Leaderboard

Popular Content

Showing content with the highest reputation on 07/28/24 in all areas

-

You should be able to pick a nice plain one around £200. The one I showed you would be in the thousands. It can also depend on certain makers. A Drocourt strike in a gorge case that means it has round moldings would cost you over £12,000. If you are thinking of buying such a clock take photos of it and post here and I can advise you, that applies to anyone wishing to buy antique clocks.3 points

-

Slowly getting things done. Blue pillowslips are back on both of the clocks. They are 2 of my keepers. I also have a cuckoo clock which needs a lot of work, but it was my mum and dad's, so it's a keeper as well. It will probably go to the right of these two on the wall. I just did some looking up and the mantel clock on the right has a Winterhalder & Hofmeier movement. That clock would weigh twice what the tall clock weighs. There is also a number stamped in the top right corner of the rear plate. Very hard to get a photo of it. I'll check it again tomorrow and write it down.3 points

-

My maths teacher was a fool, yes he would throw the board rubber at me and I would duck so the poor sod behind me got it. He gave the the cain once and asked me if it hurt so I said no. He went as red as a beetroot so he gave me another three so I laughed at him and he told me to go and sit down, the funny thing is he kept shaking and he was bloody hopeless for the rest of the lesson.2 points

-

Do you live in a humid climate? Or were your tests with 70% IPA and never ‘pure’ IPA? My experience with shellac matches nickelsilver’s and I where I live, the humidity is low. The reason I ask is that isopropyl alcohol is quite hydroscopic, it readily absorbs moisture from the air. If you leave a bottle of 99% IPA open in a humid environment, it will soon have a significant water content. 70% IPA obviously already has a significant (30%) water content. If shellac is softened by absorbing IPA which contains water, then even after the IPA itself has evaporated, the water content will remain, and will have penetrated the shellac on a microscopic level, carried by the IPA it was mixed with. This will leave the doughy mess you describe. The other variable, as touched upon is the shellac itself. Shellac is the excrement of the lac beetle. The beetles diet does alter the composition of the shellac. Shellac naturally contains a significant amount of wax. This wax must be removed if the shellac is to be used for watchmaking. If shellac containing wax is dissolved in IPA or alcohol, you get a doughy lump that never sets properly. Unless shellac is specifically being sold for watchmaking, assume it contains wax unless it is specifically sold as dewaxed shellac. I’ve found all dewaxed flake shellac to be suitable for watchmaking, and have never used shellac that comes in stick form. Best Regards, Mark2 points

-

1 point

-

Wrong again, I'm going for the record of incorrect answers @Neverenoughwatches, eat my dust.1 point

-

1 point

-

Yes 7T32, YM52 & Y182 are the same but there may not be anything wrong with the current movement.1 point

-

Reamers in jewelling tools are tapered to open the hole up by 0.1 mm and ream the last bit, but ordinarily reamers aren't tapered, just the tiniest bit on the lead edge1 point

-

The hands and second had look like it’s gone a quartz movement in the back. Cobbled up job1 point

-

The parking fee receipt is there and legally displayed its up to the traffic warden to find it Its the sort of mischievous prank i would pull Post something that describes yourself.1 point

-

I'm a bit confused by this... As I recall, that was the precursor to a horror movie about physical and psychological torture. Is the owner of the car threatening the traffic warden? How do all those tickets relate? Seems like the owner of the car is the one losing the "game".1 point

-

No clock guy but I did spend many hours sitting quietly whilst my grandparents visited their friends who had them 1 it has a seconds hand! 2faceplate is warped as it is too thin for this type of clock 3 pendulum and rod(?) look very poor quality 4 no weights, looks like it might be spring driven? 5 case looks like it’s from a 100 year old coffin that’s been dug up hope I got at least one right Tom1 point

-

Okay this gives me hope haha. Thank you for posting this. I'm currently going out of my mind with a 7s26 that for the first time i've fitted with a generic general resortes mainspring that according to here, my measurements and cousins SHOULD be the correct replacement and I simply cannot get my amplitude up to what it should be. I can tell the bridle is slipping prematurely and it's just never getting up much tension. I was told when i started to get 8217, but iv'e barely done any barrel servicing because seiko barrels arent' really made to be serviced so and i didn't have a winder till recently so this is sortof my first foray into servicing a barrel from scratch. I have some 8213 on the way from cousins and i'm REALLY hoping this resolves my amplitude issue. I can tell when i wind it there's just no tension building after about 4 rotations of the barrel. It feels like after 3 or 4 rotations the mainspring is just spinning around in there. I will report my findings when it comes and i service the barrel with 8213. This IS a brass barrel too. I can also say i have serviced one other barrel with 8217 on the same movement but with a stock seiko mainspring that has that big reverse bridle and the stuff worked fine.1 point

-

There's no reason why you can't lacquer the coils but there's also no reason why you should damage them.1 point

