knob on the drawbar and at a price I couldn’t turn down so after stripping, cleaning and repainting it is setup on a piece of kitchen worktop with a Jack motor , I have checked runout and it is half an increment on a 0.001mm dti so very pleased, I have made a replacement knob for it on the Myford and I have made very small screws on the Myford IE 12BA but find it a lot easier on a small lathe using a graver, I hope this is of els to anyone looking towards a small lathe. Dell1 point

-

You might find this site interesting. http://www.pocketwatchrepair.com/histories/ingersoll.html1 point

-

Ingersoll introduced a watch called the Yankee as far back as 1896. Has yours got a serial number?1 point

.thumb.jpg.67453f4d943c8f3fa7ef89e1b338c75b.jpg)