Leaderboard

Popular Content

Showing content with the highest reputation on 07/30/24 in Posts

-

@nevenbekriev @Neverenoughwatches @rjenkinsgb It is indeed a pressed in bush. I pushed one out of my donor's train bridge. There's a decent chance I will be able to find a direct NOS replacement, since the American watch companies produced spare parts in huge numbers. Furthermore, I was just looking over other Waltham 12s movements and they do use pressed-in jewel settings on the train. Unlike Elgin & Illinois I'm more experienced with, who used the non-friction fit settings fixed down with screws. So theoretically I could replace this with a jewel from another donor, but then I'd want to upgrade the whole thing to 15 or 17 jewels and I might as well just restore the jeweled donors instead.3 points

-

2 points

-

Balance cocks don't just 'drop in' but are usually a firm fit. You could open the holes a touch with a smoothing broach if it's too tight. BTW the hairspring doesn't look right in the top pic.2 points

-

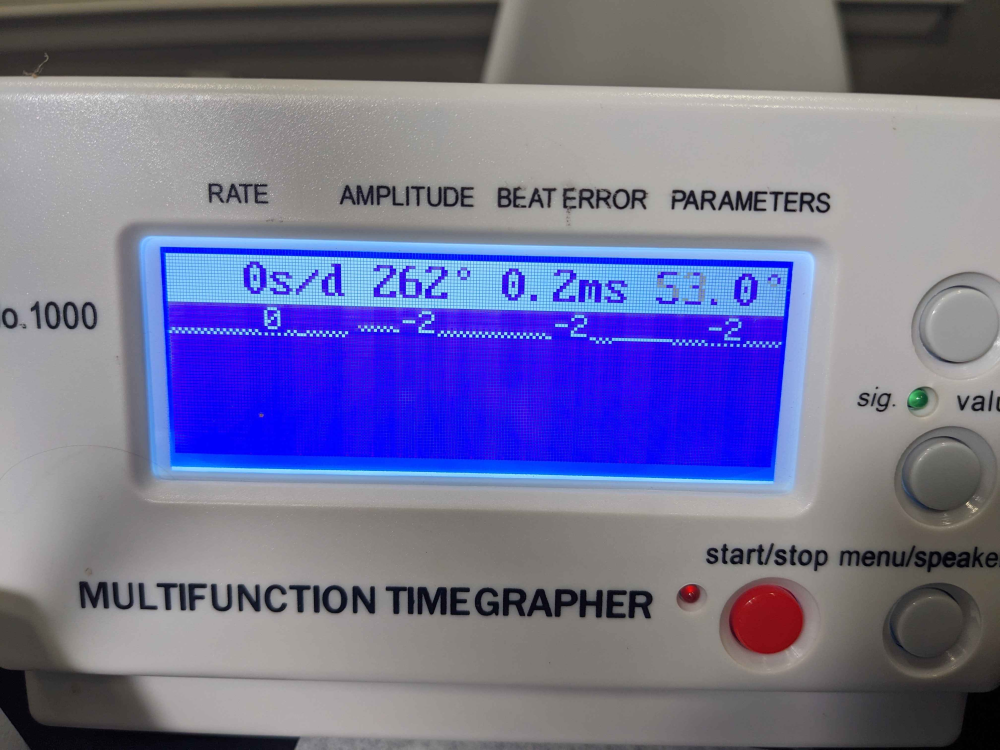

Okay interesting development here ya'll working on seikos should see. This is again a seiko 7s26 with a general resortes 2377x mainspring. So my original issue was i could not get over 230 to 240 amp and i was SURE that the bridle was slipping prematurely using 2817. I was also unsure if the generic mainspring i'm using is correct. I've cleaned and reserviced the barrel now THREE times and here were my results. 1. Did the classic five little dots and flatten them out into little smears. This got me the lowest amplitude and hte most premature slipping. 2. Tried reducing it to three little dots and flattening them. This got me about 10 extra degrees of amplitude but still very little tension on the spring. 3. And now i just did this so i expect amplitude to climb as it settles into the service but somebody here said the seiko spec sheet tells you to make a ring of braking grease across the entire barrel wall. I did four little dabs, and smeared it across the whole barrel wall as best i could. Wound it up and TENSION, like...normal tension i would expect. I threw it on the timegrapher and got the same damn 230ish amp and just let it run for 20 minutes and sat there and watched the amplitude climb higher and higher. My oilings probably all messed up since i've assembled and disassembled so many times but look at this. The delta is shit of about 35 seconds but now that it appears my amp issues might be solved i can reclean and lubricate and then i'll check the hair spring and worry about the delta. The ring technique WORKED.2 points

