Leaderboard

Popular Content

Showing content with the highest reputation on 07/29/24 in Posts

-

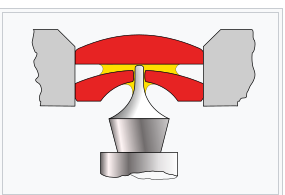

This is correct. Rather than the oil sitting in an oil sink on the top side of the hole jewel, the oil will be suspended between the flat side of the cap jewel and the convex side of the hole jewel. Place a tiny drop of oil on the flat side of the cap jewel and install it over the hole jewel which is unlubricated. Don't put any lubrication in the concave underside of the hole jewels. Image from wikipedia3 points

-

So what we have is a complete nightmare. It is a marriage but it is obvious, when a marriage is created with clocks it is done in such a way that only those with a professional eye now what to look for, but this a blind person would spot it. So first the movement, the reason it has no key holes it is a 30 hour movement they work on a continues chain or rope and you wind it up by pulling on the chain or rope it works on a single weight, some also have a tiny weight which is called a donut and it helps to feed the chain such as prevent tangling. It strikes on a count wheel on the back plate which you can just see. This dial is a bit of a mystery because the number 5 has a short tail which was used up until 1710 but the pattern should be latter? As for the sweep second hand as you can see it is a modern red one they never existed not in 30 hour movements, I’m wondering if the seller just stuck it in to make it look good the other hands are modern and the look as if they are from a battery movement. You can tell by the movement and the room it has sitting on its seat board that the case doesn’t belong. The case or should I say the hood is in the style which is called Swan neck very popular. The long door is a sign of around the nineteenth century. As you see it really is a bag of spanners. Kalanag is the winner as pictures were found and the info was very good. Thanks all for taking part in the fun3 points

-

3 points

-

I push a smoothing broach in to the hole, mark it, then measure with micrometre. But I am cheap3 points

-

Hello everybody, So I won a bidding war for a beautiful automatic Certina watch and I am super excited o receive it, I'm doing some research now but couldn't find any service manuals. I'm very familiar with Seiko, Citizen watches and swiss made vintage watches but this movement looks really different to everything I'm used to and I don't want to screw things up. The movement is Certina 919, the seller didn't include a photo of the movement but it's clearly running as you can tell from the position of the seconds hand. Any advices how to go about servicing this watch? P.S. I paid around $20 for this watch2 points