-

1 point

-

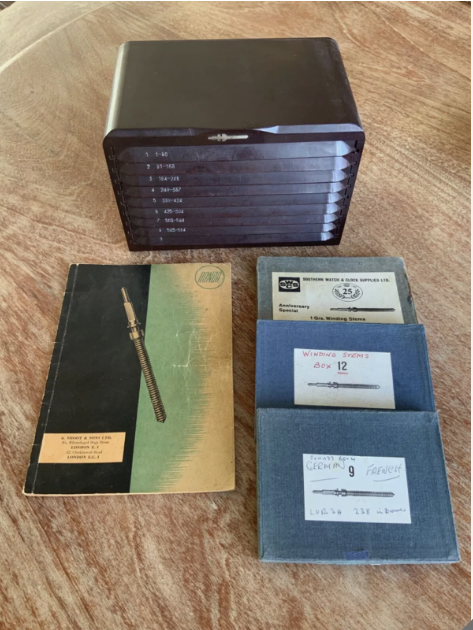

I haven't seen those type OH , the ones i have are made of bakelite and hold around 900 staffs, the stem cabinets hold around 800. Haha there is that, it might take a few years to get your money back I have seen them listed for a lot more than this.1 point

-

The ones I had were made of metal and coloured green. The wooden ones are much nicer.1 point

-

No, I live in a notoriously dry climate, in Sweden. The relative humidity seldom exceeds 30 % I haven't got the bottle of IPA in front of me. It's 10,046 kilometres away from me. But as I remember it is "pure" IPA. It is definitely not the 70 % kind you use for disinfection. I will have to check this when I get a chance. I wasn't quite aware of that, but there is a reason for rinsing water-drenched parts in IPA. This was definitely news to me. During my eight years in this hobby, I've never found this information so interesting and much appreciated. None of the shellacs I have bought from CousinsUK (flakes, clear stick, and dark brown stick) have been marketed as "dewaxed". I'll see if I can find someone selling dewaxed shellac. Maybe you've just solved a long-standing mystery that could drive anyone crazy EDIT: After a quick check, there seems to be no shortage of places that sell dewaxed shellac.1 point

-

Not that I'm competitive in any way but i bet i could beat you Rich1 point

-

May have had an unnoticed fracture/ flaw in its structure waiting to be further stressed. Glass has manufacturing flaws that can suddenly rupture with temperature random stress changes. Toughened glass can do it spectacularly for no apparent reason. No reason i can think of to use any solvent when restoring an acrylic crystal when diminishing grades of wet and dry and a final polishing paste makes a good job. Maybe a good reminder to safely store away the crystal when ipa is being used.1 point

-

Keep them coming, I'm going for a record of incorrect answers.1 point

-

Right! Let's break out the radium energy drinks and toast to that.1 point

-

I would see acetone being a problem but IPA, not so sure. That looks more like a stress fracture, chemical incompatibility I would expect “melting “ of the material rather than this. Tom1 point

-

1 point

-

1 point

-

1 point

-

Found a few things wrong that’s probably why it was sold, the top had a bit of damage to one corner so it had probably fallen, only one jewel the other has been replaced with a bush that is to long so that would cause extra friction and a bush for the escape wheel that is to long as well and probably because the escape wheel arbor has a broken pivot they tried the long bush to reach the remaining part of the pivot. As for making small mark to be able to setup the drops what marks do I go by 1st picture, I only put a very inconspicuous small mark on the side of the plate when I service them, this one has quite a few on face of plate. Well I have to start somewhere so I decided to replace the broken pivot on escape wheel first, not done one that small before although I have done a few standard torsion clock arbors but it turned out fine. Dell1 point

-

1 point

-

The last quarter coil before the stud must be concentric, yours is distorted. Removing the balance wheel for adjusting the hairspring mounted on the cock (as you mentioned) is the usual procedure. Frank1 point

-

Franken? To me. Not. My personal thought on a Franken watch, of which I have quite few, due to my lack of purchase price. Parts missing, wrong parts, broken parts, wrong screws, incorrect backs, wrong crown. All these I have. I'm working my way through them with replacement donors. If, when I get them running, they will have been Franken, but will then be part of my collection of 'watches'. Different views for different people.1 point

-

A watchmaker friend of mine did some testing on braking greases back turn of the century. I don't think Kluber was around or commonly available, and from memory it was between Glissalube A (8213 brass barrels), B (8212 aluminum barrels) and Glissalube 20 (8217). He's an ex chemist and used new barrels, which he would buy as different auto calibers came in. He milled away a window in the lid to observe the slipping. He counted the number of turns to slip, then observe the amount of slippage, holding the position of arbor and barrel for some time. Unsurprisingly the results backed up manufacturer's and Moebius' recommandations. I don't remember the super specifics, but sometimes slipping occured before full wind, sometimes continuing for a full turn or more (up to 2+ I believe). Sometimes it occured too late- which would cause rebanking and wear or breakage in the auto mech. Glissalube A did work best for brass, and B for aluminum. 8217 did work well in general, but sometimes A or B were better. I have a feeling if he had had Kluber P125 it would have been the best general option. It's good to question things, but I also think the manufacturers put a lot of effort into finding lubrication solutions that worked best, both initially and over time. This fellow bought at least a couple of dozen different barrels for these tests, mechanically and machine cleaning between greases. Not to dispute what manufacturers said, just to satisfy his own curiosity and to see which lubrication was the absolute best for a given barrel.1 point

-

Here in the Uk, actually i think its more of a yorkshire saying. A big girl, and i mean a really big unit of a girl we say " jeez wouldn’t want to mess with her she's built like a Russian shot putter " hairsprings are maybe built the same way.1 point

-

Ah right I recognize that Ronda well, and for all the wrong reasons. There's two things people do to those movements practically all the time, one is to crush the battery contact to the side with the battery. The second is scratch the coil while bending back that awkward battery retaining arm. The coils on these movements have no protective lacquer which means it wouldn't even have to be a scratched from a tool, it can be damaged just by touching with your bare fingers.1 point