-

2 points

-

2 points

-

First spring was trashed again after softening the coil next to the broken one with the bloody huge blowtorch. Then miraculously turned into a different spring. Shame the camera didn't pan back so we could see him wearing his top hat and tails and waving a wand. The sexy magician's assistant might have been the only one worth watching here Haha, I'm close behind and catching you up Ross A few therapy sessions and you'll be back to normal Ammer, i say normal.........2 points

-

Indeed! I used to obsess over end-shake which only resulted in jerky energy transfer through the train. It's like shoe size—better a little too big than a little too small. In my experience, .02mm is too small, especially on cheap Vostok and Raketa movements.2 points

-

You sound overly concerned with end shakes in gear train, it can exceed .02 mm which is fine as long as power get transferred from gear teeth and adjacent pinions with least resistance. End shake in the escapement matters. As said no oil in the concave underside of the hole jewel, because the oil runs down and find its way to the hairspring. Rgds2 points

-

1 point

-

Lol no , you have to sit exams and pass them to earn qualifications. Membership entitles you take their DLCs, at a cost obviously, free monthly magazines and i guess a few other perks.1 point

-

1 point

-

No, for a qualification you need to sit exams but anyone can join as an associate member.1 point

-

Run away Ross , run away and dont watch. Dont tell us OH, you're that impressed You're completely lost for words Definitely a special thing alright1 point

-

"What's more annoying is the people in the comments, they thing he's doing a very good special thing" "miraculously turned into a different spring Even as a novice I would never have considered such an action acceptable, or to try to con people. Going to continue running.1 point

-

What's more annoying is the people in the comments, they thing he's doing a very good special thing1 point

-

Pictures would be helpful, it doesn’t sound like a common way to do things. Tom1 point

-

1 point

-

As soon as I find one I'll post it here1 point

-

1 point

-

They're completely interchangeable just made as 7 or 17 jewel versions. If you look here it will show you which parts change with the associated jewel count. https://www.emmywatch.com/db/movement/caravelle--11dp/1 point

-

Humor or foolish endeavor? Harsh criticism welcome. eBay tells me I have purchased 5 Caravelle watches. Mean price of $17/each with shipping. Horrible cost basis by most experts' standards who seem to find $17 Omegas. The one win was a SWISS AS 1686 which I wear daily after some love and attention. I am in this far, I am going to practice on these and practice, learn, fail, cry, curse and hopefully proudly wear one on my wrist some day. Naïve newb pursuit? I will buy no more unless they are 404...he says.... Mixing and matching parts. The one pictured below was $13 landed. I needed a part. I had hoped only the dial was damaged but now I know, damage on dial likely means more damage inside. All I wanted was the main spring screw. But....it is a 17J movement. This tempts me to move all my 7J movement parts over to this plate/bridge. Would the pivots be the same size? Or is such a strategy not a good plan for a newb? Just how interchangeable are the parts in these movements? Thanks for your wisdom.1 point

-

1 point

-

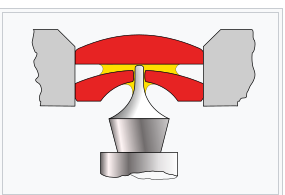

This is correct. Rather than the oil sitting in an oil sink on the top side of the hole jewel, the oil will be suspended between the flat side of the cap jewel and the convex side of the hole jewel. Place a tiny drop of oil on the flat side of the cap jewel and install it over the hole jewel which is unlubricated. Don't put any lubrication in the concave underside of the hole jewels. Image from wikipedia1 point

-

1 point

-

Short video of it running ( 2 hours at the moment) after re pivoting, milling long bush flush, adding a bush where the jewel should be in back cock ( it had a bush way to long and hole to big, replaced mainspring for an original I had in stock, I just wanted to make sure it would run before I did all the cleaning, polishing & lacquering although I will look out for a back cock with the jewel in it’s the same as the back cock on my 1000 day. Dell1 point