-

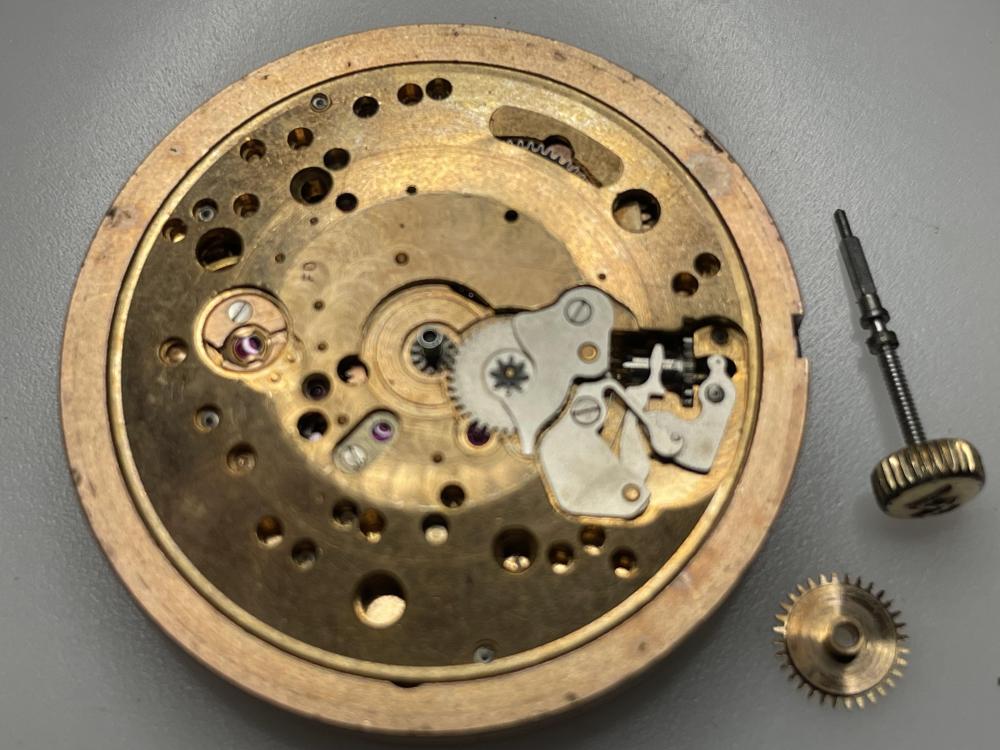

Hi all, this is one of the movements I posted in the "What do you have coming in the post" thread, a few days ago. It arrived today, with the case/movement, crystal & dial all together in the same bag. Through some miracle, that does not appear to have caused any further damage! I could see from the ebay listing that the hour wheel was not on the movement - but the hour had was still on the dial with the hour wheel attached. It looks generally good, though the centre seconds staff is broken. It tries to run but not very well, possibly due to the broken staff binding, or just dried oil & dirt. Other than the hands, it appears everything is there, including the crystal which has quite a heavy brass inner ring, and a quite decent dial. Even the case looks good (other than the dirt) with no sign of the base metal showing through anywhere. That has "W36" scratched on the back of a strap lug? The basic movement is apparently an AS1580, with Waltham mods. The automatic weight has a flange studded with jewels on both sides - 24 positions, so either 24 or possibly up to 48 jewels in the rotor, as guide bearings between the two parts of a split, pressed-together movement ring. The jewel positions are not staggered side to side, but no way of knowing if it's a single jewel or two thinner ones in each position - or a mix. I've not stripped it down any further than in the photos so far, other than taking the front half movement ring off, which was held by the case clamps of the core movement. I may get to it later in the week, depending on other work.2 points

-

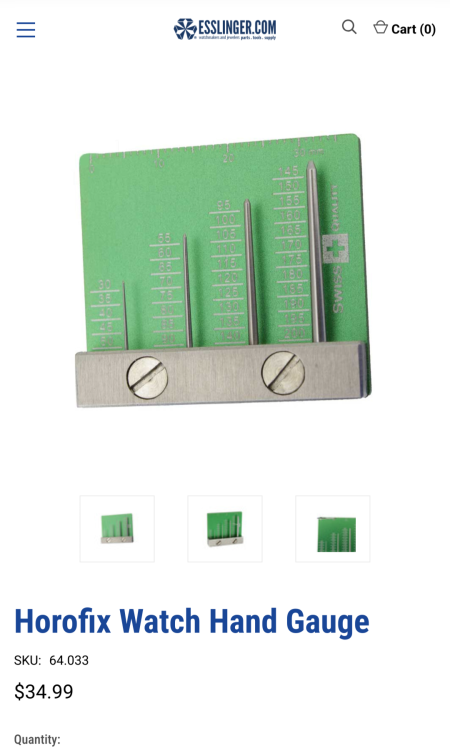

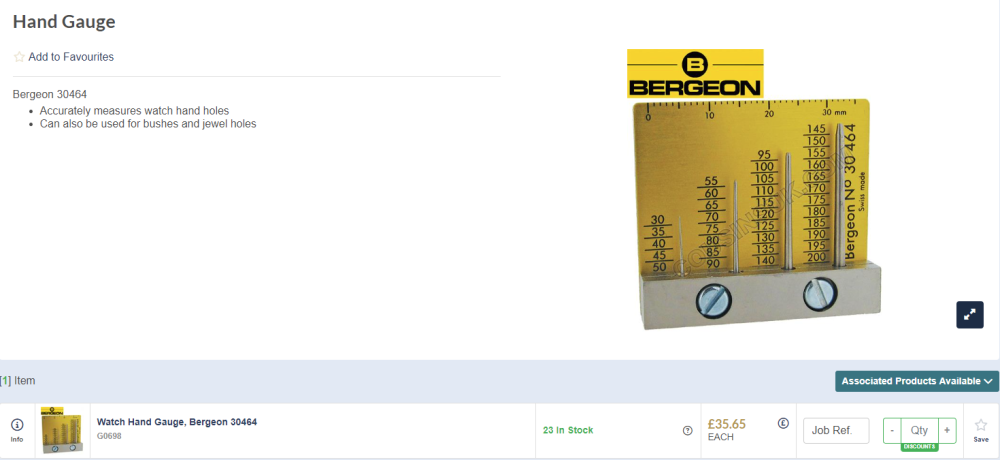

Most of the hands that need broaching or closing are second amnd chronograph sweep second hands, so the Bergeon hand gauge is pretty useless. It doesn't go down to 0.2 or 0.25 mm, so I use the same method as @mikepilk. Amazingly accurate2 points

-

Looking at thre picture, I doubt there is bushing there at all. Seems like it is just stamped. If there is a bush, then the best decision is to replace it. Another simple option is to mark the bush position, to press it out and then return in place but rotated to 180 degr. Thus the wheel position will be restored. Oil retention then may suffer, but using grease like 8200 will solve the problem. Punching to close the holle is possible, but it will change the wheel position and will spoil the look. Actually, spoiling the look here is the main danger in such repairs. One option is to fit thinny bush wit only slight enlarging the hole. The hole is to be elarged and blunted with tappered pin from the down side, then the pin cut and made flush with down surface, then new hole drilled in correct place. Then the upper, visible side of the pin has to be trimmed by slightly bigger drill bit or turned on the lathe with face plate and finally slightly punched with polished round tipped punch to form the top side and in the same time riveting the bush. Then final opening of the hole with smoothing broach... This technic alows to make the bush almost invisible. The other option is to drill the whole thing and fit new pressed bush, but keeping the center unshifted can be a chalenge. I2 points

-

2 points

-

2 points

-

We were taught in dental school that alcohol can cause crazing of the acrylic used for dentures. But I've never seen a crazed denture in my 38 years of practice. Crazed patients... yes. From my own personal experience, I once cleaned the acrylic lens of an LED torch with IPA and almost immediately a crack line started to form.2 points

-

@nevenbekriev @Neverenoughwatches @rjenkinsgb It is indeed a pressed in bush. I pushed one out of my donor's train bridge. There's a decent chance I will be able to find a direct NOS replacement, since the American watch companies produced spare parts in huge numbers. Furthermore, I was just looking over other Waltham 12s movements and they do use pressed-in jewel settings on the train. Unlike Elgin & Illinois I'm more experienced with, who used the non-friction fit settings fixed down with screws. So theoretically I could replace this with a jewel from another donor, but then I'd want to upgrade the whole thing to 15 or 17 jewels and I might as well just restore the jeweled donors instead.1 point

-

If you could find the correct movement or case it would never be worth it. These days people are after the complete originals. I wouldn't give them house room.1 point

-

The cap jewels are the correct way round. A drop of oil is placed on them and then the plates are reinstalled. End shake should only be an issue if the cap jewels are displaced1 point

-

1 point

-

As an experiment I once tried 99% IPA on an old acrylic crystal. It first went cloudy, then cracks developed. I assume that all optical lenses are not any form of acrylic, as don't lens wipes contain IPA ?1 point

-

I work on mostly pocket watches, and most of them are missing hands. I have a few fistfuls of unsorted hands coming in the mail I hope bring some order to.1 point

-

I am very curious whether you can press out a bush from the donor movement you have, if that is definitely not going to be restored? However, just examining the plates on the 16s donor movement I have, it does appear the non-jewel positions are just machined directly in to the plates, and are smaller diameter than the inserts in the jewelled version.1 point

-

1 point

-

Some details here from Cousins. https://www.cousinsuk.com/PDF/categories/7343_Certina 919.1 .pdf1 point

-

I will be interesting to see if this is a separate pressed in bearing or part of the plate itself . If the plate then accurate drilling of the correct hole position without a lathe and centering equipment....... that wont come easy. Once the hole is oval-shaped good skill with the right tools becomes necessary. Curious as to Nev's way of filling in the hole with a tapered pin and create new hole ?1 point

-

Is it one of the Waltham movements that was made with various numbers of jewels? It may be that the plate is cut to take either the brass cased jewel or a simple bush? If that is the case, you could swap the bush for one from a donor, or even fit a jewel type insert if the pivot diameter is appropriate? I wonder if the bush & jewel inserts are the same size across movements? That would make sense for mass production?1 point

-

also make sure the pivot on the third wheel is not mushroom shaped/worn.....1 point

-

I don't see the reason behind this. How would know that you have the lower and upper coil at the right height? How sure can you be that jewel setting and collet hole are aligned/ centred. Then, when you reinstall the spring , any readjustment on the overcoil , is likely to throws the lower one out of centre. Right approach is adjusting the overcoil when balance is installed, so you can check the lower coil for flatness/ exact centering and spring for being in regulator slot, after every tweak.1 point

-

My maths teacher was a fool, yes he would throw the board rubber at me and I would duck so the poor sod behind me got it. He gave the the cain once and asked me if it hurt so I said no. He went as red as a beetroot so he gave me another three so I laughed at him and he told me to go and sit down, the funny thing is he kept shaking and he was bloody hopeless for the rest of the lesson.1 point

-

I cant get right what i dont answer, so by default that makes me the winner My trained joiner's eye tells me it isn't level, my other eye tells me that i may also be wrong about that. Whats the chances of.....2 guys that go by the name of Richard, that live in Yorkshire and both of them know f. all about clocks Put sauce on it and I'll eat it mate.1 point

-

Reamers in jewelling tools are tapered to open the hole up by 0.1 mm and ream the last bit, but ordinarily reamers aren't tapered, just the tiniest bit on the lead edge1 point