-

Medical and research apparatus is often fabricated from thick sheet acrylic, and since there is usually a spray bottle of one type of alcohol or another on most lab benches, inadvertent damage often occurs. Woe be to the undergraduate helper that compromises an expensive piece of equipment by innocently wiping it down! I've even seen "No alcohol" decals on newly-purchased items as a reminder from the manufacturer. Product info often states that concentrations below 30% are moderately compatible and can be used for brief cleaning exposures, but most people stock concentrations above 60% on the bench because that is where you need to be for disinfecting activity as a surface treatment.1 point

-

Most of the hands that need broaching or closing are second amnd chronograph sweep second hands, so the Bergeon hand gauge is pretty useless. It doesn't go down to 0.2 or 0.25 mm, so I use the same method as @mikepilk. Amazingly accurate1 point

-

1 point

-

I push a smoothing broach in to the hole, mark it, then measure with micrometre. But I am cheap1 point

-

No i think you are right with this gauge the pipe diameter and length of minute and hour hands by movement ligne size. The Bergeon hand hole gauge isn't too badly priced as new. I picked mine up second hand for around 20 quid1 point

-

Sounds like it needs a service. You don't usually need to change the mainspring. I'm currently testing a cal 625 I just serviced. The hairspring looked a little 'tired' in the centre coils, but I thought I'd try it. It's giving a healthy 290° amplitude (240° after 24h) and power reserve of about 40h (spec is 30h).1 point

-

I use Moebius 8300. Put 4 dabs on the coil inside the barrel and almost immediately, the blobs will get pulled between the coils by capillary action. I think you could put 8300 on the coils in the washer and it would get sucked in also. Sometimes when I repack the grease in the bearings of my equipment, I put globs of grease between the raceways and flame it with a microtorch. The grease melts and flows into the bearings very nicely. You could try using your oven when the wife's not looking.1 point

-

They both ran but not consistently so basically I serviced them, but that did not fix any problems they already had. Thanks, everyone for your continued assistance. I know I am new at this, but I have fixed quite a few watches already so I know I can do it. I just need to keep learning and keep inspecting these parts for anything I might've missed.1 point

-

This is very good advice and here is a video showing how to inspect simply and practically.1 point

-

I throughly enjoy getting the most i can from these non jewelled movements. The wear in the plate and bridge bearings makes it tough though, this is where you need to be looking, excessive end and sideshakes is likely the cause and not really fixable below a well skilled watchmaker. I would start by inspecting all the sideshake ( look for pivots and arbors wobbling around a lot in their holes ) in the train beginning with the barrel, the sideshake is very important for maintaining good wheel teeth and pinion leaf meshing. You will learn a lot from a movement like this that will have very obvious defects that can be subtle and overlooked in jewelled movements. It will give you an idea of the precision required for movements to run smoothly. Enjoy.1 point

-

That's a clear indication there's too much friction in the wheel train. Ideally, when the train stops you should be able to see the escape wheel spin a tiny bit backwards (counterclockwise as seen from the side opposite the dial) as already mentioned by @nickelsilver. The cause may be something specific or the cumulative effect of several errors. When I get this kind of problem, I test by adding one wheel at a time. Start by checking that the arbor in the barrel spins completely freely. To test, you first need to remove the mainspring. A few years ago I started a thread that became very instructive for me. Maybe you can benefit from it too.1 point

-

The pallet stones look different, they have different angles on their faces. The pallet fork could be faulty, but there's no more (really less) reason to suspect it over a dozen other things. With the balance out, fork out, wind just a couple of clicks of wind on the barrel; the train should spin freely, and ideally the escape wheel will turn backwards a bit when it comes to a stop Balance back in, if you give it a light puff of air it should oscillate freely, and for a good 15-20 seconds (or more), and do so in both horizontal positions and several vertical positions. Balance out, fork back in. With a little power on the mainspring, the fork should snap cleanly from one banking to the other with a slight nudge. If any of these checks don't pass, figure out why and fix it before proceeding to the next check. Balance back in, wind it up, and observe that it has sufficient amplitude, and runs well in both horizontal positions and 4 vertical positions. If you see that the watch runs well in all but certain positions, that gives you clues as to where to dig further.1 point

-

…copied in quantity they could be plates for the buttons in very small elevators?1 point