-

Well, I was able to get the hairspring more centered and gave a go at truing the balance. Not perfect by far, but it has been running overnight in the dial down position. So, some progress has been made. I first worked on getting the hairspring shape to be more like the drawing. Then took the hairspring off the balance wheel, mounted it to the cock and worked on getting the collet centered on the jewel setting. What I thought were my finest tipped tweezers looked huge compared to the hairspring. There's been a good amount of borkulation on this movement. I also discovered that the hairspring collet wasn't fully pressed onto the balance staff. Also, there are some scars on the balance wheel where someone had tried to adjust beat error, right at the mouth of the collet. So much to unbork. Makes for some good experience on doing some advanced repairs and using some of the tools that I have acquired. I really like the art deco watch case and want a good running movement for it, so a donor seems a good idea at this point in my watchmaking journey.1 point

-

Ha ha , I let you go first, you,l glow in the dark. lol As said many times before, not ingest nor inhale.1 point

-

I have a few of the Ronda staff and stem cabinets but i think this one from DCN is particularly nice with the roller front and also fully loaded. Cheap ? £250 depends how you view it, individually bought stems would be well in excess of a few grand. 25 - 50 stems used and its paid for itself, gotta admit i am tempted but i already have a fairly large inventory of ronda stems i could easily end up duplicating. Anyone thats interested i think its a good investment if you're doing a lot of repairwork.1 point

-

You should be able to pick a nice plain one around £200. The one I showed you would be in the thousands. It can also depend on certain makers. A Drocourt strike in a gorge case that means it has round moldings would cost you over £12,000. If you are thinking of buying such a clock take photos of it and post here and I can advise you, that applies to anyone wishing to buy antique clocks.1 point

-

You are right it is another Chinese fake. The chinese carriage strikes always show the striking works on the back plate and not between the dial and front plate. The bell is poor and it always has two holes in it. You hardly ever have a sweep seconds hand on French carriage strikes. The platforms are normally of a white/gray metal and the platform screws are not positioned as you find with the French types which have four screws while the chinese tend to have three.1 point

-

I had some success paring down acrylic crystal lips by mounting a big blob of blue tack on the end of a cordless drill chuck. You can centre it by squidging the crystal around on the the blue tack till you are happy that it runs true. Then its just a matter of using a little coarse sandpaper and some digital calipers to chase the size down to what you needed. Its a little crude, but since you are typically only removing a few tenths of a millimetre and acrylic sands down quickly, its is a lot easier than you might think. Practice on a few scrap crystals first. The "blue tack chuck" also works for polishing acrylic crystals too. Hot glue might also work, as it parts company from whatever it is stuck to with a little isopropanol, which shouldn't damage the crystal. I may give that a try.1 point

-

Landed this Benrus within a quarter of the current 404 exchange rate, but with cheap shipping, so I'm counting it. Crystal is a lost cause, which sucks, because it's one of those that requires the ID and OD to match the case to close and seal... Bummer... Last time I attempted one of these, I had to find one with a slightly larger OD and shave it down, which was decidedly unfun. Kept would be vandals from opening/ruining it though, so that's a win! It's also missing the split stem crown, and the crown tube is somewhat less than circular. The case is all stainless though (one of my requirements to place any bid). Inside is a 17 jewel ETA 1256, which is a pretty neat movement with some cool features. Very early automatic, evidenced by a lack of shock protection (it runs if you get it going, and has been running from the automatic wind during the time I've been typing this, so that bodes well). According to the link a few lines back there, it is the "prime father of all ETA selfwinding movements ever made". Neat! It has a "springless click reverser" with a "double click wheel". I'm not sure if that's exclusively dealing with the automatic works, or if it would wind both ways if I had a crown to wind it with. Very cool watch! If I can get the crystal and crown/stem sorted out, it'll make for a very nice watch! For now though, it goes into the project box.1 point

-

do you have flake or stick shellac? If you have flake, you could put the smallest little flake at the base of the collet, then heat it up similar to a pallet warmer. Or maybe you could drop a flake in through the top opening and do the same thing? I can believe it isn't slotted. That's so strange.1 point

-

So I may not quite understand what you're asking as far as I know with most hairsprings the regulator pins or as the Swiss call them curb pins should be as close as possible to the hairspring without grabbing. Then the problem of specifically where did I get my information from is far too many sources too many years so as you're asking for an exact specific I grabbed a book from the shelf. The book is titled Watch Adjustmentv by Hans Jendritzki. I've scanned the relevant paragraph and attached the images.1 point

-

No really, I am sorry for showing this. I asked if he's trolling in the comments and still waiting for a reply.0 points